Date Code 20200324 SEL Application Guide 2020-05

Setting Up Maintenance Mode in an SEL-751

Swagata Das

INTRODUCTION

Many users prefer to enable maintenance mode in relays as an added safety when working on ener-

gized equipment. The maintenance mode function, when activated, enables a sensitively set instan-

taneous overcurrent element for faster tripping in those relays without arc-flash protection and

prevents closing of the breaker by any means (e.g., automatic reclose, remote SCADA close, or

local pushbutton close). This function is not included in the default settings of the SEL-751 Feeder

Protection Relay, but you can set it up by making a few settings changes. This application guide

shows the settings necessary to enable and disable maintenance mode in an SEL-751 by pressing a

front-panel pushbutton. The same logic can be used when setting up maintenance mode in an

SEL-751A Feeder Protection Relay as well.

ENABLING AND DISABLING MAINTENANCE MODE WITH APUSHBUTTON

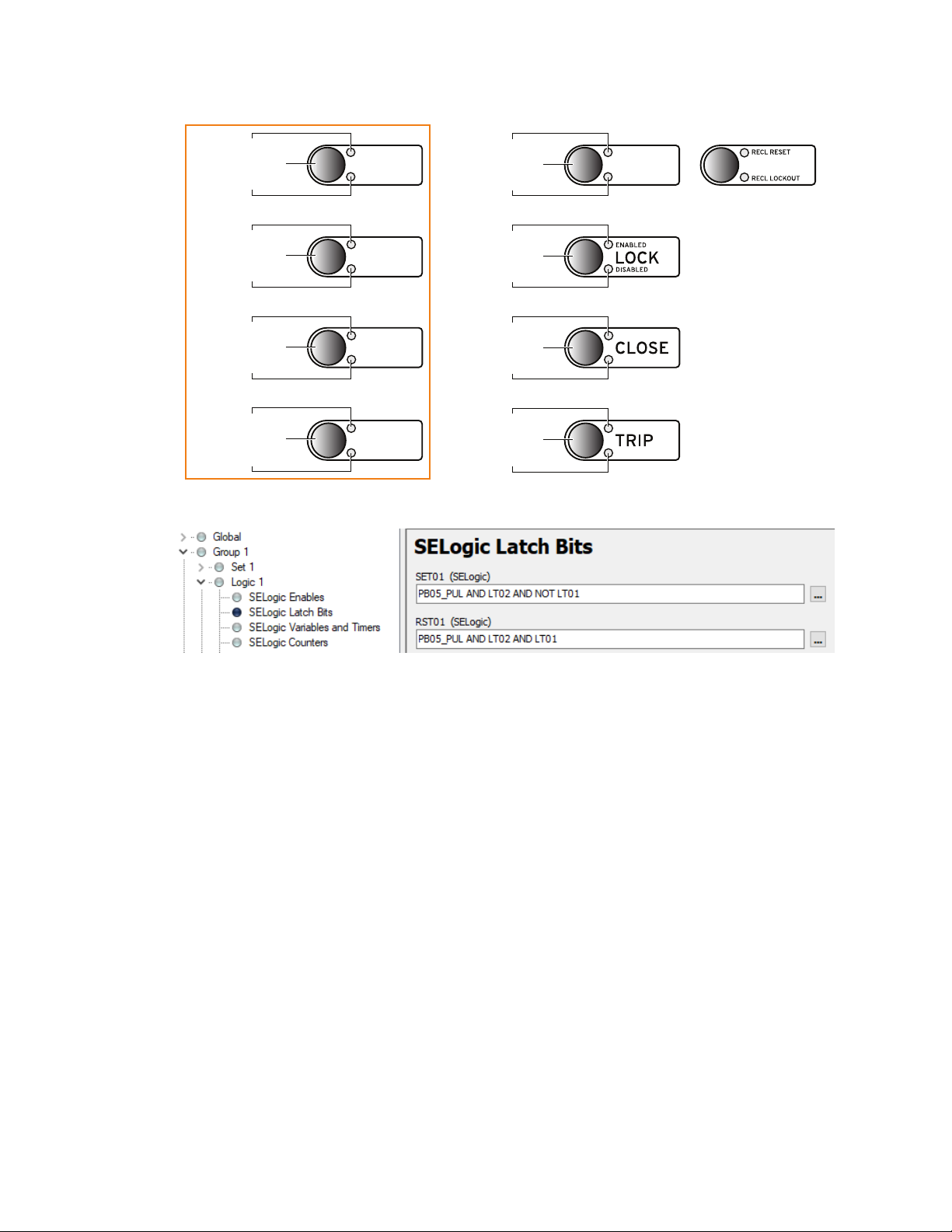

You can order the SEL-751 with either four or eight pushbuttons, as shown in Figure 1. This appli-

cation guide assumes that you have an SEL-751 with eight pushbuttons, that the relay is using the

default settings, and that the AUX1 pushbutton is being used to activate maintenance mode. Pressing

the AUX1 pushbutton asserts the PB05 and PB05_PUL Relay Word bits as shown in Figure 1. The

PB05 Relay Word bit remains asserted for as long as the pushbutton is pressed and is considered a

“follow” output. The PB05_PUL Relay Word bit asserts for only one processing interval (1/4 of a

power-system cycle) and then desserts, even if the button is still being pressed. Because we are

interested in capturing the moment the pushbutton is pressed and not in how long the pushbutton is

pressed, we use the PB05_PUL Relay Word bit in our logic. Note that instead of using the AUX1

pushbutton, you can use any other pushbutton to activate maintenance mode in your application.

Refer to Figure 1 and choose the Relay Word bit associated with the pushbutton that you are plan-

ning to use.

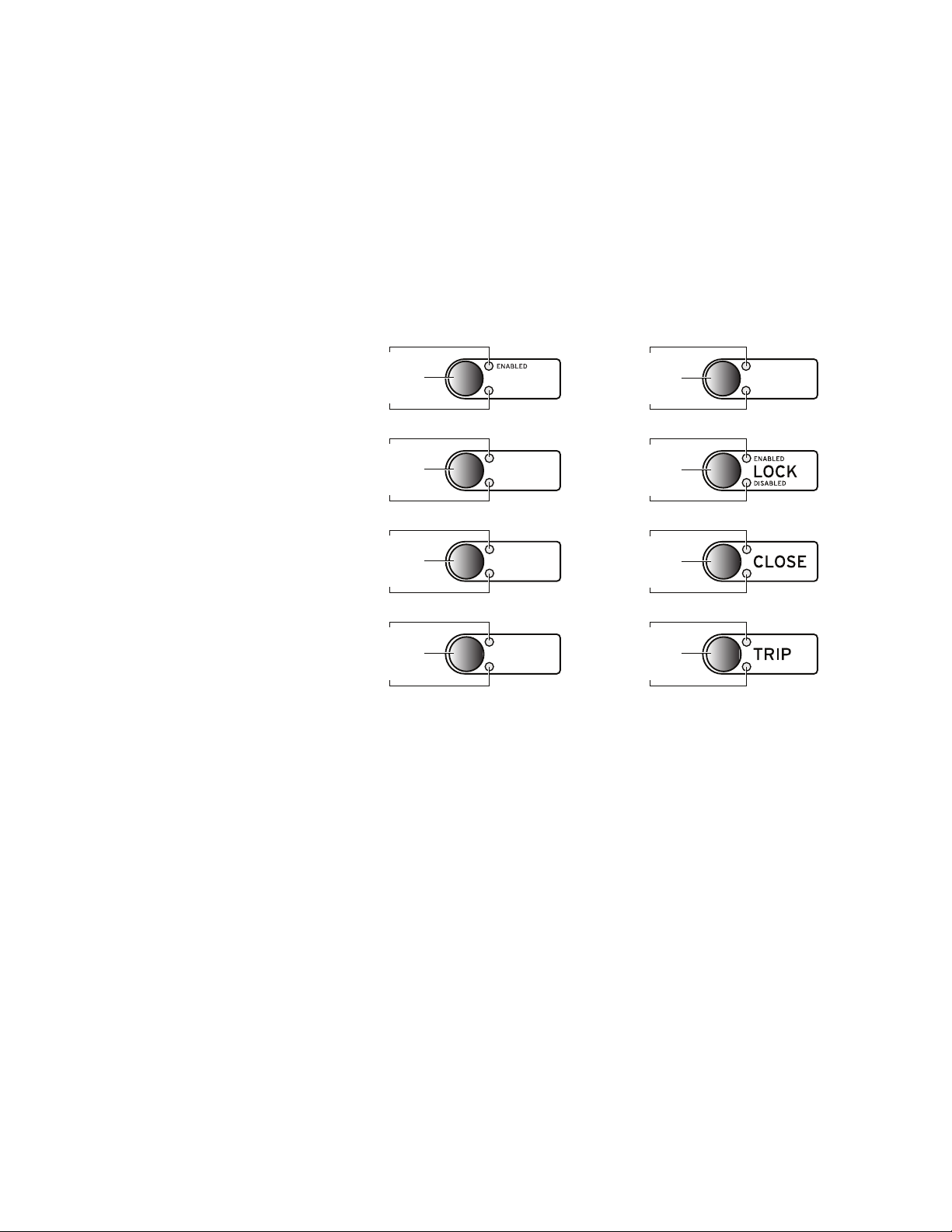

Next, we use the AUX1 pushbutton to drive Latch Bit LT01. The output of LT01 enables and disables

maintenance mode. Figure 2 illustrates the settings. Latch Bit LT01 asserts (maintenance mode

off) when 1) the AUX1 pushbutton is pressed (PB05_PUL = 1 for one processing interval), 2) the

front panel is not locked (LT02 = 1 per the default settings), and 3) the latch bit was previously

deasserted (maintenance mode on). Note that the front panel can be locked or unlocked by pressing

and holding the LOCK pushbutton for 3 s (per the default settings). Latch Bit LT01 deasserts (main-

tenance mode on) when 1) the AUX1 pushbutton is pressed again (PB05_PUL = 1 for one processing

interval), 2) the front panel is not locked (LT02 = 1 per the default settings), and 3) the latch bit

was previously asserted (maintenance mode off).

Application Guide Volume III AG2020-05