Selden Furlex Electric Instructions and recipes

597-274-E

2019-04-24

Supplementary manual

2

1. Introduction

Congratulations on the purchase of your new Furlex Electric motor unit. This manual covers installation

and operating instructions for the electric drive unit only.

Installation of the basic furling systems are described in their respective manuals (see below). The model

designation is found on the cover. Part and serial numbers are found on the gearbox, inside the respective

covers.

The Furlex Electric motor unit is compatible with the following manually operated Furlex models:

204S/304S/204TD/304TD (current models)

200S/300S/200TD/300TD (production year 1997-2015)

The electric furling unit is only to be used together with Seldén’s power supply and SEL-Bus system.

We have compiled this manual to help you install and operate your furling system safely and with ease.

Please read the entire manual before assembly and use of the product. Follow the instructions carefully

to avoid damage to the furling system and to avoid the risk of personal injury. Seldén cannot be held

responsible for any problems, damages or personal injuries arising from an improperly installed product.

Keep the manual available for future reference.

User Manual Revision history:

597-274 Revision 0.0 2017-11-06, Revision 1.0 2019-03-20

The latest version of this manual can be downloaded from www.seldenmast.com

Other Seldén documents referred to in this manual are:

595-104 Furlex 200/300S

597-132 Furlex 204/304S

595-231 Furlex 200/300TD

597-418 Furlex 204TD/304TD

597-275 Power supply & SEL-Bus system

Safety Precautions

Carefully pay attention to, and follow the instructions with the following symbols:

ATTENTION

This symbol indicates a critical moment in the assembly or technical advice.

WARNING

This symbol indicates a potentially hazardous situation. If not avoided, this could result

in serious personal injury or damage to property.

Safety notes regarding the electrical installation for the Furlex Electric:

-The installation should be done by a person with marine installations skills. You can nd your local

authorized Furlex dealer at www.seldenmast.com

-Furlex electric is intended only for sail furling purposes together with Seldén furling proles, controlled

by Seldén’s 42V motor drive system.

-Make sure the system is switched o before performing any installation or service.

-Never modify the electric system of your Furlex or its installation drawings - installation, alterations and

maintenance should be performed by a competent marine electrical technician.

-Never alter or modify the rated current amperage of overcurrent protective devices.

-Never leave the craft unattended with the Furlex Electric energized.

Choosing the correct version of Furlex Electric for your boat:

The key to a safe and properly working installation is correct dimensioning in relation to the boat size the

products shall be used on. Seldén provides dimensioning guidelines in catalogues, leaets and on the

website. If there are any questions about selecting the right product, please consult an authorized Seldén

dealer. All dealers are listed at www.seldenmast.com and divided in categories describing their competence.

For Furlex Electric we recommend authorized Furlex dealers or dealers in the category “Advanced Technical

Installations”.

3

Contents

1 Introduction ......................................................................................................................... 2

Contents ................................................................................................................................... 4

2 Furlex Electric................................ ..................................................................................... 5

2.1 Basic Packs for Furlex Electric complete kit ........................................................... 6

2.2 Furlex Electric Retrot pack..... ................................................................................. 8

2.3 Control Pack .............................................................................................................. 10

2.4 Optional parts ............................................................................................................ 11

2.5 Technical specication ............................................................................................. 12

3 Motor Unit installation ........................................................................................................ 14

3.1 Installation preparations Furlex Electric (above deck) .......................................... 14

3.2 Installation preparation for Furlex TD Electric (Through deck) ............................ 15

3.3 Installation of the furling system excluding the electric motor unit .................... 15

3.4 Step by step assembly 204E/304E ......................................................................... 16

3.5 Step by step assembly 204TDE/ 304TDE ............................................................... 18

3.6 Step by step assembly 200S/300S Retrot .......................................................... 21

3.7 Step by step assembly 200TD/300TD Retrot ..................................................... 23

3.8 Step by step assembly 204S/304S Retrot .......................................................... 27

3.9 Step by step assembly 204TD/304TD Retrot ....................................................... 32

4 Electrical Installation .......................................................................................................... 38

4.1 Installation of deck gland and connection box. .................................................... 38

4.2 Connection to Seldén Power supply and SEL-Bus system ................................. 41

5 Operation ............................................................................................................................. 42

5.1 Normal operation ...................................................................................................... 42

5.2 Unfurling ..................................................................................................................... 42

5.3 Furling ......................................................................................................................... 42

5.4 Reducing sail area .................................................................................................... 43

5.5 Emergency furling ..................................................................................................... 44

6 Trouble shooting ................................................................................................................. 45

7 Service and maintenance .................................................................................................. 46

7.1 Frequent maintenance .............................................................................................. 46

7.2 Yearly Inspection points and maintenance............................................................. 46

7.3 Every 5th year ............................................................................................................ 46

8 Technical information ......................................................................................................... 48

4

5

2 Furlex Electric

Furlex Electric is available as a complete kit for both on-deck and through-deck installation.

The electric system is also available as an upgrade of an existing Furlex by replacing the furling line,

drum and line guard assembly with the Furlex Electric Motor unit and related parts in the Furlex

Electric Retrot pack.

Low power consumption

High eciency throughout the electric power and control system. A “sleep mode” is activated to

save power when not in operation.

Powerful enough, but with precise torque limitation.

The electric motor has a computerised controller that monitors the current draw precisely. As soon

as it reaches a pre-set level it cuts out quickly enough to avoid damage to components. The torque

level is programmed into a memory chip so that each size of Furlex Electric has the correct setting.

Resistant to the marine environment

Furlex Electric has an outer cover made of an impact- and UV- resistant composite polymer.

The worm gear is enclosed in a corrosion resistant aluminum housing. The electric motor has its

own housing which is completely sealed and individually pressure tested before delivery.

Two speed operation

A double control button makes it possible to operate the

furler with great precision in the low speed mode.

By pushing both buttons at the same time, high

speed is activated.

Locks in both directions

The worm gear is self-locking (40:1) in both directions,

which means that the sail can be furled from either

the starboard, or the port side of the boat.

Emergency operation

The worm gear has a ½” socket that can be reached

from the starboard side. Seldén’s emergency line

driver is included in the delivery kit.

Compact size -minimised weight and dimensions.

The electric motor is compact, still giving enough power.

This is made possible by raising the voltage up to 42V.

Keeping weight and the dimensions in focus during the

design has resulted in a small unit.

6

Furlex 204E Furlex 304E

Included parts Qty 549-200-20 549-300-20

Halyard Swivel 1549-229-01 549-329-01

Lower Swivel 1549-200-21 549-300-21

Motor Unit 1 549-601-09 549-601-07

Protect. Hose Ø30 mm 1 319-837 319-837

Clip 2312-213 312-213

Emergency Line drive 1539-664-01 539-664-01

Top bearing assembly 1549-226-01 549-326-01

Bearing plug forward 1549-219 549-319

Bearing plug aft 1 549-220 549-320

Sailfeeder assembly 1549-223-01 549-323-01

Deck gland kit 1539-653-01 539-653-01

Locking adhesive 1312-305 312-305

Halyard U-lead kit 1508 -159-02 508-128-02

Prefeeder Pack 1 505-538-01 505-538-01

Lubricating grease 1312-501 312-501

Torx bit set 1 592-087 592-087

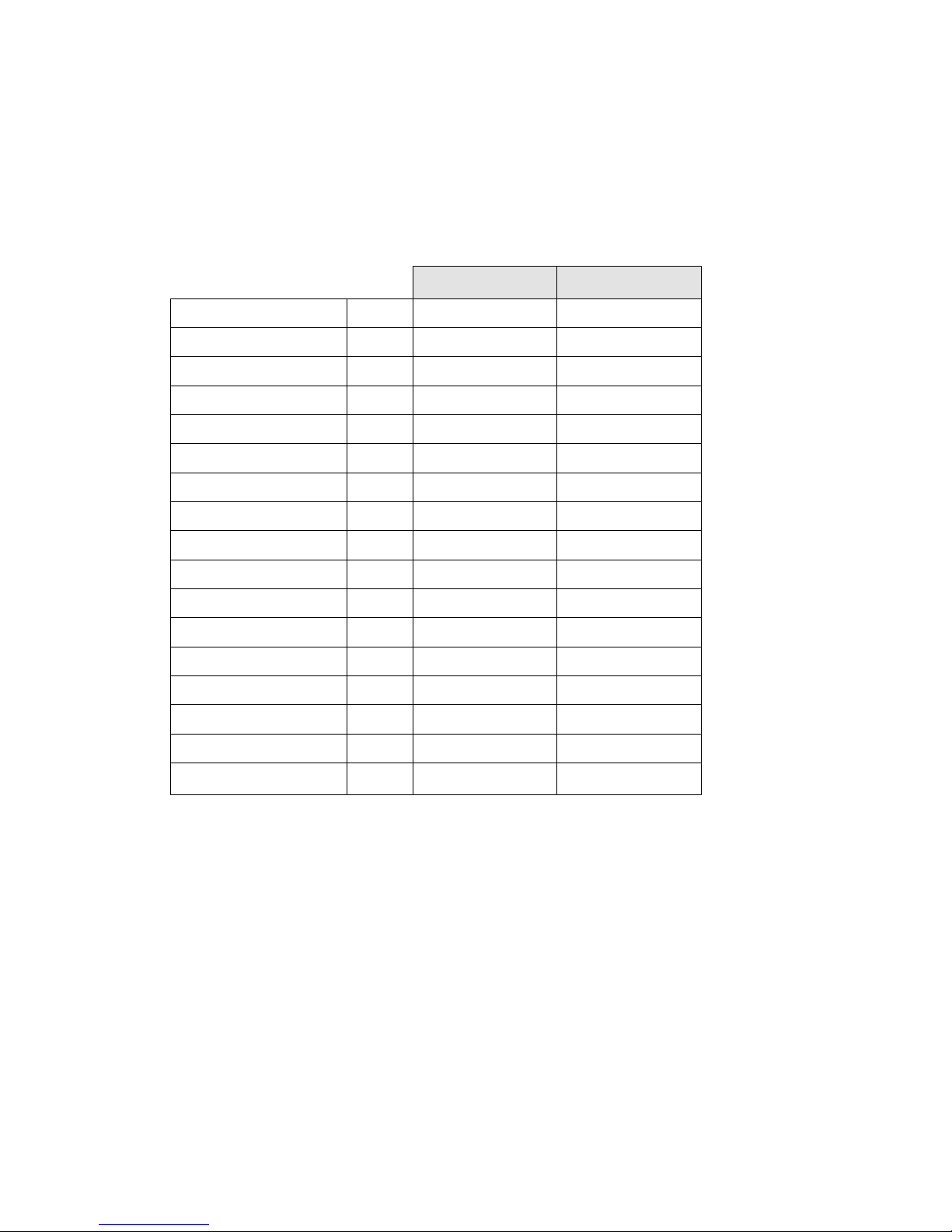

2.1 Basic Packs for Furlex Electric complete kit

When Furlex Electric is bought as a complete kit, following Furlex Electric Basic Packs are included

instead of the respective Basic Pack for manual drive. The tables below show the included parts in

each Furlex Electric Basic Pack.

Furlex Electric Basic pack: Standard

7

Furlex 204TDE ø6/7 Furlex 204TDE ø8 Furlex 304TDE

Included parts Qty 549-270-18 549-270-19 549-370-12

Halyard swivel 1549-229-01 549-329-01

Lower swivel 1549-270-11 549-270-13 549-370-13

Motor Unit 1 549- 601-16 549-601-17

Torque tube assembly 1549-272-02 549-372-02

Deck tting assembly 1549-257- 01 549-357- 01

Torque stay with bracket 1 508- 657-02 508 -657- 02

Screw 2153-006 153-062

Halyard U-lead kit 1508 -159-02 508-128-02

Preefeder pack 1505-538-01 505-538-01

Torx bit set 1 592-087 592-087

Top bearing assy 1 549-226-01 549-326-01

Low bearing assembly 1549-238-01 549-338-01

Spring pin 1166-549 166-552

Sail feeder assembly 1549-223-01 549-323-01

Locking adhesive 1312-305 312-305

Template, Deck Collar 1597-425-E 597- 426 -E

Furlex Electric Basic pack: Through Deck

8

2.2 Furlex Electric Retrofit pack

When upgrading an existing Furlex to electric drive, the retrot pack is bought as an extension of the already

existing Furlex system. The tables below show the included parts in the retrot installation kits for each

manually driven Furlex Electric model, respectively.

204S Electric Retrot 304S Electric Retrot

Forestay

dimension, mm Ø6 Ø7 Ø8 Ø8 Ø10

Item Qty 549-601-250 549-601-255 549-601-260 549-601-265 549-601-270

Motor Unit 1 549-601-09 549-601-07

Hub 1549-650 549-609

Washer 1164-540 164-543

Retain. Ring 1301-563 301-554

Ball 5539-034 539-128

Bearing roller 5319-935 319-930

Protective hose 1319-836 319-836

Deck gland kit 1539-653-01 539-653-01

Clip 2312-211 312-211

Toggle 1539-680-01 539-681-01 539-682-01 539-682-01 539-683-01

Emergency

line driver

1539-664-01 539-664-01

Furlex Electric Retrot pack for Furlex 204S/304S (current models)

Furlex Electric Retrot pack for Furlex 200S/300S (1997-2014)

200S Electric Retrot 300S Electric Retrot

Forestay

dimension, mm Ø6 Ø7 Ø8 Ø8 Ø10

Item Qty 549-601-200 549-601-205 549-601-210 549-601-215 549-601-220

Motor Unit 1 549- 601-10 549-601-08

Carrier 2549-653 549-631

Protective hose 1319-836 319-836

Deck gland kit 1539-653-01 539-653-01

Clip 2312-211 312-211

Toggle 1539-680-01 539-681-01 539-682-01 539-682-01 539-683-01

Emergency

line driver

1539-664-01 539-664-01

9

Furlex Electric Retrot pack for Furlex 200TD/300TD (1997-2017) and 204TD/304TD

(current model)

200TD Electric

Retrot

300TD Electric

Retrot

204TD Electric

Retrot

304TD Electric

Retrot

Item Qty 549-601-225 549-601-240 549-601-275 549-601-290

Motor Unit 1 5 49 - 6 01-11 549-601-12 549-601-16 549- 601-17

Carrier 2549-653 549-631 - -

Hub 1 - - 549-650 549-609

Screw MC6S 8x16 mm 2 153-006 -153-006 -

Screw MC6S 10x16 mm 2 - 15 3 - 011 -15 3 - 011

Torque stay with bracket 1 508- 657-02 508- 657-02 508 -657- 02 508-657-02

Protective hose 1319-836 319-836 319-836 319-836

Clip 1312-211 312-211 312-211 312-211

Emergency linedriver 1539-664-01 539-664-01 539-664-01 539-664-01

Lubricating grease 1312-501 312-501 312-501 312-501

Locking adhesive 1312-305 312-305 312-305 312-305

10

Furlex Electric 200/204 Furlex Electric 300/304

Genoa Cutter Genoa Cutter

Included parts Qty 532-815-90 532-815-91 532-815-92 532-815-93

Motor Control Unit

1532-815-20 532-815-21

Connection Box

1532- 487- 01 532- 487- 01

Control Buttons GENOA

1540-459-16 540-459-16

Control Buttons CUTTER

1

540-459-19 540-459-19

Connection cable Orange 3m 531-045 531-045

Connection cable Grey 3m 531-046 531-046

Connection cable Brown 3m 531-047 531-047

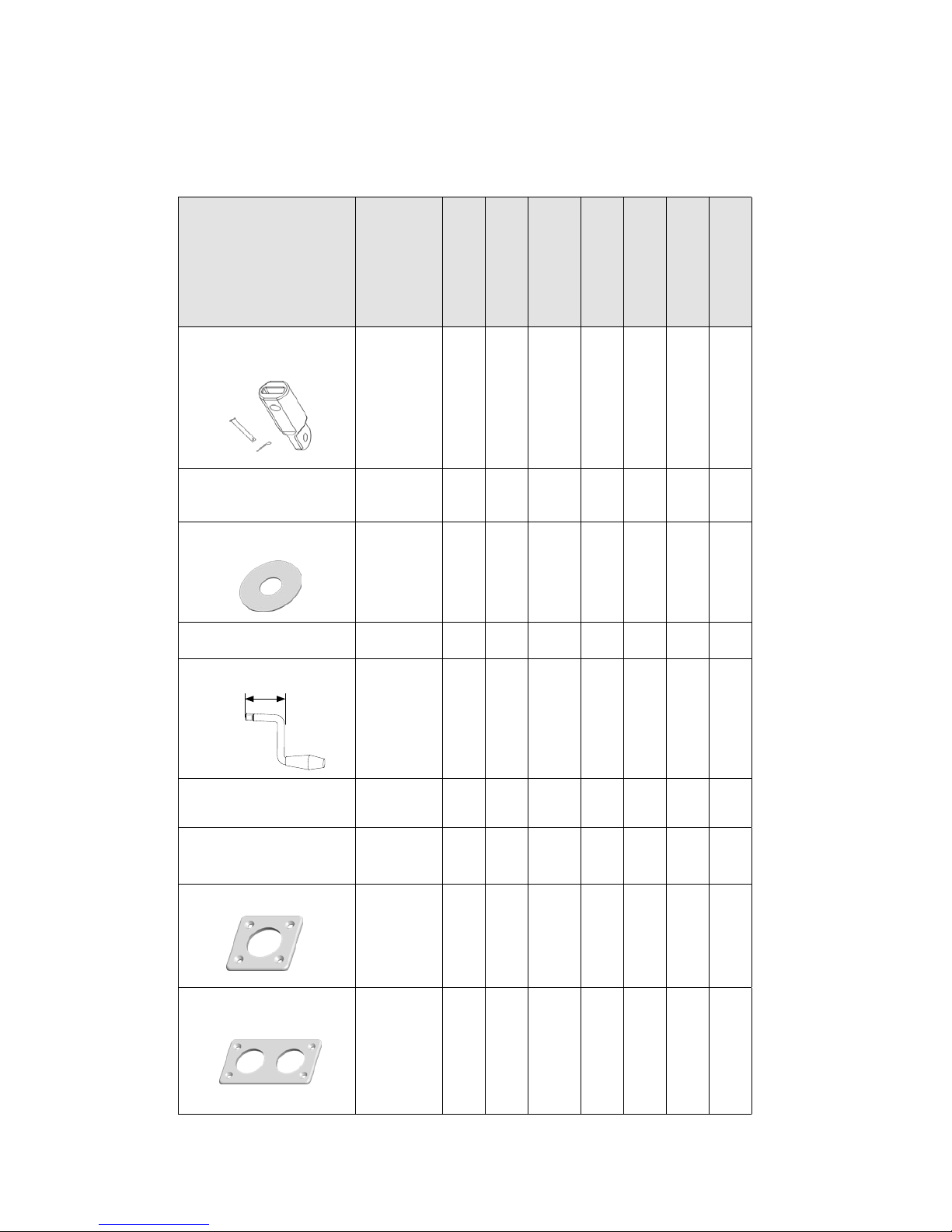

2.3 Control Pack

The Control Pack includes the parts that connect the Furlex motor unit to the Seldén Power Supply

and SEL-Bus system. The included parts are presented in the table below:

11

Item Art. No.

Furlex 204E

Furlex 304E

Furlex

204TDE/304TDE

Furlex 200E

Furlex 300E

Furlex 200TDE

Furlex 300TDE

Forestay wire 6-7 mm, eye/

fork extension link, L=90 mm

517-115 - 01 x x

Forestay wire 8-10 mm, Eye/

fork extension link, L=130 mm

517-116 - 01 x x

Shims for toggle, forestay

ø 6-8 mm

164-516 x x

Shims for toggle, forestay

ø 10 mm

164-519 x x

Short crank, emergency,

L=100 mm

533-922 x x x x x x x

Long crank, emergency,

L=32 5 mm

533-923 x x x x x x x

SEL-Bus Converter (for

custom control buttons)

532-827-01 x x x x x x x

Panel, 1 push button 540-461-01 x x x x x x x

Panel, 2 push buttons 540-462-01 x x x x x x x

2.4 Optional parts

Parts that adapt your installation to your individual boat.

L

12

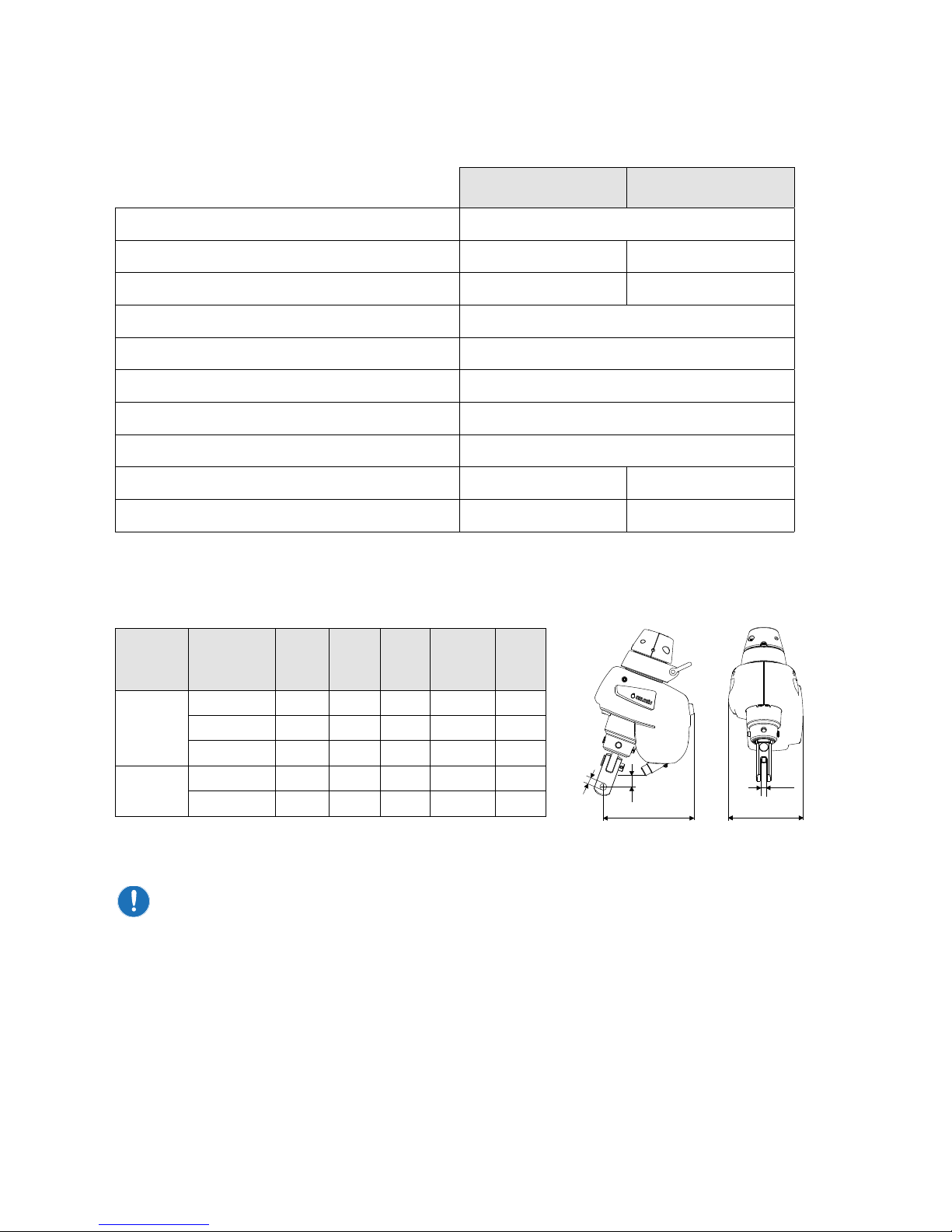

2.5 Technical specification

Electrical specication

Extension links are available if necessary to provide clearance below the unit, as listed in

chapter ”2.4 Optional parts”.

Furlex Electric 200/204 Furlex Electric 300/304

Input Voltage to motor control unit 42V

Peak Torque 60Nm 90Nm

Peak Current Consumption [42V] 18A 26A

Total Gear Ratio 122:1

Low Speed (unloaded) 30 rpm

High Speed (unloaded) 50 rpm

Efciency (Motor Control Unit + Drive Unit) 30%

Cable Size Motor Control Unit - Motor 6 mm2

Weight, Motor Unit approx 7 kg approx 7 kg

Weight, Motor Control Unit approx 1 kg approx 1 kg

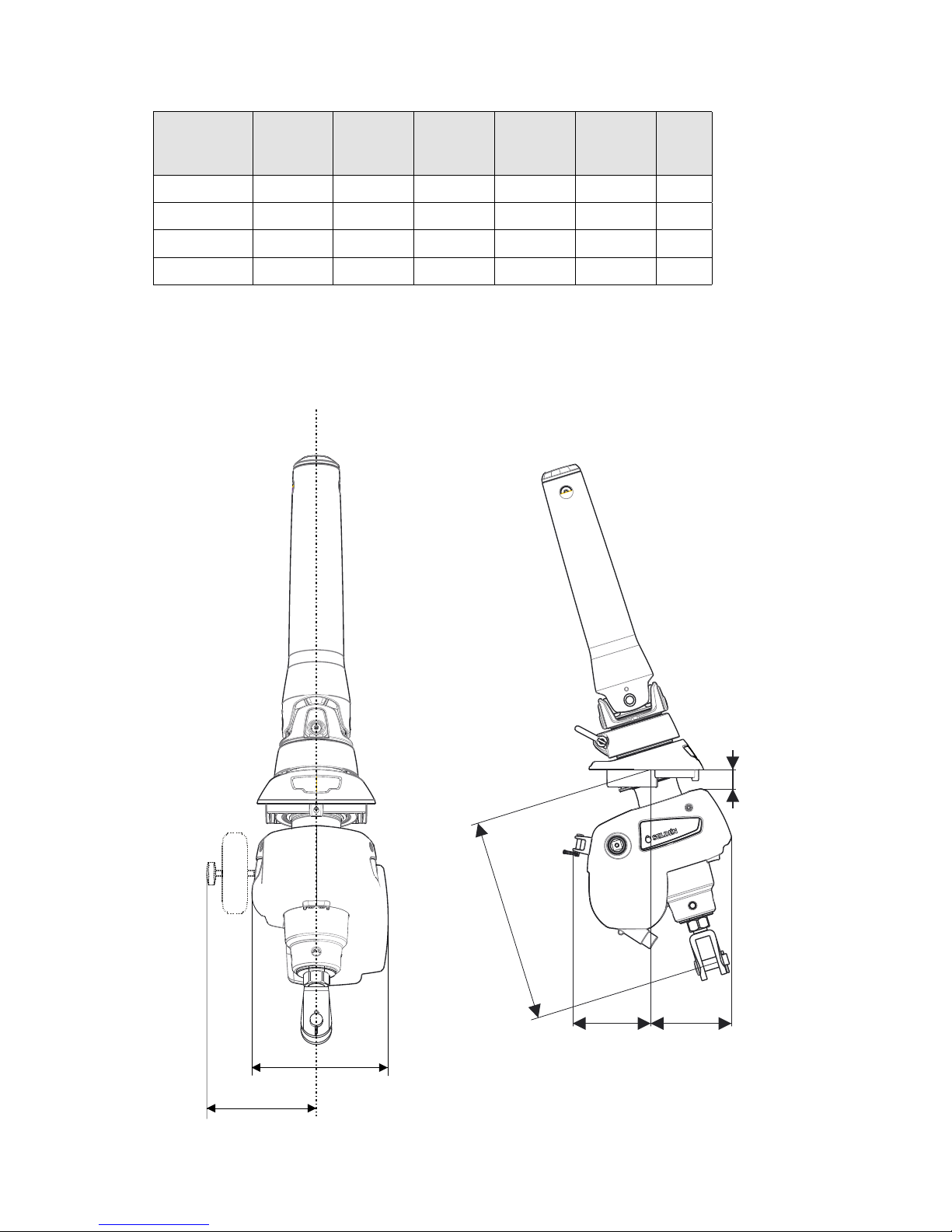

Type Forestay

diameter LHW W2 D2 H2

mm mm mm mm mm mm

204E Ø 6 180 175 12 Ø 10,5 -16

Ø 7 180 175 14 Ø 12,5 -16

Ø 8 183 175 14 Ø 14,5 -7

304E Ø 8 192 175 14 Ø 14,5 23

Ø 10 191 175 16 Ø 16,5 21,5 L

HW

W2

H2

D2

L

HW

W2

H2

D2

Main dimensions, above deck installation:

13

Type A F L1 L2 HW HW1

mm mm mm mm mm mm

200TD 290-450 20 115 114 175 170

204TD 250- 415 20 115 114 175 170

300TD 330-490 18 116 113 175 170

304TD 300-500 30 110 120 175 170

Main dimensions, below deck installation:

F

L2L1

A

HW

HW1

14

3 Motor Unit installation

3.1 Installation preparations Furlex Electric (above deck)

Space requirements

Please check so that there is enough space for the installation. The dimensions are given in the

section ”2.5 Technical Specication”.

Consider space for an anchor. Extension links are available if more space is needed below the

furler, listed in section ”2.4 Optional parts”.

Strength of the forestay attachment

Furlex Electric above deck uses a reinforced toggle capable of handling the torque load.

The forestay attachment needs to have sucient strength to handle the torque loads, with

dimensions according to the table below:

Forestay Dimension, mm

Toggle Ø6 Ø7 Ø8 Ø10

Art No 539-680-01 539-681-01 539-682-01 539-683-01

Length (H) 45 45 55 55

Ø Clevis pin (D1) 12 12 14 16

Fork Width (W1) 10,7 10,7 14,2 14,2

Ø Clevis pin (D2) 10 12 14 16

Fork Width (W2) 12 14 14 16

Forestay Dimension, mm

Extension link Ø6 Ø7 Ø8 Ø10

Art No 517-115 - 01 517-115 - 01 517-116 - 01 517-116 - 01

Length (H) 90 90 130 130

Ø Clevis pin (D1) 12 12 16 16

Fork Width (W1) 10,2 10,2 13,7 13,7

Eye (D2) 12,5 12,5 16,5 16,5

Thickness (W2) 10 10 13,5 13,5

H

W2

W1

D2

D1

W3

D1

W1

HW2

D2

15

3.2 Installation preparation for Furlex TD Electric (Through deck)

Space requirements

Please check so that there is enough space for the installation. The dimensions are given in the

section “2.5 Technical Specication”.

Make sure that there is space for the emergency line driver.

Torque bracket installation

When reefed or under full sail, the furling prole is exposed to a twisting load from the sail.

The forestay attachment of the Furlex TDE is not designed to handle this torque load.

For this reason, the Furlex TDE has a bracket at the rear part of the housing. A torque stay shall

be tted from this bracket to the side of the hull.

Without the torque stay the forestay tting may break, possibly resulting in rig failure.

3.3 Installation of the furling system excluding the electric

motor unit

For complete or retrot installation on Furlex 204/304 systems, please see:

Above deck installation: User manual 597-132 “Furlex 204S&304S”

Below deck installation: User manual 597-418 “Furlex 204TD/304TD”

For retrot installation on Furlex 200/300 systems, please see:

Above deck installation: User manual 595-104 “Furlex 200S&300S”

Below deck installation: User manual 595-231 “Furlex 200TD&300TD”

16

3.4 Step by step assembly 204E/304E

Prior to installation, follow steps in chapter 1.4-3.5 in manual 597-132. Note

that more references are made to this manual during the assembly. Protect

the drum unit and motor unit by working on a clean and soft surface. 597-132-E

1.

Slide the swivel over the terminal. Fit the

adaptor halves and connect the lu extrusion

according to point 4-5 in chapter 3.5, manual

597-132.

2.

Remove the clevis pin and split pin from

the motor unit and t the motor unit over

the hub so that the bronze gear engages

with the carriers in the hub.

3.

Note that the motor unit can be turned 90°

depending on the direction of the forestay

tting in the boat.

Align the holes in the terminal, shaft and

holder.

Fit the clevis pin and split pin.

17

4.

Fit the toggle and, if required, the optional

extension link.

5.

Attach the Furlex Electric system to the

boat by following the steps in chapter 4.3

(stepped mast) or 4.4 (un-stepped mast),

manual 597-132.

Use only Furlex Electric torque toggle

and optional extension link.

18

3.5 Step by step assembly 204TDE/304TDE

Prior to installation, follow steps in chapter 1.4-3.2 and chapter 4 in manual

597-418. Note that more references are made to this manual during the assembly.

Protect the drum unit and motor unit by working on a clean and soft surface. 597-418-E

1.

Check that motor unit ts over hub.

Check that the two locking screws (F) t.

Note that motor unit can be turned 90°

depending on the direction of the forestay

tting in the boat. Verifying what holes are

to be used at this point will help facilitate

assembly in the boat.

Finer adjustment can be made by loosening

the locking nut (N) of the fork terminal and

turning the fork. This adjustment also aects

the distance between deck and forestay

attachment - see point 2.

Remove screws and motor unit.

2.

Fit the swivel in the boat without the motor

unit to control following points:

a) Distance between forestay tting and

deck. The distance between tack ring and

deck tting should be approx. 5mm at the

front when the eye of tack-ring is pulled

upwards. If the distance needs to be

adjusted, follow the instructions in chapter

3.2, manual 597-418

b) The position of the motor unit relative to

the fork, which determines the position of

the motor unit in the boat.

Example: if the motor unit is turned

towards portside, access to the emergency

socket will improve.

F

F

N

19

3.

Fit the swivel through the deck tting and

motor unit.

Check that the emergency line driver can be

tted.

Fit the two locking screws (F).

Use locking adhesive.

4.

Fit clevis pin and split pin.

F

20

5.

Determine the position of the torque bracket.

Bracket should be perpendicular to the drive

unit and tted to the port side.

Clean and key the surface. Bond the

torque-bracket to the hull. Use a structural

adhesive.

After curing, assemble the torque stay to the

bracket in the hull.

Turn the drive unit side to side to nd the

neutral position.

Mark the torque stay at (A)

Remove stay and drill ø6.5mm hole for the

clevis pin

Cut-o excess length of the torque stay

leaving => 10mm material to the ø6.5mm

hole.

Round any sharp edges and assemble the

torque stay.

6.

Attach the Furlex Electric system to the

boat by following the steps 6-9 in chapter

5.1 “Rigging”, manual 597-418.

A

New generation 204TDE/304TDE has

no torque handling capacity and a

torque stay is therefore essential for

these models.

Maximum working load on

torque bracket:

Furlex 204TDE: 2100N

Furlex 304TDE: 3600N

Table of contents