Selecto SMF Series User manual

SMF SELECTO MODULAR FILTER

INSTALLATION & OPERATIONS MANUAL

For Single & Multi-Cartridge SMF Series Systems

Water Filtration Systems for the Food Service Industry

DO NOT USEwithwater that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system.Systems

certied for cyst reduction may be used on disinfected

waters that may contain lterable cysts.

Proud Member of:

UM-SMF-IC

Rev. 9-12-07

Installation and Operating Instructions covering all SMF water filtration systems including, but not limited to:

SMF IC600, SMF IC600+, SMF IC620+, SMF IC600+/3, SMF IC620, IC620-2 & IC620-3, SMF IM600 &

IM614, SMF IcePRO, SMF CoffeePRO, SMF Espresso 7500,SMF Espresso 12000, SMF IC600-S, SMF

SteamerGUARD Flash 2000 & 4000, SMF SteamerGUARD 7500, & SMF SteamerGUARD 12000,

1. Installation Precautions

2. Installation

Page 2

Mounting

1. M asur backplat of filt r syst m and mark hol

locations on wall (See Item ).

a. Insur marks ar l v l, th n drill hol s for

anchors (if n d d). Anchors must b prop rly

match d, to allow for w t w ight of filt r syst m.

b. S cur SMF wat r filt r syst m to wall.

Water Connections

2. Us appropriat 1/2” fittings and tubing to allow

for a flow rat of 5 to 10 Gallons P r Minut (GPM)

(See Item ). Do not overtighten ittings into

plastic parts! Warranty will be voided i parts are

cracked and/or broken due to misuse and/or

overtightening! Us only S l cto approv d, SMF

Modular fittings!

b. Conn ct wat r filt r inl t to cold wat r

supply. Us approv d fl xibl b v rag tubing wh r

possibl with corr ct siz d tub clamps. If hard

plumbing is n c ssary th n us only l ad fr sold r

and prot ct filt r housing from xc ssiv h at. Do

not sold r within 12” of plastic parts!

3. From outl t of wat r filt r us no l ss than 1/2” ID

tubing to all sp cifi d quipm nt. It is only p rmissi-

bl to d cr as lin siz wh n multipl lin s ar

b ing us d (See Item ).

* T ing th tubing should b don appropri-

at ly, for xampl 1/2” x 1/2” x 1/2”. This is only to

b don at quipm nt location if lin is to b us d for

oth r quipm nt.

Initializing Water

Filter

4. Ch ck to b sur that th cartridg is prop rly

install d. Do this by turning th cartridg count r-

clockwis wh n looking at th bottom of th cartridg ,

and th n back clockwis until th postiv stop is f lt.

(See Item ). (Also s Cartridg Changing

Instructions (Page 5) and Troubl shooting Guid

(Page 6)

5. Turn inl t ball valv to th “On” position (handl

horizontal) slowly allowing wat r to fill filt r syst m

(See Item ).

6. Purg th cartridg so that th r is no air r main-

ing by d pr ssing th r d button until a st ady str am

of wat r com s out (See Item ).

7. Purg all air from th drink syst m wat r lin s by

pr ssing th plain wat r valv on drink disp ns r for

approximat ly 1 minut , or until no air, only wat r

com s out.

8. Syst m is now op rational. Go back and ch ck

v ry conn ction for possibl l aks and fix wh r

n d d.

Cartridge Change Schedule

9. Chang cartridg onc y arly, or wh n th n dl

on th pr ssur gaug (See Item ) stays in th

“R d” ar a.

7

1

2

3

4

5

6

1

2

3

6

4

5

7

Page 3

2. Installation (Continued)

Page 4

3. Maintenance

Cartridge Replacement Schedule

1. Wh n th lin pr ssur downstr am of th filt r

housing drops to 30 psi or b low during syst m

op ration, th cartridg (s) n ds to b r plac d.

Occasional dips b low 30 psi and back ar normal.

2. For syst m backplat lab l for ord ring informa-

tion for cartridg r plac m nts.

3. S b low for Cartridg Changing Instructions.

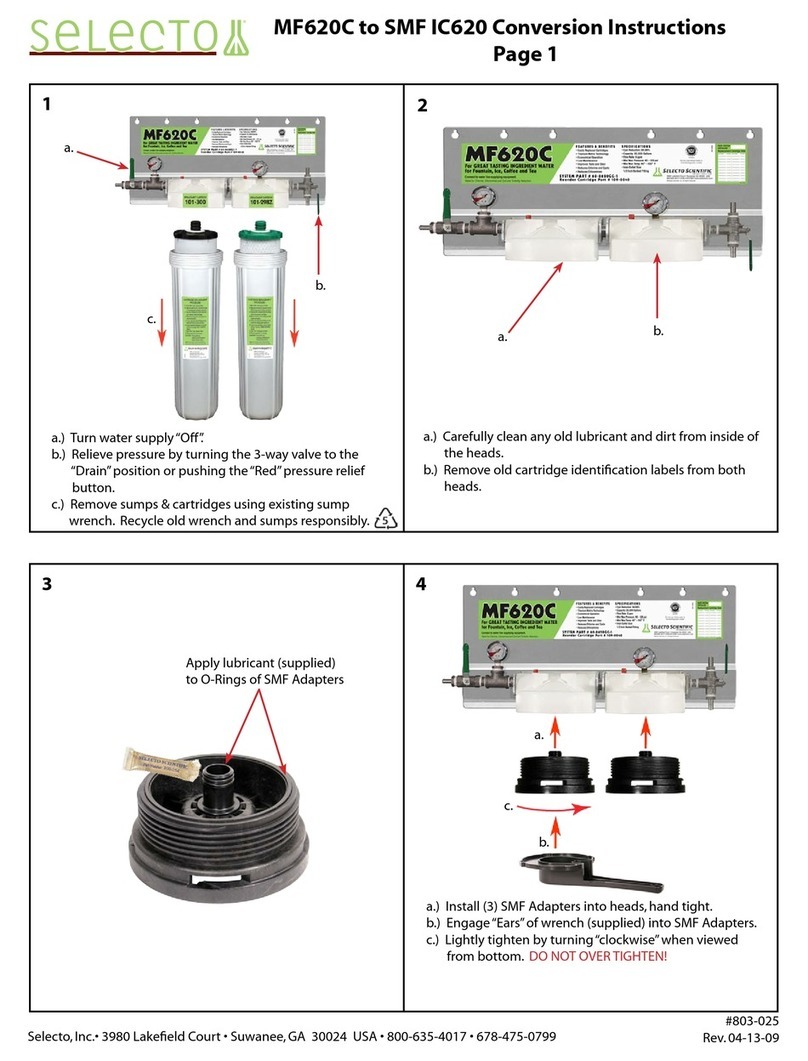

4. Cartridge Changing Instructions

Step #1

Shut off inlet valve . Push “Red” pressure relief button located

at left end of SMF filter system to relieve pressure until no more

water comes out. Grasp filter cartridge, turn counter-clockwise 1/4

turn (when viewed from bottom) and pull downward about 1 1/2” to

remove the filter cartridge. Properly dispose of old cartridge.

Step #2

Remove and discard the “Red” sanitary cap from the top of the new

cartridge. Be sure to apply sufficient lubrication (supplied) to the

O-Rings. Align ear on cartridge with notch in filter head and push

upwards to insert. Be sure to push cartridge all the way in! Turn car-

tridge clockwise (when viewed from bottom) until a definite stop is felt

and cartridge is sealed. Hand tight is sufficient. Turn on inlet valve

Flush for one minute.

It is recommended that the cartridge be changed at least yearly, when

pressure drops significantly, or when bad tastes and/or odors return.

See page 1 or system backplate label for proper replacement cartridge

part number.

5

5

6

Lubricate O-Rings

Page 5

55.. TTrroouulleesshhoooottiinngg GGuuiiddee

Leaks

All SMF Series Modular Filter Systems are factory pressure tested. It is normal to experience leaks of a few drops of

water at the various O-Ring sealed junction points at initial Start-Up only. This will subside after a few minutes as soon as

the O-Rings become under pressure and seat properly. For any leaks lasting longer than this, or those that are more

than a few drops, please see the troubleshooting points below. ote: The inlet valve must be turned “OFF” (handle

in vertical position), and pressure relieved by pushing the “Red” pressure relief button before attempting to fix any

leakage problems.

1. Leaks at threaded connection points.

This type of leak should be repaired by removing the

fitting and applying additional thread sealant compound.

Do not attempt to repair by tightening the fitting more!

Overtightening fittings into plastic parts may cause the

plastic to crack. This type of damage is considered

abuse, and not covered by the warranty!

5

6

2. Leaks at Junction of Modular Fittings to Filter Head

If leaking persists at the junction points, remove the

retainer clip carefully by inserting a screwdriver or other

object into to the hole and gently prying “UP” to remove.

Gently remove the leaking fitting by “pulling straight out”.

Apply additional lubricant (supplied) to the O-ring and

re-insert the fitting by gently “pushing all the way in” until

the shoulder on the fitting contacts the filter head.

Examine the retaining clip for any cracks from removal

and re-insert by “pushing straight down” until it is all the

way in. If retaining clip is cracked or stretched in any

way, discard it and use a new one (supplied). If the

above procedure does not cure the leak, repeat the

processes above, replacing the O-Ring (supplied). See

diagram below.

Retaining Clip

O-Ring

3. Leaks Between Cartridge and Filter Head

While looking at the top of the filter system, grasp the

cartridge and turn slightly counter-clockwise, when

viewed from bottomand then back clockwise, making

sure that the ears on the cartridge are fully engaged

into the filter head. The round locking tab in the filter

head will be engaged into the half-round recess in the

cartridge ear. See diagram below.

Round Locking Tab

4. If leakage persists, remove cartridge by following the

procedures outlined in “Step 1” of the Cartridge

Changing Instructions on Page 5. Inspect the O-Ring

on the top of the cartridge for damage. Replace with a

new O-Ring (supplied) and lubricate well with lubricant

supplied. Replace the cartridge by following the

procedures outlined in “Step 2” of the Cartridge

Changing Instructions on Page 5. See diagram below.

ew O-Ring

Lubricant

Lubricant

55.. TTrroouulleesshhoooottiinngg GGuuiiddee ((ccoonn’’tt..))

Bypassing the Filter System

The purpose of the Selecto SMF Modular Filter System is to

provide consistant safe, clean ingredient water. Bypassing

the system is not recommended. However, in the case of a

damaged or clogged filter cartridge, it may sometimes

become necessary to bypass the system. This may be

accomplished by removing the filter cartridge by following the

procedures outlined in “Step 1” of the Cartridge Changing

Instructions on Page 5, and installing the “Bypass Plug” in its

place. When installing the “Bypass Plug”, it is necessary to

properly lubricate the O-Ring using the lubricant provided.

Install the plug the same as a replacement cartridge by fol-

lowing the procedures outlined in “Step 2” of the Cartridge

Changing Instructions on Page 5. Be certain to properly

engage the “Ears” on the “Bypass Plug” fully into the round

locking tab in the filter head as outlined on the previous page.

See the diagram at right.

66.. WWaarrrraannttyy

Lubricant

Bypass

Plug

This manual suits for next models

16

Table of contents

Other Selecto Water Filtration System manuals

Popular Water Filtration System manuals by other brands

uv guard

uv guard SLT Series Installation and operation manual

Watts

Watts OneFlow OF140-4 Installation, operation and maintenance manual

Trapzilla

Trapzilla TSS-95-ECA Installation & maintenance instructions

UV Pure Technologies

UV Pure Technologies UPSTREAM instruction manual

Penguin Water

Penguin Water 200-PWRO Series manual

V-Guard

V-Guard ZENORA Series Operating Manual & Warranty Guide