Trapzilla TSS-95-ECA Installation and operating instructions

This manual suits for next models

8

Table of contents

Popular Water Filtration System manuals by other brands

ViaAqua

ViaAqua Acro-Cal manual

Nimbus Water Systems

Nimbus Water Systems Cascade Owner's manual & installation guide

Culligan

Culligan Iron-Cleer Installation and operation instructions with parts list

Steinbach

Steinbach Speed Clean 75 Installation and operating instructions

Watts

Watts Hydro-Safe QTCLDBMX-1S-.5M Installation, operation and maintenance manual

Ispring

Ispring RO500 Installation instructions & owner's manual

CWT

CWT Vulcan S10 Training booklet

Pegasus

Pegasus Aqua MRET user manual

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS MFU-10P9S Series Operating and maintenance instructions

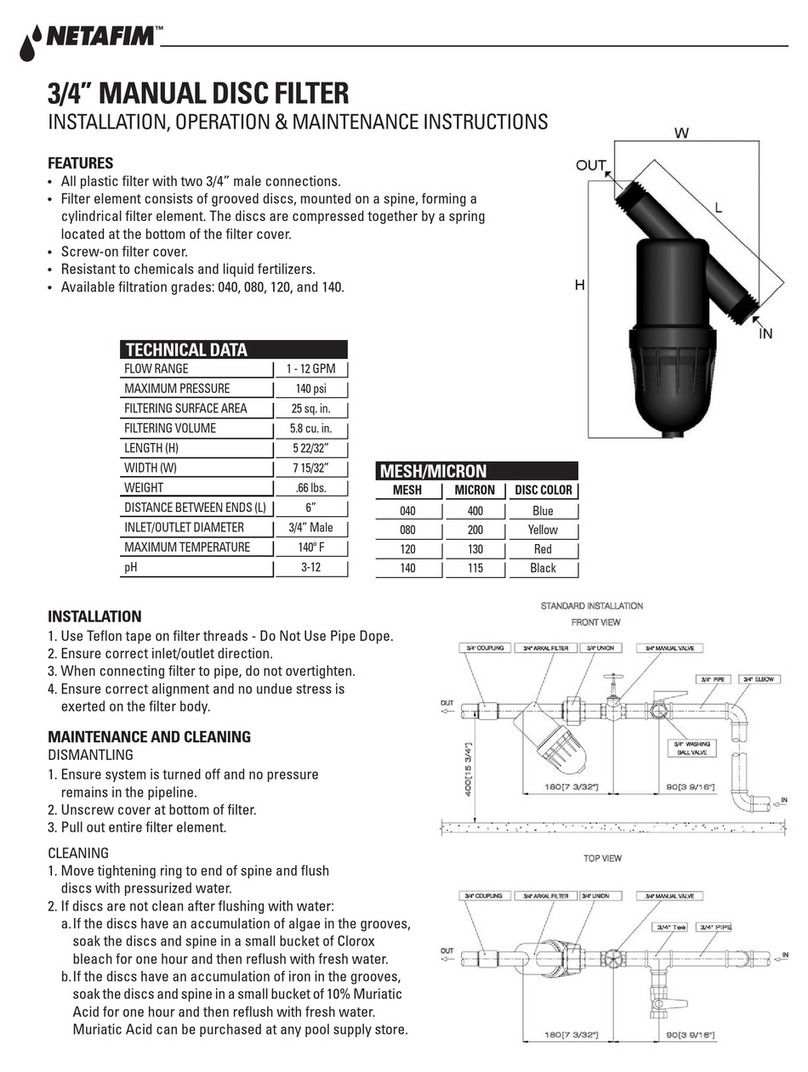

Netafim

Netafim 25AP46 Series Installation, operation & maintenance instructions

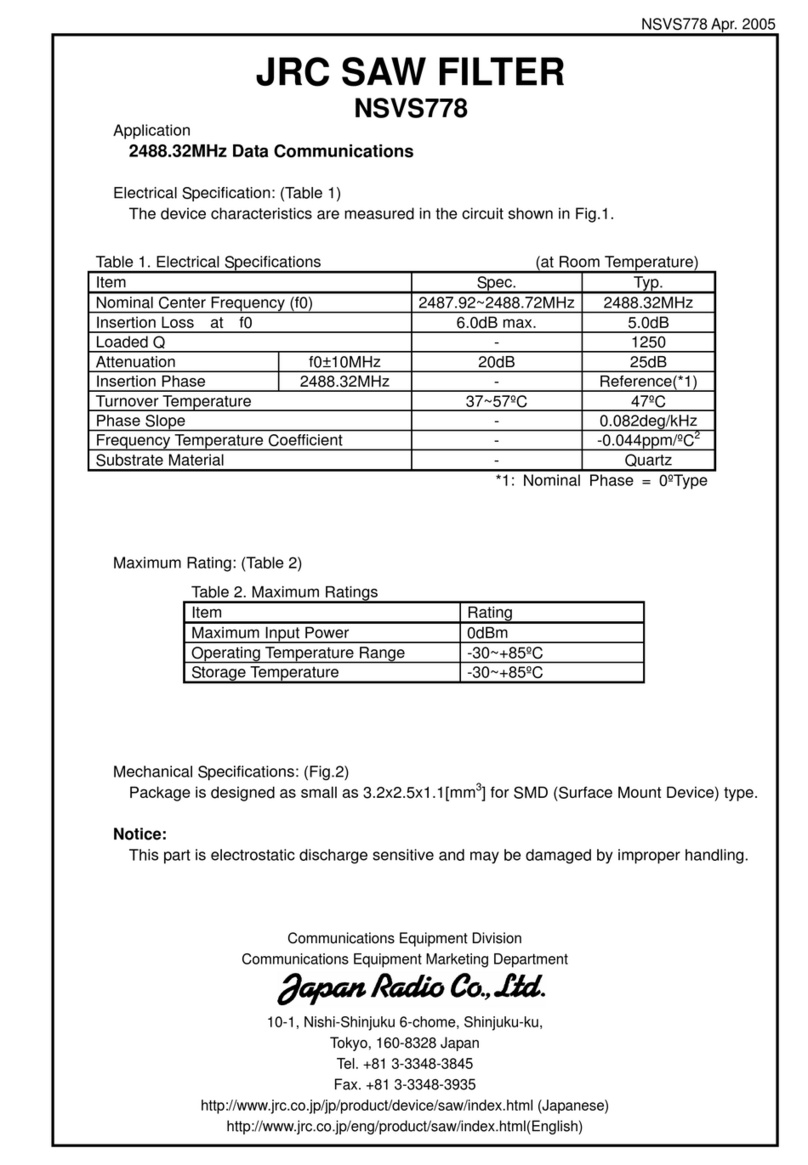

JRC

JRC NSVS778 manual

Oase

Oase Bitron Eco 120W operating instructions

Safety Zone

Safety Zone Iron Trapper ISF-150-AD Installation & Start-Up Procedures

Beko

Beko BEKOMAT 14i manual

Clarke

Clarke CAT152 FITTING & MAINTENANCE

Express Water

Express Water RO5DX installation manual

Pahlen

Pahlen Autodos M1 user manual

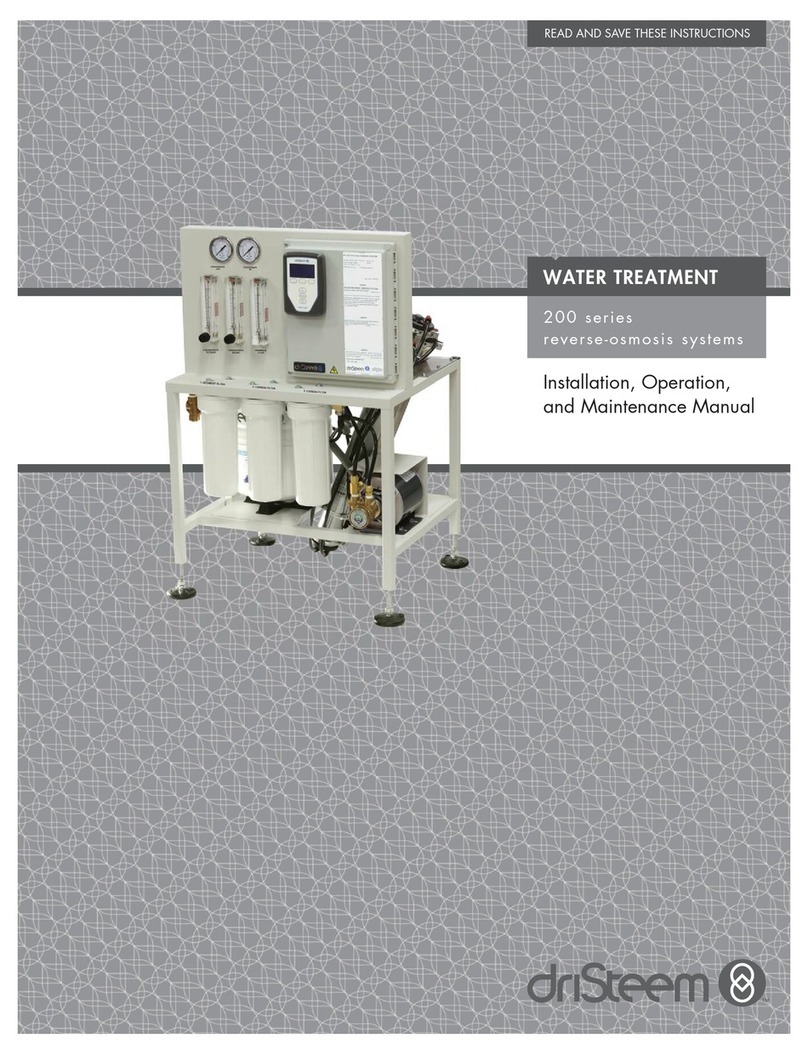

DriSteem

DriSteem RO-200 series Installation, operation and maintenance manual