Selectronic myGrid Quick start guide

IN0025 - 004952 Revision 05 –1 of 35

POWER PERFORMANCE PASSION

myGrid

Installation Notes

myGrid Installation Notes

Introduction

myGrid kits provide an easy to install, compliant, Solar Hybrid (On-Grid) or Off-Grid battery

system.

These installation notes outline all the processes required to effectively install each of the

myGrid kit configurations helping the installer to gain the most benefit from using a myGrid kit.

myGrid Installation Overview

There are two major parts to each kit:-

SP PRO or SP PRO GO Interactive Inverter Charger

Battery Enclosure including side mounted DC switchbox

The battery enclosure is designed to sit on the floor and the SP PRO or SP PRO GO is wall

mount. Connection points between these two parts have been designed to allow flexibility in

positioning to suit many varied locations.

The battery enclosures in the myGrid kit are modular and each section is called a frame. Each

frame can hold four myGrid batteries. The picture above is a two frame battery enclosure plus

left hand mounted DC Switchbox. The DC Switchbox contains the main battery circuit breaker

and the precharge/battery sense circuit breaker under a protective cover and can be mounted

on either the left hand side or the right hand side of the battery enclosure.

OR

PLUS

IN0025 - 004952 Revision 05 –2 of 35

myGrid

Installation Notes

INSTALLATION LOCATION

The myGrid kit includes short cabling for minimum losses so the SP PRO or SP PRO GO and

battery enclosure need to be installed within close proximity of each other. The battery

enclosure and the DC switchbox is suitable for installation outside however it is advisable that

the installation is somewhat protected from the elements.

The distance to the main AC Switchboard must also be considered. AC feeds are required to go

into and out of the SP PRO or SP PRO GO.

Battery Enclosure Dimensions

Dual Frame Enclosure shown.

Quad Frame enclosure is twice the width.

Single Frame Enclosure is half the height.

No minimum spacing is required either side of the battery enclosure. All maintenance access is

from the front and top.

IN0025 - 004952 Revision 05 –3 of 35

POWER PERFORMANCE PASSION

myGrid

Installation Notes

CHOOSING MANAGED CIRCUITS

When installing a myGrid kit in a Solar Hybrid system rewiring of the installations AC

switchboard may be required to split out the load circuits that need to be managed.

If all the installation’s load circuits total less than 63 amps (the SP PRO OR SP PRO GO’s feed

through capacity) it may be easiest to make all the load circuits (excluding off peak loads like

hot water) managed. This provides energy management of all the house loads via SP LINK

however the customer may need to manually manage the loads during a grid outage to prevent

a system overload.

PLACEMENT OF SP PRO OR SP PRO GO

The SP PRO or SP PRO GO needs to be mounted with sufficient clearance on all sides with

allowance for air flow and cabling. See SP PRO or SP PRO GO Instruction Manual for full

details.

ADDITIONAL PARTS TO BE SUPPLIED

Some additional parts are required to be supplied by the installer.

AC Cabling –sized to suit maximum AC demand of AC Loads and charging capacity.

25mm Conduit

Mounting hardware

Solar panels, Grid Inverter, cabling and isolators –as required

KIT CONTENTS

Battery enclosure metalwork components

Pre-assembled and wired DC switchbox

Screws for assembly of the battery box

Insulated Ring Spanner to tighten battery clamps

Torx bits to suit screws provided

DC battery cables

DC battery sense cables

Pre-assembled Battery interconnects

Selectronic SP PRO or SP PRO GO interactive inverter

Sonnenschein 330AH 6V Gel batteries

IN0025 - 004952 Revision 05 –4 of 35

myGrid

Installation Notes

Assemble Battery Enclosure –Part A

The kits are shipped ready to be assembled. Each kit comes with the required number of

frames to suit the number of batteries supplied.

The battery enclosure is modular for ease of assembly and versatility. Each frame is individually

assembled before all the assembled frames are bolted together to form the battery enclosure.

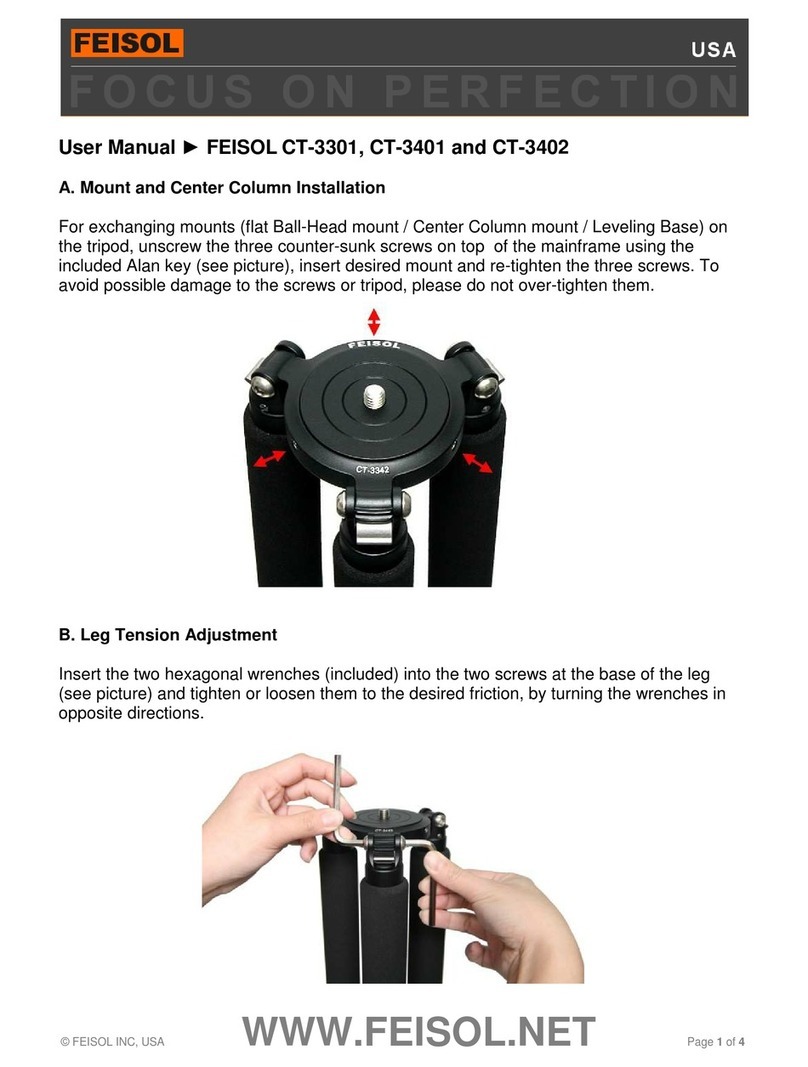

ASSEMBLE FRAMES

Each frame supplied must be assembled.

Install Frame Vents

Frame vents are installed into the bottom shelf frame(s) only.

NOTE: Frame vents are packed with the battery enclosure lid(s).

Place the Frame Vent on the shelf support angle and move in the direction shown in

Figure 1 until it contacts the inserts on the front and back faces of the frame.

Rotate the top of the Frame Vent in the direction shown in Figure 2 and push it down

into the gap between the frame bracket verticals and the shelf support.

Secure the Frame Vent to the shelf support using M4 x 12mm long screws (2 off)

supplied as shown in Figure 3.

Figure 1 Figure 2 Figure 3

IN0025 - 004952 Revision 05 –5 of 35

POWER PERFORMANCE PASSION

myGrid

Installation Notes

Install Shelfs into Frames

Place the Shelf on to the frame brackets so that the inner face of the upward fold is flush

with the inner faces of the frame brackets as shown in Figure 4.

NOTE: Both Left and Right frames brackets are identical.

Secure in place using M6 x 16mm screws (4 off) supplied.

Figure 4

Install Rear Cover to Frames

Locate the Rear Cover (with knockouts) onto the Frames as shown in Figure 5

Secure in place using the M6 x 16mm long screws (4 off) supplied.

Figure 5

M6 x 16mm long

(4 off)

Inner face of shelf

and frame brackets

to be flush

Upward fold back

M6 x 16mm long

IN0025 - 004952 Revision 05 –6 of 35

myGrid

Installation Notes

ASSEMBLE FRAMES INTO THE ENCLOSURE

The frames are assembled together to form the complete battery box.

Single Frame –skip next step

Dual Frame –assemble one frame on top off the other

Quad Frame –assemble two Dual Frames side by side

Five Frames –add one additional frame on top of a Quad frame.

Ten Frames –five dual frames side by side.

Single Frame Dual Frame

Quad Frame Five Frame

IN0025 - 004952 Revision 05 –7 of 35

POWER PERFORMANCE PASSION

myGrid

Installation Notes

Dual Frame Assembly

Place the frame assemblies together as shown in Figure 6. Frames with vents to be at

the bottom of the assembly.

Secure to each other using the M6 x 16mm long screws (2 off per side) supplied as

shown in Figure 6.

Figure 6

M6 x 16mm long

(2 off per side)

Frame without

vents

Frame with

vents

Vents

IN0025 - 004952 Revision 05 –8 of 35

myGrid

Installation Notes

Quad Frame Assembly

Place the frame assemblies together as shown in Figure 7. Ensure the frames with vents

are at the bottom.

Secure frame to frame using the M6 x 16mm screws supplied (4 screws per frame).

Figure 7

FIT DC SWITCHBOX

The DC Switchbox is fitted to the side of the battery enclosure. The DC Switchbox comes ready

to be fitted to the left hand side of the battery enclosure but may be changed to mount on the

right hand side –see Appendix B for details.

Remove the Main and Front covers from the DC Switchbox assembly.

Figure 8

No side panels

M6 x 16mm long (4 off)

on each row of frames

M6 x 16mm long (4 off)

Main Cover

Front Cover

IN0025 - 004952 Revision 05 –9 of 35

POWER PERFORMANCE PASSION

myGrid

Installation Notes

Insert M6 x 16mm long screws ( 4 off ) into the Battery Frame inserts leaving 3 to 5mm

between the screw head and the frame insert. - Refer to enlarged view in Figure 9.

Pass the large holes of the DC Switchbox over the screw heads and allow it to drop onto

the screw threads and tighten screws.

Figure 9

PLACE INTERLINK CABLES

Place into position the DC switchbox battery cables and battery interlink cables that run

between different levels within the battery enclosure. These cables run in the gap between the

frame brackets and the side plates. They are marked (A) on the applicable Battery Connections

Diagrams and need to be positioned before the side panels are fitted.

FIT SIDE PANELS

Locate the side panels on the frames and secure

using the M6 x 16mm screws supplied (4 per

panel) except where DC Switchbox is fitted.

Do not install Side Panel where

DC Switchbox is to be mounted.

Pass large holes

over screw heads

Figure 10

IN0025 - 004952 Revision 05 –10 of 35

myGrid

Installation Notes

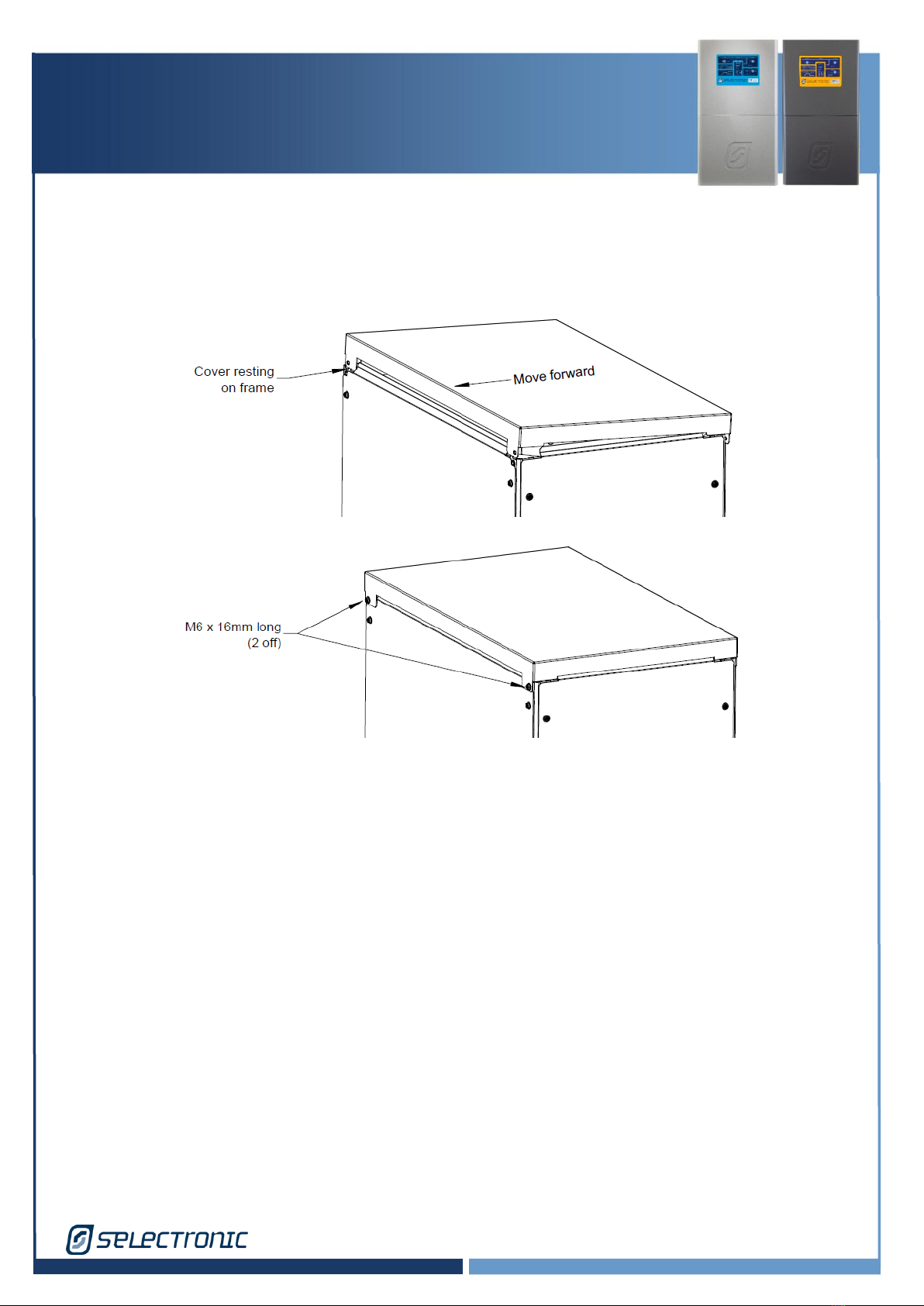

FIT TOP COVERS

Locate the Top Cover on the frames so that it overhangs at the rear and the front of the cover

is resting on the front edges of the frames as shown in Figure 11a.

Move the cover towards the front of the frames to engage the pins on the inside rear of the

cover into the inserts in the frames.

Figure 11a

Figure 11b

Lower the cover and secure it to the frames using M6 x 16mm long screws (2 off). Refer to

Figure 11b.

Position Battery Enclosure

Battery enclosure is now suitably assembled to be positioned. The battery enclosure (once

fitted with batteries) is quite heavy and must be placed on a solid surface - if to be placed on

dirt then using concrete squares for each leg is suitable. Ensure all legs are supported upon a

solid surface and the battery enclosure is level (use a spirit level to ensure battery enclosure is

level side to side and front to back).

Adequate ventilation is required. Air is drawn in from below each side panel and vented out at

the top of the front side panel.

Batteries are degraded by high temperature. Enclosure is to be placed in coolest position and

MUST be protected from direct sunlight.

Cable entry is provided at the rear of the DC Switchbox. Position the battery enclosure to

minimise cable length to the SP PRO or SP PRO GO via most appropriate cable entry point

either below or from behind.

IN0025 - 004952 Revision 05 –11 of 35

POWER PERFORMANCE PASSION

myGrid

Installation Notes

Installing the SP PRO OR SP PRO GO

Install the SP PRO or SP PRO GO as per the installation instructions.

Verify the position of the battery enclosure is suitable for the supplied length of DC cabling.

Reposition the Battery enclosure or inverter as appropriate.

CABLING

Tools –6mm hex bit, supplied with the SP PRO or SP PRO GO inverter.

Parts –25mm Flexible Conduit

Use the following diagram as a guide to install DC cabling.

The DC cables are pre-terminated within the DC Switchbox. The cabling is listed in order to

enable easy installation and routing of DC cables –

1. DC Sense and Temperature

2. Battery Negative

3. Battery Positive

DC CABLE KNOCKOUTS

Knockout three of the four 25mm gland holes;

one for battery positive,

one for battery negative and

one for battery sense and temperature cables

and fit off with conduit glands.

Contained within

Battery Enclosure

Main Battery

Circuit Breaker

Precharge / Battery

Sense Circuit Breaker

IN0025 - 004952 Revision 05 –12 of 35

myGrid

Installation Notes

BATTERY SENSE CABLING AND BATTERY TEMPERATURE SENSE

Disconnect the battery temperature sensor cable from the SP PRO or SP PRO GO expansion

card and feed it through with the Precharge / Battery Sense cable (end without M10 Ring lugs)

from DC Switchbox to the SP PRO or SP PRO GO via conduit and glands.

Strip Precharge / Battery Sense cable to bear each lead and connect into the terminals as

indicated –

B+ : Brown

B MID : Yellow

B- : White

Note: Take care to observe minimum strip lengths.

Reconnect the battery temperature sensor cable to the expansion card as indicated –

SUPPLY : Grey

BATT TEMP : Grey

Note: Temperature sensor is not polarity sensitive and can be connected either way.

MAIN BATTERY CABLING

Feed Black B- cable (without battery lug) from DC Switchbox to the SP PRO or SP PRO GO

directly below the B- terminal via conduit and glands.

Feed Red B+ cable (without battery lug) from DC Switchbox into the SP PRO or SP PRO GO

directly below the B+ terminal via conduit and glands.

Remove the pre stripped insulation and connect into the terminals as indicated –

B+ : Red

B- : Black

Note: Take care to ensure all strands go into the clamp terminals.

IN0025 - 004952 Revision 05 –13 of 35

POWER PERFORMANCE PASSION

myGrid

Installation Notes

Installing the Batteries

Warning: Batteries are very dangerous. Battery fault currents are 1,000s of amps. Please read

and adhere to the safety information provided with the batteries.

Safe practices when working with battery systems –

Remove all conductive jewellery or watches before working on batteries.

Keep any conductive tools well clear of the batteries

Only use non-conductive or insulated tools when working on or near the batteries.

Double check the connection orientation of the batteries and battery links.

Before connecting any links between battery terminals, check the voltage between

those battery terminals to be zero using a volt meter.

Care MUST be taken when connecting the battery interlinks. Please note that the

lose end of the battery interlink is live and must be prevented from shorting to

other batteries or battery terminals.

NOTE: Ensure Main Battery and Pre-charge/Battery Sense circuit breakers are in the O / Off

position before making any connections to the batteries.

BATTERY TERMINAL SIZE

The battery positive terminal is larger than the battery negative terminal. It is important to

ensure that only a RED coloured clamp is fitted to a battery positive terminal and the BLACK

smaller clamp is fitted to a battery negative terminal.

BATTERY INTERCONNECTS

The supplied battery interconnects have been pre-assembled, tightened and designed to suit

the battery configurations pictured below. There is no need to loosen any of the pre-assembled

battery interconnects. Adjust the position of the batteries by sliding them to fit rather than

adjusting the battery interconnects.

Battery Link

Used for connecting two batteries in series –battery positive to battery negative.

IN0025 - 004952 Revision 05 –14 of 35

myGrid

Installation Notes

Battery Interlink –Parallel

Used to series connect between frames of two groups of parallel batteries –two groups of

battery positive to two groups of battery negative.

Battery Interlink –Series

Used to series connect between frames - battery positive to battery negative.

IN0025 - 004952 Revision 05 –15 of 35

POWER PERFORMANCE PASSION

myGrid

Installation Notes

Battery Clamps

The battery G-Clamps lock onto the terminals using an Insulated Ring Spanner. Ensure the nut

is loosened so that the clamps can be comfortably seated onto the terminals as shown below –

NOTE: Make sure both the Positive and Negative G-Clamps are connected to the correct

terminals as indicated above.

Tightly fit the G-Clamps onto the battery terminals by gently tapping the clamps onto the

battery post. Proceed to hand tightening the nut using a ring spanner until there is no motion in

the clamp. Finally confirm that the clamp is locked onto the battery terminal by ensuring

minimal movement on the clamps.

Battery Positive and Negative

G-Clamps shown in clear

position ready to go onto

battery terminal

RED Battery Positive and

BLACK Battery Negative

Clamps shown fully

seated and locked onto

terminal.

Tighten the clamp

using Insulated

Ring Spanner

Positive

Negative

IN0025 - 004952 Revision 05 –16 of 35

myGrid

Installation Notes

BATTERY SENSE CABLING CONNECTIONS TO THE BATTERIES

The battery sense wires are connected to the batteries after the battery clamps have been

fitted and locked into place and before installing the next shelf of batteries.

Fit the battery sense connections onto the studs of the

associated battery connection and lock in place with

one of the 8mm lock nuts (skinny nuts) provided. The

connection points of each of the three battery sense

cables are shown on the battery connection diagrams

on the following pages.

NOTE: The outer sheath of the battery sense cable will need to be stripped back to enable the

connections to reach in some of the battery configurations.

BATTERY POSITIONING

The battery frames will accept 4 batteries each. Batteries can be slid into the enclosure from

the front.

Always install batteries into the lowest frame first with the shelf or lid above removed. Make all

battery interconnections and then fit shelf above or the top cover.

Repeat for shelf above as applicable.

Batteries should be placed according to the diagrams below taking careful note of battery

positive and negative positioning.

Note: The diagrams show the battery positions for DC Switchbox mounted on the left hand

side.

PARALLEL BATTERY CONNECTIONS

Note: For Parallel battery connections

ensure that battery clamps are

positioned such that the lead in and the

lead out are in opposite corners of the

battery cluster. This will ensure equal

current sharing through the parallel

strings.

IN0025 - 004952 Revision 05 –17 of 35

POWER PERFORMANCE PASSION

myGrid

Installation Notes

BATTERY CONNECTIONS

myGrid 24 VDC 8 kWh Battery Connections

Warning: Ensure Main Battery and Precharge Circuit breakers are 0 / Off position.

NOTE: Battery fault currents are 3,970 amps

4 x 330 Ah 6 V Batteries in series

Frame –One 24 VDC group made up of four series 6 VDC batteries.

Ensure batteries are placed with the positive and negative terminals as shown.

Battery Sense +ve (Brown)

Battery Sense -ve (White)

Battery Sense Mid (Yellow)

IN0025 - 004952 Revision 05 –18 of 35

myGrid

Installation Notes

myGrid 24 VDC 16 kWh Battery Connections

Warning: Ensure Main Battery and Precharge Circuit breakers are 0 / Off position.

NOTE: Battery fault currents are 7,940 amps

8 x 330 Ah 6 VDC blocks in parallel / series combination

Each frame –Two parallel 12 VDC groups made up of two series 6 VDC batteries.

Ensure batteries are placed with the positive and negative terminals as shown.

Battery Sense +ve (Brown)

Battery Sense -ve (White)

Battery Sense Mid (Yellow)

A

A

IN0025 - 004952 Revision 05 –19 of 35

POWER PERFORMANCE PASSION

myGrid

Installation Notes

myGrid 48 VDC 16 kWh Battery Connections

Warning: Ensure Main Battery and Precharge Circuit breakers are 0 / Off position.

NOTE: Battery fault currents are 3,970 amps

8 x 330 Ah 6 VDC blocks in series combination

Each frame –One 24 VDC group made up of four series 6 VDC batteries.

A

A

Battery Sense +ve (Brown)

Battery Sense -ve (White)

Battery Sense Mid (Yellow)

IN0025 - 004952 Revision 05 –20 of 35

myGrid

Installation Notes

myGrid 48 VDC 32 kWh Battery Connections

Warning: Ensure Main Battery and Precharge Circuit breakers are 0 / Off position.

NOTE: Battery fault currents are 7,940 amps

16 x 330 Ah 6 VDC blocks in parallel / series combination

Each frame –Two parallel 12 VDC groups made up of two series 6 VDC batteries.

Battery Sense +ve (Brown)

Battery Sense -ve (White)

Battery Sense Mid (Yellow)

A

A

Table of contents

Other Selectronic Camera Accessories manuals