Selkirk CF User manual

Intermediate Joist

Shield

Any Chimney

Length

Ceiling Support Assembly

Base Cap

Assembly

Lower Bucket

Round Top

Storm Collar

Flashing

Attic Insulation

Shield/Firestop

Spacer

These installation requirements are based on complete tests of the Model CF Chimney

in accorance with the Standard for 650 deg. C Factory-Built Chimneys

CAN/ULC-S629-M87.

Selkirk chimney parts are produced under the Listing Program of Underwriers

Laboratories of Canada. Each ULC Listed part carries the label specified in their

“List of Equipment and Materials”.

Manufactured by Selkirk Canada Corp. - Hamilton, Ontario

Installation Instructions for

MODEL CF

CEILING SUPPORTED

CHIMNEY

880063LT-rev.0711

GENERAL INSTALLATION RULES:

1. Situate the chimney in the structure so that it can be installed

without cutting joists, sills, plates or load bearing partitions or

members.

2. Each wood or coal appliance should have its own chimney.

DON’T INTERCONNECT.

3. There should be no draft regulators on solid fuel equipment

and smoke pipes and cleanout caps should be tight.

4.Aminimum smoke pipe length of 1 m (3 ft.) between appliance

and chimney is recommended.

5. Continuous operating flue gas temperature should not exceed

650°C (1200°F).

CREOSOTE AND SOOT FORMATION AND NEED

FOR REMOVAL:

When wood is burned slowly, it produces tar and other organic vapors,

which combine with expelled moisture to form creosote. The creosote

vapors condense in the relatively cool chimney flue of a slow-burning

fire. As a result, creosote residue makes an extremely hot fire.

With coal, which can burn with a smoky fire, this smoke also condenses

in the chimney to form soot.

The chimney should be inspected at least once every 2 weeks during

the heating season to determine if a creosote or soot buildup has

occurred.

If creosote has accumulated, it should be removed to reduce the risk of

chimney fire.

If you see deposits more than 1/16 inch thick, clean all of the chimney

parts mechanically. This means using brushes, scraping or equivalent.

Don’t start a chimney fire! With only slight deposits, try a hot fire to see

if the black deposits change to light ash, or fall down the chimney and

the inside of the appliance for deposits. Do not use chemical cleaners,

they may corrode the inside of the chimney. They may or may not

prevent or remove creosote. When they are used together with a hot

fire, it is probably the fire that is doing the work.

Depending on the rate of buildup, as you learn what is going on in the

chimney, you can adjust your cleaning schedule.

If you have any doubts about your ability to clean the chimney, of if the

deposits are very heavy and hard to remove, call a professional

chimney sweep. Do not try to burn them off.

It doesn’t matter how careful you are with loading, fuel wood selection

or draft control, you should observe the above precautions with any

wood stove or chimney installation.

CHIMNEY FIRES

AND WHAT TO DO ABOUT THEM

Your Selkirk Model CF Chimney is not intended or designed

for use as a combustion or fire chamber. It is very easy to overfire

your woodburning appliance with kindling, scrap lumber, brush or

any fast burning fuel. This can produce flames and high

temperatures all the way up the chimney, and may cause chimney

damage.

If you see your appliance or the smoke pipe glowing red, you are risking

chimney damage, or a fire. The creosote may be burning inside the

chimney. If you see flames coming out of the top, you are either

overfiring or there is a chimney fire.

If the fire in your heater has gotten out of control, or if you suspect a

chimney fire for any reason, follow these steps:

1. Immediately close all dampers and/or air entrance openings to your

appliance. This includes doors on Franklin type stoves. Block off

fireplace openings.

2. Alert your family to the possible danger.

3. Inspect your appliance and chimney surroundings for possible fire. If

in doubt, alert your fire department.

4. Do not continue to use your appliance until it and your chimney have

been thoroughly inspected. Overheating can cause metal parts to

expand, buckle and crack. If you are not certain, have a qualified

heating man disassemble all parts so they can be inspected and

replaced.

5. Do not use salt or water on the fire in your appliance. Salt is corrosive

and water will cause a danger steam explosion. You might be able to

control the fire by using ashes, sand or baking soda, since baking soda

is an ingredient used for dry chemical fire extinguishers.

6. After a chimney fire, when it is safe to do so, check internal locations

such as the attic and under the roof and keep watching for two or three

hours. There may be delayed smoldering and subsequent ignition,

even if the fire inside the chimney has been controlled.

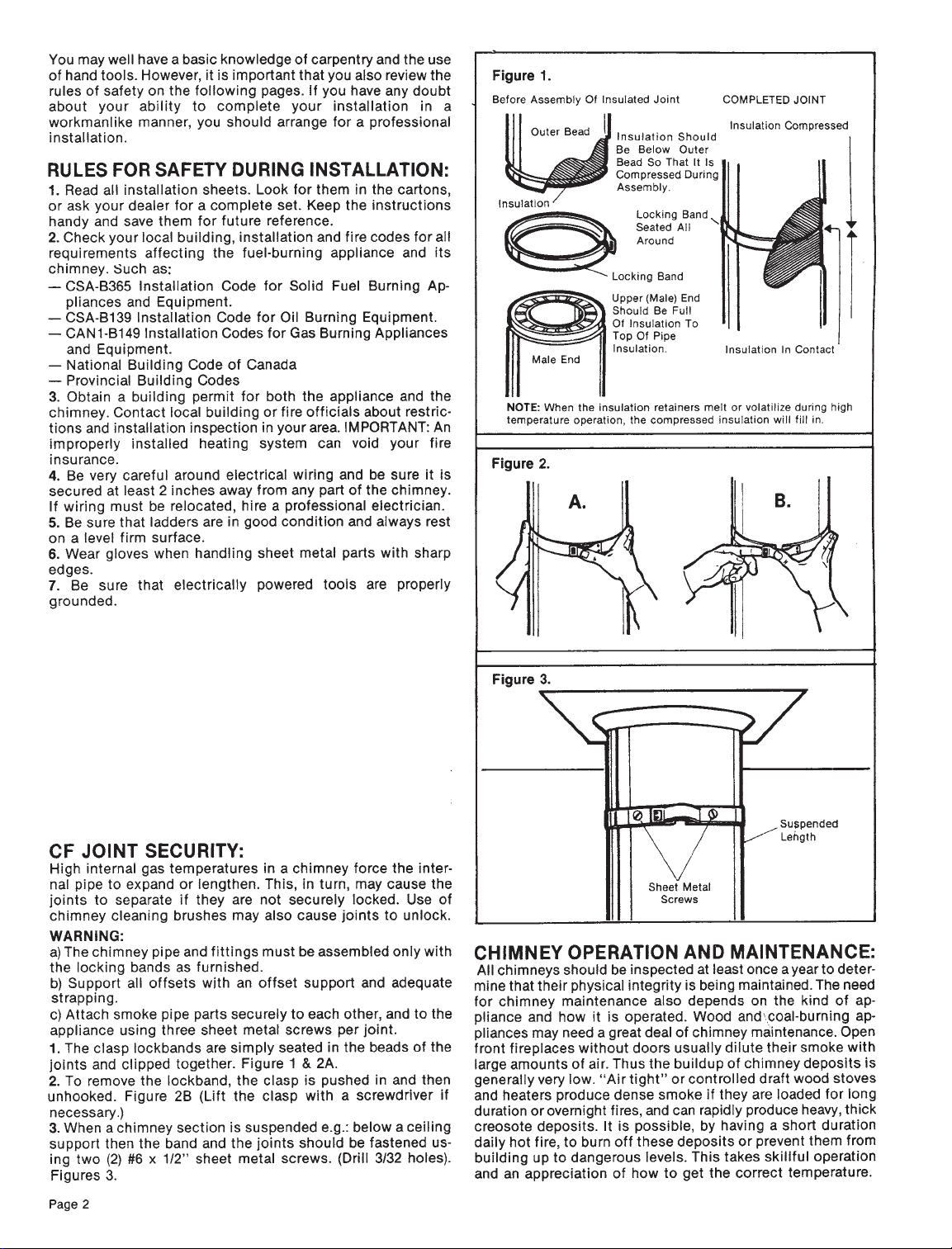

CHIMNEY OFFSETS:

One pair of (2) 15° or 30° elbows can be used to provide a sloped

offset. The maximum permissible angle with solid fuel installation is 30

degrees.

An offset data table is supplied to determine the offset desired and the

offset height.

Table 1. Framing and Support Table

Model CF Chimney

Inside Diameter 6” 7” 8”

Outside Diameter 267mm (10-1/2”) 299mm (11-3/4”) 330mm (13”)

Enclosure Framing

(Square) 369mm (14-1/2”) 400mm (15-3/4”) 432mm (17”)

* Ceiling Support

Framing (Square) 362mm (14-1/4”) 362mm (14-1/4”) 362mm (14-1/4”)

Approx. weight

kg/m (lbs/ft.) 11.5 (8) 13.5 (9) 15.5 (10.5)

Maximum Height for all supporting methods

Ceiling Support Package 12m (40’)

Interior Resupport Assembly/

Offset Support 9 m (30’) All Sizes

Wall Support Package 12 m (40’)

Roof Support 9 m (30’)

Minimum Clearance to combustibles 50 mm (2” ) all sizes

* The clearance to combustibles obtained with a correctly installed Ceiling

Support Assembly in the framed opening specified has been tested. The 2”

clearance does not apply at this location.

}

Table 2.

6” Dia 7” Dia 8” Dia

Elbow Length A B A B A B

2 x 15° 9” 76mm 457mm 473mm 400mm 473mm 483mm

(3¾”) (18½”) (3-5/8”) (18-7/8”) (3-5/8”) (19¼”)

2 x 15° 12” 102mm 191mm 105mm 508mm 112mm 530mm

(4½”) (20-3/8”) (4-1/8”) (20¾”) (4-1/8”) (20-7/8”)

2 x 15° 18” 143mm 714mm 127mm 660mm 127mm 660mm

(5-5/8”) (28-1/8”) (5¾”) (26½”) (5¾”) (26¾”)

2 x 15° 36” 264mm 1114mm 254mm 1121mm 254mm 1118mm

(10-3/8”) (43-7/8”) (10½”) (44-1/8”) (10½” (44½”)

2 x 30° 9” 187mm 495mm 203mm 537mm 200mm 543mm

(7-3/8”) (19-1/2”) (8”) (21-1/8”) (7-7/8”) (21-3/8”)

2 x 30° 12” 225mm 559mm 235mm 600mm 238mm 608mm

(8-7/8”) (22”) (9-1/4”) (23-5/8”) (9-3/8”) (23-7/8”)

2 x 30° 18” 302mm 695mm 311mm 737mm 314mm 743mm

(11-7/8”)

(27-3/8”) (12-1/4") (29”)

(12-3/8”) (29-1/4”)

2 x 30° 36” 530mm 1089mm 540mm 1130mm 543mm 1137mm

(20-7/8”) (42-7/8”) (21-1/4”) (44-1/2”) (21-3/8”) (44-3/4”)

Page 3

A

B

Attic

Insulation Shield/

Firestop Spacer

Attic Insulation

Shield/ Firestop Spacer Intermediate

Joist Shield

50mm (2")

Clearance

Enclosure Walls

Smoke

Pipe Ceiling Support Assembly

with Base Cap Assembly

Ceiling Support Assembly

with Base Cap Assembly

Smoke

Pipe Smoke

Pipe

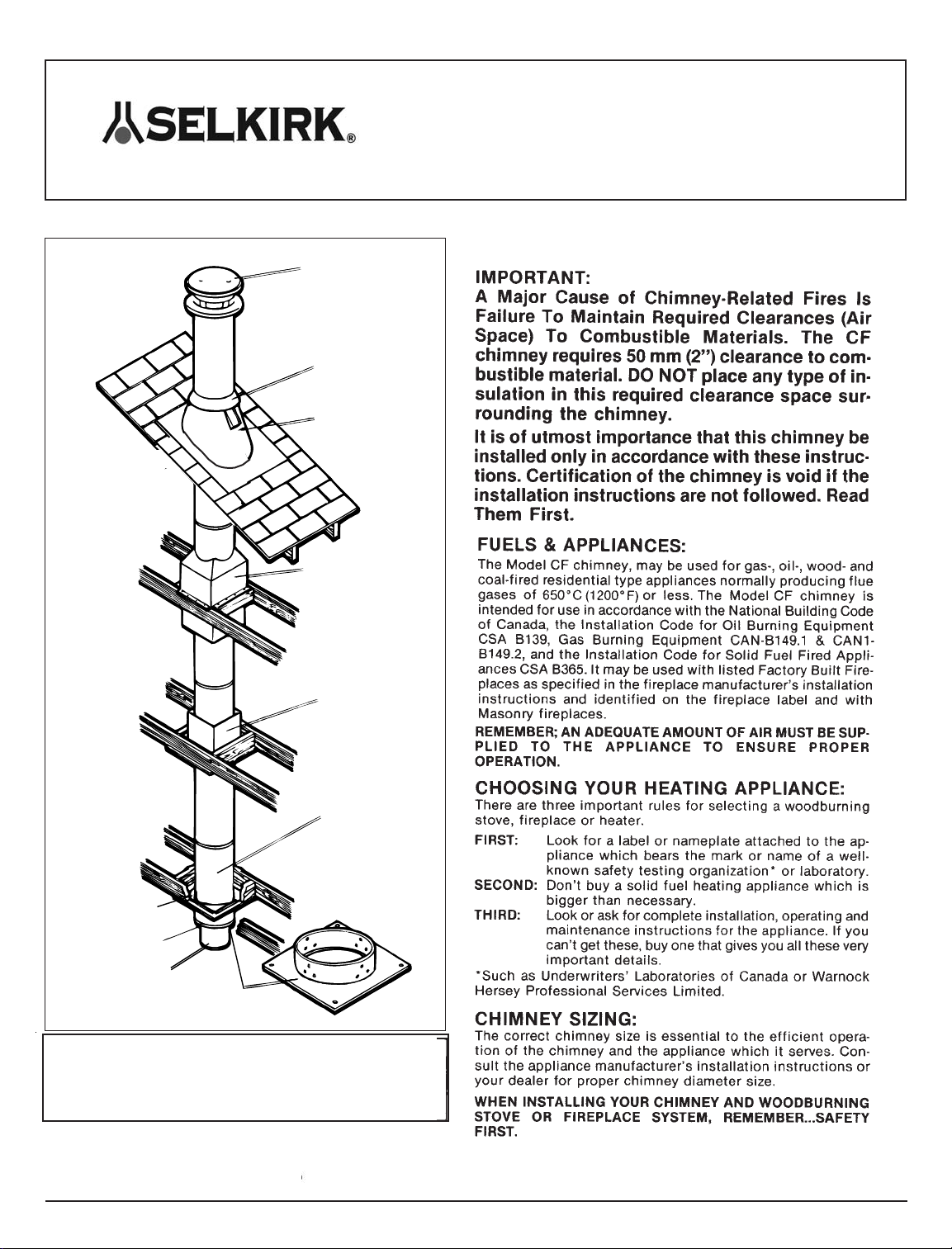

CEILING SUPPORT ASSEMBLY (See Figure 4)

1. Totally frame (all 4 sides) a level square opening with inside

dimensions 362mm (14 1/4”) square.

2. With the Lower Bucket removed, place the Ceiling Support

Assembly into the framed opening from below.

3. Drive one nail, 1-1/2” common or spiral, part way into each of

the four (4) nailing areas of the support. Check that the trim

plate is level and flush. (Figure 5)

4. Finish nailing through all pre punched holes. (12 nails total)

5. Replace the Lower Bucket. Insert the Basecap Assembly in

the bottom of the first chimney length (Figure 6).

6. Lower the first chimney length into the Lower Bucket. Ensure

the Basecap Assembly is located inside the base of the

chimney and the chimney length rests on the Lower Bucket.

(Figure 6 & 7)

NOTE: Any length of CF Chimney can be used. There is no

special “starter” length required with this Ceiling Support.

7. Additional chimney lengths may now be installed above this

support to a total height of 12 m (40”).

8. Continue the chimney installation as specified in the CF

Chimney Installation Instructions.

Ceiling Support Assembly

Trim Plate

Nails

Prepunched Hole Area

Chimney Length

Basecap Assembly

Installed in Bottom

of first chimney length

and then lowered into

the lower bucket

Ceiling Support

Assembly

Lower Bucket

Figure 5.

Figure 4.

Typical Ceiling Supported

Installations

Figure 6.

Figure 7. Chimney

Length

Label

Ceiling Support Assembly

Lower

Bucket

Smoke

Pipe

Method of assembly showing how the first chimney length is installed in the

ceiling support.

Page 4

SMOKE PIPE ADAPTER INSTALLATION:

1. The stub end of the adapter is intended to fit inside of the smoke

pipe from a solid fuel appliance, thus preventing condensate drips

at the chimney connection. See Figure 8.

2. Secure the smoke pipe from the appliance to the smoke pipe

adapter using 3 sheet metal screws per joint.

IMPORTANT: CF chimney ceiling supports have been

temperature tested using a vertical single wall connector. Ceiling

surface temperatures within and around the support were within

limits allowable in accordance with ULC Standard S629. These

tests establish that connector clearances to combustible may be

less than those permitted for untested connector installations.

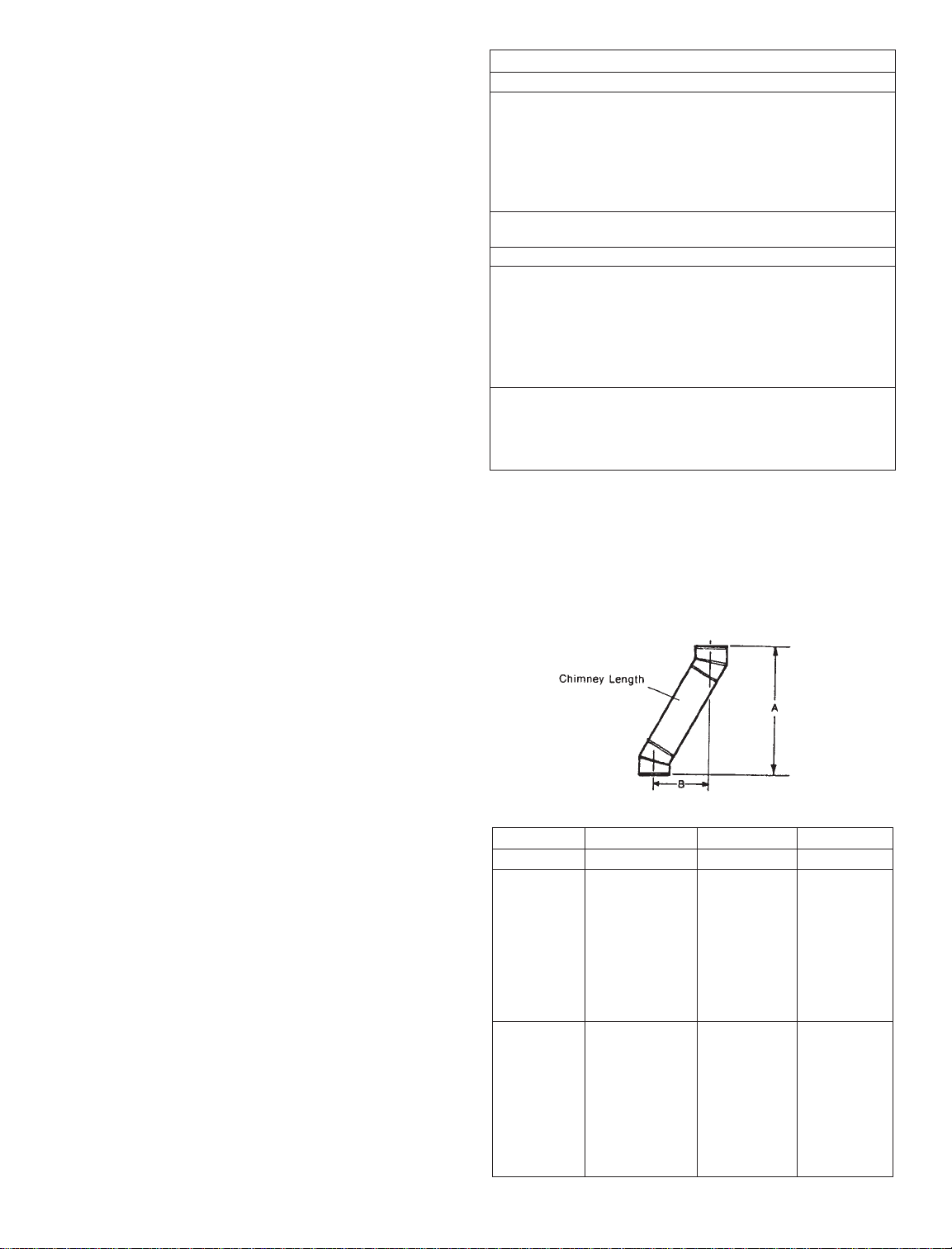

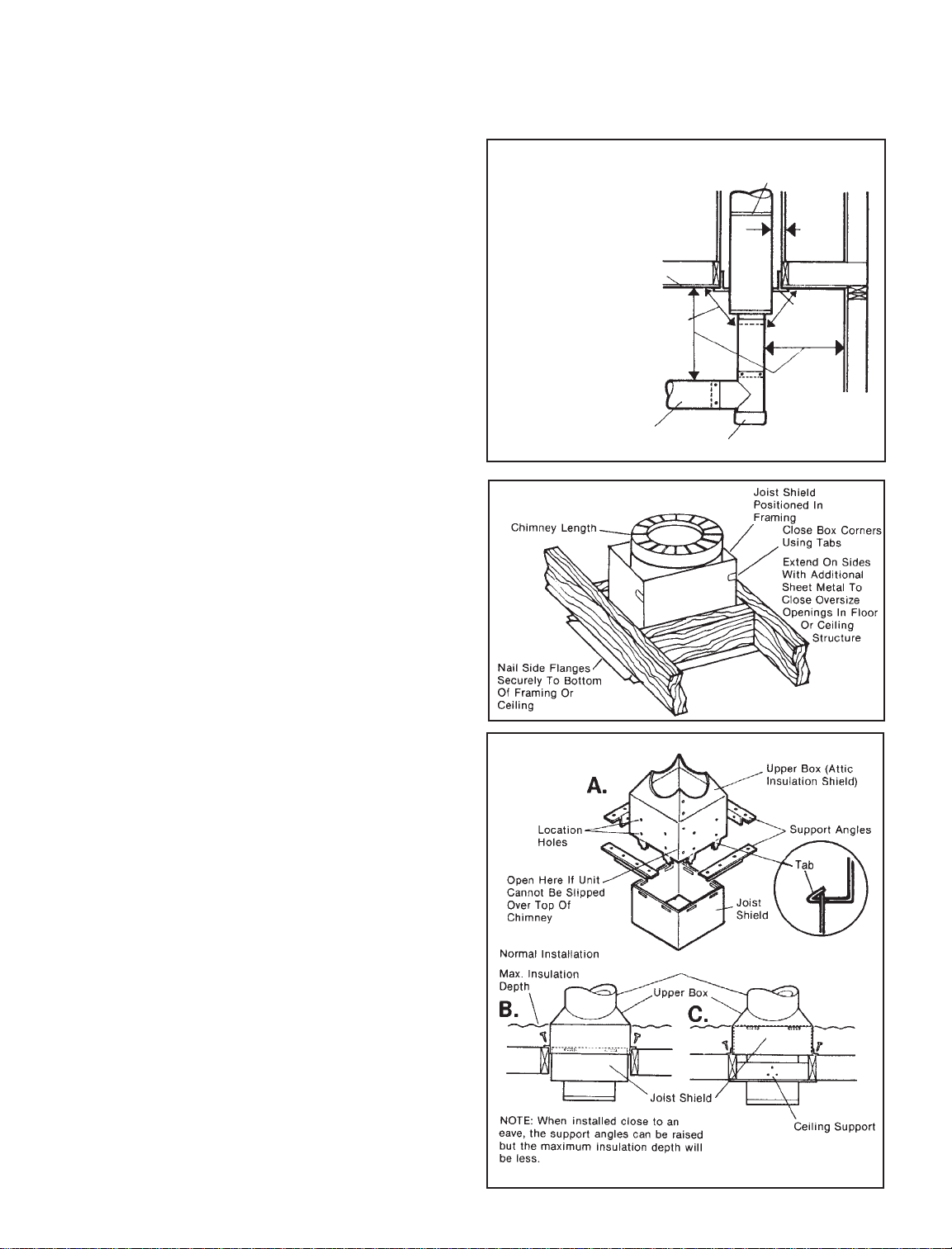

INTERMEDIATE JOIST SHIELD

INSTALLATION (See Figure 9)

This shield protects and firestops the floor joist of a house where

there is no insulation resting above the floor nor any intention of

insulation being put in.

1. Fully frame a level square opening (all four sides) for 50 mm (2”)

clerance from the outside of the chimney to the inside of the

frame. 6” – square opening 369 mm (14 1/2”)

7” – square opening 400 mm ( 15 3/4”)

8” – square opening 432 mm (17”)

2. Place the joist shield up into the framed opening.

3. Nail the side flanges into the framing or ceiling for stability.

4. If the framed opening is larger than necessary, the joist shield

outer edges must be extended by appropriate means (attaching

metal plates, 28 gauge galvanized steel or heavier) to completely

block the framed opening from any vertical air flow around the

chimney (chase installation).

5. Ceiling material can be placed over the joist shield edges,

provided 50 mm (2”) minimum clearance is maintained from the

chimney pipe.

6. Enclose the chimney when accessible to prevent any accidental

contact with the chimney.

INSTALLATION OF THE ATTIC INSULATION

SHIELD/FIRESTOP SPACER:

This sheild has three main components and is very versitile, as will

be illustrated below. The shield must be used at a ceiling level

entering an attic to prevent insulation from coming into contact

with the chimney. It also firestops this level and because it is a

firestop, DO NOT CUT the upper box.

1. Fully frame a level square opening (all four sides) for 50 mm (2”)

clearance from the outside of the chimney to the inside of

the frame.

6” – square opening 369 mm (14 1/2”)

7” – square opening 400 mm ( 15 3/4”)

8” – square opening 432 mm (17”)

2. Remove the joist shield from the inside of the attic insulation

shield (upper box).

3. Attach the joist shield to the inside tabs of the upper box. Bend

the tabs up to secure the two together.

4. Place the support angles in the most convenient set of holes

provided (with overlapping edges up, Figures 10A & B) and lower

the complete assembly over the chimney. If necessary, unscrew

the assembly to surround the chimney.

5. Nail securely into place on all four sides.

6. If the attic insulation shield (upper box) is to be used over a

ceiling support, leave the joist shield inside the upper box. The

support angles can then be installed as shown in Figure 10C.

NOTE: It is mandatory that an attic insulation shield be used.

Use locking bands at

every joint

2” min.

[50mm]

See

Note 2

See Note 1

Connector (or smoke pipe)

Drip free cap on cleanout tee

NOTE:

1. Refer to installation codes for

clearances to single wall pipe.

(Normally 450 mm (18”)

minimum cearance is required.

2. The purpose of the diagonal

arrows is to show that the

450mm (18”) clearances DOES

NOT APPLY to the vertical

connector entering a Ceiling

Support.

Ceiling

Figure 8. Connection to Lower End

Of Ceiling-Supported Chimney

Figure 9. Intermediate Joist Shield

Installation

Figure 10.

Any Chimney Length

Page 5

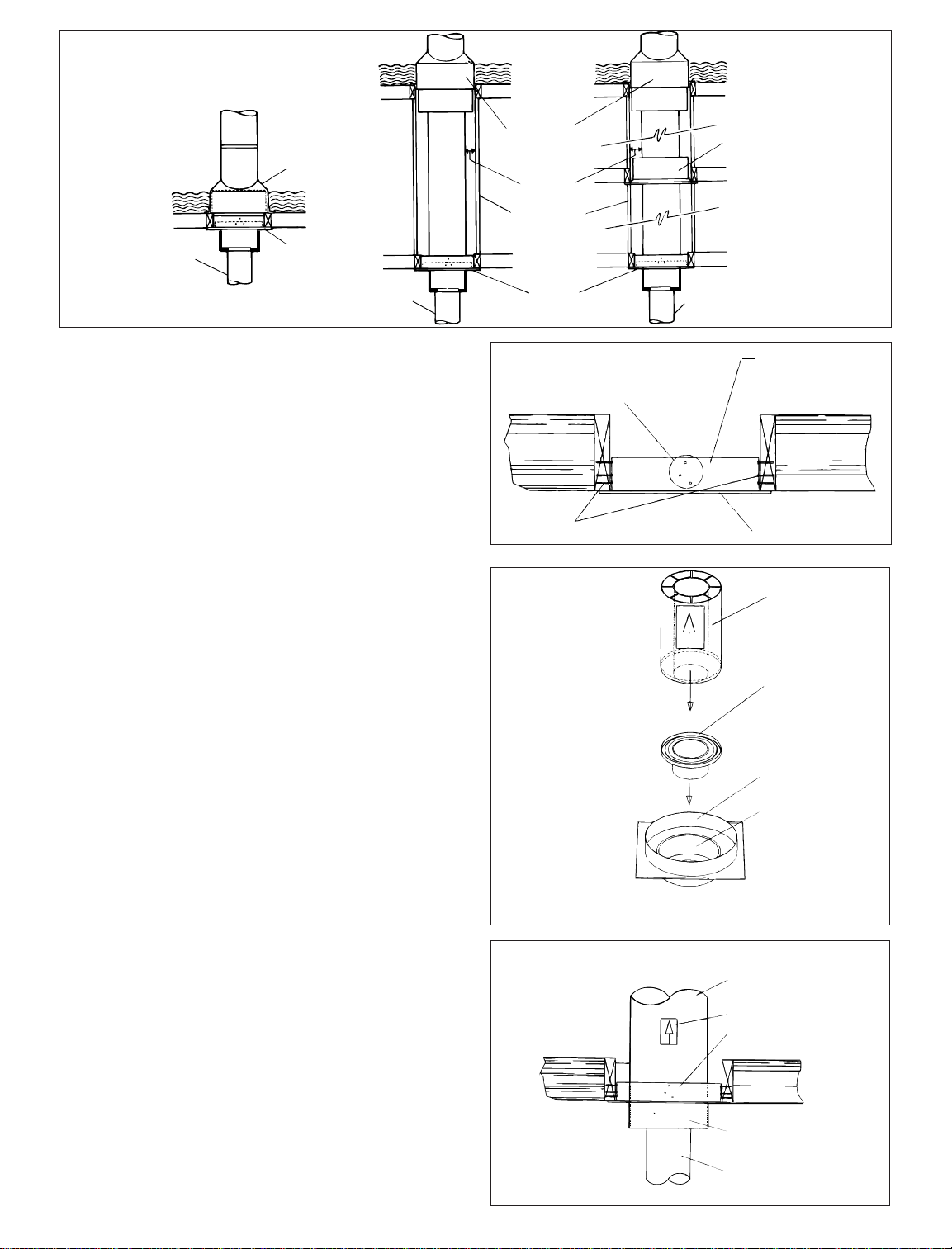

Round Top

Chimney Lengths

Locking Band

Storm Collar

Roof Flashing

50 mm (2") Minimum

Clearance To

Combustible Material

Roof Brace Kit

Additional Lateral Support For

Chimneys More Than 1.8 m (6')

Above Roof

Attic

Figure 12.

Page 6

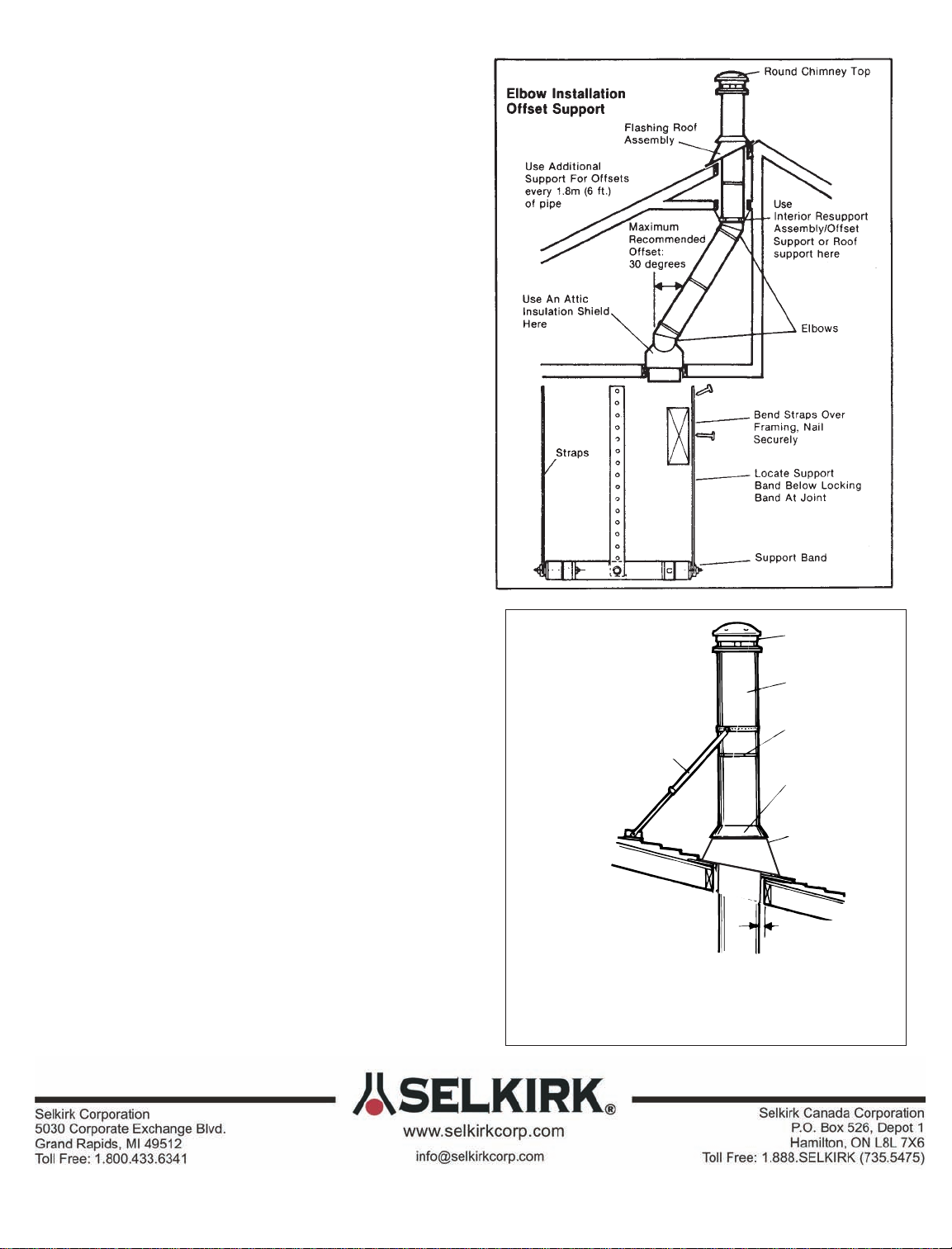

INSTALLED ELBOWS & INTERIOR

RESUPPORT ASSEMBLY / OFFSET SUPPORT

INSTALLATION (See Figure 11)

Two pairs of (four) 15 or 30 degree elbows may be used to provide

an offset in order to avoid cutting of joists and to clear other

obstructions. Offsets are within the house envelope only.

The Maximum Permissible Angle With Solid Fuel Installation is 30

Degrees.

1. The last vertical run of chimney above an offset must be

resupport using an Interior Resupport Assembly/Offset Support.

2. Securely clamp it to the pipe just above a locking band.

3. The straps are then run along the OUTSIDE of the joists and

nailed to them using 1 1/2"nails, 2 per strap.

The weight carrying capacity of the support, which depends on the

angle of the straps, and the security of attachment is adequate for

9 m (30') of Model CF Chimney pipe.

ENCLOSURE OF CHIMNEY:

The chimney must be enclosed when installed in an accessible

area to prevent damage and personal contact.

Enclosure walls should have a fire rating equal to or greater than

that required for the floors or ceilings through which the chimney

passes except in single or two family dwellings. Remember to

maintain a 50 mm (2") minimum air space clearance to any

combustible material.

ROOF FLASHING

INSTALLATION (See Figure 12)

1.Onceyouhavemarkedwherethechimneywillpenetratethrough

the roof, center, position and prepare the roof area.

2. Frame a RECTANGULAR opening to suit the pitch of the roof

and ensure that a 50mm (2") clearance is maintained to all

combustibles.

3. Finish the chimney off to its proper height. Chimneys are

required to extend at least 900 mm (3') above the highest point

where they pass through the roof of a building and at least 600

mm (2') higher than any portion of a building within 3 m (10').

4. Place the roof flashing suitable for the roof pitch over the

chimney casing and nail (1 1/2"common or spiral nails) securely

to the roof, top end (nearest roof peak) UNDER shingles, lower

end OVER shingles to provide a watershed.

5. Apply a 1/4"bead of suitable grey or white caulking compound

just above the top of the flashing cone on the chimney casing.

Slide the storm collar downward through the applied compound

and into position to ensure a waterproof joint. Apply additional

caulking compound above the storm collar as required.

6. If the chimney extends more than 1.8 m (6') above the roof, a

roof brace kit is required. See installation instructions packaged

with it.

7. Install a round top (see instructions packaged with the round

top). The round top prevents entry of moisture which might lead to

premature deterioration of the chimney.

8. The chimney may be painted with a heat resistant paint. To

improve adhesion to the Model CF chimney, degrease, dry and

follow the paint manufacture's application instructions. Refer to

their Paint Warranty (if applicable).

Figure 11.

Table of contents