SELMI TANK 200 Troubleshooting guide

A

B

C

PREFAZIONE

SELMI S.r.l. would like to thank you for purchasing our "TANK".

This manual is to be considered an integral part of the machine

and its purpose is to allow use of the machine throughout its

life, from delivery until demolition. Therefore, we suggest that

your read it carefully. Everyone working with the machine must

read this manual. It is also necessary to keep the manual in a

place accessible to operators at all times.

In the event of loss or damage of this manual, please ask

SELMI S.r.l. to send you a replacement copy.

The technical information contained in this manual belongs to

SELMI S.r.l. and must be considered proprietary.

The total or partial reproduction of the graphic design, text and

illustrations is forbidden

With a view to constant technical improvement, the company

reserves the right to make any necessary amendments to the

content of the manual, to the machine or to parts thereof.

Consequently, some of the illustrations may differ slightly from

your machine.

This document is an integral part of the “TANK”, as described in

section 1.7.4 of annex I of directive 2006/42/EC.

The Italian edition of this manual contains the original

instructions. The foreign language editions are to be considered

as translations of the original instructions.

© Copyright SELMI S.r.l.

Edition September 2019

EC DECLARATION OF CONFORMITY

The manufacturing company SELMI S.r.l., with main office in S. Vittoria D'Alba (CN) Italy – Via Statale, 151, in its capacity as manufacturer, declares, under its own

responsibility, that the machine named:

“TANK”

Serial number:

is compliant with all the provisions contained in the following directives: 2006/42/EC (machine directive), 2014/30/UE (electromagnetic compatibility) 2014/35/UE (low

voltage directive) and EC regulation 1935/2004 (contact with foodstuffs).

The norms adhered to that are used as a reference for the design, realization and testing of the machine are listed in the technical files archived at Selmi Srl.

The manufacturer also wishes to inform you that the technical file may, in the cases envisaged by the directive, be put together by the manufacturing company.

Year of construction:

Date: The liable person

TANK

0

1. General information 1

1.1. Structure of the manual 1

1.2. Messages Used 1

1.3. Aim and contents 1

1.4. Preservation of the manual 1

1.5. External components 2

1.6. Internal components 3

1.7. Details of the manufacturer 10

1.8. Identification plate of the machine 10

1.9. Identification plate of the CE marking 10

1.10. Inteded use 10

1.11. Operating environment 10

1.12. Noise level 10

1.13. Technical characteristics 9

1.14. Dimensions 9

1.15. Storage 12

1.16. Disposal 12

1.17. Warranty 12

1.18. person qualified to operate 13

2. Safety section 14

2.1. Safety information 14

2.2. Safety limitations 14

2.3. Safety symbols and plaques 15

2.4. Safety and protection devices 15

2.5. Client’s safety measures 17

2.6. Personal protection equipment 17

2.7. Residual risks 18

2.8. Applied Directives 19

2.9. Harmonized technical norms 19

3. Moving and transportation section 19

3.1. General norms 19

3.2. Packaging 19

3.3. Transportation 20

3.4. Removal of the packaging 20

4. Installation section 21

4.1. Positioning 22

4.2. Electrical connections 22

4.3. Installation of the machine 18

4.4. Commissioning 18

5. Operation section 22

5.1. Description of the controls 22

5.2. Functions of the buttons 22

5.3. Using the machine 22

5.4. Position of the user 22

6. Maintenance section 28

6.1. General information 30

6.2. General safety practice 30

6.3. Cleaning external parts

6.4. Emptying and cleaning the machine 48

7. Technical diagrams section 50

7.1. Electrical circuit diagram 50

7. Technical diagrams section 40

TANK

1

1. General information

1.1. Structure of the manual

To simplify t he reading and under standing of the

information contained in this manual and to make

searches quicker, it has been divided into sections, each

dedicated to a specific subject.

1.2. Messages used

Attention

This type of message is used to draw the reader’s

attention to more delicate or particular procedures

which, if not carried out correctly, may pose a risk

to the safety of the operator and cause damage to

parts of the machine.

Warning

This type of message is used to draw the reader’s

attention to procedures which, if not carried out

correctly or at pre-set intervals, may cause damage

to the machine or its parts, as well as to the product

being processed.

Environment

Messages relating to the environment draw the

operator’s attention to the rules to be followed to

prevent the risk of environmental damages

deriving, directly or indirectly, from use of the

machine.

Note

These messages highlight instructions, advice and

notes that can be particularly helpful during the

various uses of the machine.

1.3. Aim and contents

This manual has been drawn up in consideration of the

requirements of directive 2006/42/EC and paying

particular attention to describing all the procedures

necessary to obtain the best working conditions for the

machine and its operators, without neglecting product

quality:

The aim of this manual is, therefore, to provide the user

with all the information necessary for the correct use and

maintenance of the machine. Consequently it is absolutely

necessary:

- to meticulously follow the instructions given in the

manual during every phase of the machine’s life,

from transportation to demolition;

- for every machine operator to thoroughly read the

contents of this manual;

- for the company’s safety officer to make sure that all

machine operators have clearly understood how the

machine works

Attention

In case of doubts on the correct interpretation of

the instructions please contact the manufacturer to

obtain the necessary clarifications. All those

carrying out any kind of operation on the machine

must have thoroughly read and understood the

contents of this instruction manual.

Warning

If this manual is damaged or lost, please ask the

manufacturer or the authorised distributor in the

country where the machine is being used for

another copy.

1.4. Preservation of the manual

The instruction manual is an integral part of the machine

and must be used to train and inform professional figures

operating on the machine. Consequently, it is necessary to

follow certain simple instructions regarding its

preservation, as follows:

- store the manual in areas protected from humidity and

heat, so as not to jeopardise the quality or legibility of

any part of the publication;

- keep the manual is an easily accessible place known

to the machine operators;

- avoid handling the manual with dirty or greasy hands;

- if you think it is necessary to highlight important steps

of the manual, use non-permanent systems, to

preserve its legibility;

- do not remove, rip or rewrite any parts of the manual

for any reason.

TANK

2

1.5. External Components

1. Touch screeen

2. Product exit point

3. Right protection panel

4. Sviwelling wheels

5. Handle fro the tank cover opening

6. Cover for the mixer transmission chain

7. Emergency button

8. Rear cover for the control panel

9. Rear protection panel

10. Pedal connection point

11. Electrical panel door

12. Unload/cleaning point

13. Electrical main connection cable

1

5

8

3

6

7

4

2

9

12

13

10

11

TANK

3

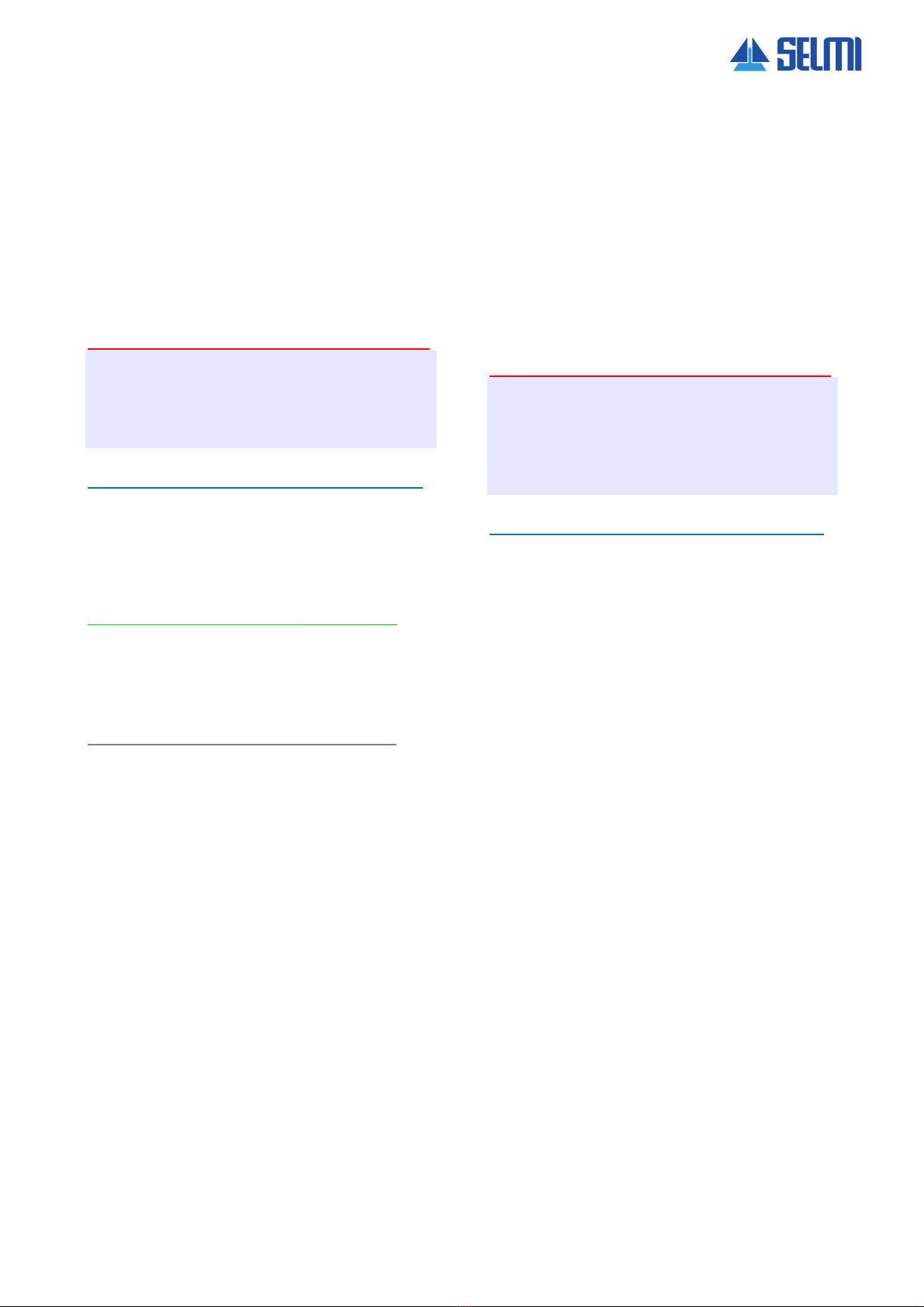

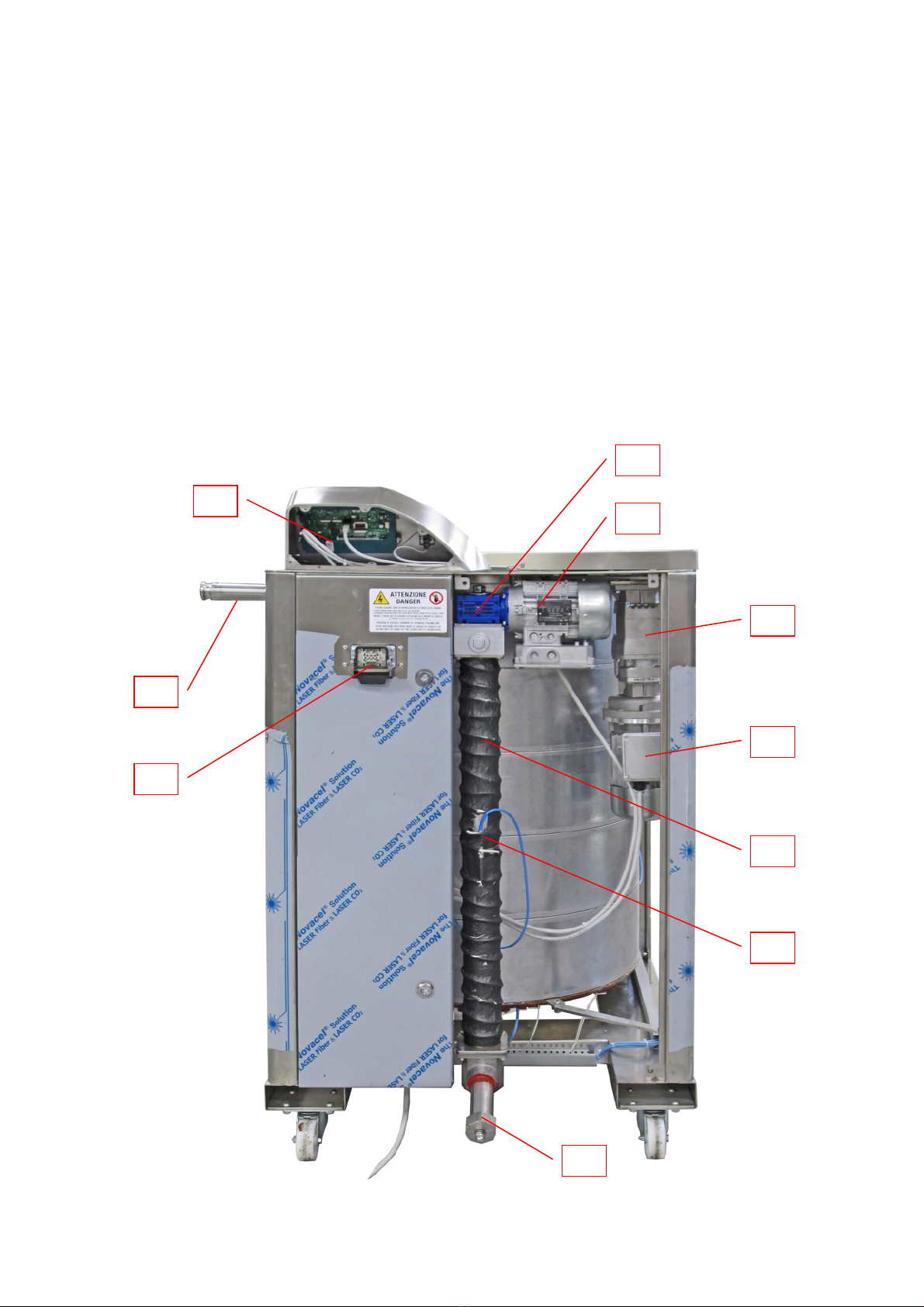

1.6. Internal Components TANK 400

1 - Mixer reducer

9 - Tank band resistance n°5

2 - Mixer motor

10 - Resistance temperature probe n° 1

3 - Column for product exit point

11 - Resistance temperature probe n° 2

4 - Unload / cleaning point

12 - Resistance temperature probe n° 3

5 - Tank band resistance n°1

13 - Resistance temperature probe n° 4

6 - Tank band resistance n°2

14 - Resistance temperature probe n° 5

7 - Tank band resistance n°3

8 - Tank band resistance n°4

10

5

2

3

4

11

12

13

14

6

7

8

9

1

4

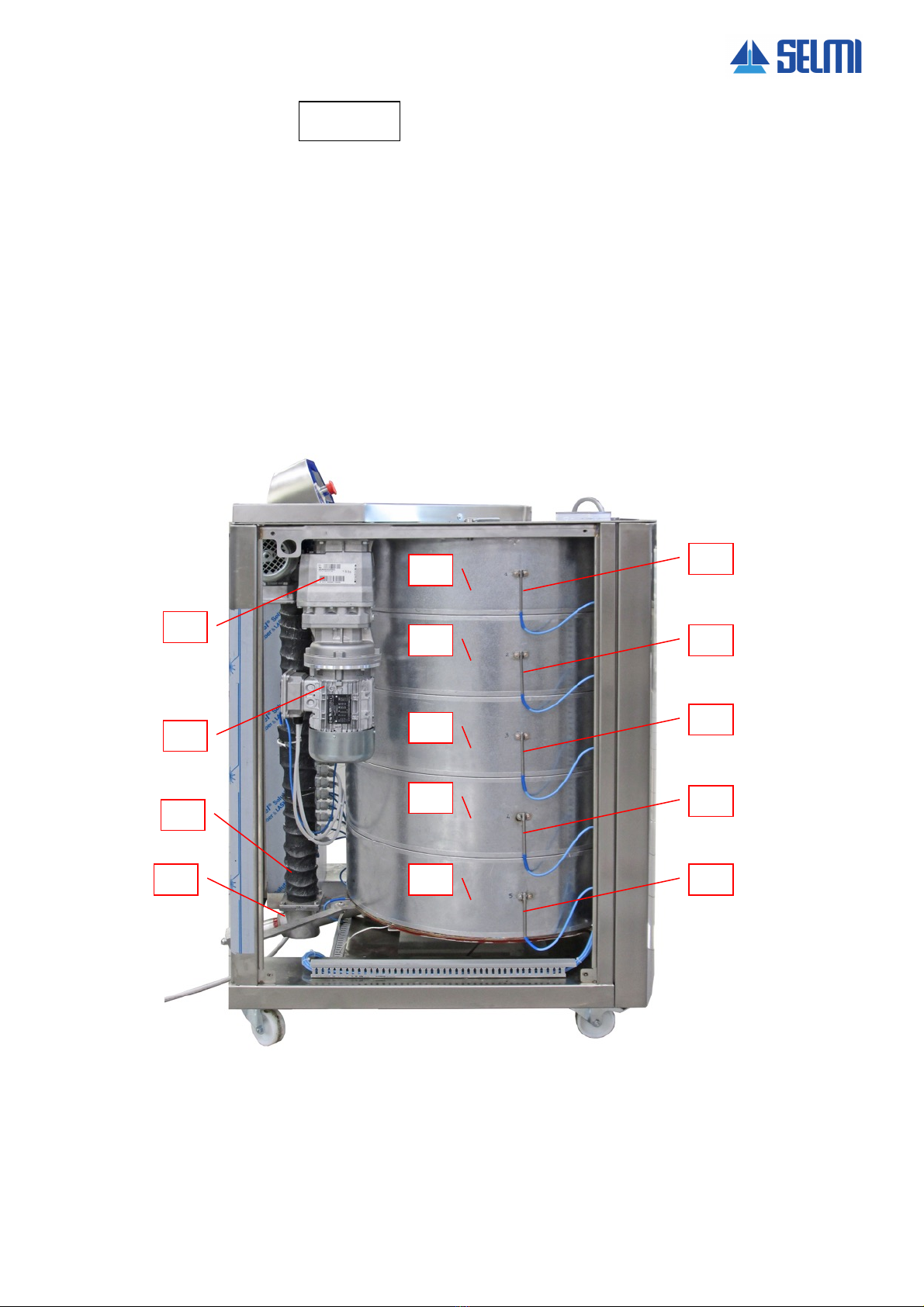

1.6. Internal Components TANK 200

1 - Mixer reducer

2 -Column for product exit point

3 - Mixer motor

4 - Unload / cleaning point

5 - Tank band resistance n°1

6 - Tank band resistance n°2

7 - Tank band resistance n°3

8 - Resistance temperature probe n° 1

9 - Resistance temperature probe n° 2

10 - Resistance temperature probe n° 3

8

5

3

9

10

6

7

1

2

4

TANK

5

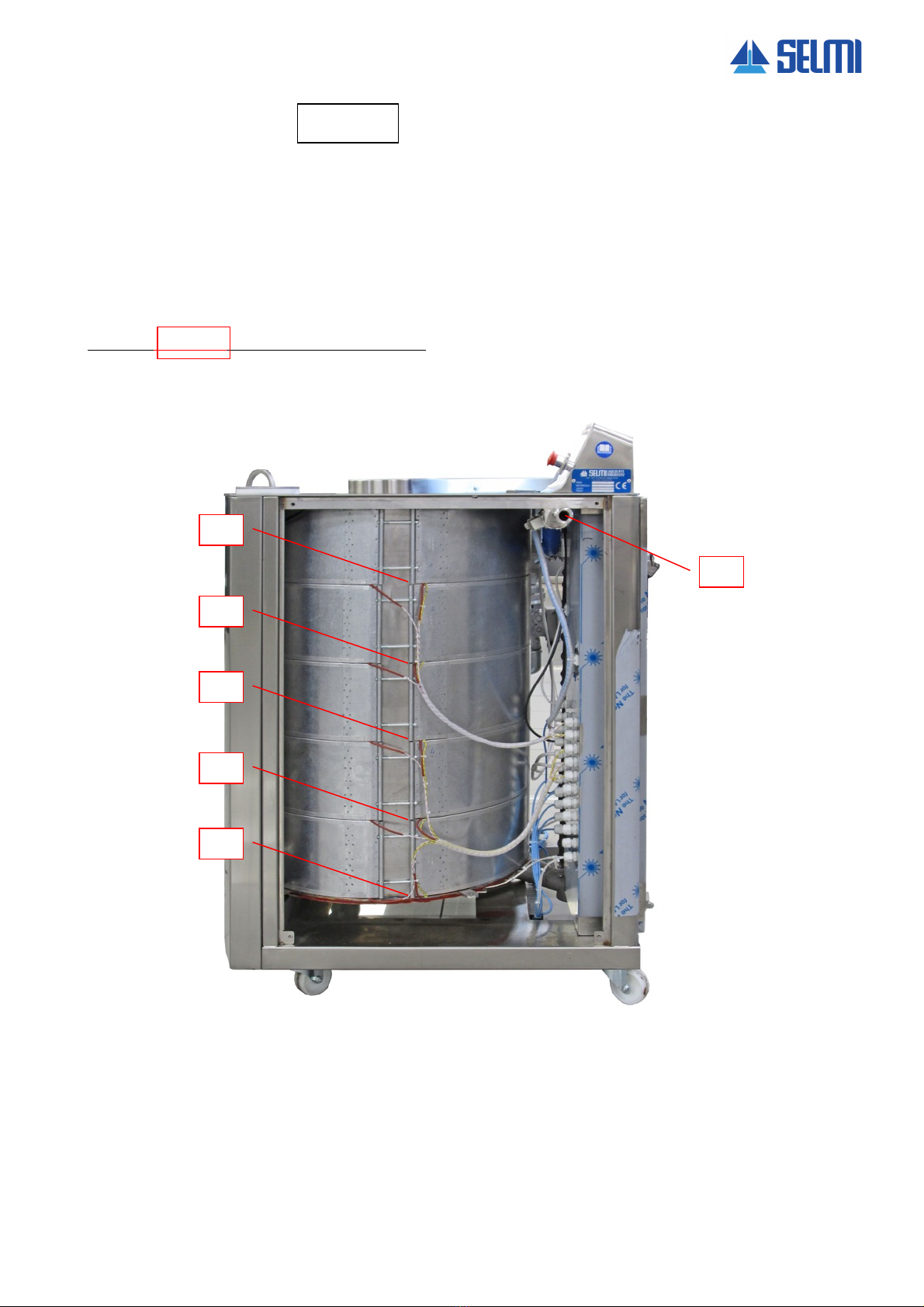

1.6. Internal Components TANK 400

FOR THE TANK 200 ONLY 3 BAND RESISTANCES

1 - Tank band resistance n° 1

2 - Tank band resistance n° 2

3 - Tank band resistance n° 3

4 - Tank band resistance n° 4

5 - Tank band resistance n° 5

6 - Product exit point

1

2

3

4

5

6

6

1.6. Internal Components

1. Toush screen

2. Product exit point

3. Pedal connection

4. Unload / cleaning point

5. Temperature probe for the column resistance

6. Column with resistance

7. Mixer motor

8. Mixer reducer

9. Product exit pump

10. Reducer

8

7

9

10

1

2

3

6

5

4

TANK

7

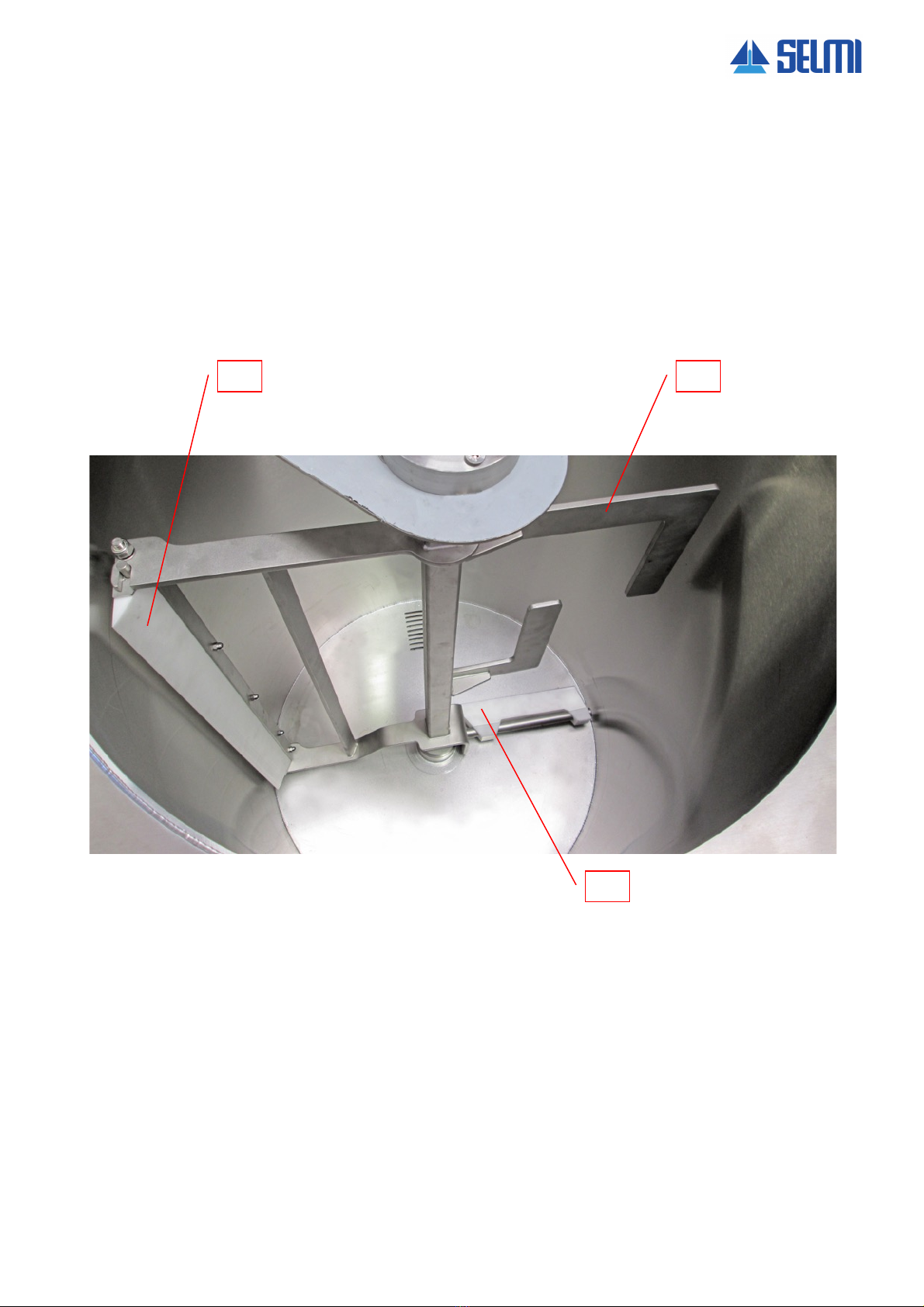

1.6. Internal Components

1. Mixer elements

2. Food grade plastic elements / scrapers for teh tank side

3. Food grade plastic elements / scrapers for teh tank bottom

1

2

3

8

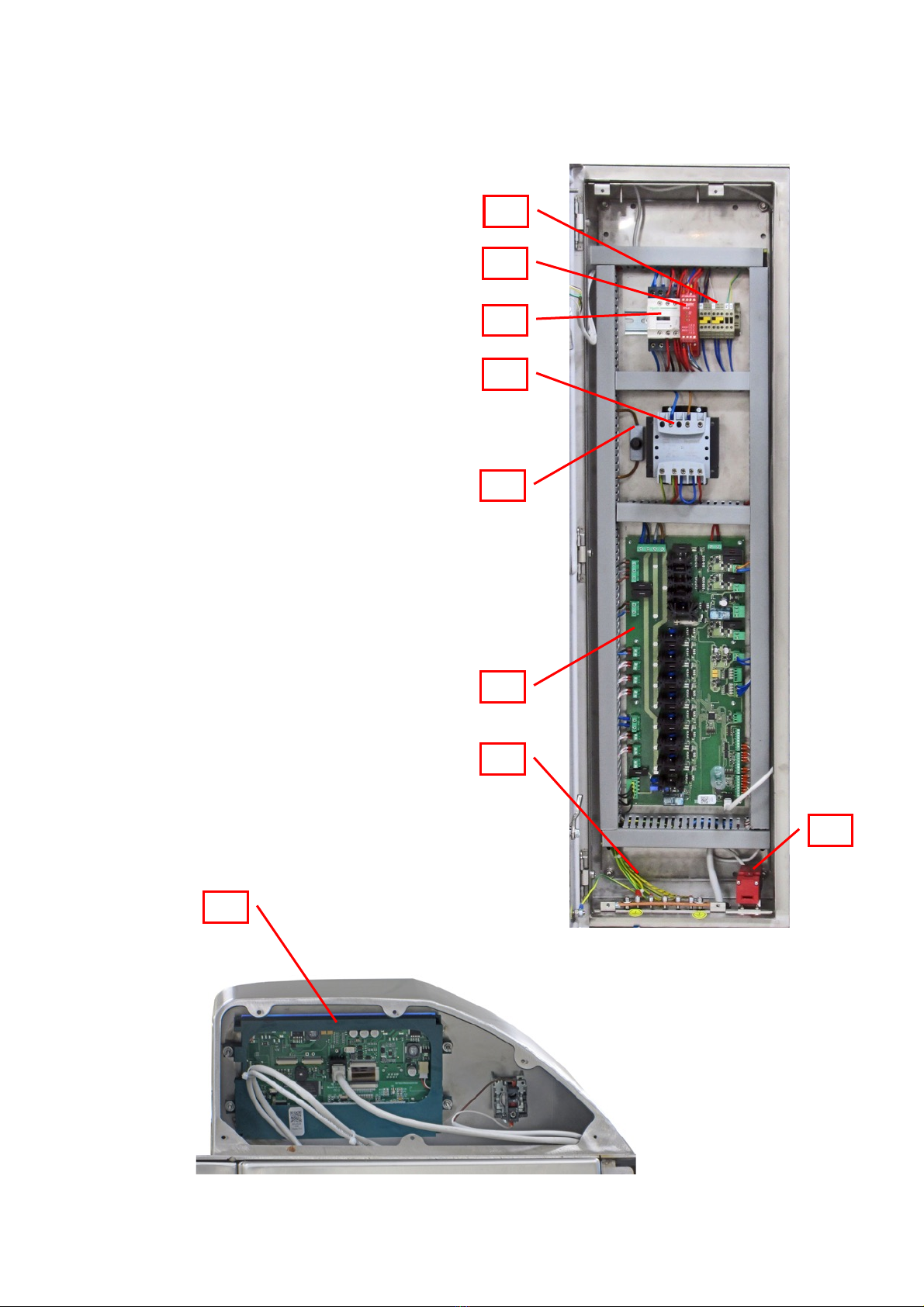

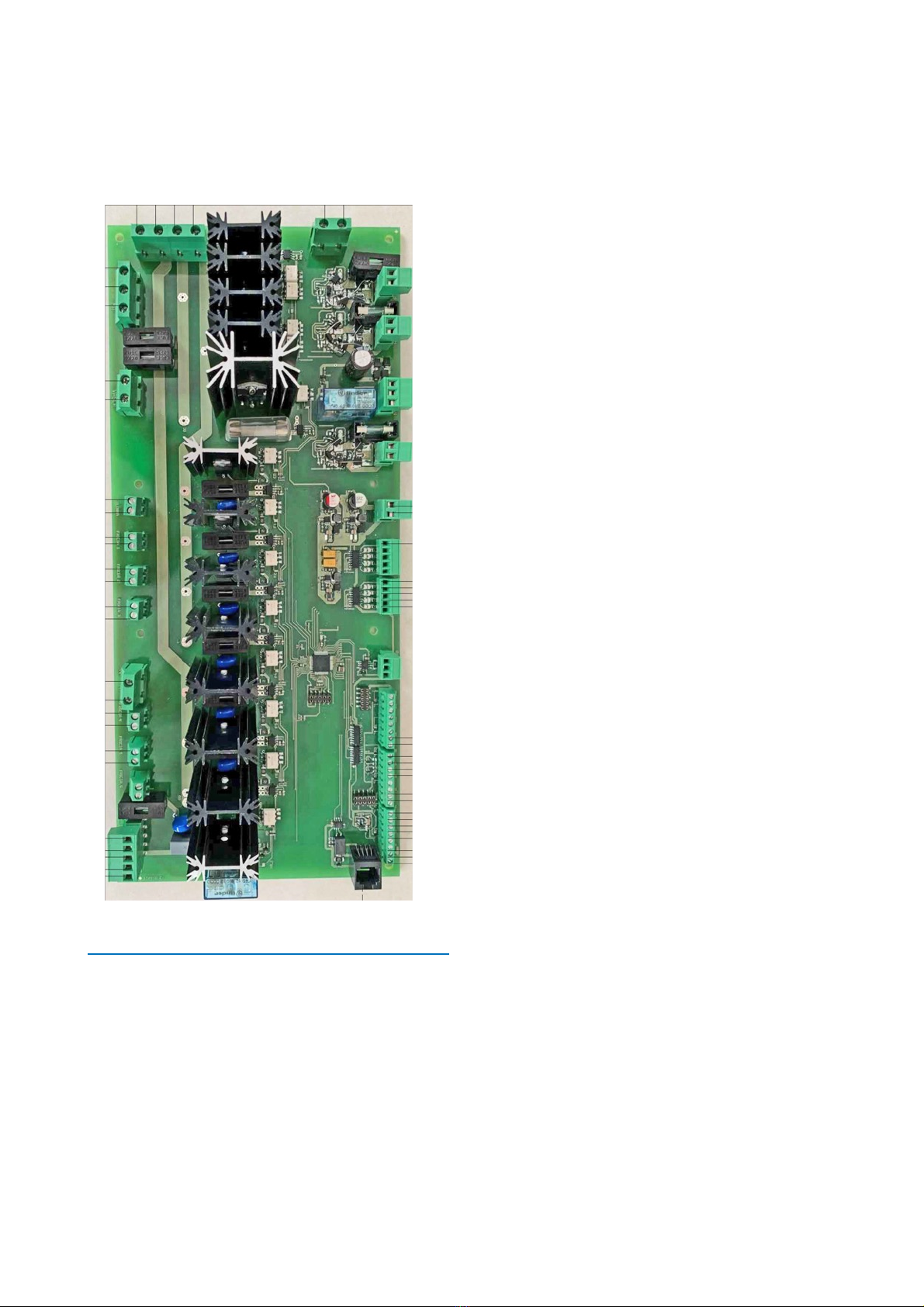

Electrical panel

1. Power board

2. Safety module

3. Main contactor

4. Transformer

5. Fuse holder

6. Power board

7. Ground connection

8. Micro security electrical panel door

9. Touch screen

9

1

5

4

3

2

6

7

8

TANK

9

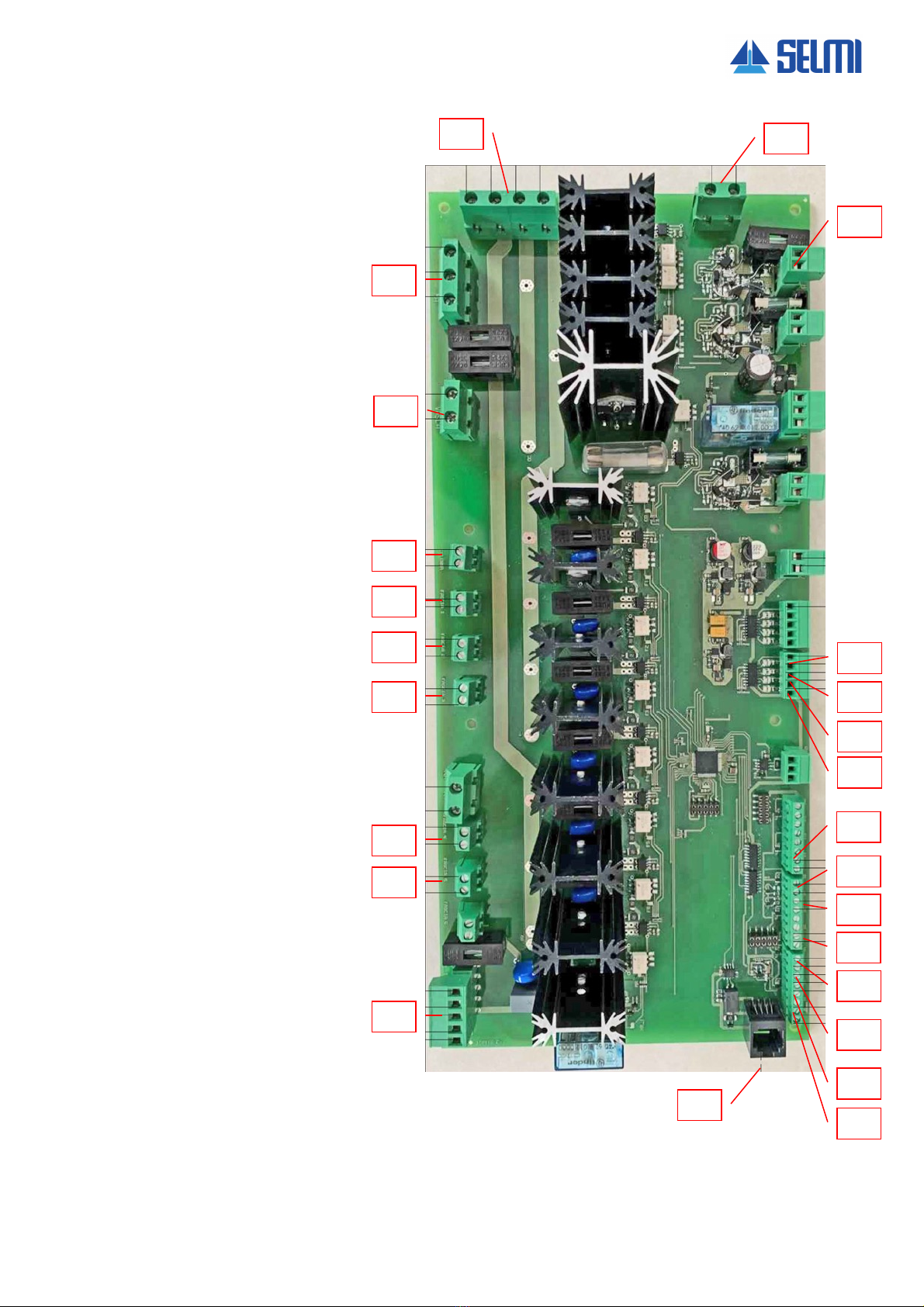

1.9. Power board

1 - Supply line 380V

2 - Mixer motor

3 - Tank bottom resisitance

4 - Column resistance

5 - Tank band resistance n° 1

6 - Tank band resistance n° 2

7 - Tank band resistance n° 3

8 -Tank band resistance n° 4

9 -Tank band resistance n° 5

10 - Pump motor

11 - Flat cable connection

12 - Probe n° 1

13 - Probe n° 2

14 - Probe n° 3

15 - Probe n° 4

16 - Probe n° 5

17 - Column probe

18 - Tank bottom probe

19 - Product exit probe

20 - Pedal

21 - Emerngency button

22 - Level sensor feed

23 - Safety level sensor

24 - Exit product pipe resistance

25 -Power board supply 24 ac

2

3

4

5

6

7

8

9

10

11

12

20

25

1

16

13

14

15

17

18

19

21

22

23

24

TANK

10

1.7. Details of the manufacturer

The machine described in this instruction manual was built

by:

SELMI S.r.l.

Via Statale, 151 – 12069 – S. Vittoria D’Alba (CN) Italia

Tel. 0172.479273 - 0172.479275 - Fax 0172.477814

www.selmi-group.it - info@selmi-group.it

1.8. Identification plate of the machine (CE marketing)

There is a plate, similar to the one shown here, on the

machine, indicating details of the manufacturer, the CE

conformity mark and the machine’s serial number. Always

state this number when communicating with the

manufacturer.

Example of identification plate on the machine structure

TYPE

SERIAL NUMBER

YEAR

WEIGHT

1.9. Identification plate of the CE marking electric panel

(low voltage)

Example of identification plate on electrical panel. The correct

data shown in the section on the machine’s technical

specifications.

1.10. Inteded use

Chocolate mixers and melters TANK 400 Continuous

chocolate mixer and melter. Entirely built in stainless steel

AISI 304. The mixer can be operated in a continuous or

intermittent mode with programmable temperatures and

timed mixing. The heating of the tank and of the exit conduit

are separately thermoregulated. Integrated pump for the

supply of the relevant machines.

Warning

A use other than that specified is considered

improper. The machine is intended for professional

use only.

Attention

Do not place any small objects near the control panel

or the tank: they could fall and enter the tank, which

would contaminate the product.

1.11. Operating environment

To guarantee proper funct ioning the machine must be

protected from atmospheric agents. Its ambient operational

temperature should be between 15C° and 25C° with relative

humidity not exceeding 70%.

The working environment must be clean, sufficiently

illuminated and away from an explosive environment.

The environmental characteristics of the installation site are

specified in section 4.

Attention

The machine’s fixed guards have a variety of

openings to allow the internal units to cool. When the

machine is running, make sure that these openings

are not covered by cloths or objects that obstruct

proper air flow.

1.12. Noise level

The phonometric tests carried out on this specific machine

model show an acoustic pressure lower than 70 dB(A).

TANK

11

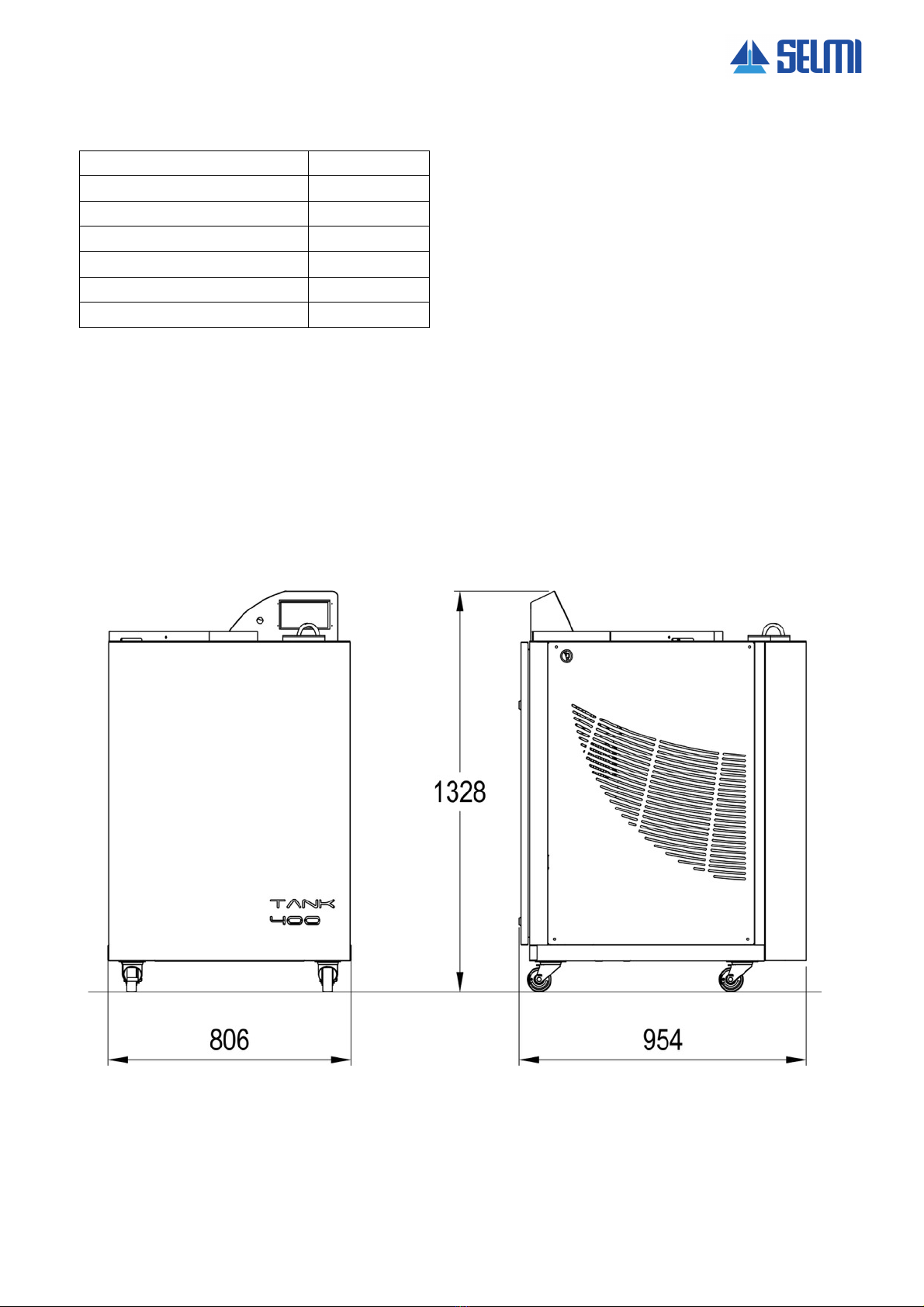

1.13 Electrical and tachnical charateristics

Total weight

300 kg

Total power installed

9 kW

Voltage

380 V

Phases

3

Frequency

50Hz or 60 Hz

Protection

IP 65

Tank capacity

200 or 350 kg

1.14 Dimensions

* This data may change according to the installation

conditions required under the contract. For the

correct data please refer to the label located inside

the electrical panel.

12

1.15. Storage

Remove the remaining product left in the machine

following the instructions in the appropriate section.

Stop the machine using the main switch and

disconnect it from the electricity main. Move it to a

spacious place (it is necessary to work all around the

machine).

Clean the tank, the removable components (i.e. screw

pump, mixer, nozzle) and the pipes as described in the

appropriate section.

Attention

It is absolutely necessary to follow the

instructions in order to insure the safety of the

operators and to avoid damaging the machine’s

removable parts.

Use a brush to cover the movable components and the

mechanical moving parts with a thin layer of food grade

lubricant. This can later be removed with an alkaline

de-greaser (Sodium Hydroxide) if the machine needs

to be re-installed.

Carry out the same operation on the machine surfaces,

taking care of avoiding the heating elements located in

the inner part of the machine.

Gather the parts (use as reference the delivery packing

list) and put them in the original packaging. Place

packets of hygroscopic salt based on silica gel in the

packaging.

Store all the parts in a sheltered place away from

atmospheric agents and in temperatures from 0° C to

40° C. Cover the parts with nylon in order to prevent

the accumulation of dust.

1.16. Disposal

Disposal will occur at the end of the working life of the

machine, which under normal conditions of use and

maintenance will be over ten years.

In the case of disposal all the components of the

machine will have to be disposed of in adequate waste

yards according to the legislation in force.

Before disposal it will be necessary to separate the

plastic or rubber parts and the electrical and electronic

material.

Environment

Parts made solely of plastic, aluminium and steel

can be recycled in the appropriate collection

centres.

According to the RoHS regulations electronic

boards and electric material should be recycled

separately in authorised collection centres.

1.17. Warranty

The manufacturer offers a warranty on this machine

model for a period of 24 months from the purchase

date, as shown on the fiscal document issued at the

time the machine is delivered.

The warranty will be void if the machine is repaired by

a third non authorized party or if fixtures and

accessories not supplied by or recommended or

approved by the manufacturer are used.

The warranty will also be void upon removal or

alteration of the plate showing the serial number and

other data.

Within the warranty period the manufacturer will repair

or replace, free of charge, parts that are faulty due to

manufacturing.

In case the repair has to take place at the

manufacturer’s site, the machine will have to be sent to

the manufacturer in its original packaging.

Transportation expenses will be covered by the

manufacturer during the warranty period.

The warranty does not cover the cleaning of the

functioning parts.

Defects not clearly attributed to the material or the

manufacturing will be examined. If the claim should

turn out to be unjustified all repair expenses, changed

parts and transportation will be charged to the buyer.

The warranty does not cover damage caused by the

following:

• accidental damage during transportation

• damage due to lack of care or procedures carried

out incorrectly

• damage due to improper use not conforming to the

warnings of the user and service manual

• components subject to wear and tear; a detailed list

is available in the components section.

Structural damage, modifications, improper alterations

or repairs can affect the functioning of the safety

mechanisms, thus making the declaration of conformity

and warranty void. Alterations on the machine can be

carried out solely by technicians authorised by the

manufacturer.

TANK

13

1.18. Professional personnel qualified to operate

the machine

The machine must only be used by authorized and

purposely trained personnel; the same precautions i s

also applicable to personnel who carry out

maintenance.

Personnel who do routine and extraordinary

maintenance must be specially trained professionals;

good knowledge of the machine is needed for

extraordinary maintenance.

Attention

Do not permit others to approach the machine

during its use or maintenance.

The following professional people, after having

received all the necessary instructions, are the only

ones allowed access to the machine:

Safety officer

The safety officer is responsible for protection and

prevention of risks in the workplace , as is mentioned in

European Directive 89/391/EEC (Safety in the

workplace), introduced in Italy with the 12/11/1994

Legislative Decree.

It is the responsibility of the safety officer to make sure

that all personnel who use/maintain the machine have

received all the instructions regarding their relative

roles contained in this manual.

Operator (user of the machine)

Operator trained and qualified for the use of the

machine (working cycle, potential adjustments, etc.).

He/she can only carry out the specific tasks described

in this manual reserved for this role.

Mechanical maintenance technician

The technician is qualified to use the machine as the

OPERATOR and furthermore to use it with the

protection disabled, to attend to the mechanical parts

for adjustments, maintenance and reparations.

He/she is not qualified to act on live electrical

installations.

The mechanical maintenance technician must have a

generic knowledge of the machine and a specific

knowledge on this machine model.

Electrical maintenance technician

The technician is qualified to use the machine as the

OPERATOR and furthermore to use it with the

protection disabled, to attend to the adjustments and

electrical installations for the purposes of maintenance

and repair.

If qualified, he/she may work when the electrical

panels, control devices, are live, provided he/she uses

appropriate personal protective devices.

The electrical maintenance technician must have a

generic understanding of the electrical panels and

specific knowledge on the electrical panel and

components of this machine.

Manufacturer

The manufacturer’s personnel are qualified to perform

all of the above-described operations.

Any operations not described in this manual may be

performed ONLY by personnel authorized by the

manufacturer.

14

2. Safety section

2.1. Safety information

Attention

The safety officer has the obligation to inform

the workers on the risks related to the use of the

machine.

Furthermore the employer must inform, educate

and train the user according to statutory laws.

The lack of compliance with the basic norms or

precautions could result in accidents during the

functioning, maintenance or reparations of the

machine. Accidents can often be avoided by

acknowledging potential hazardous situations before

they materialize. The operator must pay attention to the

potential dangers and have the training, the

competence and the necessary equipment to deal with

these tasks correctly.

The manufacturer cannot be held responsible for

accidents or damages resulting from the use of the

machine by personnel not adequately trained of having

used the machine improperly, as well as the lack of,

even partial, compliance to the safety norms and

interventions procedures contained in this manual.

The safety precautions and the warnings messages,

the operator could be subject to accidents with serious

consequences for himself and for other people.

In cases where tools, procedures, work methods or

working techniques not explicitly suggested by the

manufacturer are used, it will be necessary to make

sure that no dangers are present for the individual

carrying them out and to other alike.

Use exclusively original SELMI spare

parts. The manufacturer will take no

responsibility for accidents or damages in

the case o fuse of non-original spare parts.

If a tool not supplied by the manufacturer is installed on

the machine, the client needs to make sure that the

norms stated in Directive 2006/42/EC are adhered to. If

this new tool introduces new risks to the system then

the new system must be re-certified. In any case the

manufacturer cannot be held responsible for accidents

or damages caused by the machine if it has been

modified or equipped with non original accessories.

2.2. Safety limitations

Attention

The indications mentioned hereafter cannot

completely safeguard from all dangers that one

might encounter while using the machine; they

must be used in conjunction with common

sense and the experience of the operator, the

only indispensable measures for the prevention

of injury.

Every section has a list of specific safety measures for

different operations. The safety measures mentioned

here below are generic and should be followed for all

procedures on the machine.

The responsibilities assigned to specific people

concerning the use of the machine must be clearly

defined as stated in the “Qualified Personnel” section.

Attention

The use of the machine is forbidden to

personnel who have not been authorised or

trained by the safety officer.

Consult the manufacturer before carrying out

procedures that are not mentioned in this

manual.

Prolonged overloads or anomalies can cause the

electric motors and electrical appliances to overheat

with resultant harmful fumes. In such cases

immediately disconnect the machine from the mains

and do not approach the machine until such fumes

have been dispersed via adequate ventilation. In case

of fires do not use water jets on the machine – use

CO2 extinguishers instead.

The operator, any helping technician and the

maintenance technician must use the appropriate

personal protection equipment when working on the

machine.

It is forbidden to climb on the machine.

Do not touch the electrical wires, switches, buttons etc.

with wet hands.

The parts subject to wear and tear during the

functioning of the machine must be checked and

replaced as soon as they present noticeable signs of

wear and tear.

The manufacturer has designed and built the machine

to last for a reasonable time with the Client’s normal

conditions o fuse in mind; it is however necessary to

periodically check the components and the structure of

the machine, paying attention to any anomalous

conditions, such as, for example, cracks or

deformations. If necessary, contact the manufacturer to

ask for a complete check of the machine.

Please consult Section 4 (Installation) for the working

environmental conditions of the machine.

TANK

15

2.3. Safety symbols and plaques

The machine has a number of plaques with symbols

and/or safety messages stuck to it.

Attention

Make sure that all the safety messages are

legible and in good condition.

Replace the damaged plaques with the new ones from

the manufacturer. If a plaque happens to be on a part

that is being replaced, make sure that a plaque is

present on the new piece. For the cleaning of the

plaques consult the appropriate section (6.3).

ATTENTIO N

THE PERFORMANCE OF WORK ON ELECTRICAL EQUIPMENT

CONNECTED TO THE POWER SUPPLY IS STRICTLY

FORBIDDEN

• ANY EXCEPTIONS MUST BE AUTHORISED BY THE

EXECUTIVE MANAGER

• IN PARTICULARLY DANGEROUS SITUATIONS, ANOTHER

PERSON MUST BE PRESENT IN ADDITION TO THE

PERSON PERFORMING THE WORK

WORK MAY ONLY BEGIN WHEN THE SAFETY MEASURES

HAVE BEEN IMPLEMENTED

IN OBSERVANCE OF PRESIDENTIAL DECREE 543 ON THE

PREVENTION OF ACCIDENTS

(positioned on the door of the electrical panel)

Label indicating compulsory reading of the manual

(positioned on the front of the machine)

2.4. Safety and protection devices

Attention

The components shown here are particularly

important for the safety of the operator and the

machine. In cases of malfunction or wear they

must be replaced with spare parts supplied or

authorized by the manufacturer.

While the machine is in use all the protection

devices must be correctly installed.

The safety devices present on the machine are:

• Mushroom emergency button with mechanical

unblock mechanism.

There is an emergency stop mushroom button on the

machine. Pushing it cuts voltage to all live parts by

means of appropriate devices. To reset it, release the

emergency button by turning its head and then push

the RESET button shown in the photo.

Before starting every shift, press it to make sure that it

works properly.

• Electric panel safety microswitch

Within the electrical panel there is a safety microswitch

which disconnects the voltage every time the panel is

opened for maintenance interventions.

Attention

Periodically check that the safety microswitch is

working properly.

If faulty, please proceed immediately with its

replacement.

16

• Fusibles

Warning

If fuses keep blowing it may be an indication of a

fault of the devices installed on the machine; in

such cases contact Technical Support.

This manual suits for next models

1

Table of contents

Other SELMI Commercial Food Equipment manuals

SELMI

SELMI ROASTER CENTOVENTI Troubleshooting guide

SELMI

SELMI COMFIT Troubleshooting guide

SELMI

SELMI RS250 Troubleshooting guide

SELMI

SELMI Macchia Troubleshooting guide

SELMI

SELMI Demoulding Troubleshooting guide

SELMI

SELMI CHOCOFORM Troubleshooting guide

SELMI

SELMI TOP EX Troubleshooting guide

SELMI

SELMI Filler Troubleshooting guide

SELMI

SELMI MICRON 25 Troubleshooting guide

SELMI

SELMI SPIDER Troubleshooting guide