SELMI ROASTER CENTOVENTI Troubleshooting guide

ROASTER CENTOVENTI

manuale d'uso e manutenzione

PREFACE

SELMI S.r.l. would like to thank you for purchasing

our "ROASTER Centoventi", roasting machine with

fluidized bed.

This manual is to be considered an integral part of

the machine and its purpose is to allow use of the

machine throughout its life, from delivery until

demolition. Therefore, we suggest that your read it

carefully. Everyone working with the machine must

read this manual.It is also necessary to keep the

manual in a place accessible to operators at all

times.

In the event of loss or damage of this manual,

please ask SELMI S.r.l. to send you a replacement

copy.

The technical information contained in this manual

belongs to SELMI S.r.l. and must be considered

proprietary.

The total or partial reproduction of the graphic

design, text and illustrations is forbidden.

With a view to constant technical improvement, the

company reserves the right to make any necessary

amendments to the content of the manual, to the

machine or to parts thereof. Consequently, some of

the illustrations may differ slightly from your

machine.

This document is an integral part of the "ROASTER

Centoventi", roasting machine with fluidized bed as

described in section 1.7.4 of annex I of directive

2006/42/CE.

The Italian edition of this manual contains the

original instructions. The foreign language editions

are to be considered as translations of the original

instructions.

© Copyright SELMI S.r.l. Edition January 2015

EC DECLARATION OF CONFORMITY

The manufacturing company SELMI S.r.l., with main office in S. Vittoria D'Alba (CN) Italy –Via Statale,

151,in its capacity as manufacturer, declares, under its own responsibility, that the machine named:

"ROASTER Centoventi", roasting machine with fluidized bed

Serial number:

is compliant with all the provisions contained in the following directives:2006/42/EC (machine directive),

2004/108/EC (electromagnetic compatibility) and EC regulation 1935/2004 (contact with foodstuffs).

The norms adhered to that are used as a reference for the design, realization and testing of the machine are

listed in the technical files archived at Selmi Srl.

The manufacturer also wishes to inform you that the technical file may, in the cases envisaged by the

directive, be put together by the manufacturing company.

Year of construction The liable person

Date

4

1. General information 5

1.1. Structure of the manual 5

1.2. Messages Used 5

1.3.Aim and contents 5

1.4. Preservation of the manual 5

1.5. External components 6

1.6. Internal components 8

1.7. Details of the manufacturer 18

1.8. Identification plate of the machine 18

1.9. Identification plate of the CE marking 18

1.10. Inteded use 18

1.11. Operating environment 18

1.12. Noise level 18

1.13. Technical characteristics 19

1.14. Dimensions 19

1.15. Storage 20

1.16. Disposal 20

1.17. Warranty 20

1.18. person qualified to operate 21

2. Safety section 22

2.1. Safety information 22

2.2. Safety limitations 22

2.3. Safety symbols and plaques 23

2.4. Safety and protection devices 23

2.5. Client’s safety measures 24

2.6. Personal protection equipment 24

2.7. Residual risks 25

2.8.Applied Directives 25

2.9. Harmonized technical norms 25

3. Moving and transportation section 26

3.1. General norms 26

3.2. Packaging 26

3.3. Transportation 27

3.4. Removal of the packaging 27

4. Installation section 27

4.1. Positioning 27

4.2. Electrical connections 27

4.3. Installation of the machine 28

5. Operation section 29

5.1. Description of the controls 29

5.2. Using the machine 30

5.3.Alarms 35

6. Maintenance section 36

6.1. General information 36

6.2. General safety practice 36

Cleaning and maintenance 35

7. Technical diagrams section 39

7.1. Electrical circuit diagram 39

8. Spare part section 48

5

1. General information

1.1. Structure of the manual

To simplify the reading and understanding of the

information contained in this manual and to make

searches quicker, it has been divided into sections, each

dedicated to a specific subject.

1.2. Messages used

Attention

This type of message is used to draw the reader’s

attention to more delicate or particular procedures

which, if not carried out correctly, may pose a risk

to the safety of the operator and cause damage to

parts of the machine.

Warning

This type of message is used to draw the reader’s

attention to procedures which, if not carried out

correctly or at pre-set intervals, may cause damage

to the machine or its parts, as well as to the product

being processed.

Environment

Messages relating to the environment draw the

operator’s attention to the rules to be followed to

prevent the risk of environmental damages

deriving, directly or indirectly, from use of the

machine.

Note

These messages highlight instructions, advice and

notes that can be particularly helpful during the

various uses of the machine.

1.3. Aim and contents

This manual has been drawn up in consideration of the

requirements of directive 2006/42/EC and paying

particular attention to describing all the procedures

necessary to obtain the best working conditions for the

machine and its operators, without neglecting product

quality:

The aim of this manual is, therefore, to provide the user

with all the information necessary for the correct use and

maintenance of the machine. Consequently it is absolutely

necessary:

- to meticulously follow the instructions given in the

manual during every phase of the machine’s life,

from transportation to demolition;

- for every machine operator to thoroughly read the

contents of this manual;

- for the company’s safety officer to make sure that all

machine operators have clearly understood how the

machine works

Attention

In case of doubts on the correct interpretation of

the instructions please contact the manufacturer to

obtain the necessary clarifications. All those

carrying out any kind of operation on the machine

must have thoroughly read and understood the

contents of this instruction manual.

Warning

If this manual is damaged or lost, please ask the

manufacturer or the authorised distributor in the

country where the machine is being used for

another copy.

1.4. Preservation of the manual

The instruction manual is an integral part of the machine

and must be used to train and inform professional figures

operating on the machine. Consequently, it is necessary to

follow certain simple instructions regarding its

preservation, as follows:

- store the manual in areas protected from humidity and

heat, so as not to jeopardise the quality or legibility of

any part of the publication;

- keep the manual is an easily accessible place known

to the machine operators;

- avoid handling the manual with dirty or greasy hands;

- if you think it is necessary to highlight important steps

of the manual, use non-permanent systems, to

preserve its legibility;

- do not remove, rip or rewrite any parts of the manual

for any reason.

6

1.5. EXTERNAL COMPONENTS

1) Exhaust system roasting area

2) Exhaust system of the cooling area

3) Product exit

4) Electrical power supply

1

2

2

3

4

7

EXTERNAL COMPONENTS

1) Filters area

2) Skin collector

3) Side protection

4) Pipe for loading the product

5) Exhaust pipe roasting area

1

2

3

4

5

8

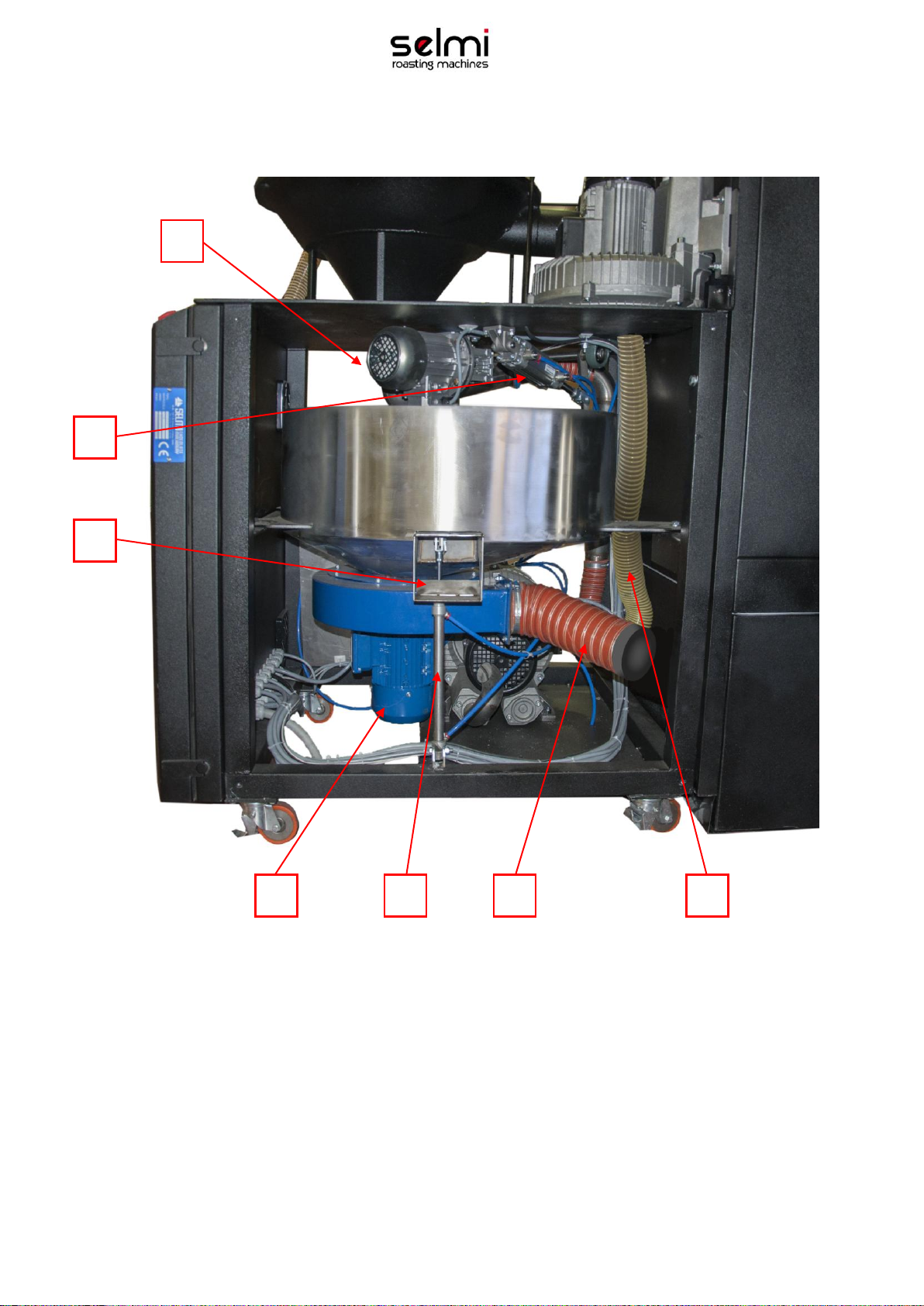

1.6. BACK SIDE OF THE MACHINE WITHOUT THE PROTECTION

1) Exhaust system roasting area

2) Filters

3) Exhaust system of the cooling area

4) Skin collector

1

2

2

3

4

9

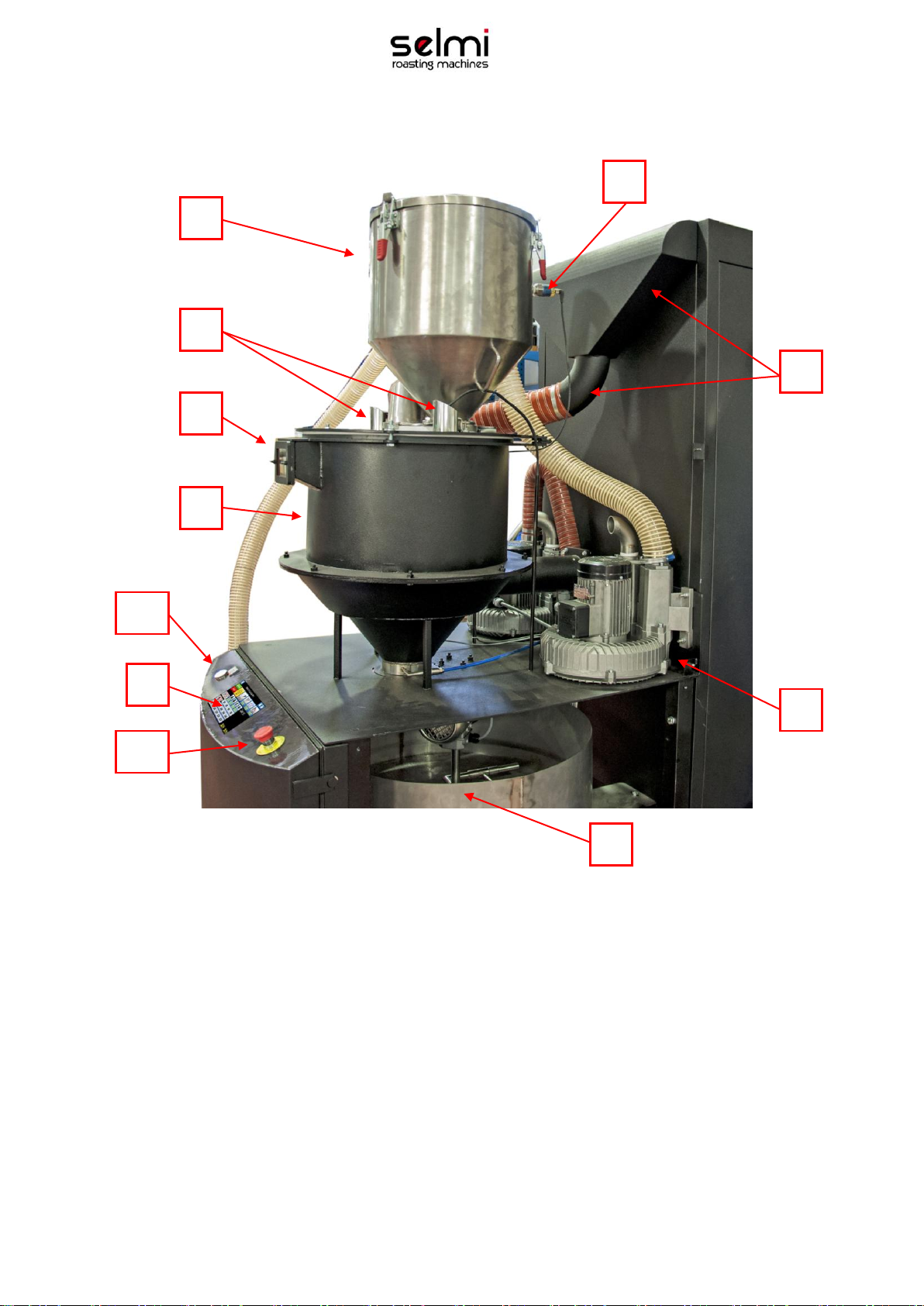

UPPER PART WITHOUT THE PROTECTION

1) Charging container

2) Window control of the roasting chamber

3) Roasting chamber

4) Control panel

5) Cooling chamber

6) Blower for charging the product

7) Exhaust system roasting area

8) Sensor level

9) Roasting chamber lights

10) Emergency button

11) Start/Reset button

5

2

4

6

1

2

2

3

2

7

8

9

2

11

10

10

UPPER PART WITHOUT THE PROTECTION

1) Roasting chamber side blower

2) Electrical resistance for the side blower

3) Roasting chamber

1

1

2

2

1

2

3

1

2

11

LEFT SIDE WITHOUT THE PROTECTION CARTER

1) Roasting chamber bottom bloower

2) Electrical resistance bottom blower

3) Connection between the roasting and the cooling chamber

4) Cooling chamber

5) Compressed air supply

6) Manometer

7) Electrical valves group

8) Electrical power supply

2

4

3

6

2

1

5

8

7

2

12

DETAIL OF LEFT SIDE WITHOUT THE PROTECTION

1) Air temperature probe (bottom)

2) Electrical resistance

3) Pipe coming from the bottom blower

1

1

2

2

1

1

2

3

1

2

13

DETAIL OF LEFT SIDE WITHOUT THE PROTECTION

1) Pipe to clean the roasting cone

1

1

2

14

RIGHT SIDE WITHOUT PROTECTION CARTER

1) Mixer motor for the cooling chamber

2) Piston for the opening/closing of the roasting chamber cone

3) Exit of the finish product

4) Cooling fan

5) Piston for unload the product

6) Exhaust pipe of the cooling chamber

7) Exhaust pipe for the aspiration blower

7

3

5

1

2

4

6

15

DETAIL OF UPPER PART WITHOUT THE PROTECTION

1) Heart product temperature probe

2) Air temperature probe (side)

3) Air compressed blow

1

3

2

16

ELECTRICAL PANEL

1) Cooling fan

2) Electrical panel door security micro

3) Power board

4) Inverter

5) Heating elements relay

6) Inverter filter

7) General contactor

8) Security protection

9) Transformer

10) 220 V Fuse protection

11) Ground connection

1

6

2

1

1

6

5

1

3

10

9

7

8

5

4

11

17

POWER BOARD

1. Absorption control bottom electrical resistance

2. Absorption control side electrical resistance

3. Mixer motor connection

4. Cooling fan connection

5. Charging product blower connection

6. 380V protection fuses

7. Connection 380V

8. Connection 24V a.c.

9. Air compressed for clean the cone

10. Solenoid pneumatic actions

A. Opening the roasting cone

B. Unload product

C. Air compressed blow

11. Fan cooling electrical panel

12. lights roasting chamber connection

13. Relay Heating resistance

14. empty

15. Sensor level charging container

16. Inverter roasting chamber bottom blower connection

17. Inverter roasting chamber side blower connection

18. Probes connections

19. Flat cable connection

20. 24V protection fuse

10A

6

8

2

3

4

16

7

5

1

9

11

12

13

14

15

17

18

19

10B

20

10C

18

1.7. Details of the manufacturer

The machine described in this instruction manual was built

by:

SELMI S.r.l.

Via Statale, 151 –12069 –S. Vittoria D’Alba (CN) Italia

Tel. 0172.479273 - 0172.479275 - Fax 0172.477814

www.selmi-group.it - info@selmi-group.it

1.8. Identification plate of the machine (CE marketing)

There is a plate, similar to the one shown here, on the

machine, indicating details of the manufacturer, the CE

conformity mark and the machine’s serial number. Always

state this number when communicating with the

manufacturer.

Example of identification plate on the machine structure

TYPE

SERIAL NUMBER

YEAR

WEIGHT

1.9. Identification plate of the CE marking electric

panel (low voltage)

ELECTRIC DIAGRAM

No.

INSTALLED POWER

KW

VOLTAGE

V

PHASES

No.

FREQUENCY

Hz

CURRENT AT FULL LOAD

A

CURRENT AT HIGHER LOAD

A

CUT OUT CAPABILITY

kA

PROTECTION

IP

Example of identification plate on electrical panel. For the

correct data, see the plate attached to the panel and the

data shown in the section on the machine’s technical

specifications.

1.10. Inteded use

Roaster Centoventi was designed to work on a continuous

cycle of automatic processing, it has a tank capacity of

20/25Kg and has the ability to roast 50Kg of coffee or dried

fruit per hour. It uses an original and exclusive air cyclone

system (vertiflow® patent) which has a temperature

sensor at the heart of the product. It is particularly versatile

for the roasting of coffee, hazelnuts, almonds, pistachios

and any other appropriate product...The machine has a

number of programs which control the heating

temperature, the roasting time, the cooling time and the

final automatic discharge of the products. The programs

can be personalised to obtain the desired grade of

roasting time after time.

Warning

A use other than that specified is considered

improper. The machine is intended for professional

use only.

Attention

Do not place any small objects near the control

panel or the tank: they could fall and enter the tank,

which would contaminate the product.

1.11. Operating environment

To guarantee proper functioning the machine must be

protected from atmospheric agents. Its ambient

operational temperature should be between 15C° and

35C° with relative humidity not exceeding 70%.

The working environment must be clean, sufficiently

illuminated and away from an explosive environment.

The environmental characteristics of the installation site

are specified in section 4.

Attention

The machine’s fixed guards have a variety of

openings to allow the internal units to cool. When

the machine is running, make sure that these

openings are not covered by cloths or objects that

obstruct proper air flow.

1.12. Noise level

The phonometric tests carried out on this specific machine

model show an acoustic pressure lower than 70 dB(A).

19

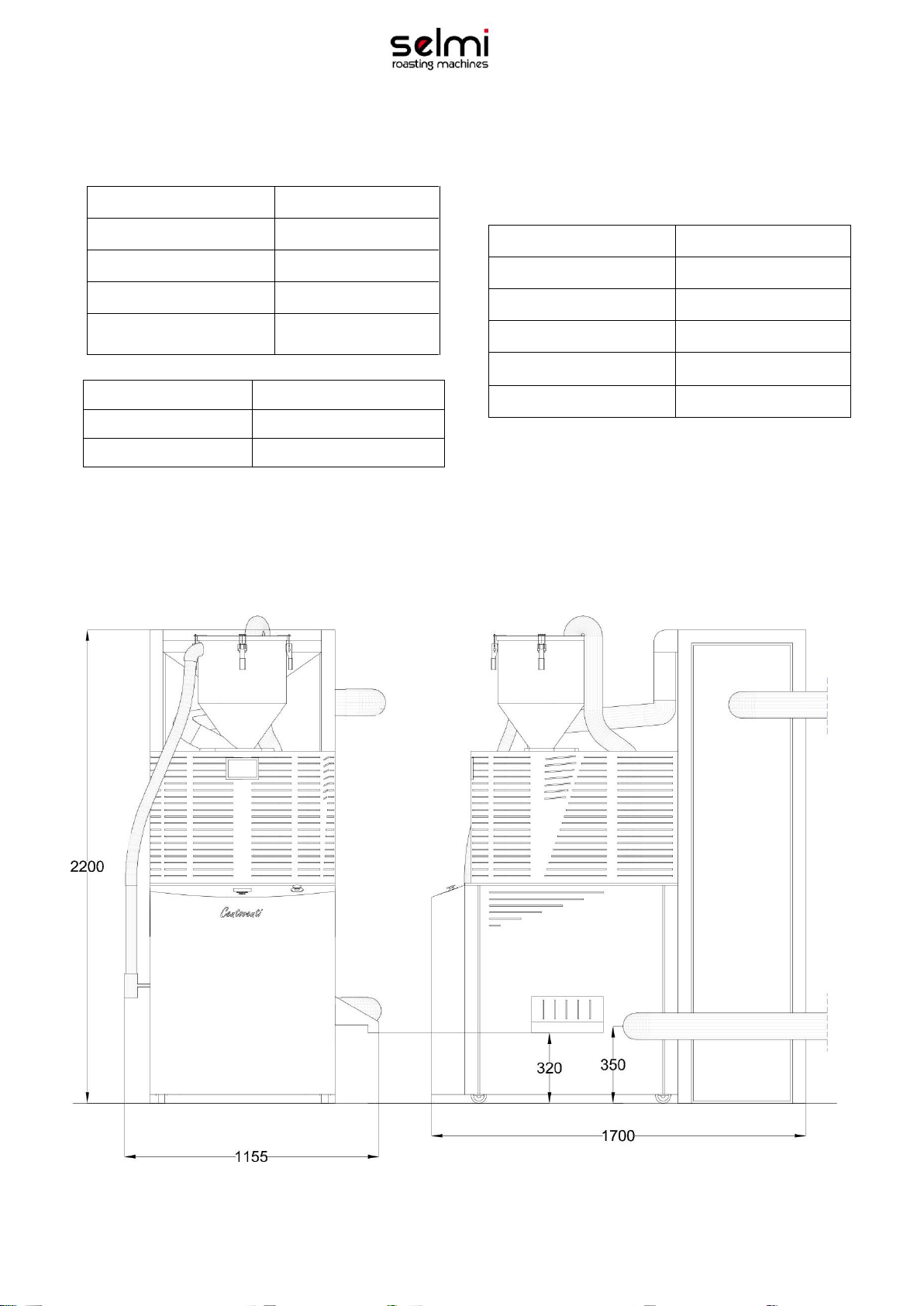

TECHNICAL CHARATERISTICS

Roasting chamber capacity:

20/25 Kg

Roasting chamber material:

inox AISI 304 L

Heating:

Electrical resistances

Controls:

Double electronical card

Weight:

500 Kg

Power installed:

22 kW

Voltage supply:

380V

Number of phases:

3

Frequency:

50Hz or 60Hz*

Noise

< 80 dB

Protection degree:

IP65

* This data can change according to the contractual

installation conditions. For correct data refer to the

plate inserted inside the electric panel..

Dimensions

Air compressed required

220 l/min

Maximum load Power:

6 bar minimum

Air charateristics

Dry and disoiled and filtered

20

1.15. Storage

Remove the remaining product left in the machine

following the instructions in the appropriate section.

Stop the machine using the main switch and

disconnect it from the electricity main. Move it to a

spacious place (it is necessary to work all around the

machine).

Clean the tank, the removable components (i.e. screw

pump, mixer, nozzle) and the pipes as described in the

appropriate section.

Attention

It is absolutely necessary to follow the

instructions in order to insure the safety of the

operators and to avoid damaging the machine’s

removable parts.

Use a brush to cover the movable components and the

mechanical moving parts with a thin layer of food grade

lubricant. This can later be removed with an alkaline

de-greaser (Sodium Hydroxide) if the machine needs

to be re-installed.

Carry out the same operation on the machine surfaces,

taking care of avoiding the heating elements located in

the inner part of themachine.

Gather the parts (use as reference the delivery packing

list) and put them in the original packaging. Place

packets of hygroscopic salt based on silica gel in the

packaging.

Store all the parts in a sheltered place away from

atmospheric agents and in temperatures from 0° C to

40° C. Cover the parts with nylon in order to prevent

the accumulation of dust.

1.16. Disposal

Disposal will occur at the end of the working life of the

machine, which under normal conditions of use and

maintenance will be over ten years.

In the case of disposal all the components of the

machine will have to be disposed of in adequate waste

yards according to the legislation in force.

Before disposal it will be necessary to separate the

plastic or rubber parts and the electrical and electronic

material.

Environment

Parts made solely of plastic, aluminium and steel

can be recycled in the appropriate collection

centres.

According to the RoHS regulations electronic

boards and electric material should be recycled

separately in authorised collection centres.

1.17. Warranty

The manufacturer offers a warranty on this machine

model for a period of 24 months from the purchase

date, as shown on the fiscal document issued at the

time the machine is delivered.

The warranty will be void if the machine is repaired by

a third non authorized party or if fixtures and

accessories not supplied by or recommended or

approved by the manufacturer are used.

The warranty will also be void upon removal or

alteration of the plate showing the serial number and

other data.

Within the warranty period the manufacturer will repair

or replace, free of charge, parts that are faulty due to

manufacturing.

In case the repair has to take place at the

manufacturer’s site, the machine will have to be sent to

the manufacturer in its original packaging.

Transportation expenses will be covered by the

manufacturer during the warranty period.

The warranty does not cover the cleaning of the

functioning parts.

Defects not clearly attributed to the material or the

manufacturing will be examined. If the claim should

turn out to be unjustified all repair expenses, changed

parts and transportation will be charged to the buyer.

The warranty does not cover damage caused by the

following:

accidental damage during transportation

damage due to lack of care or procedures carried

out incorrectly

damage due to improper use not conforming to the

warnings of the user and service manual

components subject to wear and tear; a detailed list

is available in the components section.

Structural damage, modifications, improper alterations

or repairs can affect the functioning of the safety

mechanisms, thus making the declaration of conformity

and warranty void. Alterations on the machine can be

carried out solely by technicians authorised by the

manufacturer.

Table of contents

Other SELMI Commercial Food Equipment manuals

SELMI

SELMI COMFIT Troubleshooting guide

SELMI

SELMI CHOCOFORM Troubleshooting guide

SELMI

SELMI Macchia Troubleshooting guide

SELMI

SELMI TANK 200 Troubleshooting guide

SELMI

SELMI TOP EX Troubleshooting guide

SELMI

SELMI SPIDER Troubleshooting guide

SELMI

SELMI RS250 Troubleshooting guide

SELMI

SELMI Demoulding Troubleshooting guide

SELMI

SELMI Filler Troubleshooting guide

SELMI

SELMI MICRON 25 Troubleshooting guide