SELPRO ESY 1 User manual

ESY 1~

User Manual

Specialized

Vac stepless Controllers

for

single-phase Asynchronous Motors

on Axial Centrifugal Fans

ON

Ventilated Heat Exchangers

Drycoolers Air Cooled Condensers

FAN speed Control Solutions

3

YEAR

Global

Global

Warranty

Warranty

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

1

LVD

EMC

WARNING ! HIGH LEAKAGE CURRENT First connect to Earth !

DO NOT touch the electrical parts of the circuit when the power supply is connected

under any circumstances

Safety Warnings

•We disclaim all responsibility for accident, loss or damage caused by the use of these appliances. These must be

correctly installed by qualified personnel in conformity with their intended use and, whenever needed, must undergo

correct maintenance which should be carried out while ensuring the safety of people, domestic animals and goods.

•Do NOT

tamper with or disassemble the regulator internal components; doing so will INVALIDATE THE

GUARANTEE and may cause unnecessary damage. The regulator does not contain components that can be repaired

by the user.

•The regulator must be SUITABLY AND EFFECTIVELY EARTHED by the installer, under his own responsibility,

according to the standards in force; earthing is essential for the EMC filter to operate correctly.

Precautions

•When receiving the goods, check that the packing is intact; in the event of any damage due to transportation, notify

the forwarding agent according to legal requirements.

•The regulator must be installed by qualified personnel who will connect the electric supply with GROUND

CONNECTION, attach the cables in their permanent positions and commission the plant.

•Incorrect installation of the ESY100 voltage regulator may cause damage to objects or people, so ensure the

instructions in this manual and all required security measures are read and followed carefully.

•Before supplying power to the unit, make sure that the regulator is correctly connected to the power supply and to

earth. Follow the instructions in this manual exactly and observe all safety measures in force.

•The user must be protected from the electric supply and the motor must be protected from possible overloads in

compliance with the standards in force. DO NOT touch any electrical parts of the circuit when the power supply is

connected under any circumstances.

•If the mains supply is "disturbed", which may be due to other electrical power components causing irregularities in

the supply (power contactors), it is recommended that supplementary SINGLE phase ‘SURGE ARRESTER’ filters

are installed directly on the regulator supply.

•Avoid repeatedly connecting and disconnecting the power supply to the regulator; a constant supply keeps the

regulator at working temperature and eliminates problems caused by condensate inside the protection case.

•Install the regulator out of direct sunlight, in order to protect the case from overheating. The appliance can operate at

environmental temperatures up to 50°C. Do NOT install it where this temperature may exceed, otherwise the

integrity of the regulator will be compromised, since the controller may make the user appliance operate at full load

(100%) with all consequent effects.

•The equipment must be placed vertically, in order to encourage heat dissipation and to ensure sufficient air

circulation in a free space measuring at least 150 mm above and below the regulator. If several regulators are to be

grouped together on a single electric board, please provide forced air circulation with a fan or with a sufficiently

powerful cooling unit.

Description of symbols in use in the present manual

! Attention !

Important information

Compliance with:

CE mark –Electromagnetic Emissions – Low Voltage Directives

Factory Default The highlighted characteristics are Factory STANDARD settings

PRODUCT end of life – WEEE directive

i

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

2

Contents:

Safety Warnings ....................................................................................................................................................Errore. Il segnalibro non è definito.

Precautions.................................................................................................................................................................................................................. 1

Contents ...................................................................................................................................................................................................................... 2

1. ..

EC DIRECTIVES & TECHNICAL STANDARDS ...................................................................................................................................... 3

2. .. Mechanical Dimensions ESY-1 ...................................................................................................................................................................... 3

3. .. OPERATING MODES AND APPLICATIONS............................................................................................................................................ 4

4. .. TECHNICAL CHARACTERISTICS ESY-1 ................................................................................................................................................ 5

5. .. ELECTRICAL CONNECTIONS..............................................................................................................Errore. Il segnalibro non è definito.

5.1. Power Supply Connection (Terminal Block M1)........................................................................................................................................... 7

6. .. SIGNAL CONNECTIONS for the 4 CONFIGURATIONS (ALL-in-ONE)............................................................................................... 8

6.1. OM CONFIGURATION (STANDARD SELPRO)....................................................................................................................................... 8

6.2. OX Configuration (on request)....................................................................................................................................................................... 8

6.3. OV Configuration (on request)....................................................................................................................................................................... 9

6.4. OB Configuration (on request) ....................................................................................................................................................................... 9

7. .. Electrical connection for Slave Module/s ..................................................................................................................................................... 10

7.1. Connection of SLAVE modules, SV series (0-10Vdc power units)............................................................................................................. 10

7.2. Connecting ESY-1 to SLAVE-SV / 0-10 Vdc modules (Three-/Single-phase connection)........................................................................ 10

7.3. Connection of SLAVE modules, SP series (PWM power units) ................................................................................................................. 11

7.4. Connecting SLAVE-SP modules – Power supply in phase with the Master unit (network synchronization)......................................... 11

8. .. ESY-1: CONTROL & POWER CARD IN DETAIL, ALL-in-ONE version ............................................................................................ 12

8.1. ESY-1: CONTROL & POWER CARD IN DETAIL, SLAVE-ONE versions........................................................................................... 12

8.2. LED signals .................................................................................................................................................................................................... 13

8.3. Configuration and selection JUMPERS....................................................................................................................................................... 13

9. .. Set-up of operating LIMITS and PARAMETERS...................................................................................................................................... 14

9.1. Available regulations in the standard ESY-1 version (ALL-in-ONE)........................................................................................................ 14

9.2. How to set up the operating limits for the ALL-in-ONE version).............................................................................................................. 14

9.3. How to set up the operating limits for SLAVE-ONE modules (only SLAVE-SV version) ....................................................................... 15

9.4. Table showing the scale of values for setting up the ESY-1 regulation VAC Limits................................................................................. 15

9.5. Tables for the Set-Point selection: ................................................................................................................................................................ 16

9.5.1. Set-Point values, range 0-15 bar (Transducer 4-20 mA)........................................................................................................................... 16

9.5.2. Set-Point values, range 0-15 bar (Transducer 4-20 mA)........................................................................................................................... 16

9.5.3. Set Point values, range 0-25 bar (Transducer 4-20 mA)............................................................................................................................ 17

9.5.4. Set Point values, range 0-30 bar (Transducer 4-20 mA)............................................................................................................................ 17

9.5.5. Set-Point values, range 0-45 bar (Transducer 4-20 mA).......................................................................................................................... 18

9.5.6. Set Point values, range 0-30 bar (Transducer 0,5-4,5 Vdc) ....................................................................................................................... 18

9.5.7. Set-Point values, range 10°C to 60°C (NTC probe 10kohm@25°C)......................................................................................................... 19

9.6. Regulation with Double SET-Point (optional)............................................................................................................................................ 19

10. Function diagrams & Operating parameters in MASTER & SLAVE modes ........................................................................................ 20

10.1. ESY-1 MASTER mode................................................................................................................................................................................. 20

10.2. ESY-1 SLAVE mode .................................................................................................................................................................................... 20

11. ACCESSORIES............................................................................................................................................................................................ 21

11.1. Manual Remote Control Units..................................................................................................................Errore. Il segnalibro non è definito.

11.2. Pressure Transducer for 4-20 mA & 0-5 V................................................................................................................................................. 22

11.3 Temperature Probe NTC (10 kohm@25°C)............................................................................................Errore. Il segnalibro non è definito.

11.4 RGF-MEI(4) / UNIVERSAL input Expansion Module ..........................................................................Errore. Il segnalibro non è definito.

PRODUCT end of life

The device must be disposed of separately, according to the local authority

advice.

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

3

LVD

EMC

1. EC DIRECTIVES & TECHNICAL STANDARDS

This series has been designed and manufactured for use in industrial environments, and complies therefore with the

following European Directives:

•Machine Directive 98/37 CE and following amendments

•Low Voltage Directive (LVD) 2006/95/EC

•EMC Directive 2004/108/EC

Thanks to its advanced technical solutions, the ESY100 series has obtained the CE mark in compliance with the EMC

(Electromagnetic Compatibility) directive 2004/108/EC also in household environment.

The essential requirements of the directive are satisfied by the conformity to the “generic standards” for industrial environments.

Directive Standard Code Description

98/37/CE EN 60204-1 Safety of machinery. Electrical equipment of machines.

73/23/CE EN60204-1 Safety of machinery. Electrical equipment of machines.

EN 50178 Electronic equipment for use in power installations.

89/336/CE EN 61000-3 Adjustable speed electrical power drive systems. Part 3: EMC

product standard including specific test methods.

All products have been tested in accordance with the procedures and test conditions laid down in the standards specified in the

product technical file.

Since these products are destined to be used not only as “stand alone” systems, but also as components of other machines or plants,

all compatibility tests to the standards have been performed under typical conditions of use.

In particular, the tests have been performed in a system consisting of a voltage controller RGM300, a control cable and relative

commands, a supply cable, a motor cable and a group of fans with an equivalent power to the value of the nominal current of the

controller, set to operate within specific VAC values for the single-phase regulation according to EMC requirements.

! WARNING !

The final specifications of the system or plant, in compliance with the EMC directive, are in any case

the responsibility of the installer, who must put the system into operation carefully, according to the

rules in force and following the information provided by the present manual.

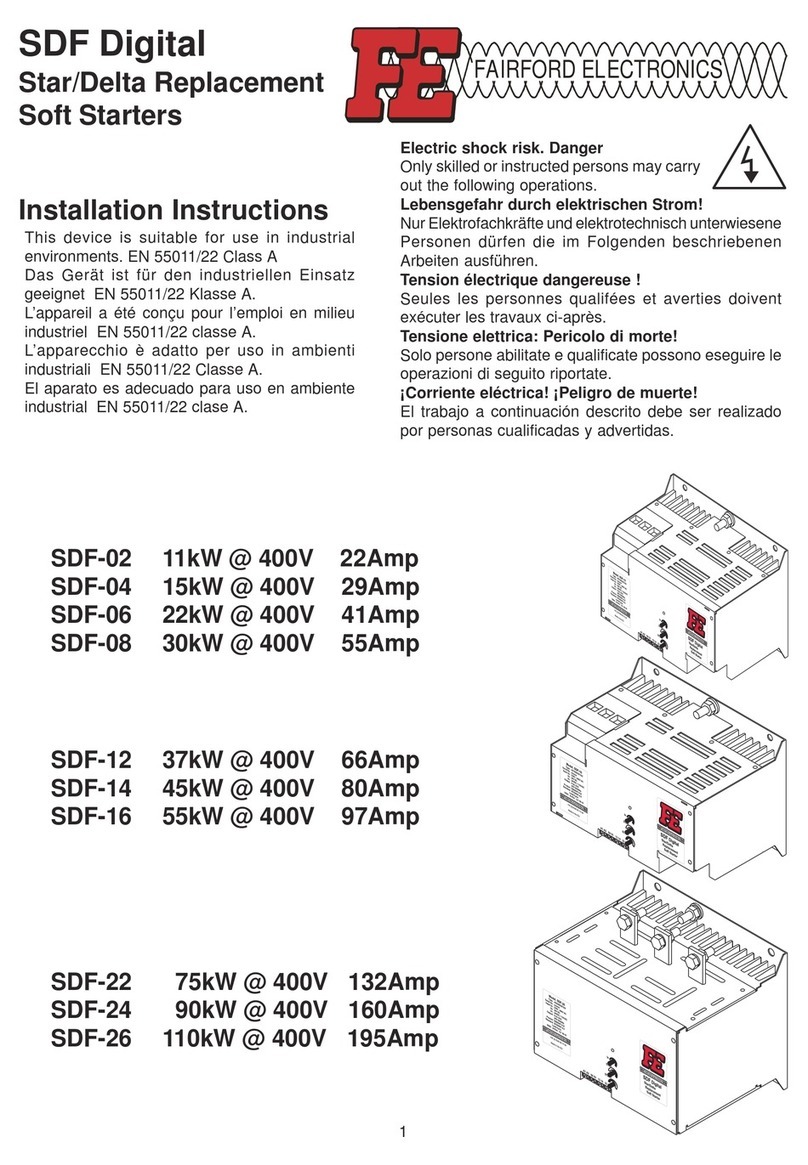

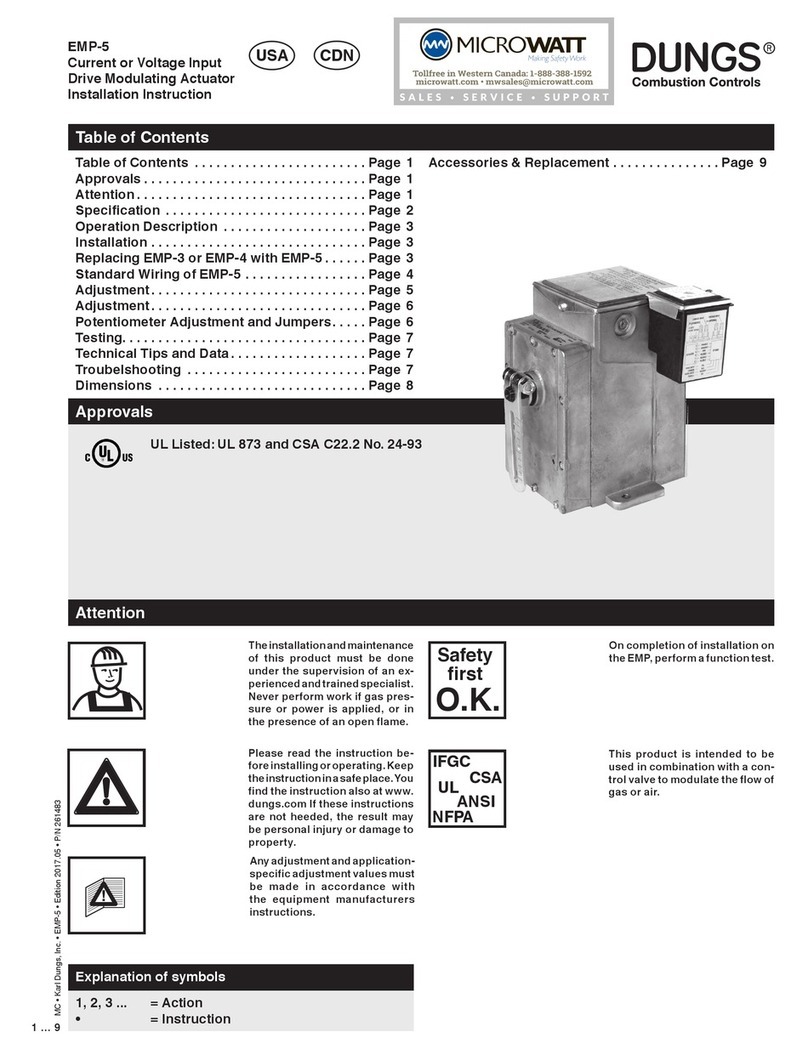

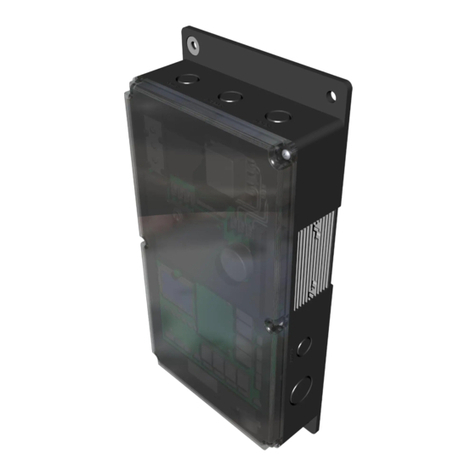

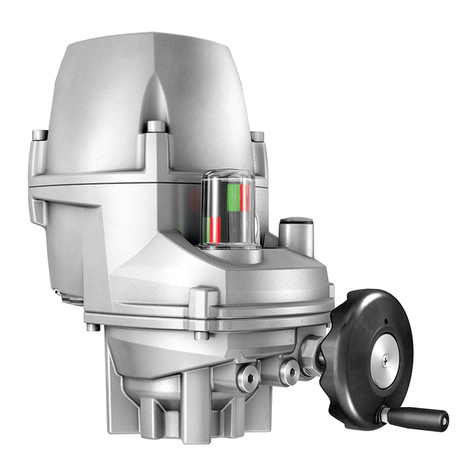

2. Mechanical Dimensions ESY-1

Model A B C D E F Kg. ∅

∅∅

∅fastening holes

ESY 08 195 162 97 195 145 162 1.4 Kg ∅

∅∅

∅5

ESY 12 195 162 97 195 145 162 1.5 Kg ∅

∅∅

∅5

ESY 16 240 152 115 195 93 210 1.7 Kg ∅

∅∅

∅5

ESY 20 240 152 115 195 93 210 1.8 Kg ∅

∅∅

∅5

8 A / 12 A

16 A / 20 A

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

4

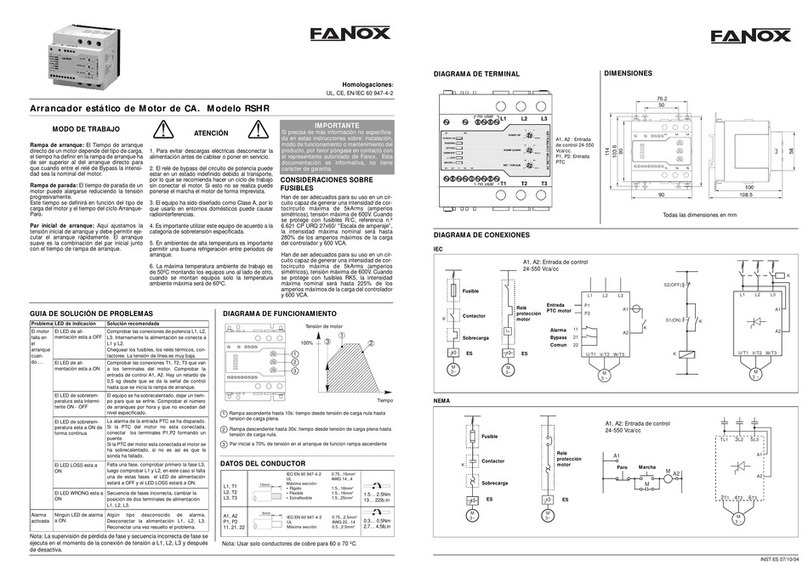

Moduli SLAVE - SLAVE units

0 - 10 Vdc PWM

MAX n.5

POWER S PPLY

ALIMENTAZIONE

PE L1 N

NTC

0- 5Vdc 0-5Vdc 0-10Vdc

SEGNALI DI REGOLAZIONE / CONTROL SIGNALS

IN1

4-20mA

IN2 IN3

4-20mA NTC

SP1 SP2

P W M

O T SP2

0-10Vdc

IN4

0-10Vdc

for C ONDENSERs

2 Input CIRC ITs

OM mode

for DRY-Cooler

1 Input CIRC IT

°C (NTC)

f or Remore Controller

1 Input CIRC IT

BAR (mA-Vdc)

0-10Vdc

(default)

FANs

3. OPERATING MODES AND APPLICATIONS

The ESY1 devices are electronic analog regulators of single-phase AC voltage, which use the phase-cutting principle (Triac) in order

to vary the output active voltage applied to a resistive or inductive load.

When connected to asynchronous high-slip electric motors of fans or pumps, they control their rotational speed in order to maintain the

key parameter within desired values. On this purpose they have been projected and specialized for control applications on Air Cooled

Heat Exchangers, used in Air Conditioning, Refrigerating, Air Handling and Ventilation Systems.

The series is available in the following versions:

- ALL-in-ONE (multi-input), with 4 control inputs, 3 inputs for mA-Vdc-NTC sensors and 1 0-10Vdc control signal, for MASTER-

SLAVE operating modes.

- SLAVE-ONE, with 1 input for 0-10Vdc (Slave-SV) or PWM (Slave-SP) control signals, to be used as single regulation units or as

additional modules in order to share out the overall controlled power, only for SLAVE operating mode.

With the ALL-in-ONE mode, the selection of input signal and operating mode are performed automatically: the controller operates

through the presently active sensor/signal and there is NO need to use any selection or programming hardware device.

The regulator selects the currently ACTIVE control signal, according to the mode preset by the Jumpers.

It is possible to modify the factory settings during the installation procedure of the device, by moving the following JUMPERS:

J1, operating mode: DIRECT - the VAC output increases as the control signal value increases

REVERSE - the VAC output decreases as the control signal value increases

J2, VAC fans at Set Point: VAC/RMP = 100% with SP = MAX, the Set-P corresponds to the fans Max-speed

VAC/RPM = 0% with SP = MIN, the Set-P corresponds to the fans Min-speed

J3, operation of trimmer P2: MIN for the Min. AC voltage limit supplied to the connected motor;

(J1 for SLAVE-SV) Cut-Off for the AC voltage limit of the connected motor;

J4, output for Slave units control: with control signal for SLAVE-SV units, with 0-10Vdc input signal

with control signal for SLAVE-SP units, with PWM input signal

While the Proportional Band (Pb) values are already factory preset (see Table: Operating Parameters), the Set Point values are

determined through a couple of 13-position rotary switches: SP and SPadj., which are intended to be used quickly and easily even by

base users. The selection of the Set Point is immediate, and two LEDs (+ & -) will show the relationship between this desired value

and the signal value perceived through the presen

tly active sensor; the Set Point will be reached when both LEDs will be off.

In addition, there are LEDs indicating the selection of the First or Second Set Point (only for optional card with double Set Point), and

a LED showing the presence of power supply.

With the SLAVE-ONE version, two types of SLAVE units are available: SV (input 0-10Vdc), and SP (input PWM).

All ESY-1 units are equipped with:

–Complete galvanic separation between AC mains supply and control inputs;

–EMC mains filter with Residential, Commercial & Light Industrial limit (conformity with PDS systems), fit to

be used with equipment directly connected to the low voltage mains supply;

–Overvoltage protection on the mains supply;

–Short circuit protection on the connection of the control sensors/signals;

–Protection filters on control inputs

The ESY-1 series is available in the sizes 8A–12A–16A–20A, with single phase supply voltage 230V/50Hz, and it is housed in a

GW–Plast 120°C case with protection degree IP55 and high impact resistance, for out of doors installations (-20T50).

The controller can be used both in Condenser mode (pressure transducer) and in Dry-Cooler mode (temperature probe) without the

need of any further configuration or programming, with two operating SET-Points (selection of Set-Point 1 & 2), beside the Remote-

SLAVE Unit mode, when driven by an external controller generating a 0-10Vdc control signal.

60Hz applications: only with factory calibration

The regulator works correctly also with 60 Hz, but it is necessary to calibrate the output signal to 100% in order to optimize

the regulation and avoid pulse and beat frequencies.

.

i

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

5

i

4. TECHNICAL CHARACTERISTICS ESY-1

POWER SUPPLY

Voltage

230V

AC

±

10

%

single phase – (on request

110V

AC

-

400V

AC)

Frequency

50Hz

standard

(60 Hz

only factory calibration)

Overvoltage Protection for installation Category

II

(

4 KV

)

OPERATING

PRINCIPLE

Electronic analog regulators of single-phase AC voltage, which use the phase-cutting principle (Triac) in order to vary the

output active voltage applied to a resistive or inductive load.

CURRENT

Rated

ESY 08

08 A

up to

50°C

environment; if over, decrease 0,4

A/°C

ESY 12

12 A

up to

50°C

environment; if over, decrease 0,6

A/°C

ESY 16

16 A

up to

50°C

environment; if over, decrease 0,8

A/°C

ESY 20

20 A

up to

50°C

environment; if over, decrease 1,0

A/°C

Starting current

(for loads upstream of the regulator)

ESY 08 16A

ESY 12 24A

ESY 16 32A

ESY 20 40A

Overload 200% of the rated current (max. 10” every 3’)

POWER Control Circuit 3VA

Thermally dissipated 1,3 W per supplied Ampere

OPERATING

CHARACTERISTICS

Master (Controller Mode)

(inputs IN1,IN2,IN3)

The output voltage varies in order to maintain the value measured by the

transducer within the proportional band (Pb = factory calibration)

Slave (Power Unit Mode)

(Input IN4)

The output voltage varies according to the 0-10 Vdc control signal applied to the

input IN4, according to the current configuration.

CONTROL

SIGNALS

AND

CONTACTS

ALL-in-ONE

standard

Config. 0M

Master (Controller)

IN 1

IN 2

IN 3

4-20 mA for 100 ohm (R)

4-20 mA for 100 ohm (R)

NTC 10kohm @ 25°C

Slave (Power Unit) IN 4 0-10Vdc for 10 kohm

On request

Config. 0X Master (Controller)

IN 1

IN 2

IN 3

4-20 mA for 100 ohm (R) ,

NTC 10 kohm @ 25°C

NTC 10 kohm @ 25°C

Slave (Power Unit) IN 4 0-10Vdc for 10 kohm

Config. 0V Master (Controller)

IN 1

IN 2

IN 3

0-5 Vdc

0-5 Vdc

NTC 10 kohm @ 25°C

Slave (Power Unit) IN 4 0-10Vdc for 10 kohm

Config. 0B Master (Contoller)

IN 1

IN 2

IN 3

4-20 mA for 100 ohm (R)

0-5 Vdc

NTC 10 kohm @ 25°C

Slave (Power Unit) IN 4 0-10Vdc for 10 kohm

Contact for Set-Point switching SP2: selection of Set Point 1 or Set Point 2 (option Double Set-Point )

SLAVE

ONE Standard

Config. SV Slave (Power Unit) IN 1 0-10Vdc for 10 kohm

Config. SP Slave (Power Unit) IN 1 PWM (PPM-Triac) control voltage 5V÷30V

OPERATING

PARAMETERS

Set-Point Regulation Easy adjustment with couple of 13-position rotary switches

Input type

4-20 mA

0 - 5 Vdc NTC 10K @ 25°C

Main Set Point (SP) 8÷18 mA 0,5 - 4,5 Vdc 10÷60 °C

Step Set Point adjustment (SPadj) 0,1 mA 0,04 Vdc 0,5 °C

Proportional Band (default) 2,5 mA 0,65 Vdc 7°C

Minimum/Cut-Off limit Adjustable from 0% to 70% of the output voltage

Maximum limit Adjustable from 100% to 0% of the output voltage

Acceleration time (default) 5”

Operating mode

DIRE

CT

(

DIR

)

VAC output increases as the input value increases)

REVERSE (REV) VAC output decreases as the input value increases)

AC voltage at Set Point Selection of

MAX

Vac

value – maximum fan speed

Selection of MIN Vac value – minimum fan speed

Lower VAC limit Selection of

Cut

-

Off

limit

(C-Off) o

Selection of MAX Vac Limit (MIN)

Slave Units AUX. control Selection for

Analog

0

-

10Vdc

signal (three / single phase supply)

Selection for logic PWM signal (same as the remote unit supply)

LED

SIGNALS

DL1 Power Supply O.K.

- Signal value is lower than Set-Point value ±30% of the Proportional Band (Pb)

+ Signal value is higher than Set-Point value

1 Set-Point 1 selection Available optional card with

Double Set-Point function

2 Set-Point 2 selection

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

6

OUTPUT SIGNALS

Config. 0M

V1

Transducer voltage supply 22V (+10/-20%) max. 25mA

V2

Transducer voltage supply 22V (+10/-20%) max. 25mA

+ 10V

Transducer voltage supply 10,0V (±1%)

OUT

Output signal for slave unit: 0-10Vdc or PWM (MAX 5 modules)

Config. 0X

V1

Transducer voltage supply 22V (+10/-20%) max. 25mA

V2

Transducer voltage supply 22V (+10/-20%) max. 25mA

+ 10V

Transducer voltage supply 10,0V (±1%)

OUT

Output signal for slave unit: 0-10Vdc or PWM (MAX 5 modules)

Config. 0V

V1

Transducer voltage supply 5,0V (±1%)

V2

Transducer voltage supply 5,0V (±1%)

+ 10V

Transducer voltage supply 10,0V (±1%)

OUT

Output signal for slave unit: 0-10Vdc or PWM (MAX 5 modules)

Config.0B

V1

Transducer voltage supply 22V (+10/-20%) max. 25mA

V2

Transducer voltage supply 5,0V (±1%)

+ 10V

Transducer voltage supply 10,0V (±1%)

OUT

Output signal for slave unit: 0-10Vdc or PWM (MAX 5 modules)

Config.SV + 10V

Transducer voltage supply

OUT

Output signal for slave unit: PWM (MAX 5 modules)

PROTECTIONS

EMC mains filter Compliance 89/336

Conformity for devices that are directly connected to the low voltage mains

Overvoltage Protection Complying with EN 61000-4-5 : overvoltage category II (4 KV)

Control Input Protection Protection from electrical disturbances of the connection

Transducer Supply Protection Protection from short circuit of the transducer output supply

CASE

Materials GW-Plast 120°C (max. temperature 120°C) aluminium, fiberglass

Protection degree IP 55 (standard)

IP 00 (on request)

MAX Heatsink Temperature 60°C

Environmental Pollution Low Pollution

Fire Resistance D Category

INSULATION

Endurance of the insulation materials

against electrical stress Long

Control Circuits

Class

I

(use of protective earthing conductor)

2000 Vac

between grounding and voltage supplied components of the device

2500Vac

between control input and voltage supplied components of the device

4000 Vac

between control input and mains supplied components

WORK

ENVIRONMENT

Working Temperature

-

20 T 50

( from –20°C to + 50°C )

Storage Temperature

-

30 T 85

( from –30°C to + 85°C )

Vibrations Lower than 1G (9.8 m/s

2

)

Ageing Characteristics 60.000 hours

INSTALLATION Wall mounting ONLY in vertical position, with N° 4 holes

∅

∅∅

∅

5 mm, providing at least 10 mm insulation around the device

The device is suitable for the installation in class I, II, III equipments .

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

7

5. ELECTRICAL CONNECTIONS

Connect the controller as shown in the figure below, paying attention to the following points.

5.1. Power Supply Connection (Terminal Block M1)

-Before supplying power to the unit, check carefully the power connection and the efficiency of EARTH

connection.

-Ensure that power conductors and EARTH CABLES have a cross section suitable to the connected load.

-Place a couple of fuses with suitable amperage upstream of the disconnector.

-Do NOT install the device in environments where ambient temperature may exceed the maximum values allowed (Tamb≤50°C).

-Mount the equipment vertically, in order to encourage heat dissipation and to ensure sufficient air circulation in a free space

measuring at least 150 mm above and below the regulator.

-If the mains supply is "disturbed", which may be due to other electrical power components causing irregularities in the supply, it is

recommended to install supplementary SINGLE phase ‘SURGE ARRESTER’ filters directly on the regulator supply.

-Do NOT alter or damage the identification stickers on the equipment.

-NEVER force the rotary switches beyond their mechanical end stops.

-The power cables (power supply and load), must be installed separately from the control cables, keeping the maximum possible

distance between the power and signal conductors.

-Do not mix power cables and signal cables in the same raceway. Where cables must cross one another, ensure they are at an

angle as near to 90° as possible to minimize interference.

WARNING : Use heat resistant cables, able to withstand a temperature rated at 90° or above.

SURGE ARRESTER : electric protection placed between the regulator supply and the earth, meant to protect the device from

transient overvoltage.

WARNING: Do NOT use differential switches with values lower than 100mA

-It is advisable to provide a by-pass switch in order to run the load even in case of disconnector failure (emergency by-pass). When

connecting the by-pass, it is necessary to keep the phase correspondence unaltered.

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

8

1

2

100%

0%

=

6. SIGNAL CONNECTIONS for the 4 CONFIGURATIONS (ALL-in-ONE)

After checking carefully all power supply connections, connect the input signal/s and supply the card.

The output voltage varies from zero Vac to 230 Vac, according to the variation of the control signal.

For the connection of the control signal, use an ordinary twisted-pair cable in disturbance-free environments, while in presence

of environmental electromagnetic disturbances use a shielded twisted cable with the screen connected to earth, keeping it as far

away as possible from other power cables.

The function modes, both always available in the present series, can be:

-MASTER with Set-Point, using the inputs In1–In2–In3 (for 4-20mA, 0-5Vdc or NTC probe)

-SLAVE, using the input In4 ( for 0-10V control signal)

The controllers of the ESY-1/ALL-in-ONE series can be set in the following four (4) configurations, described below.

The OM configuration is standard SELPRO

6.1. OM CONFIGURATION (STANDARD SELPRO)

N°

Na

me

Function OM CONF.

1 V1

Output voltage

supply

22V (+10/-20%)

max. 25 mA

2 IN1

Transducer Input

N° 1 4-20 mA

3 GND

Ground GND

4 IN2

Transducer Input

N° 2 4-20 mA

5 V2

Output voltage

supply

22V (+10/-20%)

max. 25 mA

6 IN3

Transducer Input

N° 3

NTC 10kohm

@ 25°C

7 GND

Ground GND

8 IN4

Input N° 4 (only

SLAVE control) 0-10Vdc

9 +10V

Output voltage

supply 10,0V ±1%

10

OUT

“Slave” modules

control Output 0-10Vdc / PWM

11

GND

Ground GND

12

SP2

Set-Point 1& 2

selection Contact

Open = SP1

Closed = SP2

6.2. OX Configuration (on request)

N°

Name

Function OX CONF.

1 V1

Output voltage supply 22V (+10/-20%)

max. 25 mA

2 IN1

Transducer Input

N° 1 4-20 mA

3 GND

Ground GND

4 IN2

Transducer Input

N° 2

NTC 10kohm

@ 25°C

5 V2

Output voltage supply 22V (+10/-20%)

max. 25 mA

6 IN3

Transducer Input

N° 3

NTC 10kohm

@ 25°C

7 GND

Ground GND

8 IN4

Input N° 4 (only

SLAVE control) 0-10Vdc

9 +10V

Output voltage supply +10,0V ±1%

10

OUT

“Slave” modules

control Output 0-10Vdc / PWM

11

GND

Ground GND

12

SP2

Set-Point 1& 2

selection Contact

Open = SP1

Closed = SP2

100%

0%

=

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

9

1

2

100%

0%

=

1

2

100%

0%

=

6.3. OV Configuration (on request)

N°

Name

Function OV CONF.

1 V1

Output voltage supply + 5,0V ±1%

2 IN1

Transducer Input

N° 1 0-5 Vdc

3 GND

Ground GND

4 IN2

Transducer Input

N° 2 0-5 Vdc

5 V2

Output voltage supply + 5,0V ±1%

6 IN3

Transducer Input

N° 3

NTC 10kohm

@ 25°C

7 GND

Ground GND

8 IN4

Input N° 4 (only

SLAVE control) 0-10Vdc

9 +10V

Output voltage supply +10,0V ±1%

10

OUT

“Slave” modules

control Output 0-10Vdc / PWM

11

GND

Ground GND

12

SP2

Set-Point 1& 2

selection Contact

Open = SP1

Closed = SP2

6.4. OB Configuration (on request)

N°

Name

Function OB CONF.

1 V1

Output voltage supply 22V (+10/-20%)

max. 25 mA

2 IN1

Transducer Input

N° 1 4-20 mA

3 GND

Ground GND

4 IN2

Transducer Input

N° 2 0-5 Vdc

5 V2

Uscita tensione

alimentazione + 5,0V ±1%

6 IN3

Transducer Input

N° 3

NTC 10kohm

@ 25°C

7 GND

Ground GND

8 IN4

Input N° 4 (only

SLAVE control) 0-10Vdc

9 +10V

Output voltage supply +10,0V ±1%

10

OUT

“Slave” modules

control Output 0-10Vdc / PWM

11

GND

Ground GND

12

SP2

Set-Point 1& 2

selection Contact

Open = SP1

Closed = SP2

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

10

J4=0-10V

ESY

SV

ESY

SV

ESY

OM

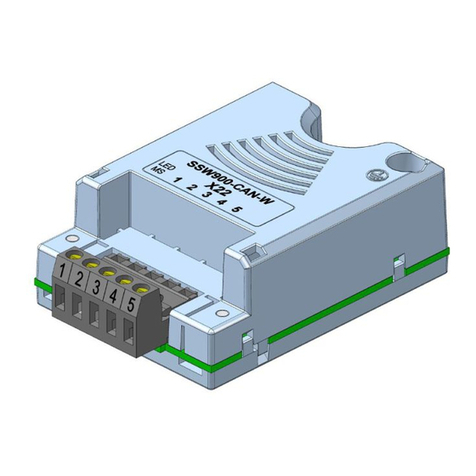

7. Electrical connection for Slave Module/s

The controllers of the ESY-1 / ALL-in-ONE series include moreover the SLAVE-ONE power units, in the two following

versions:

-SLAVE-SV with input for 0-10Vdc control signal

-SLAVE-SP with input for PWM control signal

All the models of the series share the same technical characteristics and are available in different sizes:

8 A – 12 A – 16 A – 20 A, 230Vac/50Hz, all suitable for outdoor applications, in plastic case 120°C and protection degree

IP55.

Moreover, the SLAVE-SV control unit, with control input 0-10Vdc has an auxiliary output that allows to control further

SLAVE-SP units.

By using exclusively SLAVE-SV units, it is possible to share equally the total load on the three-phases (R-S-T), so as to prevent

the risk of overloading the electric line on just one phase (regulation performed by two or more controllers, which have the 0-

10Vdc control signal in common).

The SLAVE-SV modules do not

require the same supply phase for every module connected to the 0-10Vdc control signal

(network synchronization), which is instead needed when connecting SLAVE-SP units (PWM input).

7.1. Connection of SLAVE modules, SV series (0-10Vdc power units)

SLAVE – SV module: 0-10Vdc control signal Terminal block

N°

Name Function SV CONF.

1 IN

Control Input 0-10Vdc

2 GND

Ground GND

3 10V

Potentiometer

AUX. supply

10,0V

±1%

4 OUT -

Output signal (5/30V) for

“slave PWM” modules PWM

5 OUT +

7.2. Connecting ESY-1 to SLAVE-SV / 0-10 Vdc modules (Three-/Single-phase connection)

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

11

J4=PWM

ESY

SP

ESY

SP

ESY

OM

7.3. Connection of SLAVE modules, SP series (PWM power units)

The SLAVE-SP unit allows the connection of the only PWM (PPM-Triac) control signal.

The input is optimized in order to be compatible with every device having a PWM control signal, from 5V to 30V.

All connected SLAVE-SP units require the same supply phase as the remote controller, which generates the PWM control

signal (network synchronization)

SLAVE – SP module: PWM control signal

7.4. Connecting SLAVE-SP modules – Power supply in phase with the Master unit (network synchronization)

Terminal block

1 PWM NON polarized input for

PWM control signal (from 5V

to 30V)

PWM

2 PWM

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

12

Led

DL1

MAX OUT CUT-OFF

(MIN OUT)

SP -+

J1

J2

J3

Power supply

terminal block

J4

P1 P2 P3 P4

Control signals

terminal block

SPadj

Led

Led

Double Set-Point

optional card

SP1 SP1adj

SP2adj

SP2

1

2

Led

Led

P4P3

P6

P5

1

2

-+

Led

Led

J1

Power supply

terminal block

Control signals

terminal block

DL1

Power supply

terminal block

Control signals

terminal block

SLAVE-SV (0-10V)

SLAVE-SP (PWM)

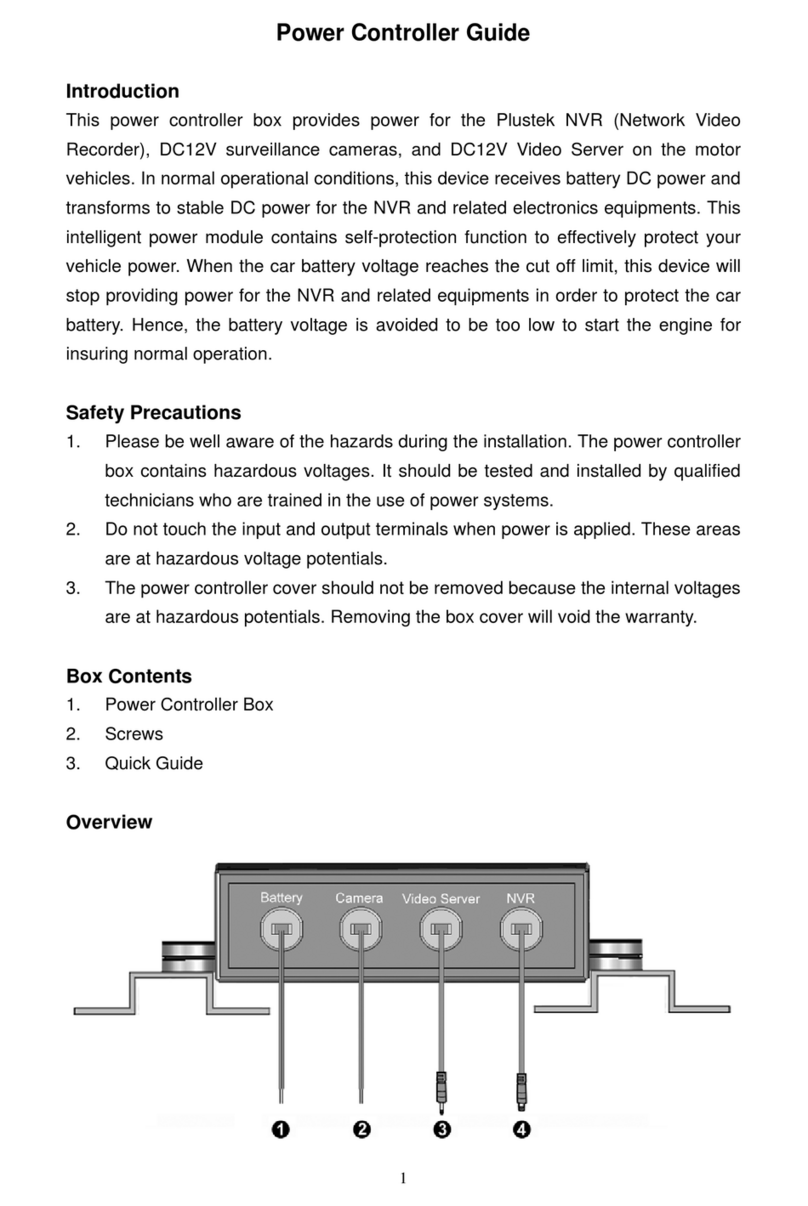

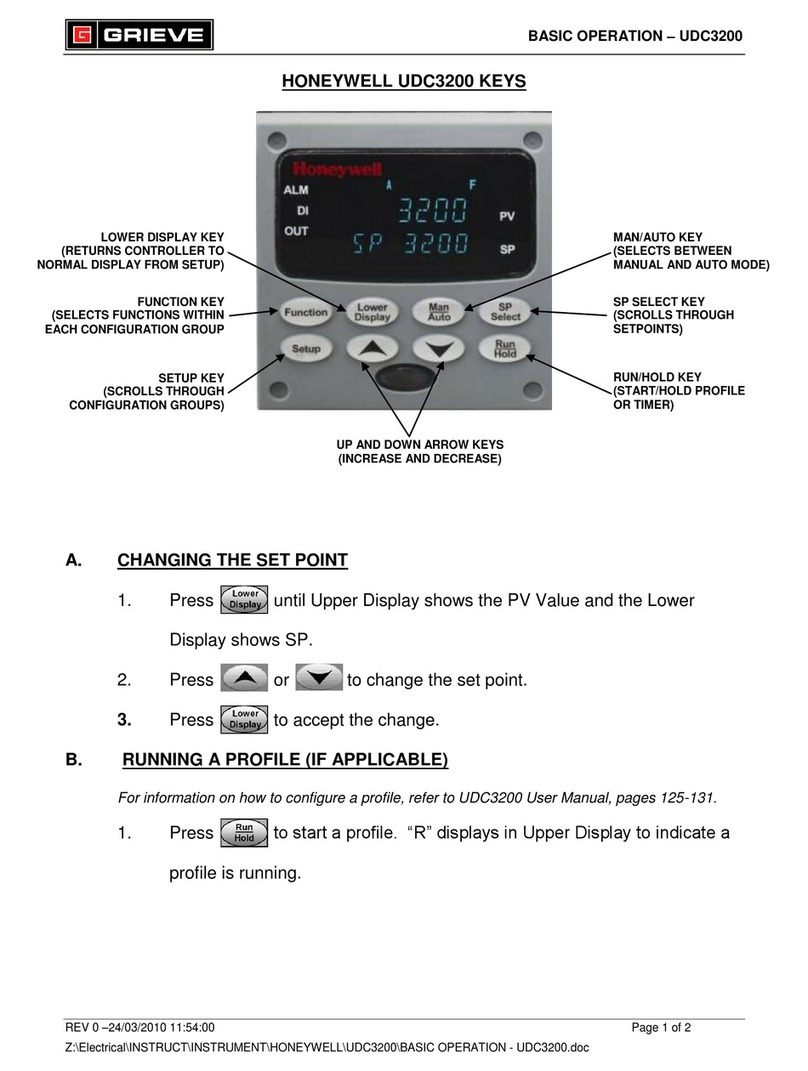

8. ESY-1: CONTROL & POWER CARD IN DETAIL, ALL-in-ONE version

8.1. ESY-1: CONTROL & POWER CARD IN DETAIL, SLAVE-ONE versions

Jumper

& LED

Description ESY-1 / ALL-in-ONE

J1 DIRECT-REVERSE mode selection

J2 VAC Output at SET-POINT

J3 CUT-OFF / MIN OUT selection

J4 EXTRA-power control Output

DL1 Power supply O.K.

DL - Set-Point higher than sensor signal

DL + Set-Point lower than sensor signal

1 Set-Point 1 ON

2 Set-Point 2 ON

Jumper

Description ESY-1 / SLAVE-SV

J1 CUT-OFF / MIN OUT selection

DL1 Power supply O.K.

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

13

230Vac

MAX out

80%

C T-Off

30%

SP

0%

100%

IN

Pb

OFF leds

(30% di Pb)

SP

OVER

SIGNAL

SP

NDER

SIGNAL

8.2. LED signals

The cards present LED signals, which point out the state and the operation of the controller. The LED signals of the

complete version ESY-1 / ALL-in-ONE are shown in the table below:

8.3. Configuration and selection JUMPERS

Before starting the set-up procedure for operating parameters and limits, it is necessary to determine the controller’s

operating modes by moving the configuration jumpers and modifying, when needed, the factory default settings.

(*J1 : symbol for configuration jumper in SLAVE-ONE version)

ATTENTION: With J2 in MAX position (Sp at MAX), the AC output voltage at Set Point is equal to the preset MAX Vac

limit value.

DL1

Green LED

Power supply O.K.

Green LED

SP higher than the signal value *

Green LED

SP lower than the signal value *

1

Green LED

Set-point 1 selection active

2

Green LED

Set-point 2 selection active

*±

±±

±30% of the Proportional Band (Pb)

Position Default Function Mode

J1

REV

DIR Regulation

characteristics

Reverse (REV)

DIR Direct (DIR)

J2

MAX

SP MAX AC output voltage at

Set-Point

MAX AC voltage to fans

MIN MIN AC voltage to fans

J3

(*J1)

CUT-OFF

CUT-OFF Type of regulation start

Start / Stop AC voltage

MIN MINIMUM rpm VAC limit

J4

PWM

0-10Vdc

Control for Extra-

power SLAVE SV or

SP units

PWM signal – SP unit

0-10 Vdc

0-10V signal – SV unit

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

14

20% 30%

C T-OFF

SP

SP

adj.

(MIN-out)

20% 30%

100% 80%

9. Set-up of operating LIMITS and PARAMETERS

9.1. Available regulations in the standard ESY-1 version (ALL-in-ONE)

The ESY-1 controllers present two regulation Trimmers for setting up the operating limits (MIN out / Cut-Off and

MAX out), the automatic regulation performs the variations of fans speed, and a couple of 13-positions rotary

switches for setting up the SET-Point of reference with ease.

9.2. How to set up the operating limits for the ALL-in-ONE version

Before starting the set-up procedure for operating parameters, it is necessary to determine the AC voltage operating

limits, within which the automatic variation of speed takes place. The limits must be set up according to the procedures

described as follows:

MAX Vac

limit

It determines the value of maximum AC voltage to be supplied to

the fan in automatic operation (from 100% to 0%), in order to

limit the maximum airflow rate or the fan noise at MAX rpm.

It is factory preset at the maximum value of ‘10’, corresponding

to the 100% of the control value.

Set up of 'MAX out' voltage value:

1) move the Jumper J1 to ON 1(REV) position;

2) turn the trimmer MAX out from position ‘10’ up to the desired value of MAX AC

voltage limit;

3) turn the Jumper J1 back to the ON 2 position

- in automatic operation, the MAX- RPM% limit of output voltage supplied to the

load corresponds to the determined AC voltage limit.

Cut-Off

limit

It determines the value of minimum AC voltage to be supplied to

the fan in automatic operation (from 25% to 80%): the starting

voltage supplied to the fan is enough to give an adequate torque to

start the fan rotation.

Set up of 'CUT-OFF' voltage value:

1) move the Jumper J3 to ON 2 position;

2) turn the trimmer from ’1’ position up to the desired AC voltage value of MIN rpm;

3) turn the Jumper J3 back to the ON 1 position

- the regulation of the fan starts from the determined CUT-Off VAC value

MIN Vac

limit

It allows to set up manually the minimum AC output voltage

supplied to the fan, from 20% to 80%, and permits to check:

- the correct phase-cutting of the controller

- the Cut-OFF set up

Set up of 'MIN out' voltage value:

1) move the Jumper J3 to ON 2 position;

2) turn the trimmer from ’1’ position, until reaching the desired MIN rpm voltage

value

- At start up the fan operates at the determined minimum Ac voltage limit

MAX-out

AC voltage limit for MAX-RPM% threshold

CUT-OFF

(MIN-out)

AC voltage limit for Cut/Off or MIN-RPM% threshold

SP

Main Set-Point 1

(see following tables for position / value correspondence)

SP adj.

Set-Point 1 for an accurate adjustment of SP

( see following tables for position / value correspondence )

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

15

10

5

7

6

4

3

2

1

MIN OUT

9

8

5

8

9

7

6

10

MAX OUT

4

3

2

110

5

7

6

4

3

2

1

CUT-Off

9

8

20% 30%

100% 80%

20% 30%

9.3. How to set up the operating limits for SLAVE-ONE modules (only SLAVE-SV version)

The following procedures allow to set up the AC voltage limits, within which the 0-10 Vdc control signal is automatically

controlled.

MIN Vac

limit

It allows to set up manually the minimum AC output voltage

supplied to the fan, from 20% to 90%, and permits to check:

- the correct phase-cutting of the controller

- the Cut-OFF set up

Set up of 'MIN VAC out' voltage value:

1) move the Jumper J3 in ON 1 position;

2) turn the trimmer from ’1’ position, until reaching the desired MIN rpm voltage

value; now the load is always supplied starting from the determined MAX AC

voltage limit

Cut-OFF

limit

It determines the value of minimum AC voltage to be

supplied to the fan in automatic operation (from 25% to

80%): this prevent the fan to be supplied with a lower AC

voltage, which would be not enough to give an adequate

torque for keeping the fan rotating.

Set up of 'CUT-OFF' AC voltage value:

1) move the Jumper J3 to ON 1 position;

2) turn the trimmer from ’1’ position, until reaching the desired MIN rpm

voltage value

3) turn the Jumper J3 back to the ON 2 position

now the load is supplied starting from the CUT-Off value

MAX Vac

limit

It determines the value of maximum AC voltage to be

supplied to the fan in automatic operation (from 100% to

20%), in order to limit the maximum airflow rate or the fan

noise at MAX rpm.

It is factory preset at the maximum value of ‘10’,

corresponding to the 100% of the control value.

Set up of 'MAX out' voltage value:

1) jumper the inputs IN and +10V: the AC voltage output is at 100%

2) turn the trimmer MAX out from position ‘10’ up to the desired value of MAX

AC voltage limit (ex.: 80%);

3) remove the jumper between IN and +10V : in automatic operation, the MAX

voltage limit supplied to the load corresponds to the determined AC output

voltage limit

9.4. Table showing the scale of values for setting up the ESY-1 regulation VAC Limits

Scale

(*) (*) (*) move the selection jumper in order to pass from

the Cut-Off limit to the MIN out limit; always

check the difference between VAC values, as shown

in the table below

Limit

ALL-in-ONE SLAVE-ONE

MAX C-OFF MIN MAX C-Off

(MIN)

1 0 40 60 55 45

2 70 65 85 80 60

3 100 90 110 120 90

4 130 115 135 160 115

5 160 135 150 190 135

6 185 150 160 210 150

7 205 160 170 215 165

8 215 170 180 220 175

9 225 180 190 225 185

10 230 185 190 230 190

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

16

89

10

11

12

131

2

3

4

56

7

SP

+1

+2

+3

+4

+5

+6

-6

-5

-4

-3

-2 -1

SP

SPadj.

+/-

89

10

11

12

131

2

3

456

7

SP

+1

+2

+3

+4

+5

+6

SP

SPadj.

-6

-5

-4

-3

-2 -1

SP

SPadj.

89

10

11

12

131

2

3

456

7

SP

+1

+2

+3

+4

+5

+6

SP

SPadj.

-6

-5

-4

-3

-2 -1

SP

SPadj.

After selecting the operating modes and setting up the operating limits, it is necessary to determine the operating point of

the regulation: the SET-POINT, on the basis of the scales and ranges referring to the connected sensor (*).

The Set-Point is easily and quickly fixed through the couple of 13-position rotary switches, named as follows: SP

(main reference point for the regulation) and SPadj. (accurate adjustment of the operating point fixed with SP).

For the selection of the Set-Point values, refer to the following tables according to the ranges and to the types of sensors

in use.

(*) The controller ESY-1 operates automatically according to the sensor/signal currently connected or in use.

9.5. Tables for the Set-Point selection:

Set

Point =

The Set-Point value is the

result of

SP +/- SP adj.

9.5.1. Set-Point values, range 4-20 mA (Transducer 4-20 mA)

4-20mA

-6 -5 -4 -3 -2 -1 +1 +2 +3 +4 +5 +6

7,00 7,05 7,15 7,25 7,35 7,45

1

7,56 7,66 7,76 7,86 7,96 8,06 8,11

7,51 7,56 7,66 7,76 7,86 7,96

2 8,06 8,16 8,26 8,36 8,46 8,56 8,61

8,51 8,56 8,66 8,76 8,86 8,96

3 9,06 9,16 9,26 9,36 9,46 9,56 9,61

9,51 9,56 9,66 9,76 9,86 9,96

4 10,06 10,16 10,26 10,36 10,46 10,56 10,61

10,51 10,56 10,67 10,77 10,87 10,97

5 11,07 11,17 11,27 11,37 11,47 11,57 11,62

11,52 11,57 11,67 11,77 11,87 11,97

6 12,07 12,17 12,27 12,37 12,47 12,57 12,62

12,52 12,57 12,67 12,77 12,87 12,97

7 13,07 13,17 13,27 13,37 13,47 13,57 13,62

13,52 13,57 13,67 13,78 13,88 13,98

8 14,08 14,18 14,28 14,38 14,48 14,58 14,63

14,53 14,58 14,68 14,78 14,88 14,98

9 15,08 15,18 15,28 15,38 15,48 15,58 15,63

15,53 15,58 15,68 15,78 15,88 15,98

10 16,08 16,18 16,28 16,38 16,48 16,58 16,63

16,53 16,58 16,68 16,78 16,88 16,99

11 17,09 17,19 17,29 17,39 17,49 17,59 17,64

17,54 17,59 17,69 17,79 17,89 17,99

12 18,09 18,19 18,29 18,39 18,49 18,59 18,64

18,04 18,09 18,19 18,29 18,39 18,49

13

18,59 18,69 18,79 18,89 18,99 19,09 19,14

9.5.2.Set-Point values, range 0-15 bar (Transducer 4-20 mA)

0-15 bar

-6 -5 -4 -3 -2 -1 +1 +2 +3 +4 +5 +6

2,82 2,86 2,96 3,05 3,14 3,24

1

3,33 3,43 3,52 3,62 3,71 3,80 3,85

3,29 3,33 3,43 3,52 3,62 3,71

2 3,80 3,90 3,99 4,09 4,18 4,27 4,32

4,23 4,27 4,37 4,46 4,56 4,65

3 4,74 4,84 4,93 5,03 5,12 5,21 5,26

5,17 5,21 5,31 5,40 5,50 5,59

4 5,68 5,78 5,87 5,97 6,06 6,15 6,20

6,11 6,15 6,25 6,34 6,44 6,53

5 6,62 6,72 6,81 6,91 7,00 7,09 7,14

7,05 7,09 7,19 7,28 7,38 7,47

6 7,57 7,66 7,75 7,85 7,94 8,04 8,08

7,99 8,04 8,13 8,22 8,32 8,41

7 8,51 8,60 8,69 8,79 8,88 8,98 9,02

8,93 8,98 9,07 9,16 9,26 9,35

8 9,45 9,54 9,63 9,73 9,82 9,92 9,96

9,87 9,92 10,01 10,10 10,20 10,29

9 10,39 10,48 10,57 10,67 10,76 10,86 10,90

10,81 10,86 10,95 11,05 11,14 11,23

10 11,33 11,42 11,52 11,61 11,70 11,80 11,84

11,75 11,80 11,89 11,99 12,08 12,17

11 12,27 12,36 12,46 12,55 12,64 12,74 12,79

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

17

89

10

11

12

131

2

3

456

7

SP

+1

+2

+3

+4

+5

+6

SP

SPadj.

-6

-5

-4

-3

-2 -1

SP

SPadj.

89

10

11

12

131

2

3

456

7

SP

+1

+2

+3

+4

+5

+6

SP

SPadj.

-6

-5

-4

-3

-2 -1

SP

SPadj.

12,69 12,74 12,83 12,93 13,02 13,11

12 13,21 13,30 13,40 13,49 13,58 13,68 13,73

13,16 13,21 13,30 13,40 13,49 13,58

13

13,68 13,77 13,87 13,96 14,05 14,15 14,20

9.5.3. Set Point values, range 0-25 bar (Transducer 4-20 mA)

0-25 bar

-6 -5 -4 -3 -2 -1 +1 +2 +3 +4 +5 +6

4,69 4,77 4,93 5,08 5,24 5,40

1

5,55 5,71 5,87 6,03 6,18 6,34 6,42

5,48 5,55 5,71 5,87 6,03 6,18

2 6,34 6,50 6,65 6,81 6,97 7,12 7,20

7,04 7,12 7,28 7,44 7,59 7,75

3 7,91 8,06 8,22 8,38 8,53 8,69 8,77

8,61 8,69 8,85 9,00 9,16 9,32

4 9,47 9,63 9,79 9,94 10,10 10,26 10,34

10,18 10,26 10,41 10,57 10,73 10,88

5 11,04 11,20 11,35 11,51 11,67 11,82 11,90

11,75 11,82 11,98 12,14 12,30 12,45

6 12,61 12,77 12,92 13,08 13,24 13,39 13,47

13,31 13,39 13,55 13,71 13,86 14,02

7 14,18 14,33 14,49 14,65 14,80 14,96 15,04

14,88 14,96 15,12 15,27 15,43 15,59

8 15,74 15,90 16,06 16,21 16,37 16,53 16,61

16,45 16,53 16,68 16,84 17,00 17,15

9 17,31 17,47 17,62 17,78 17,94 18,09 18,17

18,02 18,09 18,25 18,41 18,57 18,72

10 18,88 19,04 19,19 19,35 19,51 19,66 19,74

19,58 19,66 19,82 19,98 20,13 20,29

11 20,45 20,60 20,76 20,92 21,07 21,23 21,31

21,15 21,23 21,39 21,54 21,70 21,86

12 22,01 22,17 22,33 22,48 22,64 22,80 22,88

21,94 22,01 22,17 22,33 22,48 22,64

13

22,80 22,95 23,11 23,27 23,42 23,58 23,66

9.5.4. Set Point values, range 0-30 bar (Transducer 4-20 mA)

0-30 bar

-6 -5 -4 -3 -2 -1 +1 +2 +3 +4 +5 +6

5,63 5,73 5,91 6,10 6,29 6,48

1

6,67 6,85 7,04 7,23 7,42 7,61 7,70

6,57 6,67 6,85 7,04 7,23 7,42

2 7,61 7,79 7,98 8,17 8,36 8,55 8,64

8,45 8,55 8,74 8,92 9,11 9,30

3 9,49 9,68 9,86 10,05 10,24 10,43 10,52

10,33 10,43 10,62 10,80 10,99 11,18

4 11,37 11,56 11,74 11,93 12,12 12,31 12,40

12,21 12,31 12,50 12,69 12,87 13,06

5 13,25 13,44 13,63 13,81 14,00 14,19 14,28

14,10 14,19 14,38 14,57 14,75 14,94

6 15,13 15,32 15,51 15,69 15,88 16,07 16,17

15,98 16,07 16,26 16,45 16,64 16,82

7 17,01 17,20 17,39 17,58 17,76 17,95 18,05

17,86 17,95 18,14 18,33 18,52 18,70

8 18,89 19,08 19,27 19,46 19,64 19,83 19,93

19,74 19,83 20,02 20,21 20,40 20,59

9 20,77 20,96 21,15 21,34 21,53 21,71 21,81

21,62 21,71 21,90 22,09 22,28 22,47

10 22,65 22,84 23,03 23,22 23,41 23,59 23,69

23,50 23,59 23,78 23,97 24,16 24,35

11 24,54 24,72 24,91 25,10 25,29 25,48 25,57

25,38 25,48 25,66 25,85 26,04 26,23

12 26,42 26,60 26,79 26,98 27,17 27,36 27,45

26,32 26,42 26,60 26,79 26,98 27,17

13

27,36 27,55 27,73 27,92 28,11 28,30 28,39

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

18

89

10

11

12

131

2

3

456

7

SP

+1

+2

+3

+4

+5

+6

SP

SPadj.

-6

-5

-4

-3

-2 -1

SP

SPadj.

89

10

11

12

131

2

3

456

7

SP

+1

+2

+3

+4

+5

+6

SP

SPadj.

-6

-5

-4

-3

-2 -1

SP

SPadj.

9.5.5. Set-Point values, range 0-45 bar (Transducer 4-20 mA)

0-45 bar

-6 -5 -4 -3 -2 -1 +1 +2 +3 +4 +5 +6

8,45 8,59 8,87 9,15 9,43 9,72

1

10,00 10,28 10,56 10,85 11,13 11,41 11,55

9,86 10,00 10,28 10,56 10,85 11,13

2 11,41 11,69 11,97 12,26 12,54 12,82 12,96

12,68 12,82 13,10 13,38 13,67 13,95

3 14,23 14,51 14,80 15,08 15,36 15,64 15,78

15,50 15,64 15,92 16,21 16,49 16,77

4 17,05 17,33 17,62 17,90 18,18 18,46 18,60

18,32 18,46 18,75 19,03 19,31 19,59

5 19,87 20,16 20,44 20,72 21,00 21,28 21,43

21,14 21,28 21,57 21,85 22,13 22,41

6 22,70 22,98 23,26 23,54 23,82 24,11 24,25

23,97 24,11 24,39 24,67 24,95 25,24

7 25,52 25,80 26,08 26,36 26,65 26,93 27,07

26,79 26,93 27,21 27,49 27,77 28,06

8 28,34 28,62 28,90 29,19 29,47 29,75 29,89

29,61 29,75 30,03 30,31 30,60 30,88

9 31,16 31,44 31,72 32,01 32,29 32,57 32,71

32,43 32,57 32,85 33,14 33,42 33,70

10 33,98 34,26 34,55 34,83 35,11 35,39 35,53

35,25 35,39 35,67 35,96 36,24 36,52

11 36,80 37,09 37,37 37,65 37,93 38,21 38,36

38,07 38,21 38,50 38,78 39,06 39,34

12 39,62 39,91 40,19 40,47 40,75 41,04 41,18

39,48 39,62 39,91 40,19 40,47 40,75

13

41,04 41,32 41,60 41,88 42,16 42,45 42,59

9.5.6. Set Point values, range 0-30 bar (Transducer 0,5-4,5 Vdc)

0-30 bar

-6 -5 -4 -3 -2 -1 +1 +2 +3 +4 +5 +6

3,10 3,22 3,47 3,71 3,96 4,20

1

4,45 4,69 4,94 5,18 5,43 5,67 5,79

4,32 4,45 4,69 4,94 5,18 5,43

2 5,67 5,92 6,16 6,41 6,65 6,89 7,02

6,77 6,89 7,14 7,38 7,63 7,87

3 8,12 8,36 8,61 8,85 9,10 9,34 9,47

9,22 9,34 9,59 9,83 10,08 10,32

4 10,57 10,81 11,06 11,30 11,55 11,79 11,91

11,67 11,79 12,04 12,28 12,53 12,77

5 13,02 13,26 13,51 13,75 14,00 14,24 14,36

14,12 14,24 14,49 14,73 14,97 15,22

6 15,46 15,71 15,95 16,20 16,44 16,69 16,81

16,57 16,69 16,93 17,18 17,42 17,67

7 17,91 18,16 18,40 18,65 18,89 19,14 19,26

19,01 19,14 19,38 19,63 19,87 20,12

8 20,36 20,61 20,85 21,10 21,34 21,59 21,71

21,46 21,59 21,83 22,08 22,32 22,56

9 22,81 23,05 23,30 23,54 23,79 24,03 24,16

23,91 24,03 24,28 24,52 24,77 25,01

10 25,26 25,50 25,75 25,99 26,24 26,48 26,60

26,36 26,48 26,73 26,97 27,22 27,46

11 27,71 27,95 28,20 28,44 28,69 28,93 29,05

28,81 28,93 29,18 29,42 29,67 29,91

12 30,15 30,40 30,64 30,89 31,13 31,38 31,50

30,03 30,15 30,40 30,64 30,89 31,13

13

31,38 31,62 31,87 32,11 32,36 32,60 32,73

User Manual ESY-1 / rev. 9 15.01.2008 www.selproweb.com

19

89

10

11

12

131

2

3

456

7

SP

+1

+2

+3

+4

+5

+6

SP

SPadj.

-6

-5

-4

-3

-2 -1

SP

SPadj.

Gnd

SP2

+10V

O T

5

8

9

7

6

10

4

3

2

1

9

10

5

8

7

6

4

3

2

1

C T-OFF

(MIN O T)

MAX O T

SP2

SP1

89

10

131

2

3

4

561

SP1

SP1

+1

+2

+3

+6- 6

-5

-4

-3

-2-1

SP1 adj .

7

89

10

131

2

3

4

562

SP2

SP2

+1

+2

+3

+6- 6

-5

-4

-3

-2-1

SP2 adj .

7

+4

+5

+4

+5

11

12

11

12

89

10

11

12

131

2

3

4

56

7

SP2

+1

+2

+3

+4

+5

+6

-6

-5

-4

-3

- 2 -1

SP2

SP2 adj.

+/-

Gnd

SP2

+10V

O T

89

10

11

12

131

2

3

4

56

7

SP1

+1

+2

+3

+4

+5

+6

-6

-5

-4

-3

- 2 -1

SP1

SP1 adj.

+/-

9.5.7. Set-Point values, range 10°C to 60°C (NTC probe 10kohm@25°C)

10-60 °C

-6 -5 -4 -3 -2 -1 +1 +2 +3 +4 +5 +6

2,00 2,50 3,00 3,50 4,00 4,50

1

5 5,50 6,00 6,50 7,00 7,50 8,00

7,00 7,50 8,00 8,50 9,00 9,50

2 10 10,50 11,00 11,50 12,00 12,50 13,00

12,00 12,50 13,00 13,50 14,00 14,50

3 15 15,50 16,00 16,50 17,00 17,50 18,00

17,00 17,50 18,00 18,50 19,00 19,50

4 20 20,50 21,00 21,50 22,00 22,50 23,00

22,00 22,50 23,00 23,50 24,00 24,50

5 25 25,50 26,00 26,50 27,00 27,50 28,00

27,00 27,50 28,00 28,50 29,00 29,50

6 30 30,50 31,00 31,50 32,00 32,50 33,00

32,00 32,50 33,00 33,50 34,00 34,50

7 35 35,50 36,00 36,50 37,00 37,50 38,00

37,00 37,50 38,00 38,50 39,00 39,50

8 40 40,50 41,00 41,50 42,00 42,50 43,00

42,00 42,50 43,00 43,50 44,00 44,50

9 45 45,50 46,00 46,50 47,00 47,50 48,00

47,00 47,50 48,00 48,50 49,00 49,50

10 50 50,50 51,00 51,50 52,00 52,50 53,00

52,00 52,50 53,00 53,50 54,00 54,50

11 55 55,50 56,00 56,50 57,00 57,50 58,00

57,00 57,50 58,00 58,50 59,00 59,50

12 60 60,50 61,00 61,50 62,00 62,50 63,00

62,00 62,50 63,00 63,50 64,00 64,50

13

65 65,50 66,00 66,50 67,00 67,50 68,00

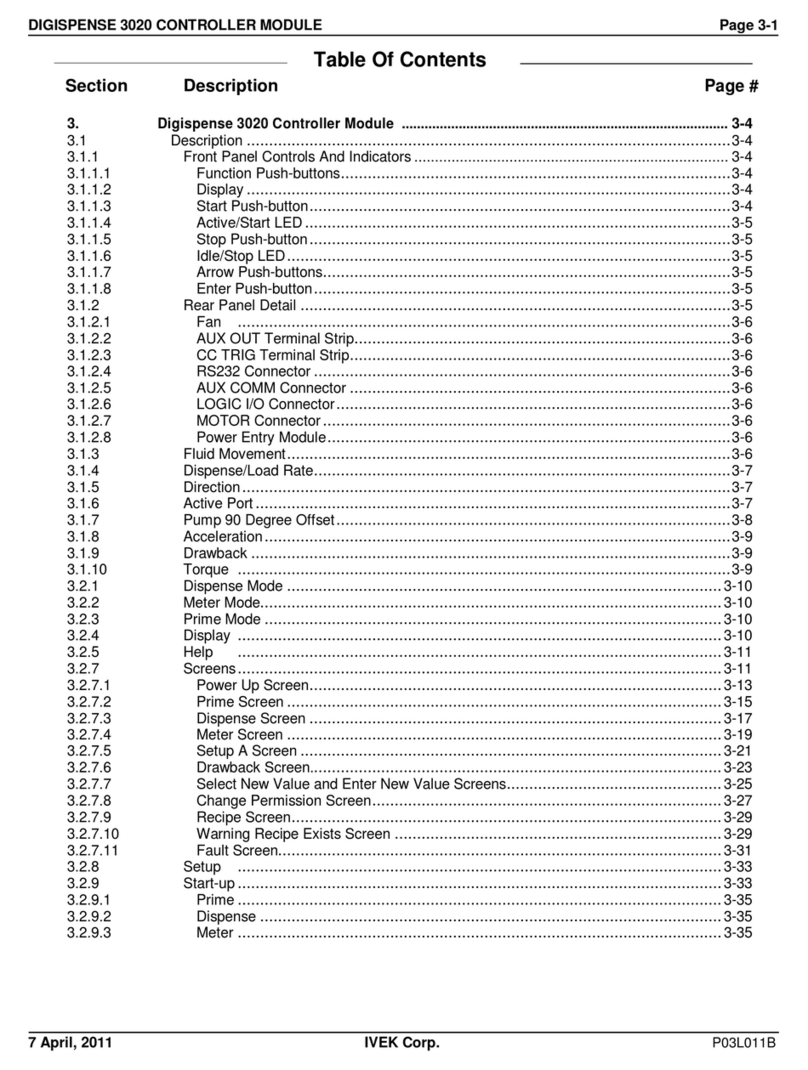

9.6. Regulation with Double SET-Point (optional)

The controller ESY-1 has been designed to be connected to an optional card with the Double Set-Point function, which allows to

determine two operating points: SP1 & SP2. The inclusion of the optional card is factory preset and must be requested when placing

the order.

In order to select the CUT-OFF / MIN out and MAX out values, follow the indications given in the table above.

For the selection of Set-Point 1 & 2 use the input SP2 + GND on the terminal block, as indicated below.

MAX OUT

Maximum RPM/VAC limit

MIN OUT

Minimum RPM/VAC or Cut-Off limit

SP1

Main Set-Point 1

(see following tables for position / value correspondence)

SP1 adj.

Set-Point 1 accurate adjustment

(see following tables for position / value correspondence)

SP2

Set-Point 2

(see following tables for position / value correspondence)

SP2 adj.

Set-Point 2 accurate adjustment

(see following tables for position / value correspondence)

In order to pass from Set-Point 1 to Set-Point 2,it is necessary to close the preset contact between terminals.

SET-POINT 1 operation SET-POINT 2 operation

SP1

Set-Point 1 SP2

Set-Point 2

SP1 adj.

Set-Point 1

adjustment SP2 adj.

Set-Point 2

adjustment

Led 1

Led SP1 = ON Led 2

Led SP2 = ON

SP2

OPEN SP2

CLOSED

This manual suits for next models

4

Table of contents

Other SELPRO Controllers manuals