3

The Installation and Operating Instructions specify basic principles for mounting, connection, adjustment, operation,

maintenance, and repairs of electric explosion-proof actuators. The fundamental prerequisite is that assembly, operation,

maintenance, and revisions are performed by skilled technicians qualified for operation and works on explosion-proof

electric devices and the works are supervised by a professionally qualified expert instructed in a demonstrable way.

1. APPLICATION

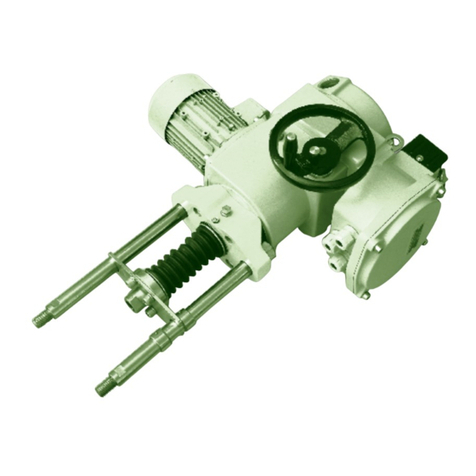

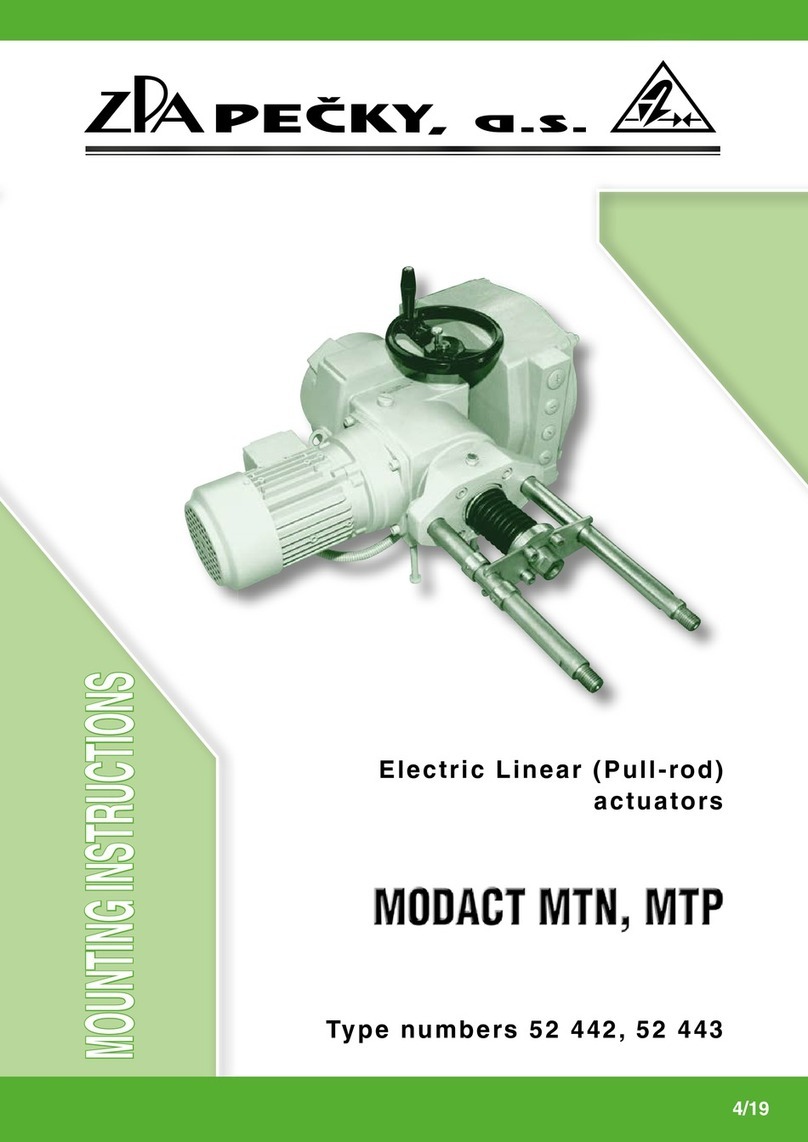

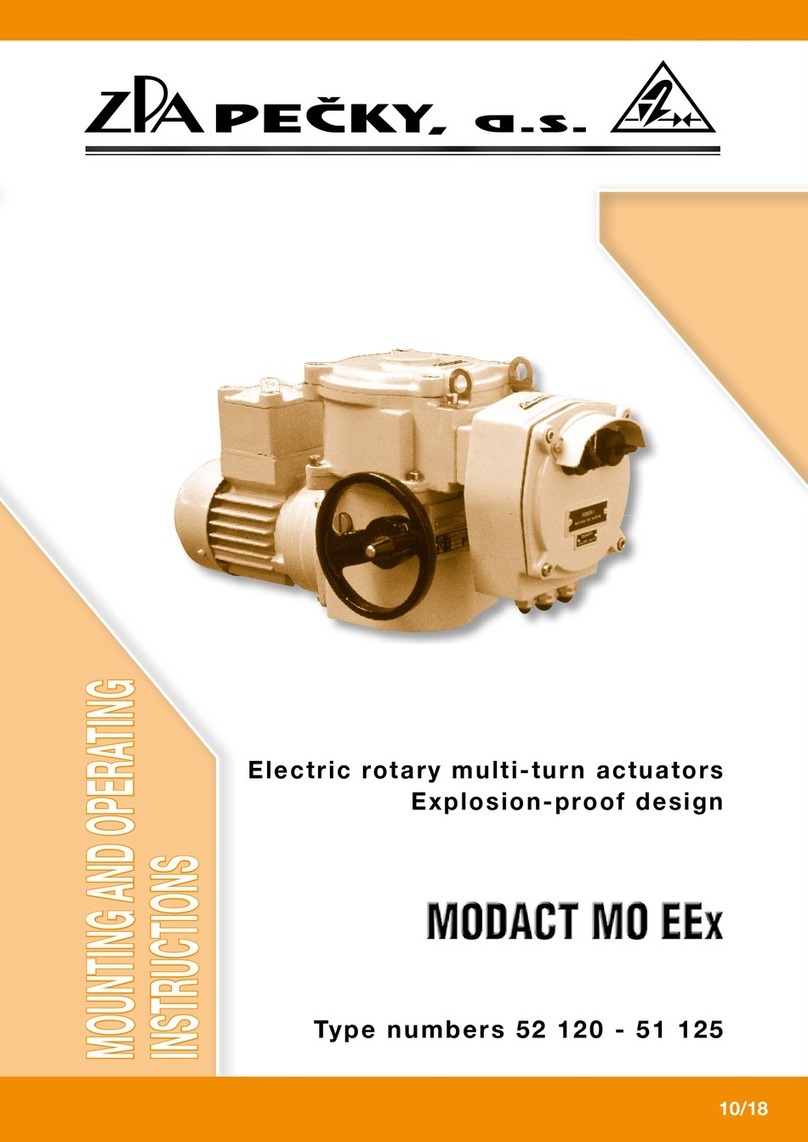

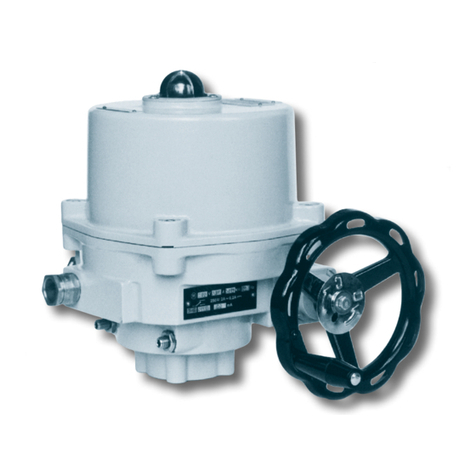

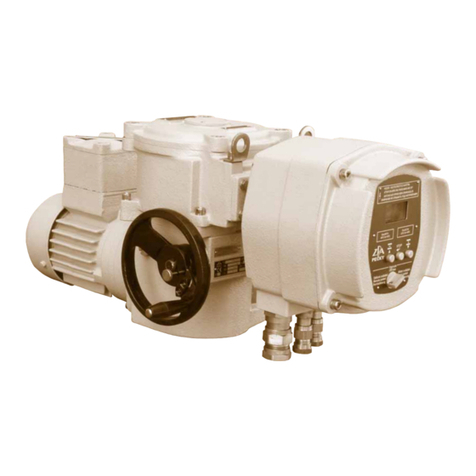

The actuators are designed for shifting valves with reversing rotary motion in circuits of remote control and

automatic control. They can also be used for other devices for which they are suitable with their characteristics and

parameters. Special cases are to be discussed with the manufacturer.

MODACT MOKPED Ex electric actuators in non-explosive version are intended for control and operation in an

environment with danger of explosion of explosive gaseous atmosphere in zone 1 and zone 2 and for areas with

flammable dust in zone 21 and zone 22 according to ČSN EN 60079-10 (332320). The actuators are designed in

compliance with the standards ČSN EN 60079-0:2013 and ČSN EN 60079-1:2008 for explosive gaseous atmosphere

and with the standard ČSN EN 60079-31:2014 for areas with flammable dust.

These are non-explosive electric appliances of the group II, category 2, in areas where occurrence of explosive

atmosphere created by gases, vapours or mist – “G“ is probable. The actuators can also be used in areas with

flammable dust according to ČSN EN 50281-1-3. The actuators are labelled with a sign of protection against explosion

and symbols of the group and category of appliance II 2GD.

The entire electric actuator is designed as explosion-proof enclosure “d” with marking according to the performed

certification as follows:

II 2GD Ex d IIC T6 Gb -25 ≤ Ta ≤ 55 °C

Ex d IIB T6 Gb -50 ≤ Ta ≤ 55 °C

Ex tb IIIC T80°C Db -50 ≤ Ta ≤ 55 °C

The electric actuator must not be subjected to heavy charging, eg. an intense flow of a dust-air mixtures in order

to prevent the occurrence of creeping electrostatic discharges.

Nomenclature

Environment with explosion danger – Environment in which an explosive atmosphere can be created.

Explosive gaseous atmosphere – A mixture of flammable substances (in the form of gases, vapours or mist)

with air under atmospheric conditions in which, after initialization, burning

spreads out to non-consumed mixture.

Explosive dust atmosphere – mixture of flammable substances in the form of gas, vapour, mist and dust

with air, under atmospheric conditions, in which, after ignition, combustion

spreads to the entire unburned mixture.

Maximum surface temperature –

The highest temperature created during operation under the most unfavourable

conditions

(however within approved limits) on any surface part of the electric

device, which could induce ignition of surrounding atmosphere.

Closure – All walls, doors, covers, cable bushings, shafts, rods, pull-rods, etc. which

contribute to the type of protection against explosion and/or to the level of

protection (IP) of the electric device.

CONTENS

1. Application ...........................................................................................................3

2. Operating conditions; Operating position ........................................................................5

3. Operation mode; Service life of actuators ........................................................................7

4. Technical data .......................................................................................................8

5. Actuator outfit .......................................................................................................8

6. Elektric parameters .................................................................................................9

7. Description ...........................................................................................................9

8. Adjustment of electric actuator .................................................................................. 10

9. Assembling and putting the electric actuator into operation ................................................ 31

10. Operation and maintenance of electric actuators ............................................................. 40

Tables ............................................................................................................. 42–44

Dimensions of the actuators MODACT MOKPED Ex ........................................................... 45–48

List of spare parts ..................................................................................................... 49