SELWOOD D75 User manual

Table of Contents

1Contact Details........................................................... 2

2Amendment Record................................................... 2

3Associated Documentation....................................... 2

4Glossary ..................................................................... 3

5Ordering Spares......................................................... 3

5.1 Body Unit Service Tool Kits.......................................... 3

5.2 Spares Kits .................................................................. 3

6Introduction................................................................ 4

6.1 Upon Receipt............................................................... 4

6.2 Scope .......................................................................... 4

6.3 Disclaimer.................................................................... 4

6.4 Conditions of Warranty................................................. 4

6.5 Conformity ................................................................... 4

6.6 Environmental Conformity............................................ 4

6.6.1 Spillages...................................................................... 4

6.7 Intended Use................................................................ 5

6.8 Foreseeable Misuse..................................................... 5

6.9 Manual Symbols .......................................................... 6

7Health & Safety........................................................... 7

7.1 Health & Safety at Work Act 1974................................ 7

7.2 Viton Material............................................................... 7

7.3 California (USA) Proposition 65 Warning Act................ 7

7.4 Workstation.................................................................. 7

7.5 Personal Protective Equipment (PPE).......................... 8

8Pump Components.................................................... 9

8.1 Component overview ................................................... 9

8.2 Separator System ...................................................... 10

8.3 Unique Selprime System............................................ 10

8.4 Non-return Valve (NRV)............................................. 11

8.5 Body Unit Label.......................................................... 11

9Performance............................................................. 11

10 Draining Body Unit Compartments......................... 12

10.1 Draining the Body Unit of Worked Fluid...................... 12

10.2 Draining the Body Unit of Oils .................................... 12

11 Lifting/Storage/Transportation................................ 13

11.1 Lifting......................................................................... 13

11.1.1 Pump Dimensions...................................................... 13

11.1.2 Recommended Lifting Technique............................... 14

11.2 Upon Receipt of the Body Unit................................... 15

11.3 Storage...................................................................... 15

11.4 Shelf Life.................................................................... 16

12 Installation and Commissioning ............................. 17

12.1 Pump Lubrication....................................................... 17

12.2 Commissioning Period............................................... 17

12.3 Post Commissioning Period....................................... 17

12.4 Installation Example................................................... 18

12.5 Maximum Allowable Flange Loads............................. 20

12.6 Pipelines.................................................................... 21

12.6.1 Pipeline Installation.................................................... 21

12.6.2 Suction Line................................................................21

12.6.3 Strainer.......................................................................22

12.7 Understanding the Pump’s Curve ...............................23

12.7.1 Pump’s Curve, Efficiency and BEP .............................23

12.8 Operating away from BEP .........................................23

12.8.1 The Correct Pump for the System...............................24

12.8.2 NPSH Explained.........................................................25

13 Body Unit Pre-operation...........................................26

14 Checks Whilst Operating .........................................27

14.2 Blockages...................................................................28

14.3 Running Dry ...............................................................29

15 Periodic Maintenance...............................................30

15.1 Serviceable Components............................................32

15.2 Fastening Torques......................................................33

16 Trouble Shooting......................................................34

16.1 Internal Component Recognition.................................34

16.2 Performance Drop......................................................34

16.3 Air Handling Performance & Lubricant Leaks or

Contamination................................................................................35

17 End of Life.................................................................37

18 Vacuum Test.............................................................38

19 Major Servicing.........................................................39

19.1 Servicing Prerequisites...............................................39

19.2 Air Pump Assembly....................................................40

19.2.1 Air Pump Suction Valve..............................................40

19.2.2 Air Pump Discharge Valve..........................................43

19.2.3 Neck Seal...................................................................44

19.2.4 Air Pump Drive Rod Assy & Bearing...........................45

19.2.5 Refitment of Air Pump.................................................48

19.3 Volute Removal & Refitting.........................................50

19.3.1 Removal.....................................................................50

19.3.2 Refitting of the Volute .................................................51

19.4 Wear Plates................................................................52

19.4.1 Rear Wear Plate.........................................................52

19.4.2 Fron Wear Plate .........................................................54

19.5 Impeller & Mechanical Seal ........................................55

19.5.1 Removal.....................................................................55

19.5.2 Fitment.......................................................................56

19.6 Impeller End Lip Seals................................................59

19.6.1 Remove of Lip seals...................................................59

19.7 Separator Assembly ...................................................61

19.7.1 Float...........................................................................61

19.7.2 Peel Valve..................................................................63

19.8 Delivery Valve Assembly ............................................67

20 Assembly Tools........................................................68

20.1 Tooling .......................................................................68

21 Declaration of Incorporation....................................69

22 Notes.........................................................................70

Page 2 of 70

1 Contact Details

Selwood Ltd

Bournemouth Road

Chandler’s Ford

Eastleigh

Hampshire

United Kingdom

Telephone contact: +44 (0) 23 8026 6311

Enquiries: info@selwood.co.uk

Website: www.selwood.co.uk

2 Amendment Record

Initial

Date

Action

ECN

Issue

SR

06/09/2023

Creation of Manual.

25927

A

Table 1: Amendment record, any changes to this manual must be recorded within table.

3 Associated Documentation

It is important that associated documentation is understood before using the pump, the latest issues can be found

on the Selwood website or by contacting a member of the Selwood team.

▪D75 Body Unit Parts List

▪Pump data sheets

▪Installation Drawing

Out of hours emergency service

(UK Pump Rental Breakdown & Equipment

Hire)

Monday to Friday: 5 pm to 8 am

Weekends and Bank Holidays: 24 hours

Tel: 03330 142 000

Page 3 of 70

4 Glossary

Term

Description

MSDS

Material safety data sheet

BU

Body unit

PPE

Personal protective equipment

NRV

Non-return valve

Running dry

The pump is running with no fluid moving through.

Head

The height in meters the unit will pump from the delivery valve when pumping clean water.

NPSH

Net positive suction head is a measurement of pressure in head on the suction side of the

pump, less the vapour pressure. This measurement is taken at the centre line of the

impeller.

RPM

Rotations per minute

dB

Decibel –a relative unit of measurement for sound.

SWL

Safe working load

ATEX

Atmospheres explosive: the risk of combustible gases within the ambient air.

Cavitation

A phenomenon where vapour bubbles form in a liquid when the pressure drops. Once the

pressure increases again, the bubbles collapse sending shock waves that may damage the

machinery or its components.

Driver

A power source that rotates the body unit shaft via a coupling. Internal combustion engines

or electrically powered motors are the most common.

C of G

Centre of gravity: this is a hypothetical centre point in a body of matter that dictates the

behaviour of the object, when acted upon by gravity.

IC engine

Internal combustion engine

NEMA

National Electrical Manufacturers Association

IEC

International Electro-technical Commission

Nominal

pressure (PN)

This specifies the maximum pressure a flange can withstand at a reference temperature of

20oC.

RPM

Revolutions per minute –the number of times the drive shaft completes a full revolution

within a minute.

5 Ordering Spares

Only the manufacturer’s or factory approved parts should be used when servicing the pump. It is advisable to hold

a small stock of spare parts to cover breakdown circumstance, these can be viewed in the body unit’s parts list

and purchased from Selwood’s sales team:

Telephone: +44 (0) 2380 250137

Enquiries: PumpSalesOffice@Selwood.co.uk

When ordering spare parts:

1. Always quote the pump serial number or machine serial number located on the plate fastened to the pump.

2. Always quote the ten-digit part number for the component, not the item reference number.

3. Always quote the description of the component.

5.1 Body Unit Service Tool Kits

For correct fitment of serviceable components, it is recommended to use special service tools. See servicing

sections for correct application of the tools and section 19.2 for a complete list.

5.2 Spares Kits

Visit the body unit’s parts list for spares kits that contain the necessary parts when performing a body of work.

Page 4 of 70

6 Introduction

Selwood has a full product range for all applications, including solids handling, high volume drainers, high head,

hydraulic submersible, chopper and positive displacement pumps. Please visit our website for a full range of

products.

Selwood products are extremely robust and reliable. Pumps are manufactured with quality, longevity and reliability

in mind to meet the needs of the most challenging environments. Accessible, removable and replaceable parts

allow easy maintenance, resulting in a longer life of the pump.

6.1 Upon Receipt

All Selwood products undergo a strict inspection process before leaving the workshop. Upon receipt of your

product, fully inspect the condition to ensure there has been no damage in transit.

6.2 Scope

This manual is for installing and maintaining Selwood’s D75 body unit only. This manual is written for units

received without a power source, which typically would be an IC (internal combustion) engine or an electrical

motor.

Procedures within this manual and associated literature must be carried out by a competent and trained person

only. Read and fully understand this manual before commencing the work.

6.3 Disclaimer

Although every effort has been put into the creation of this publication, Selwood cannot be held liable for any

injuries consequential of errors in this publication; Selwood’s manufactured products and associated parts are of

a hazardous nature.

This manual was originally written in English and should be referred to as the original source of information in the

event of any discrepancies between the original instruction and translated copies. Selwood reserves the right to

alter specifications and information given in this manual without prior notice.

The products of Selwood are designed, developed and produced in Selwood’s Chandler’s Ford facility. Many

features are covered by world-wide patents.

6.4 Conditions of Warranty

Selwood pumps are built for the rigours of rental and world-renowned for their quality, robustness and longevity.

Breakdowns are rare but if things do go wrong, we are committed to putting them right as quickly and efficiently

as possible.

If there are any issues regarding the pump’s warranty, refer to the website to complete a warranty form.

6.5 Conformity

This partly completed machinery must not be put into service until the final machinery or installation into which it

is to be incorporated has been declared in conformity with the provisions of Directive 2006/42/EC, where

appropriate.

6.6 Environmental Conformity

Oils, fuels and liquids captive to Selwood pumps may be hazardous to the environment and must be contained

and disposed of according to local laws. Failure to comply can incur substantial financial penalties, it is good

practice to:

▪Place the pump on a drip tray to further protect against fluids escaping the pump.

▪Constantly maintain all equipment and rectify any leaks immediately.

6.6.1 Spillages

Should a spillage occur, use absorbent material to clear the spillage as quickly as possible. Ideally use a dedicated

spillage kit to retain and remove such a spillage. Do not hose the area down or use any detergents and do not

allow the spilled liquid to enter drainage or water systems. Spillages must be reported to the local authorities.

Dispose of all absorbent materials in accordance with local laws.

Page 5 of 70

6.7 Intended Use

These highly efficient Selprime pumps are easy to couple, maintain and are highly robust. Perfect for use within

the following applications:

▪Clean water with fine solids

▪Screened sewage

Only operate the pump outdoors - modifying exhaust extraction for indoor use is not permitted.

The unit will be expected to operate continuously but be subject to general checks and maintenance as defined

within this manual.

6.8 Foreseeable Misuse

▪This pump is not suitable for explosive environments (ATEX) where fuels can be found in the ambient air. If

our pumps are used in explosive environments without the correct measures, the engine could overspeed or

cause an explosive hazard. However, parts are available as an option to minimise the risk of overspeed,

including engine overspeed shutdown valves and spark arrestors. Please contact your Selwood

representative.

▪Only deploy the pump on fluids within the pump’s capabilities. The pump’s specifications are listed within the

data sheets, located on our website.

▪Running the pump off curve can cause cavitation, bearing damage or recirculation of the flow. All of these

affect the pump’s efficiency and may lead to a premature breakdown.

▪Adhere to local environmental law when dealing with any liquid captive to the pump. Check the type of liquid

that the pump has been employed on before commencing the work, residues could be hazardous to health.

If in doubt, flush thoroughly with clean water before operation. Pumps deployed on sewage must be

thoroughly cleaned and sterilised after use.

▪Never run the pump against a closed valve, this does not include the body unit non-return valve (NRV).

▪Working with liquids exceeding 40 °C in temperature is not recommended as this may shorten the life of

internal components.

▪Liquid pressure may still be present even after shutdown of the pump. Attention should be paid to delivery

lines that are long or rise through any height, as these can contain large volumes of liquid. These lines must

be isolated and drained down before commencing work. Sudden release of this liquid can cause serious injury

to the operator; either directly or indirectly through the rotational motion it can induce.

▪Never insert anything into a running pump while the suction or delivery lines are disconnected.

▪Before starting any work, ensure the body unit is isolated from the electrical power supply either by the isolator

switch or, by disconnecting the pump at the battery and placing a sign in clear view: ‘DO NOT SWITCH ON,

MAINTENANCE IN PROGRESS!’. Selwood pumps have auto start facilities and may receive a start signal at

any time.

▪Operators must be skilled, competent and familiar with the product before use.

Page 6 of 70

6.9 Manual Symbols

Comply with literature.

Warning: hot surface with risk of burns.

Relevant information.

Warning: heavy loads. This symbol draws

attention to items or work which carry

higher risks of injury from lifting. Adhere to

local legislation involving lifting in these

instances.

Warning: personal injury.

Warning: explosive potential.

Warning: toxic exhaust gases.

Warning: environmental damage.

Warning: flammable substances.

Warning: corrosive substances.

Warning: risks from electricity that may

result in shock, burns or death.

Warning: To proceed with any work, the

pump must be disconnected from the

power supply. If an isolator switch is in use,

this must be locked in the closed position.

Page 7 of 70

7 Health & Safety

DANGER

Non-compliance with this section could result in injury or loss of life.

It is the responsibility of the employer to ensure correct PPE and safe working procedures are in place. Full PPE

is always recommended, and steel toe cap boots, eye protection (safety glasses), coveralls & high visibility vests

are essential. Certain tasks throughout this manual will reiterate additional items of PPE by attaching symbols

within Table 2.

7.1 Health & Safety at Work Act 1974

As manufacturers of pumps and associated equipment we wish to inform you that in compliance with section 6 of

the Health and Safety Act 1974, safety precautions should be taken when using our products.

Our aim is to ensure our products are safe and without risk to health when correctly used. Nevertheless,

appropriate health and safety precautions must be taken, and you are requested to have special regard to the

operational and safety requirements.

7.2 Viton Material

Components of this product may be fitted with seals or ‘O’-rings that are manufactured from Viton (synthetic rubber

and fluoropolymer elastomer) or similar materials.

Temperatures exceeding 400oC (720oF) produce a corrosive acid that cannot be removed from the skin. If signs

of material decomposition are evident, or if in doubt, wear chemical resistant gloves.

7.3 California (USA) Proposition 65 Warning Act

Diesel engine exhausts and some of its constitutes are known in the state of California to cause cancer, birth

defects and other reproductive harms.

7.4 Workstation

Where possible, carry out maintenance and servicing work in a clean workshop that considers all local safe

working procedure and local legislations. When work is to be carried out on site, it is essential that all onsite risk

assessments are filled out, and work is carried out in a clean and safe space.

Page 8 of 70

7.5 Personal Protective Equipment (PPE)

Ear Defence

Noise level at operator position is over

80 decibels when running, always

wear ear defence within the vicinity of

running pumps. Failure to comply

could result in hearing damage or

loss. Ear defence must be worn when

operating powered tools.

High Visibility Vest

Working around large machinery, vehicles

and moving plant can lead to crush and

traffic related injuries when people make

unintended contact with vehicles. High

visibility clothing improves visibility of

pedestrians and is essential.

Safety Footwear

Dropped objects including tools can

cause impact injuries, especially to

feet and toes. Working in certain

environments also introduces slip and

fall risks. Slip resistant safety footwear

with steel toe caps is essential.

Respiratory Protective Equipment (RPE)

Diesel exhaust fumes are hazardous to

health and can cause harm to the

respiratory system. Wear RPE when in

contact with diesel exhausts, paints,

solvents and other COSHH items that

contain hazardous air born chemicals

detrimental to human health.

Thick Disposable Gloves

Protection against cuts, skin

irritations, dermatitis and toxic or

corrosive substances captive to

Selwood pumps and substances

hazardous to health.

Protective Clothing

Full body protection from skin irritations,

dermatitis, and toxic or corrosive

substances. Ensure that coveralls are

clean before use.

Safety Glasses

Eyes must be protected from debris,

dust, smoke and corrosive chemicals.

Head Protection

To protect the head from falling objects or

striking against fixed objects.

Table 2: Health and safety symbols.

Page 9 of 70

8 Pump Components

8.1 Component overview

Figure 1: Body unit components. Direction of Rotation (DoR) indicated by white arrow.

Component

Description

Shaft end

The location where the driver is connected via a coupling; the coupling used is dependent on

the application and can be found in the pump’s parts list, if applicable. Contact Selwood for

further assistance.

Mechanical

seal

An almost perfect seal between the worked liquid and pump oils that allows a rotating

component and stationary component to operate together without overheating.

Impeller

Selwood’s D75 body units utilise the semi-open impeller which allows small solids to pass

freely between the curved vanes, whilst offering high efficiency capable of producing high

heads and flow.

Volute

The volute houses the impeller and assists with the flow of the liquid which is expelled through

the casing’s nozzle.

Separator

This controls the amount of air to liquid ratio within the pump and is explained later in this

chapter.

Delivery valve

Within is an NRV (non-return valve) in the form of a weighted flap or mechanical hinge, this

is detailed later in this chapter.

Air pump

Driven by the main pump shaft via a reciprocating drive rod, its task is to draw air from the

suction tube. This is detailed later within this chapter.

Suction tube

An intermediate component allowing the fitment of the separator and the connection of the

pipework.

Bearing

housing

As the name suggests, a housing to support the bearings, flushing chamber and associated

components, providing protection and a means to lubricate.

Table 3: Components relating to Figure 1

Air Pump

Delivery

Valve

Separator

Suction Tube

Bearing

Housing

Volute

Mechanical

Seal &

Impeller

Page 10 of 70

8.2 Separator System

Step

Stage

Image

1

The air pump drawers air from the suction

tube (white arrows).

2

The worked fluid displaces the removed air.

3

Rising water pushes the ball into the seat.

4

The ball is attached to a peel valve via a

connecting rod, which stops worked fluid

from passing the air pump (carryover). The

pump is now primed.

8.3 Unique Selprime System

Step

Stage

Image

1

Rotary motion from the engine/motor drives

the body unit main shaft.

2

Rotary motion is transformed to

reciprocating motion via the main shaft’s

eccentric and air pump connecting rod.

3

The actuator piston moves up and down

within the casting. A rubber seal encased in

the casting and secured to the actuator

peripherals creates the differences in

pressure (with assistance from 3 inlet/outlet

valves) needed to remove air from the

suction chamber.

Page 11 of 70

8.4 Non-return Valve (NRV)

The NRV can be found within the delivery chamber, although designs may slightly vary throughout the range, the

principles are the same. Suction lift can be affected by a dis-functional NRV, see servicing sections in this manual

to address.

Step

Stage

Image

1

Once the driver is running and the volute

is primed, liquid pressure builds.

2

The rise in pressure within the volute

causes the NRV to open.

3

Throughout operation the NRV will stay

open, providing the suction tube strainer

is fully submerged and there is no loss of

liquid pressure.

4

Once the driver ceases to run, liquid

pressure will decrease and the NRV will

close, stopping the worked liquid within

the pipework returning to the suction

side.

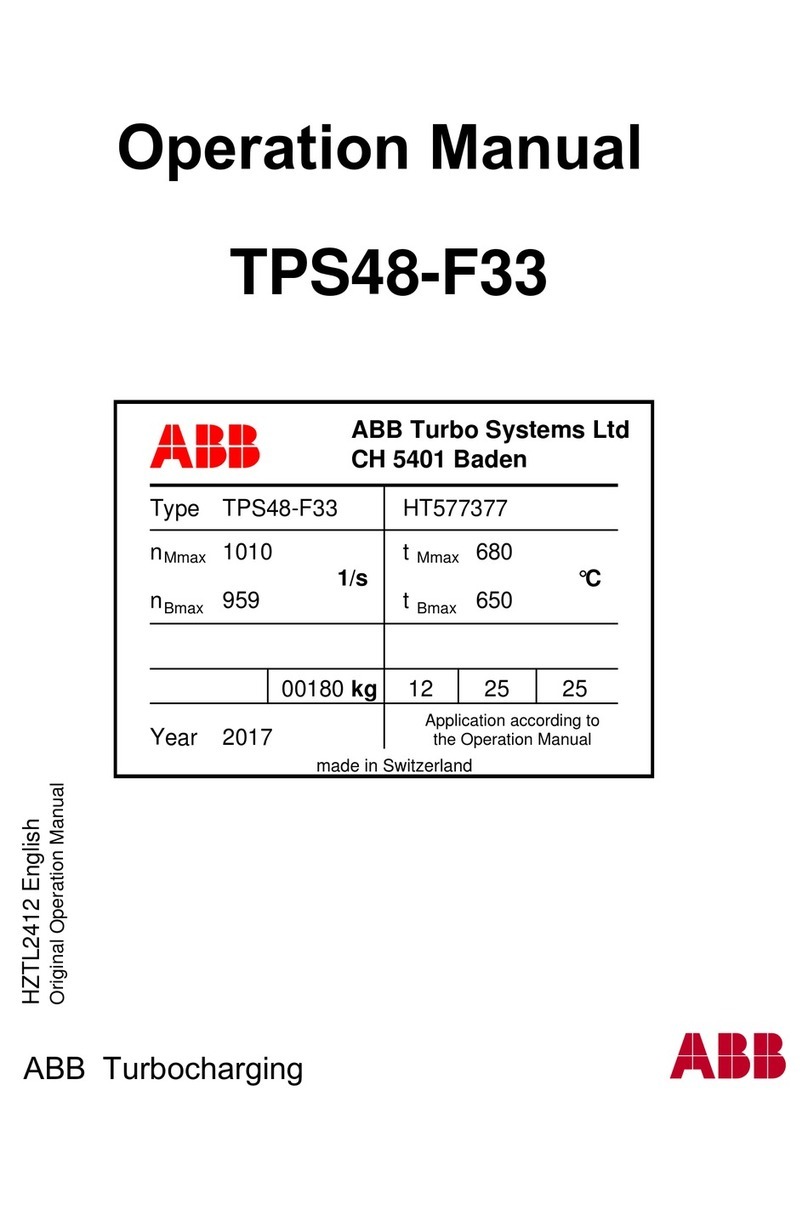

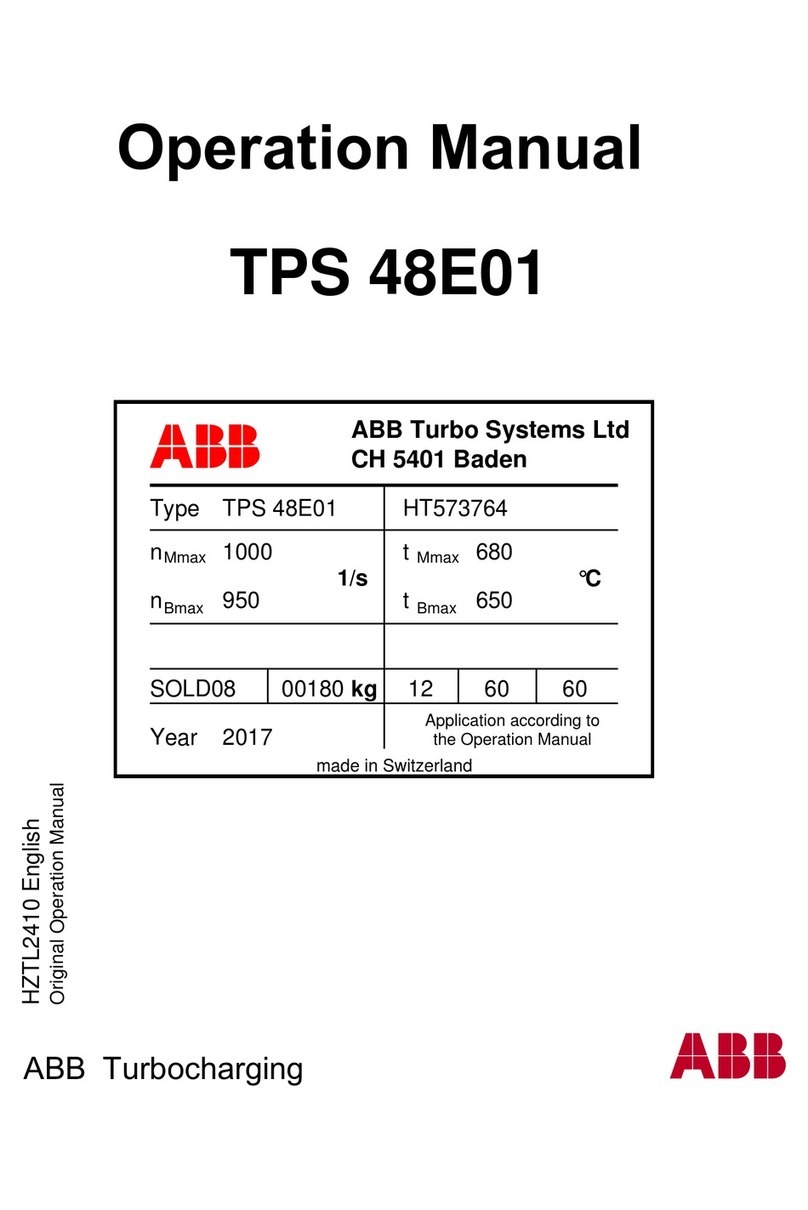

8.5 Body Unit Label

Each body unit is clearly identified with a body unit label such as

that depicted below. The location of the label may vary depending

on the body unit variant.

Term

Description

P/N

The top level 10-digit part number of the pump variant.

S/N

A unique number specific to each pump.

Year

The year of manufacture.

MAX RPM

The maximum running speed of the pump; this must not be exceeded.

Max pressure

The maximum pressure of the delivery in bar.

9 Performance

Specification

Value

Max speed

2000 rpm

Max head

23 m

self-priming lift

8.8 m

Max pressure

See body unit label

Max flow

See body unit label

Suction connection type

Solid spigot with 2.5 inch thread

Discharge connection type

Solid spigot with 2.5 inch thread

Max solid capacity

16 mm

Inspection

plate

Worked liquid

within the

volute

NRV

Page 12 of 70

10 Draining Body Unit Compartments

CAUTION

Oil Grade

Liquids captive to the pump can be damaging to the environment and must be disposed of in

accordance with local law. Drip trays are always recommended when operating & maintaining

Selwood pumps.

Failure to drain the body unit and delivery pipework in freezing conditions could result in damage

to the pump’s casting.

10.1 Draining the Body Unit of Worked Fluid

Step

Action

Image

1

Stop and isolate the body unit from its power supply.

2

Shut off the delivery and suction lines as close to the

body unit as possible.

3

Use a container to capture the escaping fluids from

all the drain points.

4

Release all drain valves to evacuate work liquid.

5

Close all drain taps once the pump is drained.

10.2 Draining the Body Unit of Oils

Step

Action

Image

1

Place a suitable container in position under the

respective drain plug (A, flushing chamber. B,

bearing housing).

2

Remove respective chamber filler cap (C, flushing

chamber. D, bearing housing), failure to do this may

create an air lock and stop the oil from draining.

3

Remove drain plug (A/B) respectively and allow the

oil to drain.

4

Closely inspect the oils for contamination or

miscolouring which may indicate faulty components,

please see troubleshooting sections for further

assistance. It may be necessary to flush the

chambers to remove all debris.

5

Once ready to refit drain plug, clean and apply

‘Loctite 572’or equivalent (pipe sealer).

A

B

D

C

Page 13 of 70

11 Lifting/Storage/Transportation

11.1 Lifting

CAUTION

Do not compromise safety when performing any manual lifting task. Selwood pumps are

designed so that manual lifting is to a minimum. However, where necessary, reference local

legislation and guidance. Any parts or assemblies with a notable mass are stated within the

servicing sections of this manual.

When lifting any Selwood products, refer to local legislation and guidance. If in doubt, contact

Selwood or a local lifting specialist. All lifting equipment including forklifts must be fully serviced

and inspected in accordance with local legislation.

11.1.1 Pump Dimensions

Note that dimensions are approximate. View the supplied installation drawing for exact dimensions.

Figure 2: Left, body unit top view and dimensions. Right, body unit side view and dimensions.

Length (mm)

Width (mm)

Height (mm)

Mass (Kg) -

no oil

571

358

490

84

Length

Width

Height

Page 14 of 70

11.1.2 Recommended Lifting Technique

CAUTION

Adhere to following guidelines when lifting the body unit:

▪Never in any circumstances allow personnel under suspended loads.

▪Ensure that lifting equipment can lift the gross weight of the pump.

▪Ensure all lifting equipment has been inspected and is compliant with local legislation.

▪Visually inspect lifting equipment for deformed material, corrosion, scoring & cracks. Check

components such as rivets, springs and latches are intact and functioning correctly. If

equipment is found to be defect, do not proceed with lift.

▪Ensure the correct PPE is worn in accordance with workshop/on-site regulations.

▪Pay attention to dimensions such as height, width, length, mass and C of G found within the

pump’s installation drawing.

Adhere to the following instructions when using strops to lift the body unit:

1. Three strops are required: two of equal length and one of sufficient length to secure the delivery valve neck.

2. Ensure lifting strops and corresponding body unit surfaces are dry so friction is increased.

3. Secure strops as seen in below image. Strop securing delivery valve neck must be taut to stop the unit

rotating.

4. Before committing to the lift, raise the unit slightly to ensure a level lift. If uneven, lower the unit and adjust

strops. Repeat until the unit lifts level.

Figure 3: Strop positions when lifting the body unit.

Page 15 of 70

11.2 Upon Receipt of the Body Unit

Although great care is taken to ensure the quality of our product, it is advisable to check the following upon receipt.

▪Check the body unit for any obvious physical damage to the castings and components.

▪Check all pipework between the air pump and separator is present and secure.

▪Check the delivery valve operates and correctly seats.

▪Check the oil levels as seen in section 13.

▪Follow section 0 to rotate the shaft, it is normal that the shaft is harder to rotate in certain positions due to the

eccentric.

11.3 Storage

When storing the body unit, adhere to the following:

▪Temperatures must be above -10°C and below +40°C. The relative humidity must be below 60%.

▪Do not store outside.

▪Protect the pump from mechanical shocks and vibrations, as this can cause brinelling (the permanent

indentation of a hard surface) to the components such as bearings. This may also cause damage to seal

faces.

▪Suction and discharge must be sealed to prevent dirt, debris and moisture build-ups. The body unit is supplied

with protective caps.

▪Bare shaft ends and any bare metal surfaces must be coated with an anti-corrosion treatment.

▪Secure shaft keys in place with a grip tie or similar.

▪To stop the build-up of dust and dirt, use a dust sheet. Do not use plastic coverings as this will create a build-

up of moisture underneath. If shrink wrap is used, cut holes to ventilate the product.

▪Do not store the unit on concrete flooring or directly on the ground, it must be stored on a wooden frame or

pallet, bolted in position with holes in the body unit feet and supported under the suction tube where necessary

to prevent the unit toppling over.

Page 16 of 70

11.4 Shelf Life

MUST READ

The body unit has a recommended storage limitation of two years before a service is necessary,

this is due to the internal parts life expectancy.

It is good practice to rotate the body unit’s drive shaft 4 ½ turns every two weeks to stop the seizure of internal

components. Proceed as follows:

1. Assemble a nut and bolt as specified in the below table (the amount of thread revealed must be a minimum

of the bolts diameter).

2. Coat the bolt threads with an anti-seize paste.

3. Tighten the bolt to the shaft thread until the nut bottoms out, then tighten the nut.

4. Rotate the shaft at least four and a half revolutions, ensure the shaft rests in a different position.

5. Loosen the nut and remove the bolt.

Figure 4: Left, shaft rotation. Right, nut attached to bolt with correct amount of thread revealed.

Body unit

Bolt size

D75

M10 X 1.5 - 6H

Page 17 of 70

12 Installation and Commissioning

CAUTION

Before commissioning the body unit for operation, completely read, understand and adhere to

section 6.7: ‘Foreseeable Misuse’.

If there is a risk of accidental contact by the operator, the exhaust system should be lagged or

screeded and the outlet directed away from the operator or nearby personnel. Engines should not

be run in hazardous explosive environments. All rotating parts that cause a hazard to the operator

or personnel must be guarded in accordance with local legislation.

The body unit is not supplied with control systems, electrical connections or an emergency stop,

this is the responsibility of the manufacturer when building the complete pumping unit in

accordance with local legislation.

Note that it is essential It is essential that earth terminals are connected to an earth point and care

should be taken to ensure that the correct sized conductors are selected to suit the current and

distance to be carried.

Noise emissions when this unit is installed to the driver:

▪The A-weighted emission sound pressure level, where this exceeds 70dB(A) at workstation.

▪The peak C weighted instantaneous sound pressure value, where this exceeds 63 Pa (130

dB in relation to 20 µPa) at workstation.

▪The A-weighted sound power level emitted by the machinery, where the A-weighted emission

sound pressure level at workstation exceeds 80 dB(A).

When these noise levels are required, the uncertainties surrounding these values shall be

specified.

The body unit does not require any utility e.g., electrical/water supplies.

When selecting a power source for the body unit, for example, an IC engine or electric motor, refer

to the body unit data sheet on the Selwood website and installation drawing supplied with the

pump. For further instruction, please contact your Selwood representative.

12.1 Pump Lubrication

It is most important to maintain the correct levels of oil in the flushing chamber and bearing housing (see section

13 for correct oil level), and to ensure that the oil is of the recommended quality and free from contamination.

Selwood recommend the use of the following products, which should be applied as per the following table. In

some territories, the following grades may be known under different trade names, please contact Selwood if

problems occur in identifying the correct product.

Component

Lubricant

Bearing housing

15W-40 oil

Flushing chamber

15W-40 oil

Actuator bore

Morris EP K2 grease

Impeller bore

Morris EP K2 grease

Paper gaskets

Morris EP K2 grease

Table 4: Body Unit lubrication.

12.2 Commissioning Period

Drain both pump chambers within 100 running hours of commissioning either a new or rebuilt pump and refill with

new oil. For the engine sump, refer to handbook.

12.3 Post Commissioning Period

If the pump is driven by a diesel engine, the oil in both pump chambers should be drained and renewed

simultaneously with the time schedule laid down by the engine manufacturer. This will usually require the oil to be

drained and replaced every 250 running hours. Under no circumstances should the period for the body unit exceed

500 running hours without oil being replaced in both chambers.

Page 18 of 70

12.4 Installation Example

If the body unit has been purchased as a single item, this section details some of the necessary installation

requirements when coupled with a motor/engine.

Step

Action

Image

1

The skid base is a standard part for supporting the

pump’s components, as well as absorbing and

dissipating vibrations & forces to the ground. The

base is necessary for securing the unit

components in position once aligned. Place the

base to firm level ground capable of supporting

the weight. Use anti-vibration (AV) mounts where

appropriate, these are required when coupling the

pump to an IC engine.

2

When installing a diesel engine, a flywheel

mounted coupling can be used. The coupling

must be selected with consideration to the engine

& body unit torque, speed and torsional

vibrations.

Couplings are selected for their

performance qualities unique to the

pump in hand, these are not

interchangeable between variants of

pumps. Doing so, will drastically shorten the life

of the pump.

3

Both the body unit and driver must be aligned on

two planes and rigidly mounted onto a chassis,

failure to do this will shorten the life of the

coupling. Refer to the fitment instructions supplied

with the selected coupling for further information.

AV mount

Skid base

Other manuals for D75

1

This manual suits for next models

2

Table of contents