SEMAPI DSP Logger Expert User manual

User Manual

Measurer and Analyzer

Ver.: 2.0

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

2

Measurer and Analyzer

Introduction:......................................................4

Quick Measurement:...........................................5

Bearing Analysis:............................................... 5

Spike Energy Level:........................................... 5

Home:............................................................... 6

Input parameters:.............................................. 7

Parameters copy:.............................................. 9

Class ISO10816:............................................... 9

Bearing Analyzer: ............................................ 10

Additional indicators:....................................... 13

Channel change:............................................. 14

Trend function:................................................ 14

Channel change:............................................. 15

Record:........................................................... 16

Return:............................................................ 16

Measurement Change:.................................... 16

Spike Energy Level:......................................... 17

Channel change:............................................. 20

Measurement change:..................................... 20

Standard table:................................................ 23

Additional indicators:....................................... 23

Channel change:............................................. 25

Trend function:................................................ 25

Channel change:............................................. 26

Record:........................................................... 27

Return:............................................................ 27

Measurement Change:.................................... 27

Function Dual Channel:.................................... 28

Dual channel:.................................................. 30

Record:........................................................... 31

Alerts of machine status: ................................. 32

Vibration analyzer: ............................................34

Input parameters:............................................ 34

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

3

Preconfigured measurements:......................... 35

Acceleration:................................................... 36

Velocity:.......................................................... 36

Analyzer:......................................................... 38

Scalar measurements:..................................... 43

Multivariable:................................................... 45

Channel change:............................................. 45

Spectral measurements:.................................. 46

Spectrum / waveform:..................................... 49

Waveform Measurements:............................... 50

Channel change:............................................. 50

Dual channel measurements and triaxial:.......... 51

Channel change:............................................. 53

Triaxial measurements:.................................... 54

Channel change:............................................. 55

Instructions for use:......................................... 56

Troubleshooting: ..............................................57

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

4

Introduction:

This module measures and analyzes mechanical

vibrations and variable AC and DC power. It groups

all the measurements of the DSP Logger Expert on

all its inputs, allowing the user to select vibration

measurements with pre-configured settings for

expert analysis or configurations designed to search

for other sources of or complex analyses of

vibrations.

The firmware contained in Option 1 of the DSP

Logger Expert is selected with the arrow keys or

directly with the 1 key.

Entering this firmware shows two options on the

screen, as shown in the following display.

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

5

Quick Measurement:

This firmware contains 3 types of vibration analysis,

which are performed fully automatically.

It enables a simple load of the machine parameters

to be analyzed, allowing the system to capture,

analyze, and monitor vibration levels associated with

mechanical failures.

Bearing Analysis:

This tool defines an accurate calculation of the state

and condition of the bearing to test for bearing

and/or lubrication failure.

To do this, you must enter the estimated RPM of the

machine.

Spike Energy Level:

This tool defines an enveloping measurement value

of the Energy Spike ® analyzing bearing condition

and the values of bearing failure frequencies.

These calculations are performed automatically,

requiring the value of the estimated RPM, the model,

and the manufacturer of the bearing.

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

6

ISO 10816 Measurements:

This measurement tool performs an analysis of

machine speed, adjusting the settings to the

requirements of ISO 10816 and evaluating the

condition of the states covered by the rule.

The input data that this tool requires involves the

classification of the machine in the norm groups.

In addition to the input of the RPM value, the meter

system expert shows vibrational levels for the

balancing, alignment, and rotation of the machine

backlash.

Home:

When entering the quick measurement by the icon

you will enter the settings window:

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

7

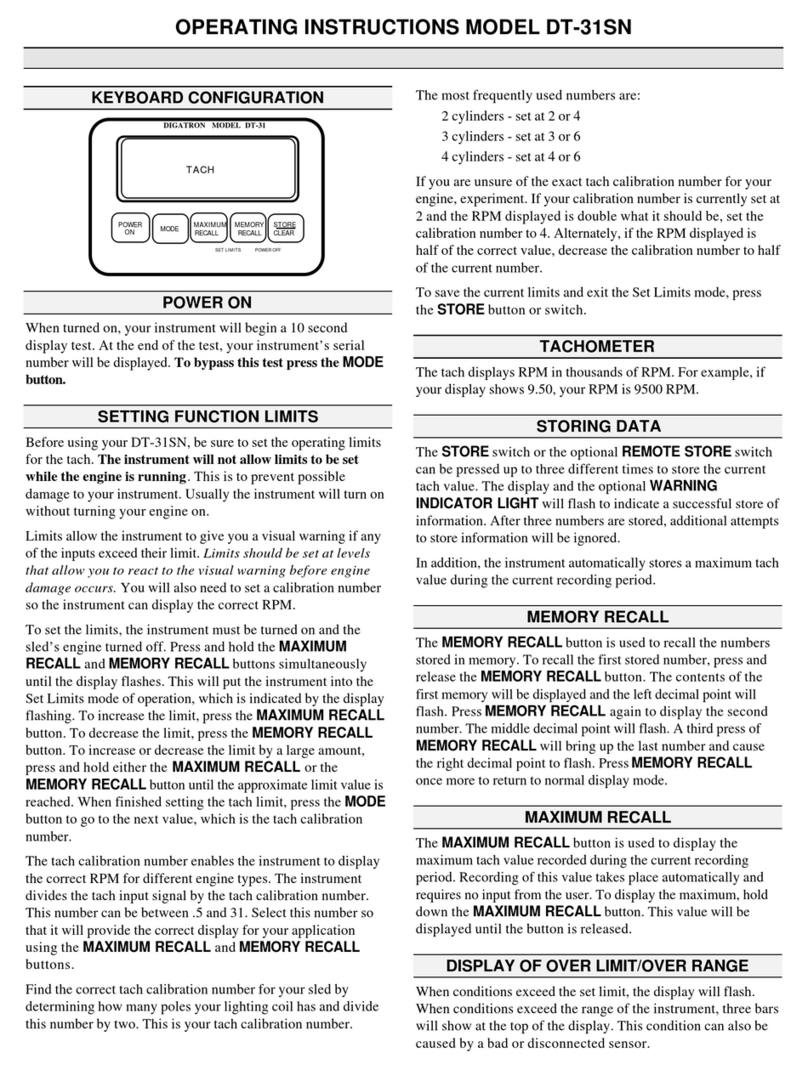

Input parameters:

The parameter display indicates the status of the six

(6) inputs of the DSP Logger Expert according to the

connected and disconnected sensors.

The entries are grouped into 3 (three) groups for

Channel A and Channel B, each taking the X, Y, or Z

direction.

Red indicates no sensor signal.

Green confirms that the sensor and cable are in

good condition.

The parameter window displays all the fields

necessary for analysis calculations.

The only required field for the use of the tools is the

RPM.

The parameter window is divided into two (2)

segments. The left corresponds to Sensor 1, and

the right corresponds to Sensor 2.

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

8

Code

Identification Number or TAG

Name

Machine Name

Point

Name or Nomenclature of the point

Obs.

Specific observations

RPM

The approx. revolutions of the point

Manufacturer

Bearing Mark of the point

Model

Bearing Model of the point

The input bearing manufacturer can be viewed by

selecting the list that has the system and factory

preloaded.

Model selection is performed via a selection of all the

bearings corresponding to the selected

manufacturer.

You can enter the bearing model by placing the first

number or the complete number of the bearing, so

the position will be close to or an accurate bearing.

Recommendation

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

9

Parameters copy:

The parameter window contains a tool to copy the

parameters entered in sensor A or B.

The parameters that are not copied from one sensor

to the other bear manufacturer and model data.

When activated, the system will request the copy

from one sensor to the other.

Class ISO10816:

ISO class is selected depending on the measuring

machine.

Part 3: Industrial machines with nominal power

above 15 kW and speeds between 120 and 15000

RPM.

The criteria for the vibration of this standard apply to

a set of machines with a capacity exceeding 15 kW

and a speed between 120 RPM and 15,000 RPM.

The criteria are only applicable to vibrations

produced by the machine itself and not to vibrations

that are transmitted to the machine from external

sources. The effective value (RMS) vibration velocity

is used to determine the condition of the machine.

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

10

Bearing Analyzer:

The first step is the entry of the parameters in sensor

1 and/or 2.

Once the parameters load, press F4 to activate

NEXT.

The menu functions F1 to F4 will change to the next

options.

Function F1 allows you to select analysis options.

This is done by pressing the F1

key until you reach the desired

option.

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

11

Once there, confirm with the ENTER key.

Once confirmed, the measurement screen will be

presented online as measured from the first moment

of visualization.

The Bearing Analysis screen, shown above,

measures the input channel to the RMS value. The

red HOLD frame on the right keeps the maximum

value detected from the start of measurement or

since reset to zero using the #key.

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

12

The spectral measurement corresponds to an

acceleration range of 800 lines with a maximum

frequency of 10 kHz.

On this configuration, the system calculates the

state of bearing and lubrication.

Each of these indicators shows a different status:

Bearing Lubrication

ACEPTABLE ACCEPTABLE

ACCEPTABLE CAUTION

CAUTION EMERGENCY

CHANGE

IMMEDIATE

The measurement is presented online.

To stop the measurement, press the

ESCAPE button.

To restart the measurement, press the

ENTER button.

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

13

The status indicator measurement is at the top of

the screen, indicated by different colored circles.

In process measurement outside

Measurement stopped (flashing indicator)

Continuous measurement process

Additional indicators:

The following values are shown on the right side of

the screen:

0.P.: 0-Peak scalar value.

PP: Peak-Peak scalar value.

F.C.: Crest Factor scalar value.

Also shown are four (4) detected maximum peaks in

the spectrum, which indicate amplitude and

frequency.

The cursor function is activated with 1 key.

The indication appears for amplitude and frequency.

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

14

Channel change:

Press F3 to change the channel.

This key will display the measurement of the

selected channel.

Another channel change option is to select the

function Overall Dual Channel (see pages 25 to 29)

Save data:

Press F4 to save measurement data.

Trend function:

The F2 key activates the screen that shows a trend

graph of the measurement on the selected channel.

The trend graph shows all measurements for a

maximum of 2 (two) minutes.

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

15

The trend display shows the trend of the values

entered, with an up or down arrow coinciding with

the comparison of the last inserted value.

Declining value

Increasing value

Channel change: Press F3 to change the channel.

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

16

Record: Using F2, you can save a time period of entered

measurements.

Once activated, start and end data recording by

pressing the F2 key again. Recording will also end

automatically when the set time of maximum

recording is completed.

Return: F4 will return spectrum measurements.

Measurement Change:

From the trend screen, you can directly access the

other tools by pressing F1.

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

17

Spike Energy Level:

If the parameter data were pre-loaded for another

application, you can directly enter this function. If

not, you must complete the input parameter steps

(Pages 4, 5 and 6)

The tool screen shows the most relevant parameter

values of the measurement.

The main screen shows the value or level Energy ®

Spike with the color that corresponds to status of

the measurement.

Below the levels level status, data shows the

bearings, including the make and model.

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

18

The graph shows the values and status of the fault

frequencies:

The bearings are composed of several clearly

differentiated components: inner race, balls or

rollers, cage, and outer race. The deterioration of

each of these elements will generate one or more

characteristic frequencies in the spectrums, allowing

for quick and easy identification. The four possible

frequencies of bearing damage are:

BPFO (Ball pass frequency of the outer race): The

physical number of balls or rollers that go through a

point outside the track each time the axis makes a

full rotation.

BPFI (Ball pass frequency of the inner race): The

physical number of balls or rollers that go through a

point inside track each time the axis makes a full

rotation.

BSF (Ball spin frequency):

The physical number of turns made by a ball bearing

each time the axis makes a full rotation.

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

19

To view the envelope spectrum, press function key

F2.

In the spectrum envelope, the components can be

observed corresponding to bearing failure,

identifying the fault frequencies, and the values of

the peaks corresponding to each frequency.

It also shows the Energy ® Spike level with the color

that corresponds to status of the measurement.

Below the state with the SP level, bearings data is

shown, including make and model.

Measurer and Analyzer

User Manual

User Manual • Version 2.0_2013

www.semapi.com

20

Channel change:

Change the channel by pressing F3.

When activated, this key will display the

measurement of the selected channel.

To return to the screen bearing fault frequencies,

press function key F2.

Measurement change:

From the Trend screen you can directly access the

other tools by pressing F1.

Other manuals for DSP Logger Expert

1

Table of contents

Other SEMAPI Measuring Instrument manuals