SENSYS SBL10 User manual

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 2 / 69

Version 1.27

Content

1General Remarks 5

2Safety Instructions 7

2.1 Advice in Case of Malfunction 7

2.2 Advice for Devices with Battery Supply or Accumulator 8

2.3 Cleaning Advice 8

3Product Description 9

3.1 Measurement Principle of the Sensor 9

3.2 Areas of Application 9

3.3 Component Description 11

4Control and Display Unit Functions 14

4.1 Overview 14

4.2 Operation Modes 14

4.3 Measurement Ranges 15

4.4 Acoustic Signal 16

4.5 Power Supply and Battery Check 16

4.6 Compensation 17

4.7 Function Test 18

5Preparing the Survey 19

6Carrying out the Survey 21

6.1 Getting Started 21

6.2 Area Surveys 21

6.3 Underwater Surveys 23

6.4 Borehole Surveys 23

6.5 Identify Objects Properties 24

6.5.1 Object Sizes 24

6.5.2 Position of the Object 25

6.5.3 Estimating the depth using the Half-Width Method 26

6.6 Use as a Compass 27

7Data Acquisition via PDA 28

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 3 / 69

Version 1.27

7.1 Connecting SBL1 10 unit to the PDA 29

7.1.1 Connecting an external GPS with the PDA 31

7.2 Start and Setup of Software 32

7.3 Configuration of GPS connection 35

7.4 Projects 39

7.4.1 Project Settings 41

7.5 Field Measurements 43

7.6 Borehole Survey 47

7.6.1 Borehole Fields 48

7.6.2 Preparing the SBL10 51

7.6.3 Measurement of Boreholes 51

7.7 Line Measurements 54

7.8 Referencing 56

7.8.1 Referencing Field Measurements 56

7.8.2 Referencing of Boreholes 58

7.9 Exporting Measurement Data 60

7.9.1 Field Measurements 60

7.9.2 Borehole Measurements 62

7.10 Data Transfer 63

7.10.1 Data Transfer via Cable 64

7.10.2 Data Transfer via USB flash drive 64

8 Maintenance 65

9 Troubleshooting 66

10 Technical Data 67

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 5 / 69

Version 1.27

General Remarks1

Manual SBL10

Copyright © SENSYS 2019

All rights reserved.

Version: 1.27

Valid for the following versions:

Hardware: Rev. 05.00 and higher

MonSX: Rev. 01.02-00/00 and higher

SENSYS

Sensorik & Systemtechnologie GmbH

Rabenfelde 5

15526 Bad Saarow OT Neu Golm

Germany

Telephone: +49 (33 631) 5 96 50

Fax: +49 (33 631) 5 96 52

email: info@sensys.de

Internet: www.sensys.de

No part of this manual may be reproduced, copied or otherwise duplicated without written permit

from SENSYS.

All information contained in this manual may be subject to changes without prior notice. SENSYS

will not explicitly inform third parties about these changes.

All technical information contained in this manual has been compiled with greatest care. The

manual has been double-checked by the customer support team of SENSYS. Nevertheless it may

contain errors. SENSYS does not guarantee that this manual is free of errors and does not grant

warranty or liability on damages resulting from error in this manual. However, the author will be

grateful for feedback by third parties who have noticed errors in this document.

The hardware and software described in this manual is the unrestricted property of SENSYS. It is

protected by copyright acts and international agreements on intellectual property against

unauthorized reproduction and copying.

The following brand names and trademarks have been registered by the owners listed below:

MAGNETO® is a registered trade mark of Dr. Andreas Fischer

DLMGPS® is a trade mark of Dr. Andreas Fischer

MXPDA® is a trade mark of Dr. Andreas Fischer

Windows® is a registered trade mark of Microsoft Corp.

When using lwip with SENSYS products, then it is used under the following license conditions:

lwIP is licensed under the BSD license:

Copyright (c) 2001-2004 Swedish Institute of Computer Science.

All rights reserved. Redistribution and use in source and binary forms, with or without

modification, are permitted provided that the following conditions are met:

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 6 / 69

Version 1.27

1. Redistributions of source code must retain the above copyright notice, this list of conditions and

the following disclaimer.

2. Redistributions in binary form must reproduce the above copyright notice, this list of conditions

and the following disclaimer in the documentation and/or other materials provided with the

distribution.

3. The name of the author may not be used to endorse or promote products derived from this

software without specific prior written permission.

This software is provided by the author as is and any express or implied warranties, including, but

not limited to, the implied warranties of merchantability and fitness for a particular purpose are

disclaimed. In no event shall the author be liable for any direct, indirect, incidental,

special,exemplary, or consequential damages (including, but not limited to, procurement of

substitute goods or services; loss of use, data, or profits, or business interruption) however caused

and on any theory of liability, whether in contract, strict liability, or tort (including negligence or

otherwise) arising in any way out of the use of this software, even if advised of the possibility of

such damage.

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 7 / 69

Version 1.27

Safety Instructions2

Prior to using the device please read the following safety instructions:

Please read this manual thoroughly prior to assembling or operating the device.

Please follow the installation and operating instructions in this manual! SENSYS and its partners

assume no liability for damages due to actions that are not mentioned in this manual.

Advice in Case of Malfunction2.1

To avoid injuries, electrical shocks and the destruction of components, do not use

damaged supply cables or components!

Please replace damaged or missing parts only with original parts from SENSYS. Otherwise there

might be a danger of short circuits, overcharge, mixing of the polarity and electrical shock. Please

perform only maintenance as described in this manual or as taught by the producer in special

training courses.

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 8 / 69

Version 1.27

Advice for Devices with Battery Supply or

Accumulator

2.2

Batteries or accumulators may explode when used inappropriately.

Please pay attention to the following instructions:

• use only batteries or accumulators that were specified by the producer for this device

• take care of the correct polarity when inserting batteries or the accumulators

• never expose batteries or accumulators to high temperatures or fire

• keep the battery terminal dry and keep it away from contact with conductive materials

Please pay attention to the following safety instructions in order to prevent damages on

the device:

After using the device or in case of disuse for a longer period of time, please remove the batteries

or the accumulators.

Damages caused by the inappropriate use of the accumulators (short-circuit, drain, mechanical

damages) and consequential loss cannot be claimed as guarantee.

The disposal of the accumulators and batteries should only take place in the collecting

basins or points designed for this purpose.

Cleaning Advice2.3

Please use a moist and soft cloth for cleaning the device.

The contact of water with the electronic circuitry and with the contacts of the plugs and the plug

sockets has to be avoided. Damaged cables and plugs as well as casings of the sensor should not

be cleaned with water.

Don’t clean the device with chemical substances or with mechanical additives. This may

cause damages of the components!

After cleaning the device respectively the single components, please put them into the provided

case for transport. If the interior of the case got wet, please dry it before using it again.

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 9 / 69

Version 1.27

Product Description3

The iron locator SBL10 is a rugged and highly sensitive vertical difference magnetometer. It is used

for locating ferromagnetic objects in the ground. The aluminum made device is very light-weight

and very easy to handle. Once the batteries are inserted, the SBL10 is immediately ready for

operation.

Ferromagnetic objects in the vicinity of an operating SBL10 unit are indicated by a moving display

pointer and by an acoustic signal. In addition to the build in sensor probe, a second sensor probe

can be connected to the SBL10 unit by using a connector cable. This additional probe is used for

borehole and offshore surveys.

Also available as an option is a PDA which can be used for recording of field and borehole survey

data. If required, a GPS can also be connected to the SBL10 when working with a PDA.

Furthermore headphones are available to be used with the SBL10 unit.

Measurement Principle of the Sensor3.1

The earth's magnetic field and the magnetic field that every ferromagnetic object has, are the basis

on which the SBL10 is working. Whenever these two magnetic fields superimpose each other, a

magnetic interference field is established. These interference fields can be measured. The farther

away a ferromagnetic object is from the device, the lower is the measured value of the interference

field.

The SBL10 unit measures this interference field with two single-axis Fluxgate sensors. The

sensors are placed in series in a certain vertical distance from each other (sensor bottom

separation). The value of the magnetic interference field results from the difference between values

of the lower sensor and the values of the upper sensor. The SBL10 display indicates this difference.

At the same time, an acoustic signal can be heard.

The value of the interference field that is caused by a ferromagnetic object depends on different

parameters. Some of the parameters are:

·

The size of the ferromagnetic object.

·

The objects position in the ground.

·

The magnetic permeability of the object.

·

The object's own magnetic field.

Areas of Application3.2

The device was designed to locate ferromagnetic objects in the ground. When being used in its

standard version, the SBL10 can only be used for measurements on the surface or in shallow

waters. An option is available allowing the use of the SBL10 unit for borehole or underwater

surveys. For this kind of surveys, an additional probe and a special connector cable is required.

The connection between the additional probe and the connector cable is watertight. However, the

control and display unit as well as the battery compartment are not designed for under water

deployment.

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 10 / 69

Version 1.27

The conditions of measurement as well as the physical limits of the device need to be considered

when working with the SBL10. Only trained staff should work with the device.

Before starting to work with the device, the operator needs to make sure to be free of

any metal (e.g. belt buckle, mobile phone, keys, etc.). Otherwise this metal, in particular

when it has ferromagnetic properties, will falsify the measurement results.

The operator also needs to perform a function test before starting to work with the device. An

explanation on how to carry out this test is given in Chapter 4.7 Function Test .

When being used for EOD purposes, the device may only be used by specially qualified

and trained staff.

The national regulations for explosive ordnance disposal need to be followed at any time

when working with the device!

18

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 11 / 69

Version 1.27

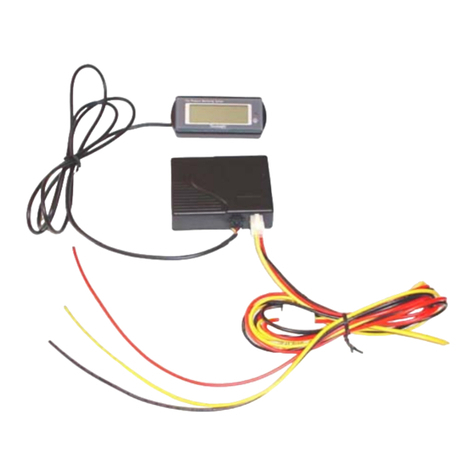

Component Description3.3

The device consists of different components:

1 - Control- and display unit

2 - Carrier tube

3 a/b - Right/Left battery compartment

4 - Hinge with locking screw

5 - Probe

6 - Carrying belt

Control and DisplayUnit

The splash-proof control and display unit is fixed to the carrier tube. It has three basic

functions:

1. DisplayFunction:

·

displays measurement values on the pointer instrument

·

indicates measurement values by an acoustic signal

·

displays the mode on the LED mode display

·

displays the state of charge of the batteries in the device on the battery meter

2. Instrument Settings:

·

mode selection button for mode setting

·

volume control buttons for volume setting the volume

·

rotary switch for measuring sensitivity setting

·

setting of the acoustic signal

3. Other Functions:

·

compensation

·

functional test

The data transfer interface is located on the SBL10's front end. As an option, additional interfaces

for connecting the borehole probe and the headphones are available.

Carrier Tube

The carrier tube connects the control and display unit with the power supply. The control and

display unit is located in the front part of the carrier tube. The two battery compartments that

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 12 / 69

Version 1.27

guarantee the power supply of the device are fixed to the end of the carrier tube. When surveying

with the SBL10 unit, the operator is holding the device at the carrier tube.

Battery Compartments

The device features two battery compartments. Each battery compartment takes three 1.5V single-

cell batteries (LR 20) or three 1,2 V rechargeable batteries (HR20) which are the redundant power

supply of the device. In case one compartment fails or if the batteries are empty, the other

compartment will take over without any interruption. The battery compartments need to be closed

tightly by using the provided caps.

Probe

The probe is water-proof and contains two Fluxgate sensors as well as the magnetometer

electronics. A knuckle joint fixes the probe to the control and display unit. As it is fixed on a swivel

hinge, the position of the probe can be modified according to the needs of the operator. It can be

fixed in the position that is best for the operator by using the locking screw.

Transport Case

A transport case is supplied along with the SBL10 unit for transporting and storing the device. The

case is water- and dust-proof (IP67) and is equipped with an automatic air pressure compensation

valve, two locks and a handle.

Borehole Probe (Option)

In addition to the standard version, the SBL10 can be delivered with an additional borehole probe.

The additional probe can be used for borehole surveys but also for underwater surveys. A special

cable is connecting the control unit to the probe via 7-pin MIL connector. The internal probe is

disabled automatically when the borehole probe is connected. This connection is watertight.

The borehole probe FGM400/38, which is delivered along with the SBL10 unit, is

intended for the use with specific systems only. Make sure the borehole probe

FGM400/38 is only being used with compatible systems. Otherwise the operator will

inevitably obtaining false readings from the probe.

Headphones (Option)

Headphones will be delivered with the SBL10 unit upon request. A 4-pin MIL connector is being

used to connect the headphones with the control and display unit. Once this connection is

established, the SBL10's internal speaker is automatically switched off.

Carrying Belt

The SBL10 2-point carrying belt consists of the following components:

·

2x strap with buckle

·

1x belt with clip, movable shoulder pad and two buckles

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 13 / 69

Version 1.27

The carrying belt is used as listed below:

·

Pull first strap under upper part of carrying tube

·

Pull the buckle through the strap

·

Pull second strap under lower part carrying tube

(between battery compartment & carrying tube)

·

Pull the buckle through the strap

·

Buckle up the straps and the belt

·

Adjust length of the belt

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 14 / 69

Version 1.27

Control and Display Unit Functions4Overview4.1

1 - Display unit

2 - Mode display (steady when using

internal probe, blinking when

connecting external probe)

3 - Battery display

4 - Mode selection

5 - Decrease volume

6 - Increase volume

7 - On/Off and selection of

measurement range

8 - Compensation

9 - Function test

Operation Modes4.2

The device features four different modes, which are set by pressing the „MODE“-button (4).

Mode 1:

Standard mode. All ferromagnetic objects are measured and displayed.

Fields of application: area, borehole and underwater surveys

Mode 2:

Exclusively used for locating objects with a large magnetic interference field. Objects having a small

magnetic interference field are not displayed due to the increased inertia of the display.

Fields of application: area surveys

Mode 3:

Auto-compensation mode is used for locating objects when a constant magnetic interference field

is influencing the survey e.g. during surveys closed to wire fence. If the distance to the constant

magnetic interference field stays the same, this mode can be used for locating all additional

ferromagnetic objects. The compensation of the survey area starts automatically as soon as the

SBL10 unit is kept still.

Fields of application: area surveys in the surroundings of constant interference fields.

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 15 / 69

Version 1.27

When using Mode 3 make sure to keep moving the SBL10 unit at all time during the

survey. Otherwise the reading of the objects to be measured will be compensated and

therefore objects may remain undetected.

Mode 4:

Compass Mode: The different cardinal points can be determined in this mode.

Measurement Ranges4.3

The readings can be displayed in various measurement ranges, which can be set by the operator.

The setting of the measurement range depends on the object that has to be located. The smaller or

the deeper the object is to be found, the smaller is the expected reading. The smaller the reading,

the smaller the selected measurement range has to be. The SBL10 unit features 9 different, linear

measurement ranges. The operator can choose a measurement range between 3 and 20,000 nT

(full-scale). The required measurement range can be set by using the rotary switch (7) of the

control and display unit.

An overview of the available measurement ranges is given below.

Measurement range for mode 1, 2 and 3:

Measurement Range

(Sensitivity= 1 graduation mark)

Full Scale

(10 graduation marks)

0.3

3 nT

1

10 nT

3

30 nT

10

100 nT

30

300 nT

100

1,000 nT

300

3,000 nT

1,000

10,000 nT

3,000

30,000 nT

The measurement values of the probe are displayed by the pointer movement in the display unit.

The scale span varies from 0 up to ±10 graduation marks. According to the set measurement range

(0.3 up to 3,000), the operator can calculate the measured value in nT. To do so, the displayed

interval needs to be multiplied by the set measurement range.

Example:

Displayed Value : 5

Set Measurement Range: 100

Reading Value in nT: 5 •100 = 500 nT

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 16 / 69

Version 1.27

Acoustic Signal4.4

In addition to readings on the optical display, an acoustic signal can be heard. The frequency of the

acoustic signal is increasing proportionally to increased readings.

Whenever the device is ready for operation, an acoustic signal can be heard (clicking noise) in

regular intervals. The higher the measurement value of an object the higher the frequency of the

tone will be. The signal will change to a continuous tone when the reading approaches full range of

the display unit.

The operator chooses between two sound profiles. Press and release the volume buttons (5 + 6) at

the same time to toggle between the profiles. If the change was successful, a confirmation tone can

be heard. The selected sound profile remains set even when turning off the SBL10.

Profile 1

The pitch of the tone in In this profile is the same for positive and negative readings. The size of the

reading can be derived from the sound. However it is not possible to derive the polarity from the

sound.

Profile 2

There are different pitches of the tone for positive and for negative readings in this profile. This

allows the operator to derive sizes of the reading as well as its polarity from the sound.

The volume is controlled by two buttons (5 + 6) on the control and display unit. The tone can be

muted by pressing (5) repeatedly.

The set volume is valid for loud speakers and headphones. To avoid injuries, make sure

to decrease the volume when switching from speaker to head phone operation.

Power Supply and Battery Check4.5

The SBL10 unit is equipped with two battery compartments, each taking three 1,5 V batteries

(single-cell batteries/LR20) or three 1,2 V rechargeable batteries (HR20). When working with it, at

least one battery compartment needs to be filled with batteries. If both battery compartments are

used, then the compartments are forming a redundant power supply. During operation battery

voltage is supervised permanently. As soon as the voltage of the active compartment is insufficient

to operate the SBL10, a switch over to the redundant compartment is taking place. There is no

interruption during the switch over.

Information about the status of the batteries can be seen on the control and display unit's battery

display (3) . Only failure states are displayed during normal operation.

The red LED of the battery display is lighting up for one of the following reasons:

·

Batteries are empty and have to be replaced

·

The battery compartment is empty

·

Something is wrong (e.g. compartment lid not closed or locked)

When pressing the „TEST“ button (9), the battery level is displayed for 2 seconds. Afterward the

display for the active battery compartment is blinking twice.

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 17 / 69

Version 1.27

The display has the following meaning:

Full.

Half-full.

Almost empty,

to be replaced soon

Empty,

replacement required

Please take in consideration, that for using rechargeable batteries the SBL10 needs a

specialized firmware.

For charging rechargeable batteries (HR20) follow the instructions of the respective

charger manual.

Compensation4.6

Caused by background magnetic fields due to geological structures, the SBL 10 unit is measuring

and displaying readings even in the absence of any ferromagnetic objects. This makes it hard to

detect objects whose magnetic fields have a flux density close to the one of the background fields.

By compensating the device the readings of the background magnetic field are suppressed.

The device can be compensated in mode 1 and 2 (not in mode 3 and 4). The measurement range

is selected according to operators needs.

Follow the steps below for compensation:

·

Go to an area with no ferromagnetic objects. Only the background field will be measured.

·

Press the “COMP” button (8) and do not move the probe while compensation is in progress. You

will hear a sound once the compensation is completed.

·

The pointer of the display unit should show zero once the compensation is completed.

Make sure the operator is completely free of metal during compensation!

While you can repeat the compensation process as often as you like, you cannot reverse it. To

revert compensation, power cycle the device.

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 18 / 69

Version 1.27

Function Test4.7

When pressing the „TEST“ button (9), a battery check as well as a device test is carried out. During

this test, a defined signal is sent to the probe forcing the pointer to move 8 scale divisions (given a

compensation has been carried out prior to the self test) from zero to the right (positive range). If

so, the device has passed the test and is ready for operation. The functional test can be carried out

in mode 1, 2 or 3 in all available measurement ranges.

Carry out the function test in metal-free surroundings only. The operator also needs to

be completely free from metal to prevent distorted test results.

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 19 / 69

Version 1.27

Preparing the Survey5

Step 1: Inserting the Batteries

To run the device at least one battery compartment has to be equipped with batteries. To ensure a

better balance and the possibility of a redundant supply power, we recommend filling always both

compartments. To insert batteries, open the compartment cap by turning it counter clockwise.

Insert three single-cell batteries LR20/HR20 with positive terminal pointing into the tube first; then

close the cap carefully by turning it clockwise. If the cap is not placed and locked correctly, the

battery compartment will indicate an error and will be unusable.

Step 2: Preparing the Probe

Using the internal probe see Step 2a

Using the external probe see Step 2b

Step 2a: Aligning the Internal Probe

Loosen the locking screw at the hinge (4). Bring the probe to a vertical position. Now tighten the

locking screw again to prevent the probe from moving accidentally during the survey.

When using the device in borehole and/or underwater surveys, the internal probe

remains in its transport position (parallel to the carrying tube).

Step 2b: Connecting the External Probe (for borehole surveys only)

·

Make sure the rotary switch (7) is in "OFF" position.

·

Check all sealings (D) for integrity. Never use damaged sealings for borehole and/or underwater

surveys.

·

Connect the probe to the probe cable. Make sure to follow the steps below at all times in the given

sequence:

1. Connect the 7-pin plug (A) to the probe.

2. Screw the sealing cap (B) tightly without using any tools.

3. Screw the fitting (C) onto the sealing cap without using any tools.

·

Connect the remaining cable end to the 7-pin MIL connector of the SBL 10 control and display

unit.

·

Turn on the SBL 10 unit by using the rotary switch.

Once the borehole probe has been recognized correctly, the mode display (2) starts blinking after

the SBL10 has war turned on. The internal probe will be turned off automatically. The scan for

connected probes is carried out once after turning on the SBL10. Disconnecting the borehole probe

+49 33631 59 650

info@sensys.de

www.sensys.de

Manual

SBL10 20 / 69

Version 1.27

is done in the reverse order. Always unscrew the fitting first; then remove the sealing cap and finally

the 7-pin connector. While doing so, the device has to be turned off.

If the fitting is not unscrewed prior to unscrewing the sealing cap, then damages can be

caused to the cable when disconnecting the sealing cap.

Step 3: Preparing the Survey

·

Turning the device on

By turning the rotary switch (7) of the control and display unit to the right, the device is turned on.

The rotary switch is also used for selecting the measurement range (according to the objects that

are to be located). A self test is started automatically. During this self test, all the LED’s in the

control and display unit will light up. Afterward the pointer in the display will fully move to the left and

right side of the display. A short acoustic signal can be heard. Mode 1 is activated automatically

once the test is finished.

·

Compensation

If the display pointer does not point to zero in the beginning of a survey, the device requires

compensation as described in Chapter 4.6 Compensation . Once the compensation is

completed, the pointer points to zero while the desired measurement range is selected.

·

Function Test

We recommend to carry out a function test prior to each survey. To do so, simply follow the

instructions given in Chapter 4.7 Function Test .

·

Measurement

The survey can be started now. The selected mode, measurement range and the method of

measuring depends on the area that is being surveyed (area survey, borehole survey, underwater

survey) and the objects that are supposed to be detected. Further information on this topic can be

found in Chapter 6 Carrying out a Survey .

·

Turning the device off

Turn the rotary switch (7) to the „OFF“- position (completely to the left) to turn off the SBL10.

The device should be restored in the equipment case after each survey. After borehole/underwater

surveys, the connector cable has to be disconnected from the control and display unit as well as

from the external probe. For safety reasons, take the batteries out of the battery compartment

whenever the device is not being used for a longer period of time.

17

18

21

Table of contents

Popular Measuring Instrument manuals by other brands

Tektronix

Tektronix TLA 7F1 instructions

Dwyer Instruments

Dwyer Instruments WT2-10 Specifications-installation and operating instructions

horiba

horiba LAQUAtwin-Na-11 instruction manual

Apogee

Apogee SP-212 owner's manual

Extech Instruments

Extech Instruments 480826 user guide

Secure

Secure Elite 440 installation guide