Semi-auto EXS-128 Manual

EXS-128 AUTOMATIC STRAP MACHINE

OPERATION &MAINTENANCE MANUAL

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

SAFETY INSTRUCTIONS

Read these safety instructions before operating

or servicing your strapping machine.

1. Before operating the machine, please fit over voltage and under voltage protection to the machine.

2. Wear eye or face, and hand protection. Do not wear loose clothing.

3. Keep hands or other parts of the body out of the strap chute area during operation.

4. The temperature of the heater plate is very high. Do not touch.

5. Do not insert strap while there is not a package on the operation table.

6. Do not replace any safety parts of different specifications.

7. Shut off all electric power after machine operation or servicing machine.

8. Do not use water or steam to clean the machine.

9. Keep this operation manual with your strapping machine. Refer to it often.

- 1 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

TABLE OF CONTENTS

Assembly of arch and machine --------------------------------------------------3-7

Important safety information ------------------------------------------------------8

Chapter 1 Explanation and specification --------------------------------------9

Chapter 2 Safety instruction ------------------------------------------------------10

Chapter 3 Exterior machine -------------------------------------------------------11

Chapter 4 Switches -----------------------------------------------------------------12

Chapter 5 Preparation for operation --------------------------------------------13-15

Chapter 6 Operation ----------------------------------------------------------------16

Chapter 7 Stop Operation ---------------------------------------------------------16

Chapter 8 Shutting down ----------------------------------------------------------16

Chapter 9 Repair and maintenance ---------------------------------------------17

Chapter 10 Adjustment -------------------------------------------------------------18-19

Chapter 11 Trouble shooting ------------------------------------------------------20-22

- 2 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

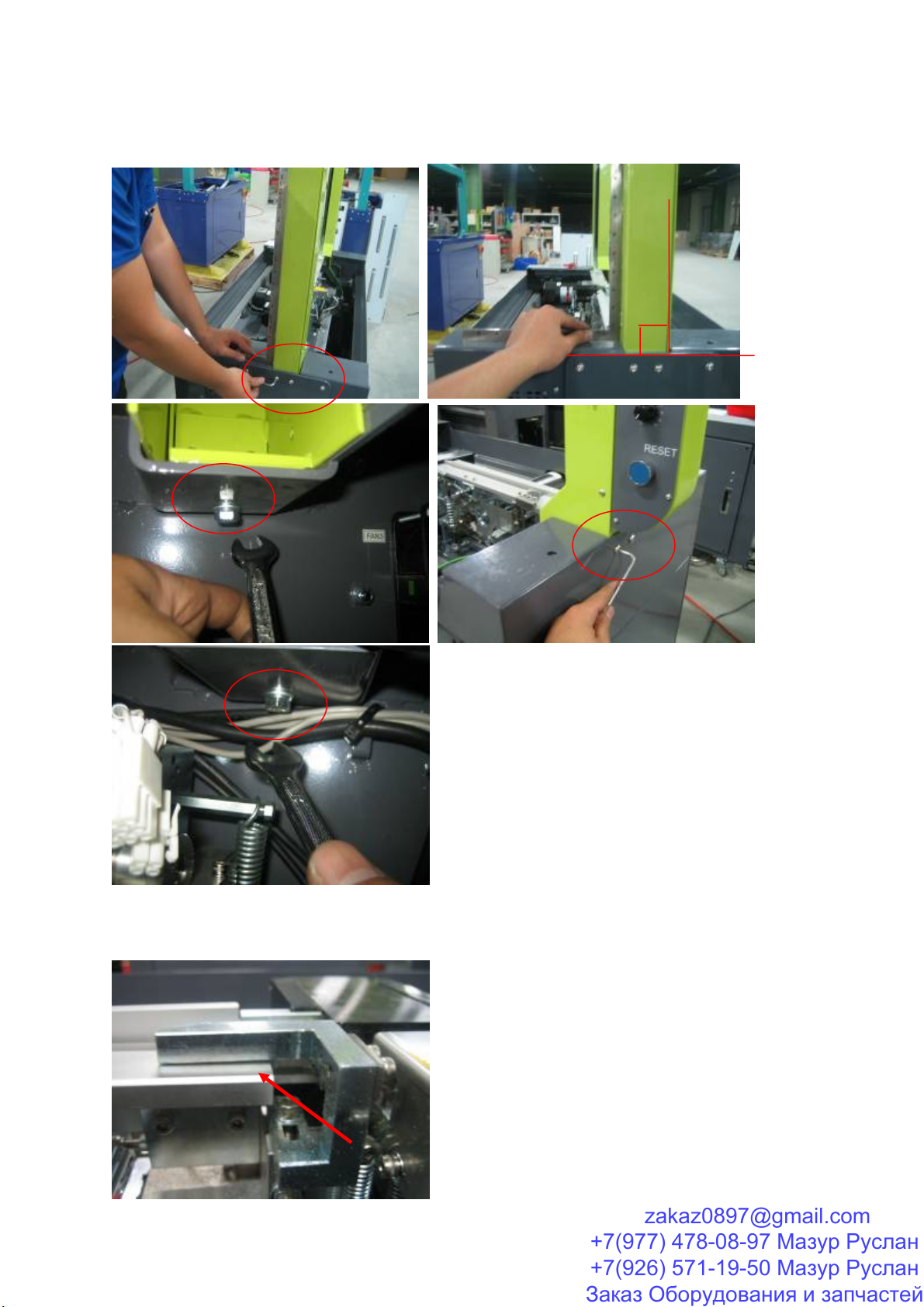

Assembly of arch

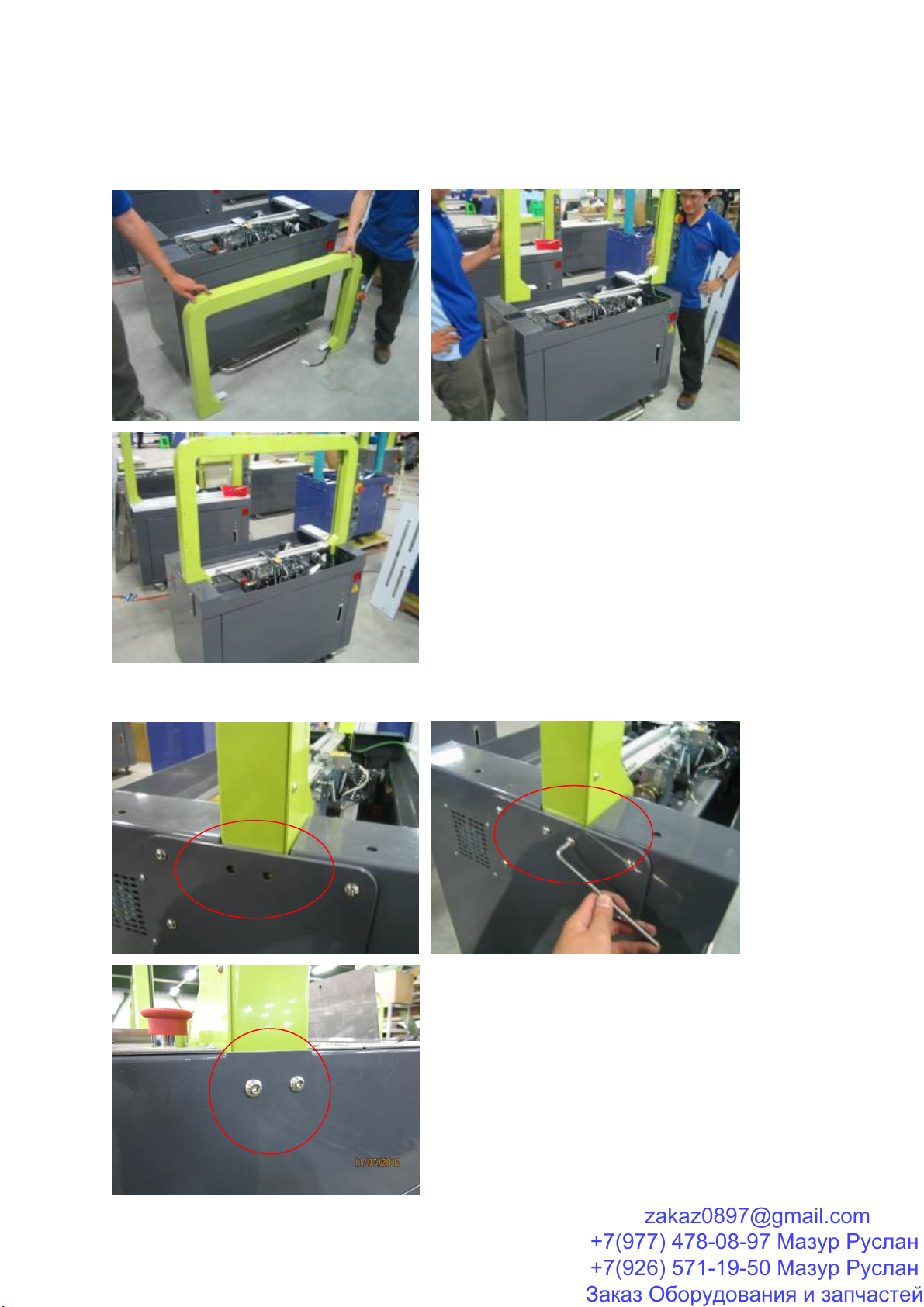

1. INSET THE ARCH INTO THE MACHINE BODY

2. LOCATE THE SCREWS OF BOTH SIDE, BUT DON’T TIGHTEN

- 3 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

3. LOCATE THE SCREWS BELOW OF THE ARCH, BUT DON’T TIGHTEN

4. TIGHTEN THE SCREWS OF BOTH INSIDE OF ARCH

- 4 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

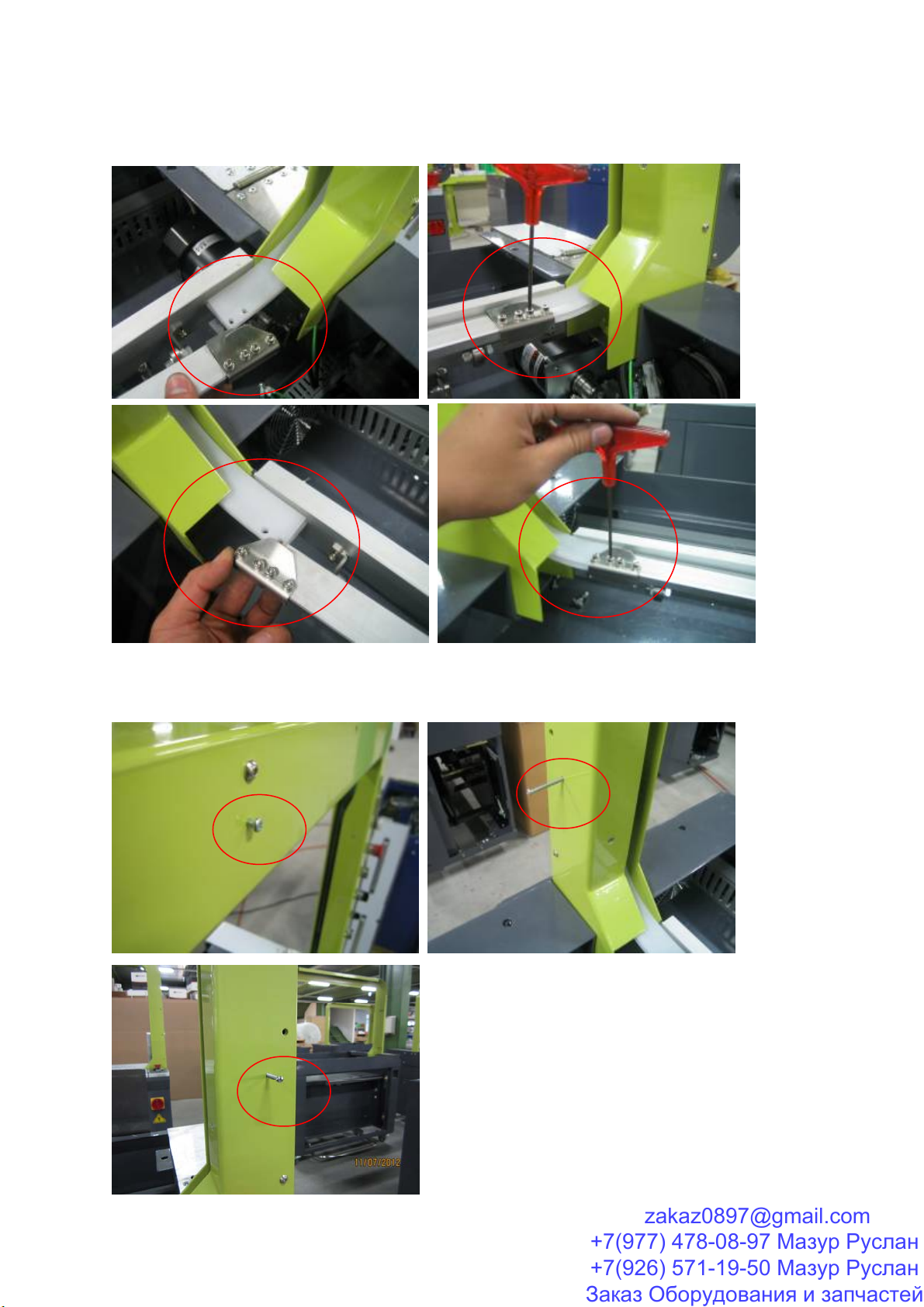

5. ALIGN THE RIGHT & LEFT BANDWAY AND CORNER BANDWAY AND THEN

TIGHTEN THE SCREWS

6. MOVE OUT THE 3 FIXED SCREWS ON THE ARCH

- 5 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

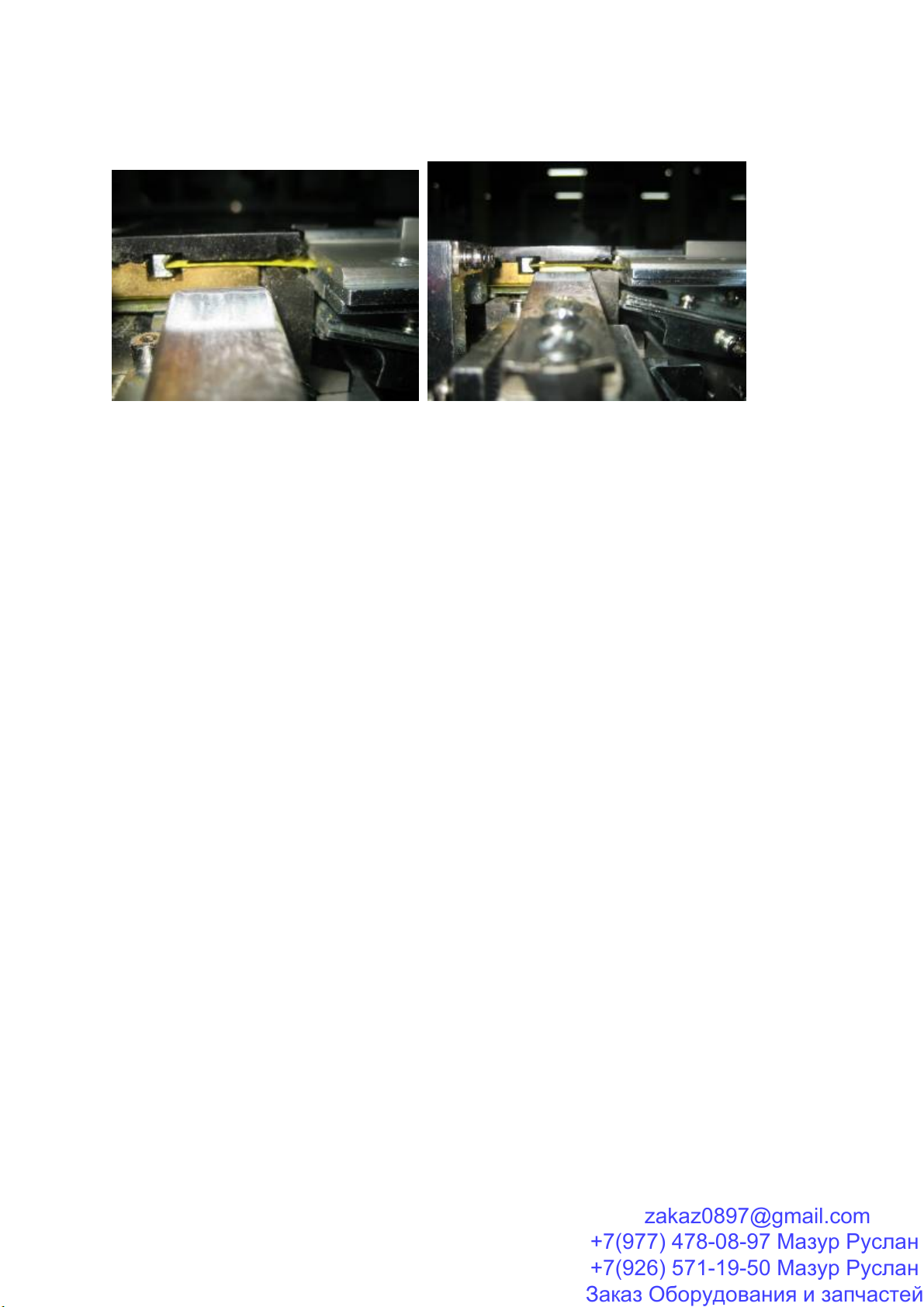

7. CONFIRM THE ARCH AND MACHINE IS 90°,AND THEN TIGHTEN THE SCREWS

8. CONFIRM THE LEFT BANDWAY MOVE SMOOTH, IT SHOULD BE A GAP BETWEEN

THE ADJUSTMENT BLOCK

- 6 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

9. CONFIRM THE PP STRAP FEED IN SMOOTH FROM RIGHT BANDWAY TO THE

HEAD

- 7 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

Important Safety Information

Following safety instructions give warning for the operation of strapping machine.

Read these safety instructions carefully before the operation of the machine.

CAUTION: Avoid placing hands or limbs in this area

Operation

(1) Floor Locking for your safely, to use Floor Locking is recommended.

Turn the floor Locking Bolt1 until the bottom surface of it presses against Floor with which the machine

is not moved even when the machine is pushed lightly.

(2) Before the operation, make sure that all the guards are fitted to the machine.

(3) Never put any part of your body into or close to any moving section of the machine. Otherwise, you may

be hurt.

(4) Before the operation, make sure that any safety device has not been moved.

(5) Never put your hand onto the wiring label when the machine is operated.

(6) Fully follow to the operation instruction.

(7) Use the specified power source.

(8) Do not put strap or string onto any part of your body.

(9) To avoid overloading of the machine, keep recommended load limits.

- 8 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

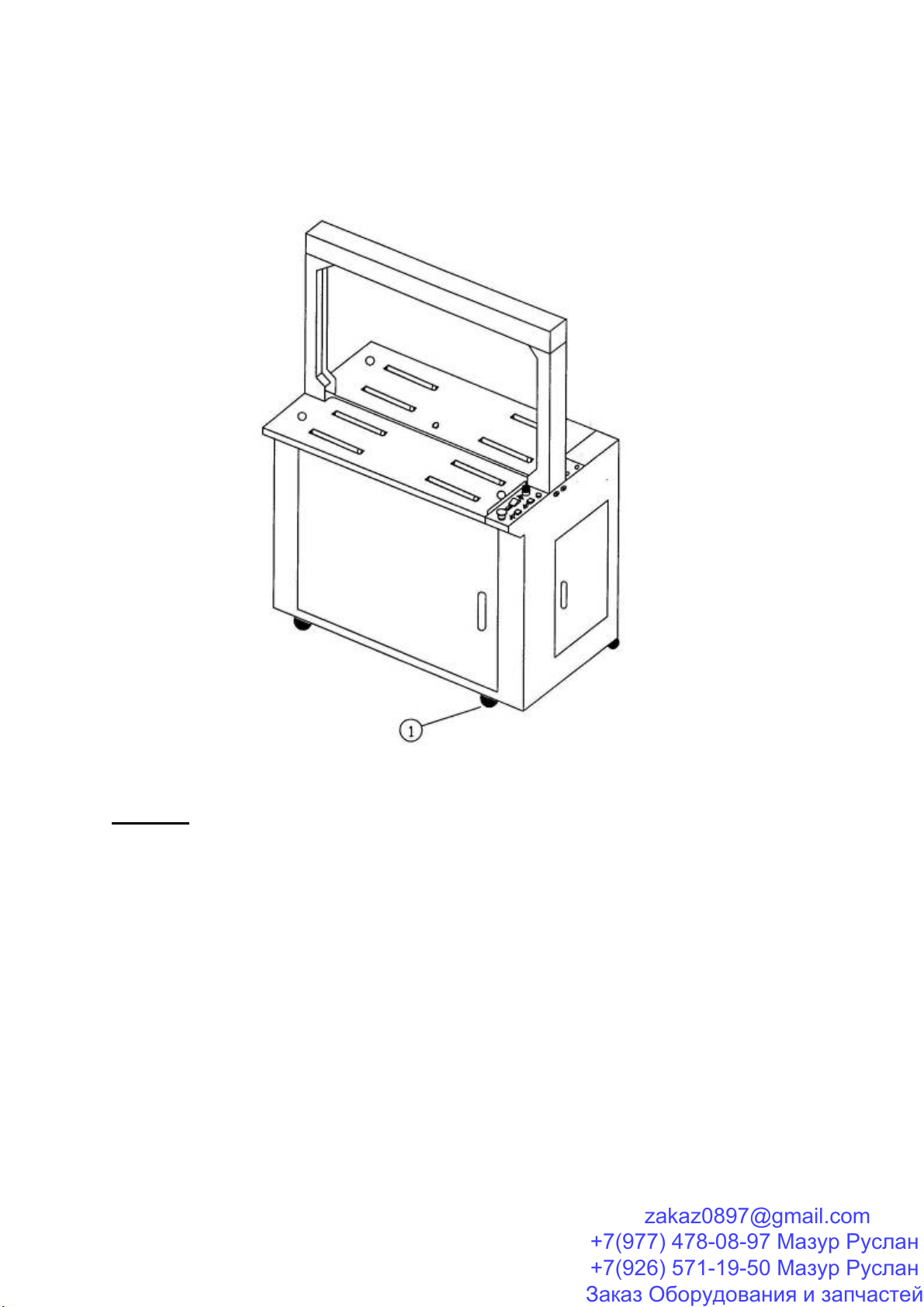

Chapter 1 Explanation and Specification

1-1 Explanation

This machine is a strapping machine which applies a strap to an object automatically.

The following accessories are attached to the machine.

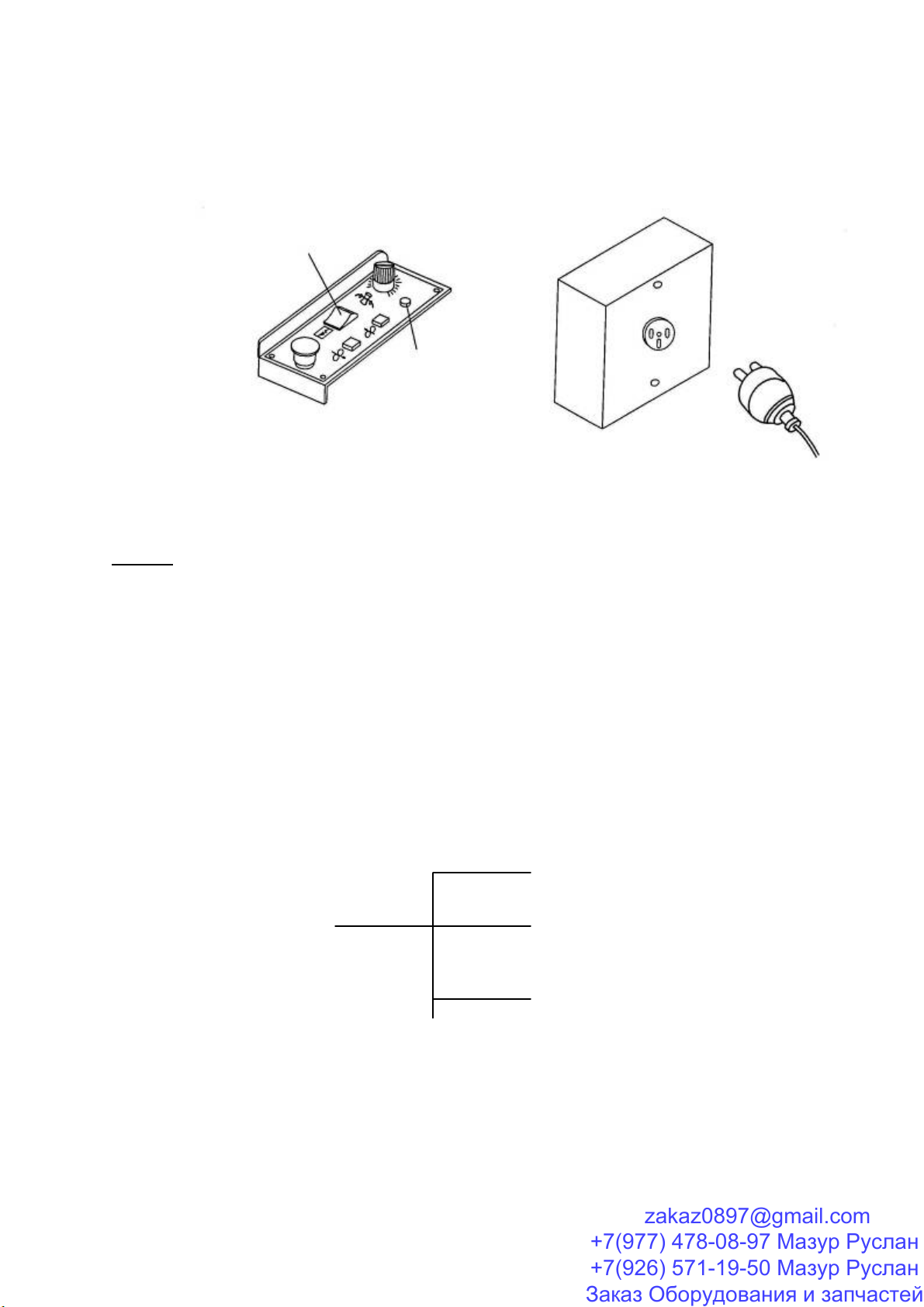

1-2 STANDARD ACCESSARIES *Optional accessories

DESCRIPTION QTY Foot Switch

INSTRUCTION MANUL PARTS-LIST 1 VOLUME

TOOLS 1SET

SWITCH KEY (4-09000-200) 1 PC

SCREWS, NUTS, WASHERS, ETC

Warning: Do not use the attached tools, for repairing the machine.

Warning: Do not attempt to maintain or repair the machine until power source has been disconnected and

locked out.

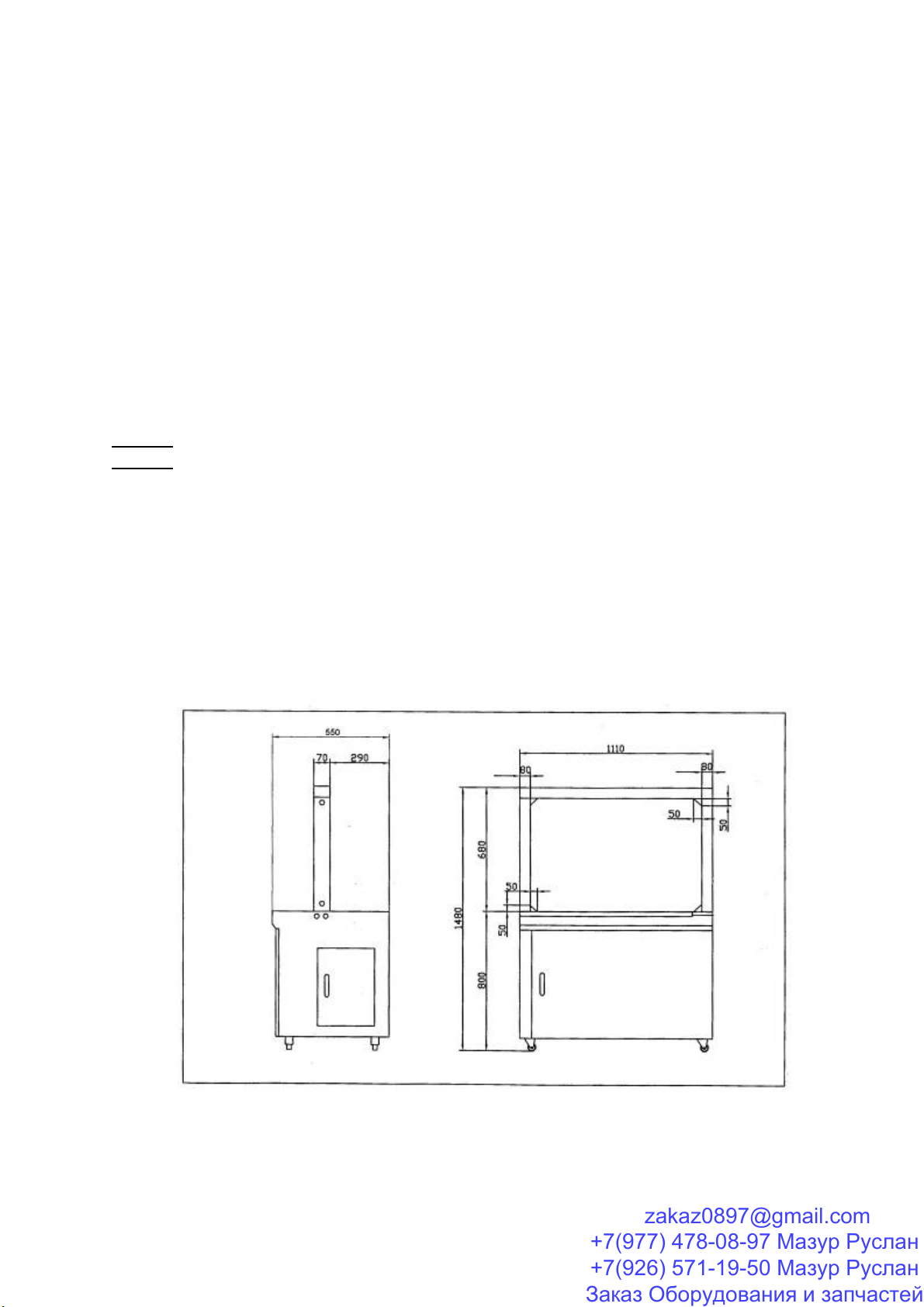

1-3 Specification (Standard Specification)

[Strapping Machine Unit]

Dimensions: Refer to the follow figure.

Weight: 175 Kg

Strapping Speed: 28-30strap/min

Dimension of package: Maximum: W850mm H600mm

Minimum:W80mmH30mm

Strap to be used: 9-15mm width.

- 9 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

Chapter 2 Safety instruction

Electric shock may strike you if you

touch the electric box ,transformer ,

motor or any electric parts while the

power is not switch off.

Never touch the running belts, as

it may catch you hurt

Heater become over

380℃.never

touch heater plate

and heater cover

otherwise you may be hurt

You may be hurt ,if

you put your finger

into the smoke fan

while power is ON.

You may be caught to hurt

if you put your finger or hand

below the heater arm while

operating

- 10 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

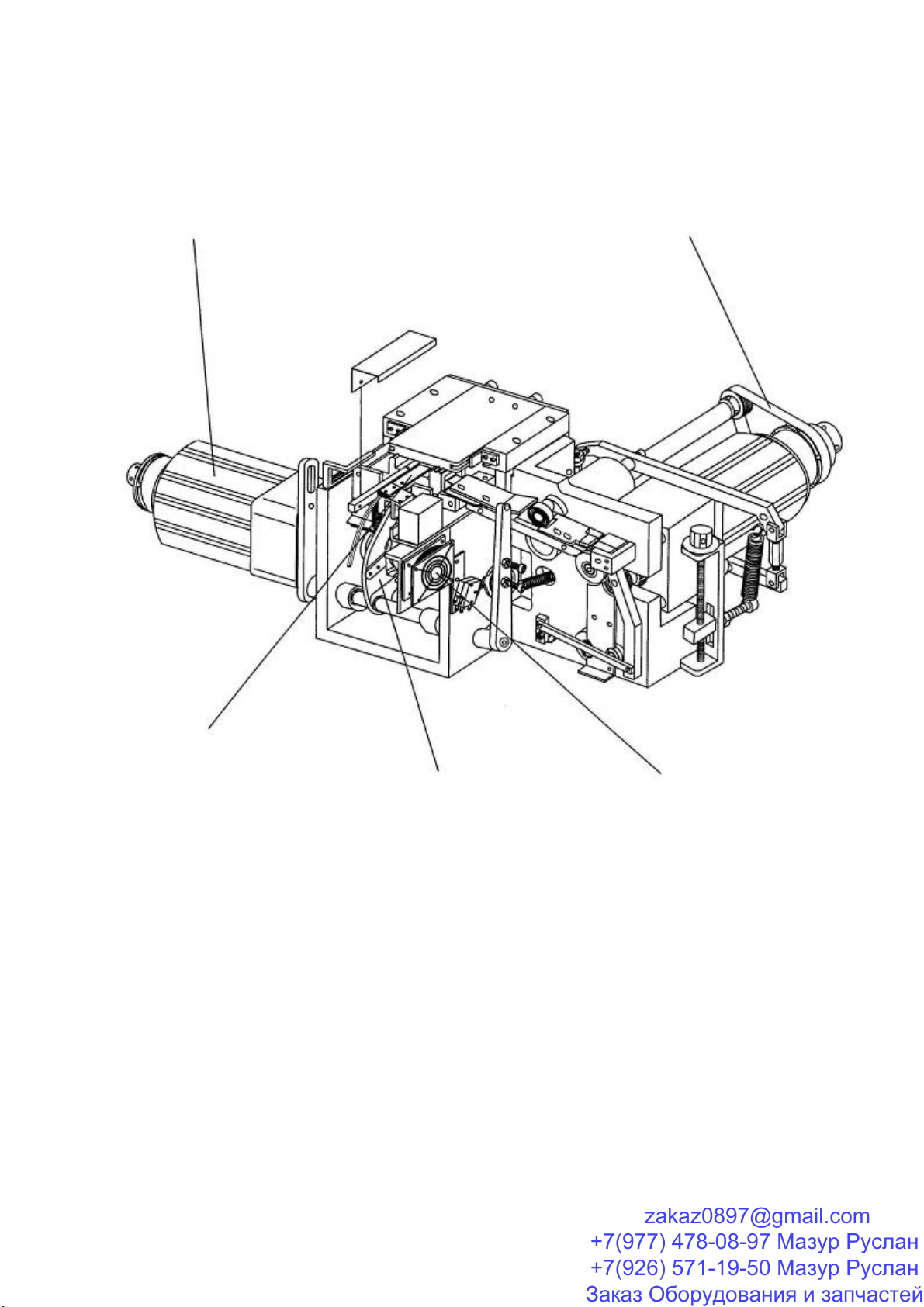

Chapter 3 Exterior machine

arch unit

cabinet unit

electrical unit

Sealer unit

pre-feed unit

reel and

break unit

pool unit pp strap

FIGURE 1: MAJOR COMPONENTS, CUTAWAY VIEW

guide

holding gripper welding clamp

entry guide

end holding gripper

top cover

cam (6)

FIGURE 2: MAJOR COMPONENTS: SEALER UNIT

feed unit

holding

gripper

cam(1)

welding

clamp

cam(3)

hot-knife

cam(4)

end

gripper

cam(5)

cam(7)

reset cam strap guide

back strap cam

anvil

cam(2)

flap cammotor

brake

- 11 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

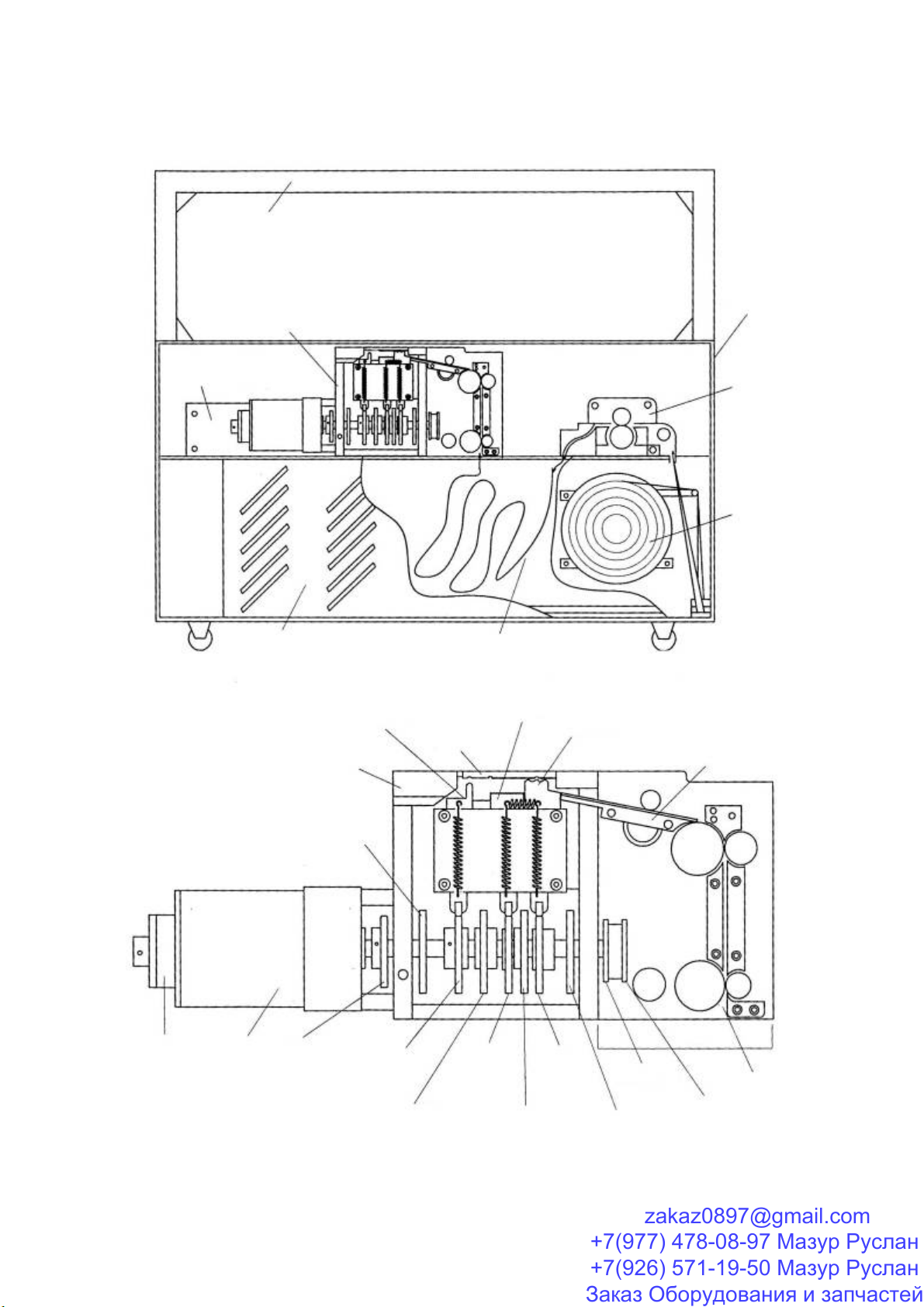

Chapter 4 Switches

EMG. Stop

Power Lamp

Tension Dial

StartButton

Strap Feed / Back Switch

Symbol Name Function

Power Switch

The machine gets ON by press the switch and the power lamp is

light. When the switch is pressed again, the machine gets OFF.

.

Start Button

The switch has 2 roles:

1. To start strap.

2.To return the cam shaft to the origin and set strap in the arch

Strap Feed / Back

Switch

Use this switch to keep this switch to Right until the strap is feed or

to Left until the strap is back.

Tension dial

To adjust tightening stroke.

Strap is tightened strong by turning right.

Strap is loosened strong by turning left.

- 12 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

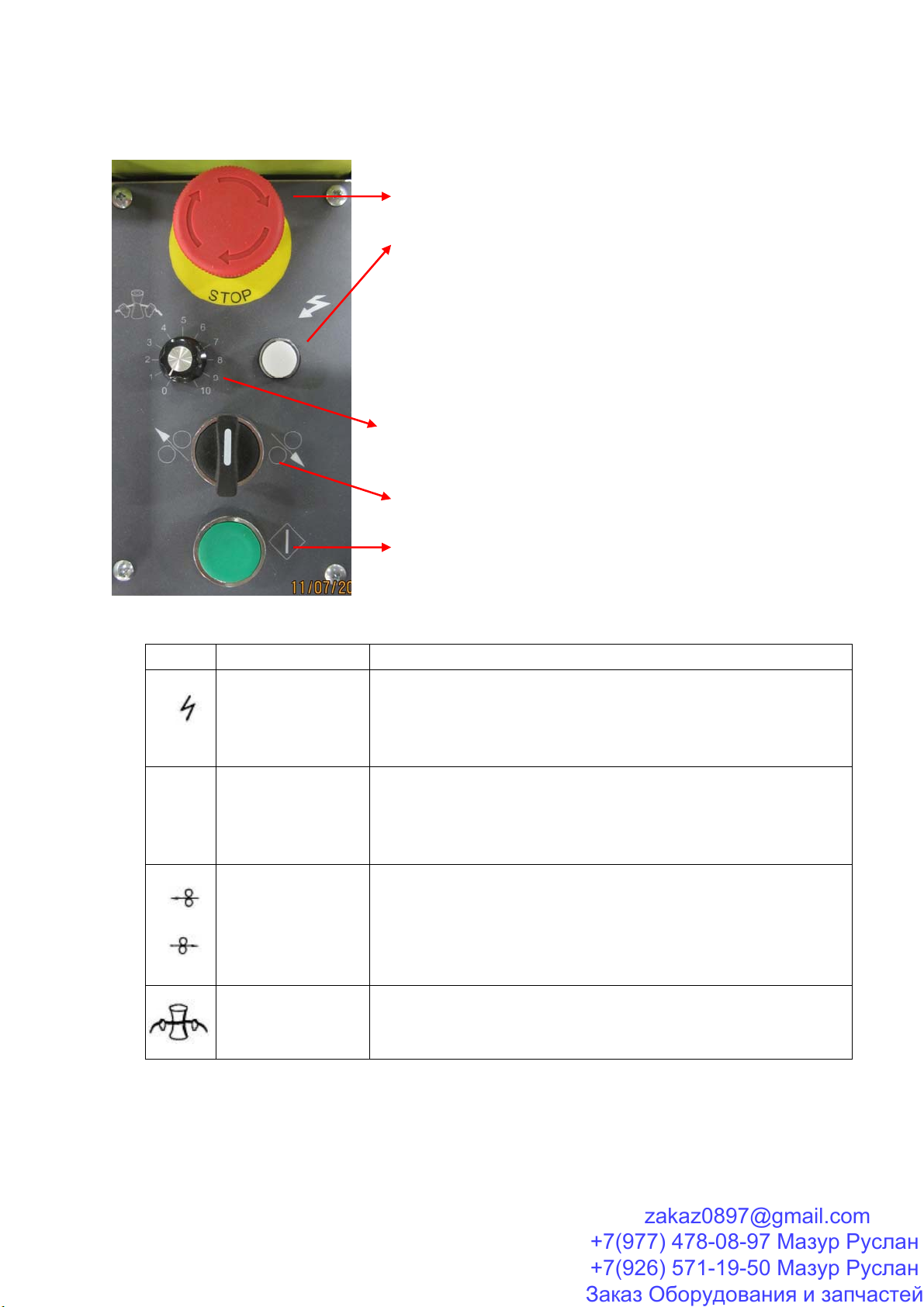

Chapter 5 Preparation for Operation

5-1 Connecting Electric Power

Power Switch

Power lamp

[Procedures]

Step [1] Press the power switch to turn the power OFF

Step [2] Insert the plug in the outlet.

Warning: If the earth grounding wire is not connected an operator may get hurt due to electric shock.

Step [3] Turn the power on by pressing the power switch. power lamp starts

[Notes]

The machine can start while the heater has reached the temperature for strap welding (about 1 Min.)

The machine may not operate when the power voltage ≤90%standard voltage

The following states occur just after power ON

Th

epowerlamplights

Setting the power switch ON The heater temperature starts increasing

Th

eductfanrotates

- 13 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

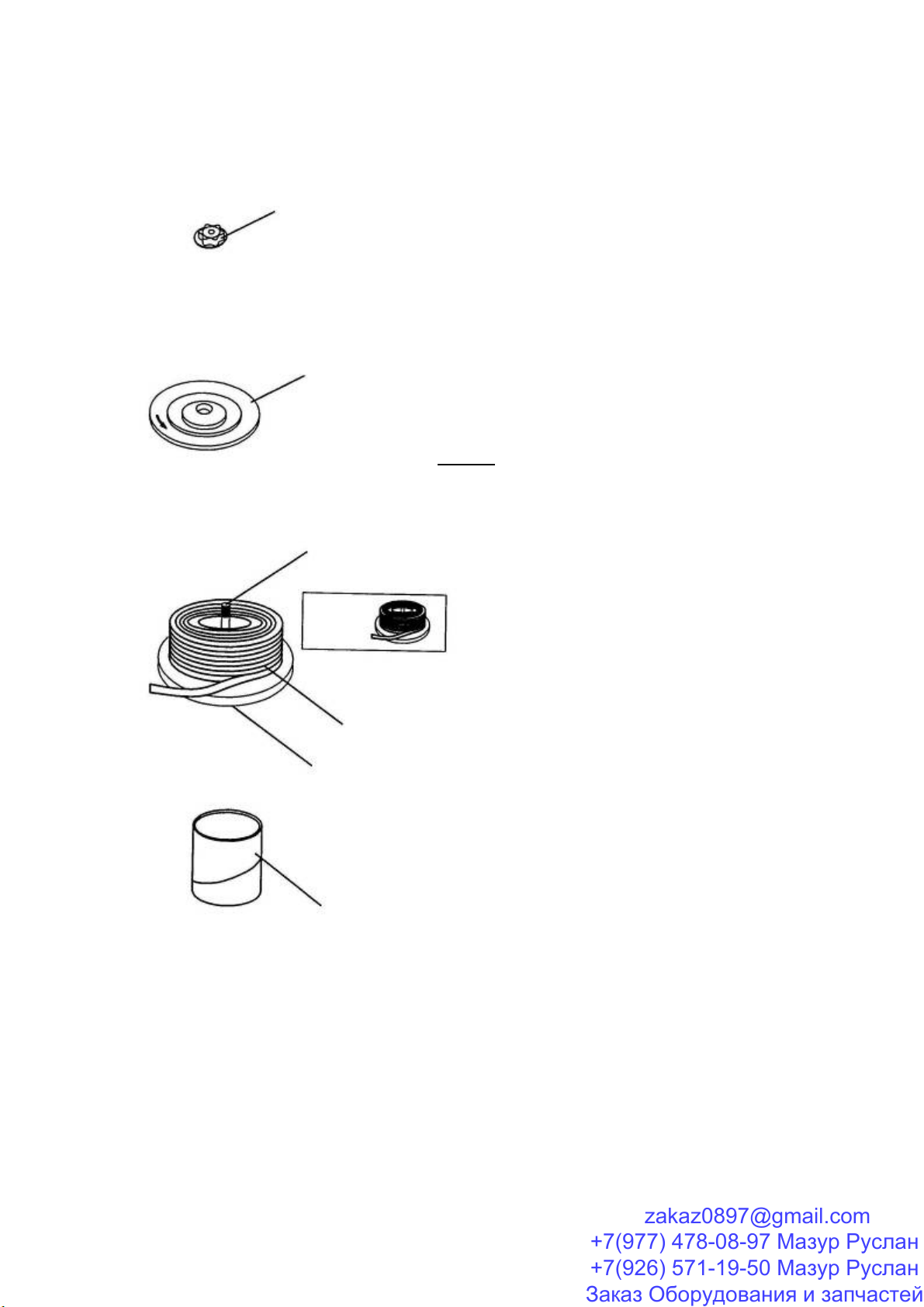

5-2 Setting Strap Coil

Thrust Nut [Procedures]

Step

[1]

Remove the thrust nut by turning it anti-clockwise and

remove the reel plate (left).

Remove the empty strap core.

Reel Plate (right) Step [2]

Fit a new strap coil in the reel plate (right). At this time,

set the coil in such a way that the strap winding

direction is clockwise.

Caution:

If the coil is set counterclockwise, re-set it, because the

reel brake does not work well at that way.

Reel Shaft

St

ep[3]

Fitthereelplate(left)inthereelshaft.

Step[4]

Finally,tightenthethrustnutstrongly.

Reel Plate (left)

Reel Coil

M

a

k

e sure

the strap

clockwise as

shown.

Strap Core

[Notes]

TO place the empty strap core under the reel place (left) make this job easier.

If the coil setting direction is wrong, the reel brake does not work well, and a normal operation is

not possible due to loose strap.

- 14 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

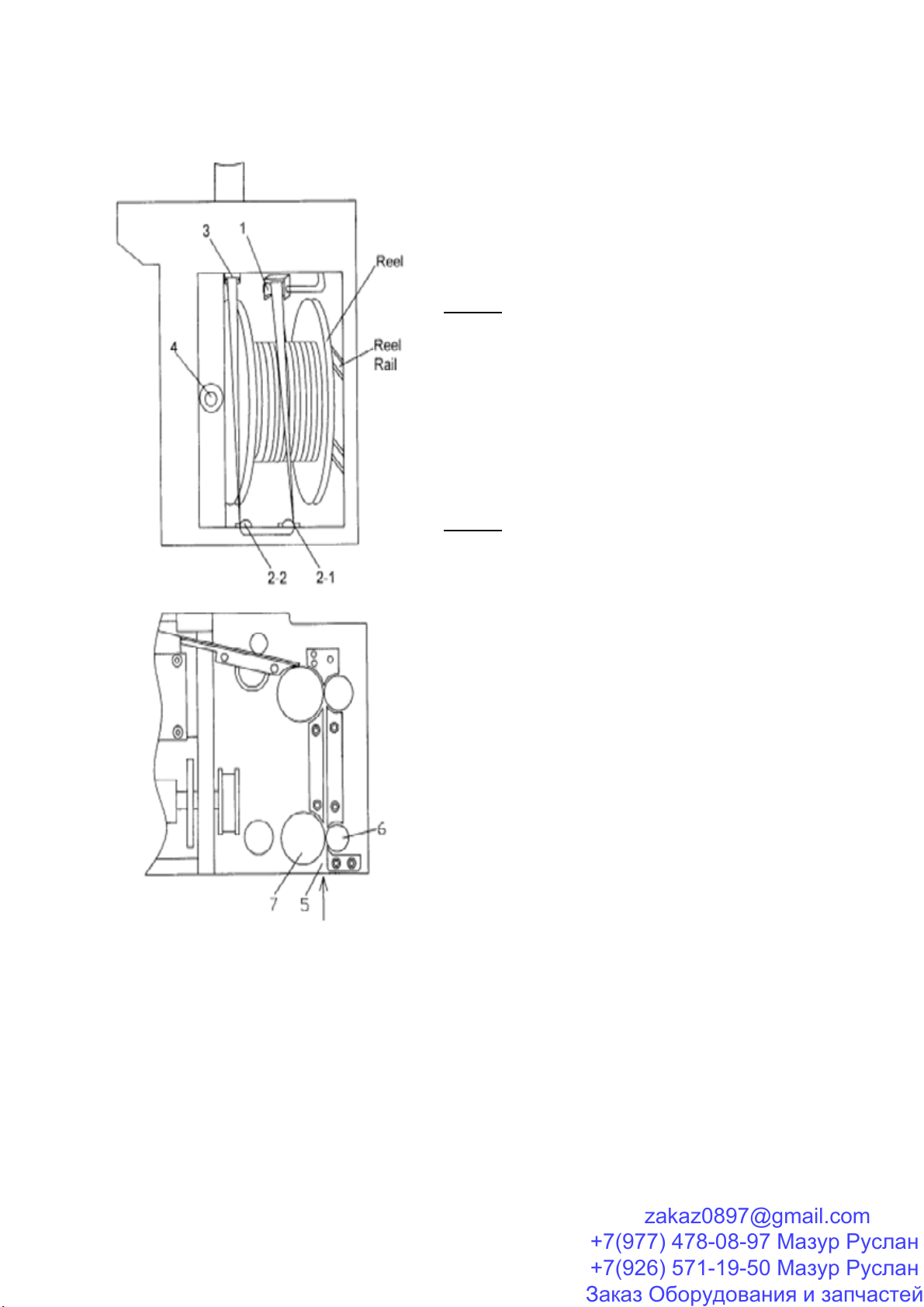

5-3 Thread of strap

[Procedures]

Step[1]

Place the reel onto the rail and push the reel, until

the reel shaft falls into the reel slot.

Caution : When putting the reel onto the rail, set it in

such a way that the strap end comes out up the reel.

Step [2]

Please install the P.P. strap through the brake

roller(1) then refer to the draft for installing the p.p. strap

through the free roller(2-1) and (2-2),then press the

lever(4) and insert the strap into the entrance (3) till it

reaches the pool unit.

Caution : If the strap end is split or bend, strap may

catch and block the machine side. At this time you

should cut the strap end, and then try to thread the

strap again.

Step [3]

Draw the end of pp strap in pool cabinet (refer to

FIG.10) and insert it into strap guide (5) through out

the roller(6) and (7) about 15mm.

Step [4]

Close the door and press the power button to make

the machine be ON.

Step [5]

Press the feed strap button and the strap is sent to

the arch fully.

[NOTE]

If the strap is not set to the arch properly, the strap is discharged out of the strapping automatically

Check the strap end, if the strap end is split or bent, cut it and reuse the procedures for threading

the strap into the entrance..

- 15 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

Chapter 6 Operation

[Procedures]

Step [1] Place the object on the center position of the sealing head.

If the object is light, it needs to be held while it is strapped. Please do not hold the place where

the strap is being put.

Step [2] Depress the start button. the strap will be put automatically on the object.

Do

not operate the machine if the heater can not reach temperature for welding

(About

1 Minute long for heater temperature rising)

Caution: The strap may hurt your hands if you do not wear gloves.

Step [3] the jammed strap is caught at pre-feed roller, pull out the strap and cut it, then set the strap as

the chapter 5-3.

Step [4] the buzzer will make a sound while the strap is empty from the reel coil

Chapter 7 Stop Operation

If it is necessary to stop the strapping during operation, press the power switch to off, the machine stops. To

restore the operation, do the following procedures.

[Restoration procedure]

Step [1] Grab the strap with the hand and pull it.

Step [2] Keeping this state, press the start button. The strap grabbed with the hand is discharged out of

the strapping and a new strap is set to the arch automatically

Step [3] Follow the procedures in chapter 6.

Chapter 8 Shutting Down

To shut down the machine, following the procedures are as below:

[Procedures]

Step [1] Press the power switch on “OFF”

Step [2] Disconnect the plug to the outlet.

Step [3] Wind back the strap from pool to the strap coil as follows.

(1) Pull up the brake lever with the left hand, then turn the

reel plate with the right hand in the direction of winding

the strap.

(2) When the reel plate being to turn heavy, stop winding back.

Caution: If too much strap is remained in the pool, trouble may occur when resuming strapping activity.

Step

[4] Cleaning

Cleaning is very important to prevent the machine from trouble and enjoy longer life.

Remove strap leftover, cut dust ect. stick to especially the sealer ect.

The details, contact us or your dealer.

Remarks: This machine is a non oiling type, you don’t have to make daily oiling.

-

- 16 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

Chapter 9 Repair and maintenance

(1) The maintenance of the machine shall be done only by people who has been authorized by distributor.

(2) Before maintaining the machine, cut off all power sources.

(3) Use appropriate tools and devices for maintenance and repair.

(4) Repair and maintenance should be conducted only by well-trained service persons.

Other Notes

(1) Do not touch the heater and surrounding area before they are fully cooled down.

The heater reaches about 380℃

(2) Install the machine on horizontal floor and keep the surrounding area free from dust and pieces of cut

off the strap.

(3) If there is any obscure point about the machine operation and the maintenance,

Please contact with the service engineer.

- 17 -

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

Chapter 10 Adjustment

Warning: Before adjusting portion of the machine, cut the power first, and then make adjustment after

receiving instructions

10-1 Adjustment of Heater Temperature

Turn the heater temperature knob to the right to increase the temperature and turn left to reduce the

temperature. Depending on the type and size of the strap, the heater temperature may need to be If the

temperature is too short, the strap can not be welded; on the contrary, the strap will be welded over and

break. (Please refer to the diagram on the right)

10-2 Adjustment of cooling Timer

The timer is to adjust the press cooling time for the strap welding portion. The time is set long by turning this

knob clockwise and set short by turning counterclockwise. The range of the time is 0-0.4sec. The standard

setting is in the scale 4(0.15sec.). If the time is too short, the strap will break when the tension is bigger.

10-3 Jog switch

When something wrong with the machine you could press this button to run the machine step by step to

analysis the problem.

10-4 Auto/manual switch

You can choose the mode by pressing the button to change the operation automatically or by hand

10-5 Adjustment of Strap-collected Length in the Pool

This is to adjust the length of the strap collected in

the pool with the prefeed roller. The length gets long

when loosening the bolt and moving back the

balance block. The length gets short when loosening

the bolt and moving ahead the balance block. The

length of the strap is according to the size of the arch.

If the length is too long, not only the strap will not be

Balance block

Bolt

- 18 - SwitchBalance bar

Supporting

point

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

feed/turned back smoothly, but also the strap will be

distorted; If the length is too short, one packing circle

can not be finished.

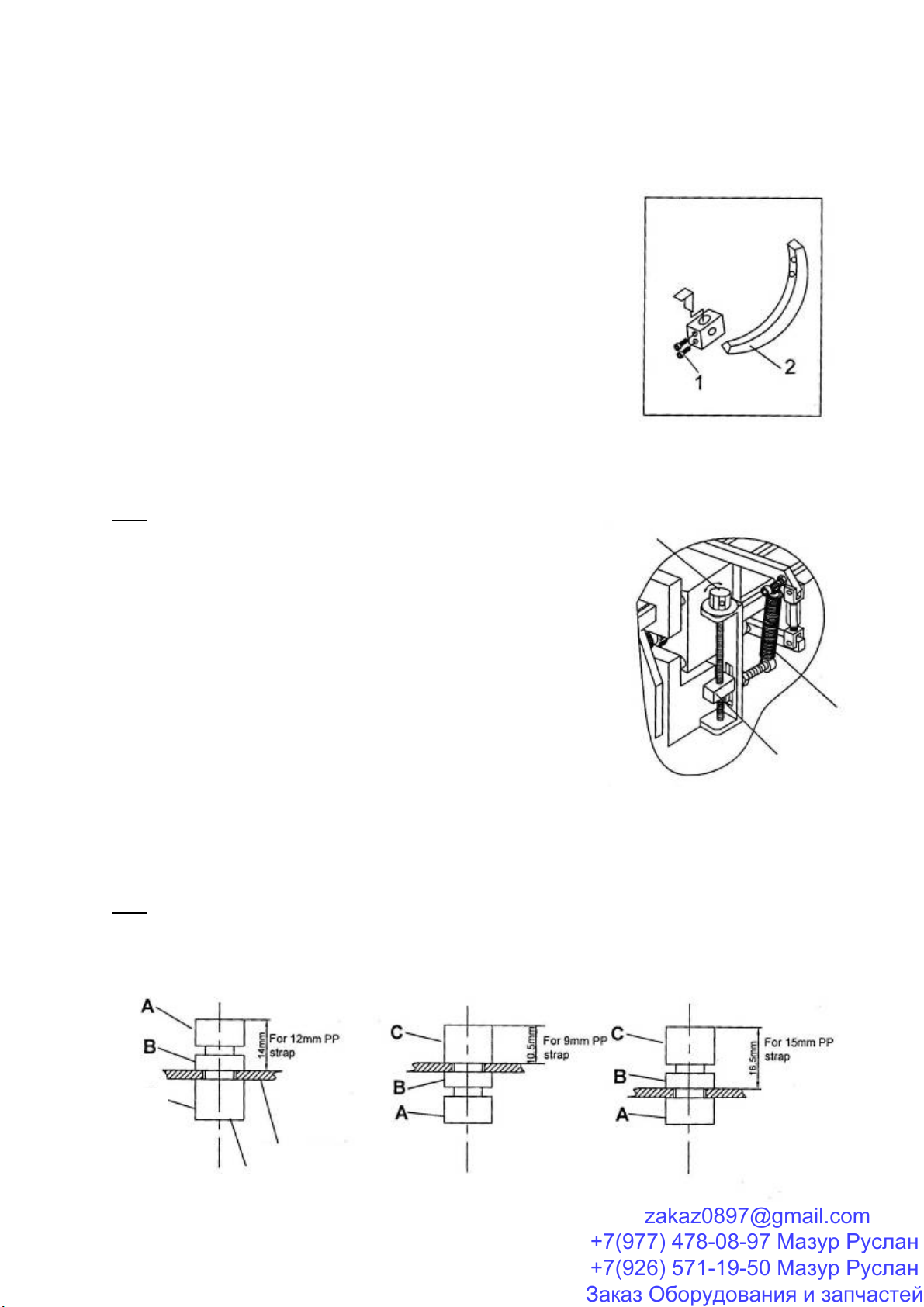

10-6 Reel Brake Adjustment

Loosen the bolts(1) and move the brake belt(2) to adjust the brake

belt stronger or weaker. When the strap becomes much loose on

the strap coil, change the position to tighten it.

10-7 Feed Roller Pressure Adjustment

To adjust the tension of the spring, rotate the knob to move the

position of the spring hook. Spring tension becomes weaker when

the knob is rotating clockwise, and it become stronger when the

knob is rotated anti-clockwise.

Note: Setting position depending on the type of strap, strap

thickness, air temperature (season) and other conditions. The user

may have a micro-adjustment. In common currency, the position is

set in the factory. If spring tension is too strong, strap will be

distorted because of over pressure. On the contrary, the end of the

strap can not reach the right position where the switch is sensed.

Knob

Spring hook

Feed tension spring

10-8 Position Adjustment

Refer to FIG. 10 POOL UNIT, you need change the position of the part item 11 and item 12 according to the

width of PP strap. You have to turn over the item 12 by 180℃from 12mm strap to 9mm or 15mm, and

change the position of the item 11 shown as follows:

Note: Please refer to FIG.9, you can loosen the screw NO.111 when you change the position of the item

11.Lock the screw tightly when you finish your setting.

C

- 19 -

Refer to FIG.9 item 11

Refer to FIG.9 item 12

+7(977) 478-08-97 Мазур Руслан

+7(926) 571-19-50 Мазур Руслан

Заказ Оборудования изапчастей

Table of contents