Semtronics SmartLog X3 62580 User manual

TB-6123 Revision 10/06

Page 1 of 12

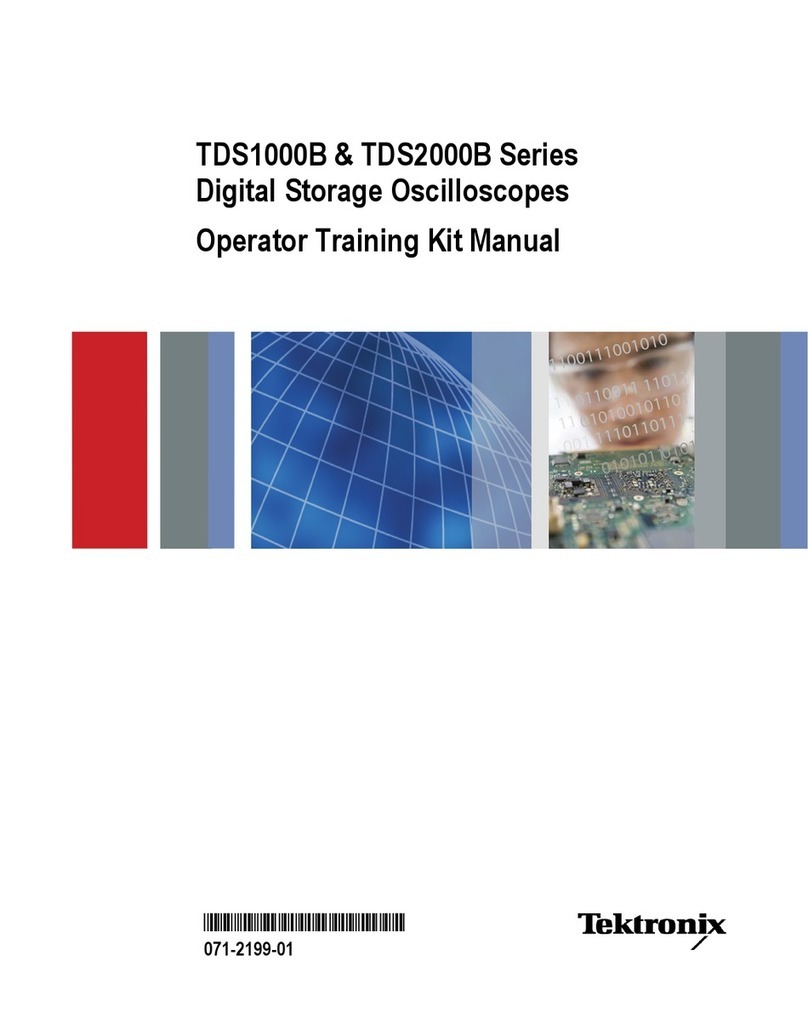

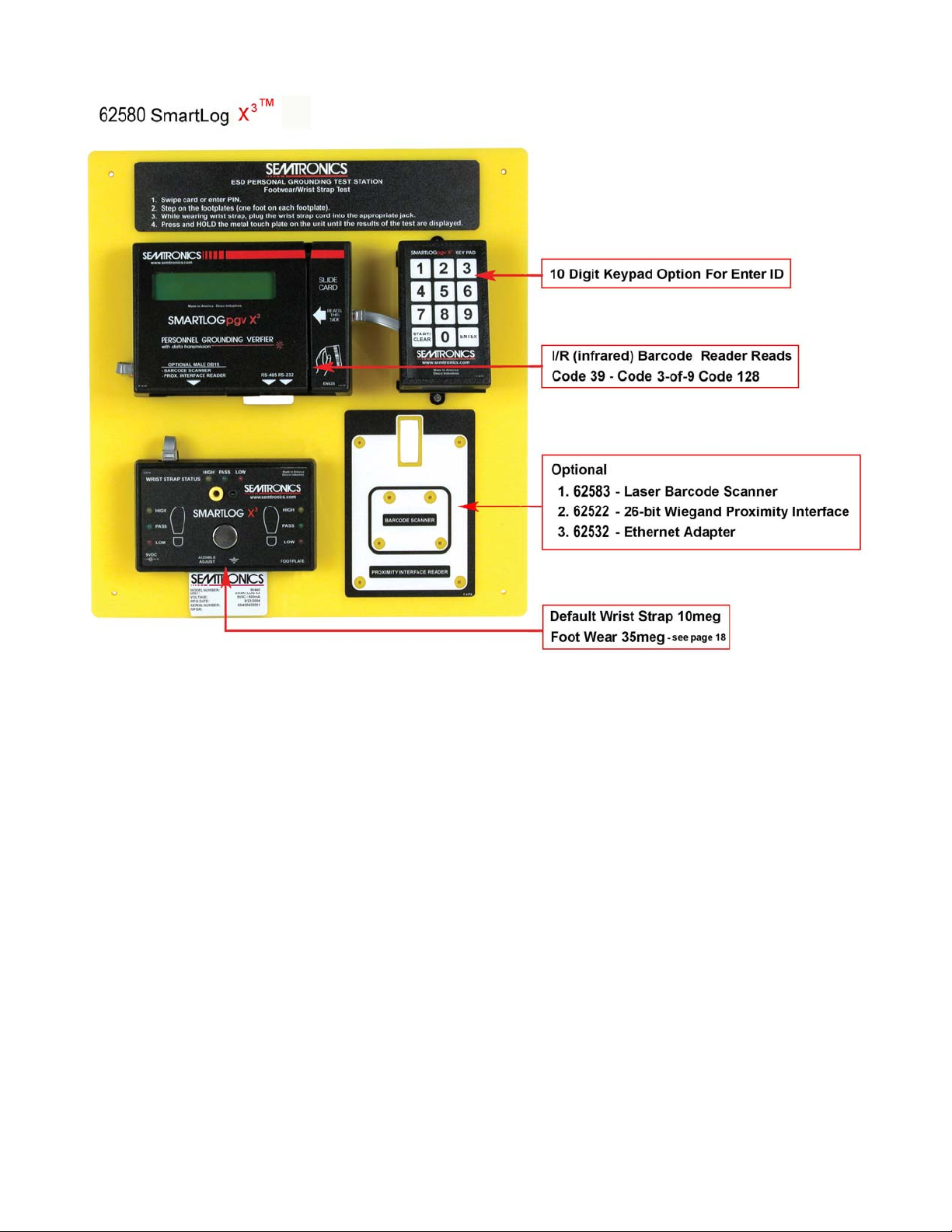

62580 SmartLogX3™

Wrist Strap and Footwear Tester

Automated ESD Record Keeping

Personal Grounding Verifier with Data Transmission

Hardware & Software Setup Instructions

For sales and Service in

North America contact:

ESD Systems.com

www.esdsystems.com

Phone: 508-485-7390

Fax: 508-480-0257

Corporate Office:

3651 Walnut Avenue,

Chino, CA 91710

Phone: (909) 627-8178

Fax (909) 627-7449

For sales and service in Europe and Asia

contact:

OK International - European Headquarters

Eagle Close, Chandlers Ford,

Hampshire, SO53 4NF U.K. England

http://www.okintl.com/locations

Tel: +44 (0)23 8048 9100

Fax: +44 (0)23 8048 9109

TB-6123 Revision 10/06

Page 2 of 12

Carefully unpack the Semtronics 62580 SmartLogX3™ wrist strap and footwear tester.

62580 SmartLogX3™ comes factory default and ready to install without any changes to clock’s

configuration. If a second SmartlogX3™ is being added or is going to be “Daisy-Chained”, refer to

next set of instructions for configuring clocks on a daisy-chain.

Note: Unit is not designed to work in high humidity environments where RH% is above 65 RH%.

Unpack and verify the following are included:

-1 SmartlogX3™ on yellow mounting plate with tester and keypad

-1 Dual foot plate

-1 Stereo cable for dual foot plate

-1 SmartlogX3™ 6.03 software

-1 AC adapter 12VDC 500mA center pos.

-1 DB9 serial adapter

-1 25” straight data cable

-4 mounting anchors

-4 mounting screws

TB-6123 Revision 10/06

Page 3 of 12

1. Configuration of Clocks Setting, Mounting and Cable Connection

Figure 1. Back Side of SmartlogX3™

A. Clocks Baud Rate, ID, Parity, Daylight Option and Port expand

Referring to Figure 1.

1. Plug the 120 volt AC power supply into the unit and then to the appropriate AC source.

Refer to Figure 1. to locate power input jack. The SmartLogX3™ will cycle through a self

diagnostic program. The time and date will appear on the screen when the diagnostics is

completed. Step 2 should not be performed until this is completed.

NOTE: If any of the below settings are not correct, press the Advance button

until the correct value appears on the display.

2. From the end of the self diagnosis, press the Menu button six times only (you’re giving a

20 sec limit to do so, or clock will need to be reset by disconnecting power adapter to re-

enter set-up menu). Refer to Figure 1 for Button locations.

3. Baud Rate should be set at 9600 (factory default). Press Enter for the next screen.

4. Parity should be set for ODD (factory default). Press Enter for next screen.

5. The SmartLogX3™ ID is a 2 digit field with valid I.D. number 00 through 63. Each

SmartLogX3™ should have a different I.D.# if on the same communication line. The

SmartLogX3™ should be numbered sequentially starting with 00, so that automatic

polling in the software will not be interrupted.

6. The Daylight Option is to enable daylight savings in the clock.

TB-6123 Revision 10/06

Page 4 of 12

7. Port expand should be set to yes (factory default).

8. Press Enter button once more to cycle to next setting before hitting Menu button to exit.

Note: Setting will not change if you don’t cycle to the next setting (by hitting the Enter

button).

B. Terminator Jumper, RS-485 Switch, RS-232 Switch and Relay Terminal

1. Terminator Jumper needs to be jumper only if clocks are in a daisy-chain. Jumper the

first SmartlogX3™ and the last SmartlogX3™ on the daisy-chain only. Stand alone

SmartlogX3™ does not need to be jumper.

2. RS-485 comes default on SLAVE position (right side) and does not need to be switched

unless unit is on a daisy-chain. For units on a daisy-chain set RS-485 to MASTER (left

position) for the first SmartlogX3™ (master clock) only.

3. Relay Terminal, The relay connections can be made on the back of the SmartLogX3™

(refer to figure 1) and can be used to control doors, gates, etc. The relay can hold a max

of 5A 250VAC/30VDC and 10A125VAC.

B. Cable Connections

Refer to Figure 2

1. IMPORTANT PC to First SmartlogX3™ Data Connection: Be sure to use the cable

provided inside box with unit. Connect the cable from the right port (RS-232) of the

SmartlogX3™ to the DB9 serial adapter connected to an open serial port on the PC

used. Cable is non-inverted and flat type when laid across table top if user desires to

make his/her own cable. Make sure cable is no longer than 50ft from the PC to the first

SmartlogX3™.

2. SmartlogX3™ to SmartlogX3™ Data Connection: These cables are different from the

cable supplied in the box with the SmartlogX3™. These cables are inverted and are the

same type of cables used in wiring of home telephones. Connect these cable to the left

port (RS-485) of first Smartlog™ to the left port (RS-485) of the second SmartlogX3™

only.

Note: No other clocks except the first clock (master clock) will use the right port (RS-

232), all other will connect through the left port (RS-485) in parallel, a RJ11 splitter will

be needed for daisy-chaining more than two units.

C. Mounting the SmartLogX3™And Scanner (Optional)

1. Mount SmartlogX3™at convenient location, makes sure to mount the SmartLogX3™ at a

height above the floor where all operators can see the display of the SmartlogpX3™ and

perform the necessary tests. Mount the barcode scanner to where all users are able to

reach the scanner. Use the anchor and screws provided with the SmartlogX3™.

TB-6123 Revision 10/06

Page 5 of 12

Figure 2. Data Cable Connections and Clock Settings

2. SmartlogX3™ Hardware

A. 10 Digit Key pad can be use to manually punch in ID badge number if no card is present.

Press CLEAR, enter ID number and press ENTER to start test.

B. Tester. Wrist strap test range is 1Meg to 10Meg Ohms. Footwear test range is 1Meg Ohms to

35Meg Ohms standard. SmartlogX3™ would have to be sent in to factory if test ranges is need

to be set differently. Tester test voltage is 12.0 VDC @ 0.40mA max for wrist strap and

footwear.

C. I/R Barcode Reader reads the barcode from the right hand side.

TB-6123 Revision 10/06

Page 6 of 12

TECHNICAL SUPPORT:

USA

Semtronics

3651 Walnut Avenue

Chino, CA 91710

Tel: (909) 627-8178

Fax: (909) 627-7449

NOTE: Unauthorized servicing or modifications to your monitor will void the product warranty and

may create dangerous conditions. Servicing should be performed only at the factory, or by a

Semtronics approved technician.

LIMITED WARRANTY

Semtronics expressly warrants that for a period of one (1) year from the date of purchase,

Semtronics 62580 will be free of defects in material (parts) and workmanship (labor). Within the

warranty period, a unit will be tested, repaired, or replaced at our option, free of charge. Call

Customer Service at 909-627-8178 (Chino, CA) or 781-821-8370 (Canton, MA) for Return Material

Authorization (RMA) and proper shipping instructions and address. Include a copy of your original

packing slip, invoice, or other proof of date of purchase. Any unit under warranty should be

shipped prepaid to the Semtronics factory. Warranty replacements will take approximately two

weeks.

If your unit is out of warranty, Semtronics will quote repair charges necessary to bring your unit up

to factory standards. Call Customer Service at 909-627-8178 for proper shipping instructions and

address. Ship your unit freight prepaid.

WARRANTY EXCLUSIONS

THE FOREGOING EXPRESS WARRANTY IS MADE IN LIEU OF ALL OTHER PRODUCT

WARRANTIES, EXPRESSED AND IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE WHICH ARE SPECIFICALLY DISCLAIMED. The express

warranty will not apply to defects or damage due to accidents, neglect, misuse, alterations,

operator error, or failure to properly maintain, clean or repair products.

LIMIT OF LIABILITY

In no event will Semtronics or any seller be responsible or liable for any injury, loss or damage,

direct or consequential, arising out of the use of or the inability to use the product. Before using,

users shall determine the suitability of the product for their intended use, and users assume all risk

and liability whatsoever in connection therewith.

TB-6123 Revision 10/06

Page 7 of 12

62100/62102

DUAL INDEPENDENT FOOTWEAR AND WRIST STRAP TESTER

Installation and Operating Instructions

The Semtronics Dual Independent Footwear and Wrist Strap Tester is designed to test personal

grounding devices, wrist strap and ESD footwear, to satisfy the requirements and the

recommendations of the ESD Association.

Per ANSI/ESD S20.20 Paragraph 6.2.2.2 Personnel Grounding Guidance “A log should be

maintained which verifies that personnel have tested their personal grounding devices. (Wrist

Straps and ESD Footwear)”

Per ESD- S1.1 paragraph 6.1.3 Frequency of Functional Testing “The wrist strap system should be

tested daily to ensure proper electrical value.”

Per ESD Handbook TR 20.20 paragraph 5.3.2.4.2 Additional User Wrist Strap Testing “Proper

testing of the wrist strap includes the resistance of the groundable point on the end of the cord, the

cord itself, the resistor, the cord-to cuff snap connector, the resistance of the interface of the cuff,

the cuff/wrist interface, and the resistance of the person between the wrist and the hand that

contacts the test electrode.”

Per ESD Handbook TR 20.20 paragraph 5.3.2.2.2 Wrist Strap Ground Cord “At first glance, the

ground cord appears to be a relatively simple assembly. However, the design requirements are

considerable, given the wide range of user applications and the durability requirements of constant

tugging, flexing, and dragging over the edge of workstation tops and equipment chassis.”

Per ESD SP9.2 Appendix B – Foot Grounder Usage Guidance

“Compliance verification should be performed prior to each use ( daily, shift change, etc.). The accumulation

of insulative materials may increase the foot grounder system resistance. If foot grounders are worn outside

TB-6123 Revision 10/06

Page 8 of 12

the ESD protected area, testing for functionality before reentry to the ESD protected area should be

considered.”

The test resistance limits for footwear and wrist strap tests are controlled by the DIP

switches inside the tester. For a configuration different than the default settings, remove the

unit from the sign, remove the back of the case, and reset the DIP switches inside the unit

as desired.

Footwear resistance range selection.

DIP switches 1 & 2 control the “HIGH” limit for the footwear test selection as follows:

Switch 1 Switch 2 High Limit Resistance

ON ON 10 Megohms (1 X 107)

OFF OFF 35 Megohms (3.5 X 107)DEFAULT SETTING

ON OFF 100 Megohms (1 X 108)

OFF ON 1 Gigohm (1 x 109)

*At 1 Gigohms high limit resistance, a dirty footplate could result in a false pass. When using this setting,

special care must be taken to keep the footplate clean.

DIP switches 3 & 4 control the “LOW” limit for the footwear test selection as follows:

Switch 3 Switch 4 Low Limit Resistance

ON OFF 100 Kilohms (1 X 105)

OFF ON 1 Megohms (1 X 106) DEFAULT SETTING

OFF OFF 10 Kilohms

The “Optional” settings allow the use of custom resistance values when installed.

Wrist strap test option selection.

DIP switch 5 must be “ON” (DEFAULT SETTING) for the wrist strap test to be active. If the

wrist strap test is disabled by DIP switch 5 being “OFF”, the 3 LEDs for this test will remain “OFF”

at all times.

The “LOW” limit for the wrist strap test is set to 1 Meghms and can not be changed by the user.

DIP switch 6 in the “ON” position (DEFAULT SETTING - USA) sets the “HIGH” limit for the

wrist strap test to 10 Megohms (107). DIP switch 6 in the “OFF” position (DEFAULT

SETTING – EUROPE) sets the “HIGH” limit for the wrist strap test to 35 Megohms (3.5 X

107).

TB-6123 Revision 10/06

Page 9 of 12

Installation

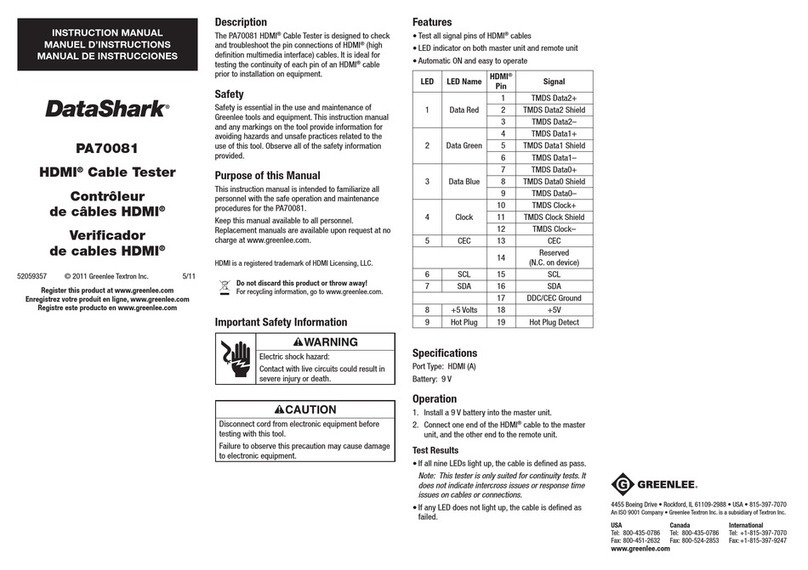

Insert one stereo plug of the 62103 Stereo Plug to Stereo Plug into the stereo jack on the bottom

of the tester. (See Figure 1.) Insert the other end of the stereo plug into the stereo jack at the

back of the foot plate. Verify that both plugs are fully inserted and tight.

Pin 1 Pin 2 Pin 3 Alarm Adjustment Connect stereo wire to footplate

1 & 2: closed/on standby

2 & 3: opened/on standby

2 = com

A relay with both “normally open” and “normally closed” contacts is included for your

convenience. The terminal block on the bottom of the tester has terminals for “normally

closed,” “common,” and “normally open” going from left to right. (See Figure 1.)

Operation

Pushing the touch plate on the front panel starts the test. During the test all LEDs will be

“OFF” to indicate that a test is in progress. The touch plate must remain depressed until

the test results are displayed. Depending on the configuration of the tester, the test could

require up to three (3) seconds.

The resistance is checked from the touch plate to the corresponding foot plate for each foot

and from the touch plate to the wrist strap connector jacks through the operator. A wrist

strap must be plugged into the appropriate jack before the touch plate is depressed if the

wrist strap option is activated. (See “wrist strap option selection” on page 2 above.)

The 62100/62102 can test both single and dual wrist straps. Single wrist straps are plugged

into the banana jack on the left side of the tester. (See Figure 2.) Dual wrist straps are

plugged into the phono jack on the left side of the tester. (See Figure 2.) The phono jack

(dual wrist strap) is above the banana jack (single wrist strap). Automatically determines

what type of wrist strap is being tested.

The LEDs will turn off while the test is in progress; the test results for each foot and wrist

strap will then be displayed for approximately three (3) seconds. If all test results are

“SAFE” the internal relay will be activated while the test results are displayed. The relay can

be used for opening an electric lock to an ESD sensitive area. The maximum contact rating

is: 1A@30VDC. 0.3A 110VAC, 0.5A 125VAC.

TB-6123 Revision 10/06

Page 10 of 12

If any of the test results are failed “HIGH” or “LOW” an audible alarm will sound. The LED(s)

indicating the failed test will be displayed for approximately three (3) seconds, and the internal

relay will not activate.

CALIBRATION AND PERIODIC TESTING:

The accuracy is specified as:

1. +5% for 1 Megohms and lower resistance ranges.

2. +10% for 1 Megohms and higher resistance ranges.

Does not require calibration and cannot be calibrated.

A periodic check (once every 6 to 12 months) using a precision resistance box should be

performed to verify proper operation.

A limit comparator, the 62080, can be purchased for the convenient periodic.

The 62080 contains 14 standard resistors to check the following high and low limit ranges:

1. 10K low

2. 10K safe

3. 100K low

4. 100K safe

5. 1M low

6. 1M safe

7. 10M safe

8. 10M high

9. 35M safe

10.35M high

11.100M safe

12.100M high

13.1G safe

14.1G high

TESTING PROCEDURE:

Wrist strap operation test.

1. Insert the 62080/62100/62102 test plug into the dual wrist strap connector on the

62100/62102.

2. Select the “1M low” range on the rotary switch of the 62080/62100/62102.

3. Press and hold the touch plate of the 62100/62102 until the test is completed. The results of

the test should be “fail low” for the wrist strap.

4. Select the “1M high” range on the rotary switch of the 62080/62100/62102 and repeat the

test. The results of the test should be “pass” for the wrist strap.

TB-6123 Revision 10/06

Page 11 of 12

5. Select the “10M safe” or “35M safe” setting, whichever one is appropriate, on the

62080/62100/62102 and repeat the test. The results of the test should be “pass” for the

wrist strap.

6. Select the “10M high” or “35M high” setting, whichever one is appropriate, on the

62080/62100/62102 and repeat the test. The results of the test should be “fail high” for the

wrist strap.

Footwear operation test.

1. Insert the 62080/62100/62102 test plug into the foot plate cable connector on the

62100/62102.

2. Select the appropriate “fail low” range on the rotary switch of the 62080/62100/62102.

3. Press and hold the touch plate of the 62100/62102 until the test is completed. The results of

the test should be “fail low” on both feet.

4. Select the appropriate “safe low” setting on the 62080/62100/62102 and repeat the test. The

results of the test should be “pass” on both feet.

5. Select the appropriate “safe high” setting on the 62080/62100/62102 and repeat the test.

The results of the test should be “pass” on both feet.

6. Select the appropriate “fail high” setting on the 62080/62100/62102 and repeat the test. The

results of the test should be “fail high” on both feet.

TB-6123 Revision 10/06

Page 12 of 12

TECHNICAL SUPPORT:

USA Europe

Semtronics Charleswater

3651 Walnut Avenue Unit 17, Millbrook Business Park, Sybron Way

Chino, CA 91710 Crowborough, East Sussex, TN6 3JZ, U.K.

Tel: (909) 627-8178 Tel: 01892 665313

Fax: (909) 627-7449 Fax: 01892 668838

LIMITED WARRANTY

Semtronics expressly warrants that for a period of one (1) year from the date of purchase, Semtronics

62100/62102 will be free of defects in material (parts) and workmanship (labor). Within the warranty

period, a unit will be tested, repaired, or replaced at our option, free of charge. Call Customer Service at

909-627-8178 (Chino, CA) or 01892 665313 (Crowborough, U.K.) for Return Material Authorization (RMA)

and proper shipping instructions and address. Include a copy of your original packing slip, invoice, or other

proof of date of purchase. Any unit under warranty should be shipped prepaid to the Semtronics factory.

Warranty replacements will take approximately two weeks.

If your unit is out of warranty, Semtronics will quote repair charges necessary to bring your unit up to

factory standards. Call Customer Service at 909-627-8178 for proper shipping instructions and address.

Ship your unit freight prepaid.

WARRANTY EXCLUSIONS

THE FOREGOING EXPRESS WARRANTY IS MADE IN LIEU OF ALL OTHER PRODUCT WARRANTIES,

EXPRESSED AND IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE WHICH ARE SPECIFICALLY DISCLAIMED. The express warranty will not apply to defects or

damage due to accidents, neglect, misuse, alterations, operator error, or failure to properly maintain, clean

or repair products.

LIMIT OF LIABILITY

In no event will Semtronics or any seller be responsible or liable for any injury, loss or damage, direct or

consequential, arising out of the use of or the inability to use the product. Before using, users shall

determine the suitability of the product for their intended use, and users assume all risk and liability

whatsoever in connection therewith.

Table of contents