VII Brief introduction of Mechanism

performance

The hardness gauge consists of a fuselage, a test force applying mechanism,

a measuring indicator mechanism and a test piece support mechanism (see figure

1). The fuselage is a closed shell. Except for the table, the lead screw and the

handling handle, the other mechanisms are all installed in the fuselage shell to

keep clean.

The test force exerting mechanism consists of spindle, lead screw, blade,

weight buffer, weight transform mechanism, handle and so on.

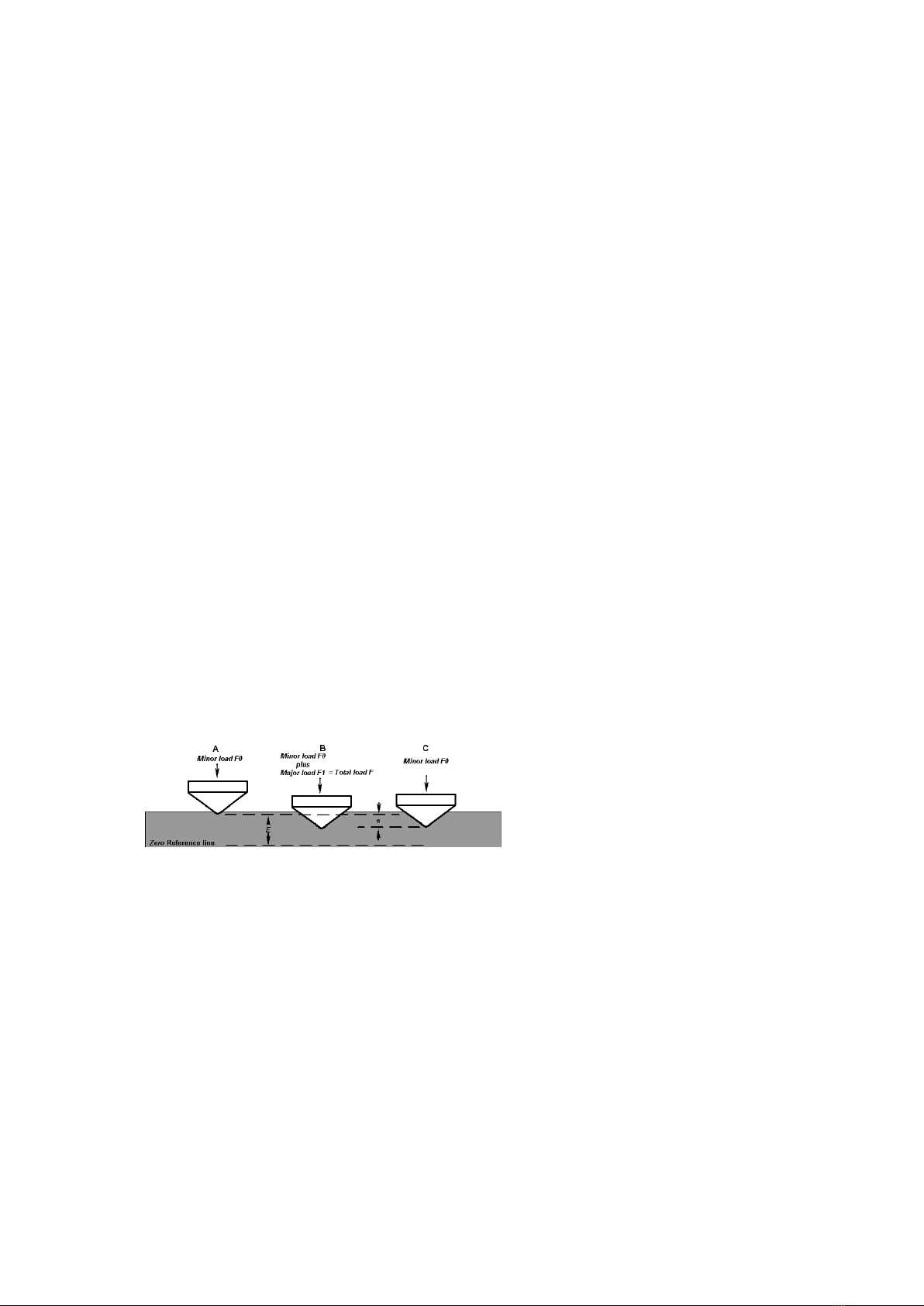

The initial test force is mainly caused by the weight of parts such as spindle

(1) circular knife (2) long diamond knife (3) large lever (4) and small lever (21)

and the measuring pressure of indicator (24). When the specimen is in contact

with the pressure head and continues to rise so that the large and small lever is in

the horizontal position (indicator small pointer refers to Yu Hong point, the large

pointer is vertical up) due to the weight of the lever, etc., and the measuring

pressure of the indicator, The head can be subjected to (10kg) 98.07N of the

initial test force.

The total test force is composed of the main test force (generated bythe

weight of the weight) plus the initial test force, and two weights (10) and a hanger

ring (11) are arranged on the rack shaft (8) of the buffer (7). When the piston of

the buffer is lowered by the pull handle (15), the rack shaft (8) top rod (9) and

the hanger ring (11) weight (10) are also lowered with the pull handle (15), The

weight of the weight (10) and the ring (11) acts on the large lever (4) so that the

head is subjected to the total test force.

The fuselage is equipped with a weight variable load frame (12). When the

handle (13) is rotated to different positions, three different total test forces of

1471N or 980.7N or 588.4N can be obtained.

The oil needle (14) is used to apply the main test force to maintain a certain

speed and to avoid the impact phenomenon.

The handle (15) is used to apply the main test force, and the handle (16) is

used to remove the main test force. When the handle (15) is pulled, the cam (17)

and the gear (19) begin to rotate, and the rack shaft (8) push rod (9) and the

buffer piston fall with each other, At the same time, the handle (16) is rotated

8