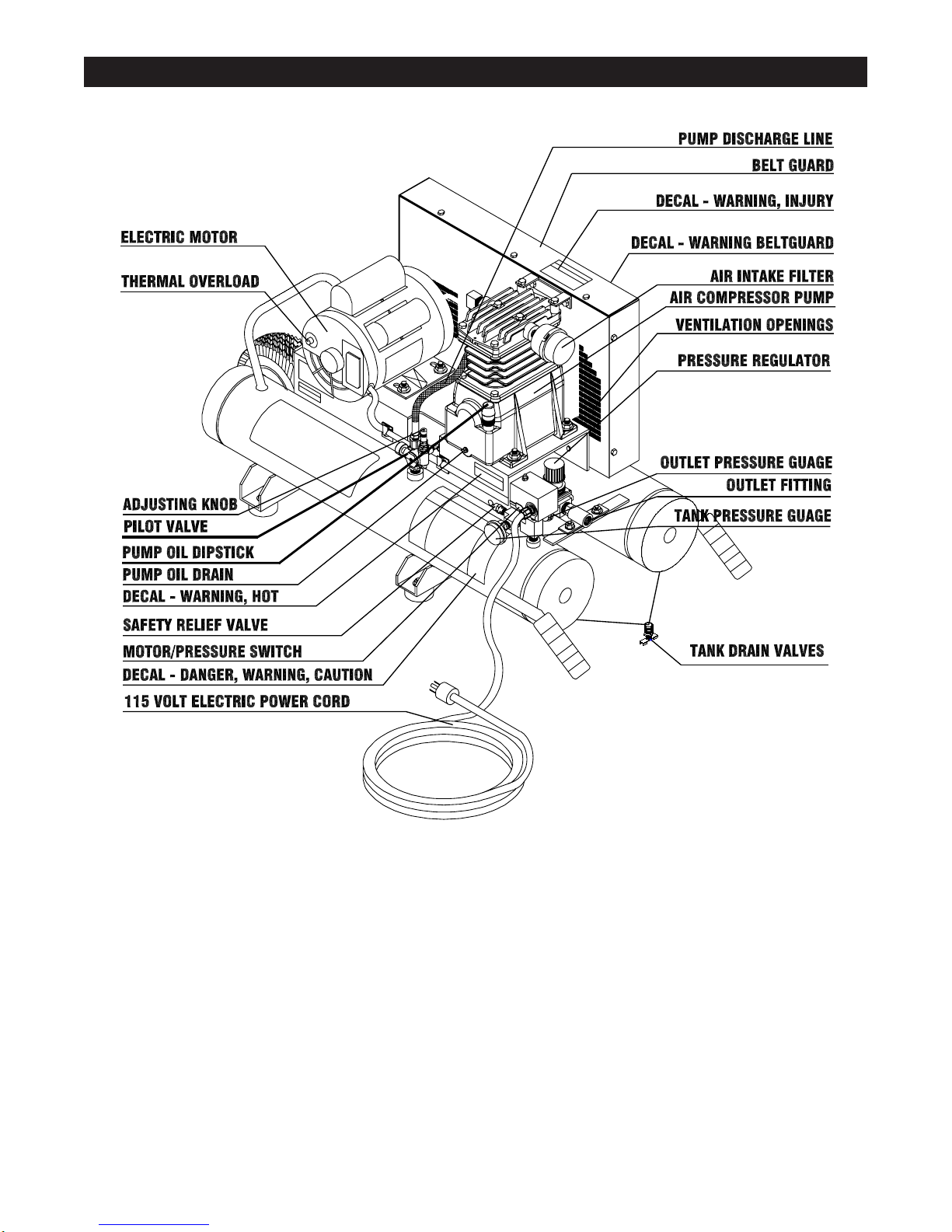

Senco®Electric Air Compressor Manual 2003 9

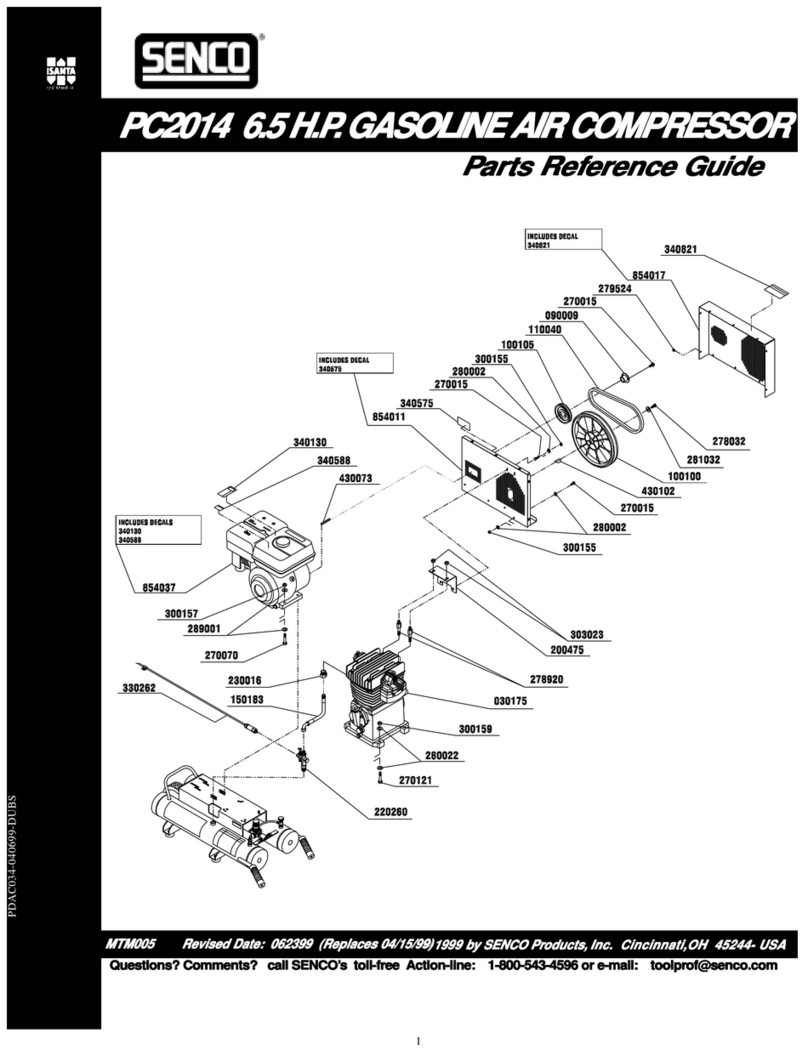

MOTOR/PRESSURE SWITCH:

This switch is used to start or stop

the air compressor. Moving the

switch to the "Auto" (On) position

will provide automatic power to the

pressure switch which will allow

the motor to start when the air tank

pressure is below the factory set

"cut-in"pressure. WhenintheStart/

Stop Option, the pressure switch

stops the motor when the air tank

pressurereachesthefactorset"cut-

out"pressure. Forsafetypurposes,

this switch also has a pressure

releasevalvelocated on the sideof

the switch designed to automati-

cally release compressed air from

the air compressor pump head and

its discharge line when the air com-

pressor reaches "cut-out" pressure

or is shut off. This allows the motor

to restart freely. Moving the switch

to the "Off" position will remove

power from the pressure switch

and stop the air compressor.

MOTOR THERMAL OVERLOAD:

The electric motor has a manual

thermal overload protector. If the

motoroverheats for anyreason,the

thermal overload will cut off power,

thus preventing the motor from be-

ing damaged. Wait until the motor

is cool before pressing the thermal

overload button to reset and begin

working again.

AIR INTAKE FILTER: This filter is

designed to clean air coming into

the pump. To ensure the pump

continually receives a clean, cool,

dry air supply this filter must always

be clean and ventilation opening

free from obstructions. Replace fil-

ter when necessary.

AIR COMPRESSOR PUMP: To

compress air, the pistons move up

and down in the cylinders. On the

downstroke, air is drawn in through

the air intake valves while the

exhaust valves remain closed. On

the upstroke, air is compressed,

the intake valves close and com-

pressed air is forced out through

the exhaust valves, into the dis-

charge line, through the pilot valve

and into the air tank.

PILOTVALVE: Whentheadjust-

ing knob is turned completely

clockwise to the fully closed po-

sition, the air compressor oper-

ates in the Start/Stop Option.

When the adjusting knob is

turned completely counterclock-

wise to the fully open position,

the air compressor operates in

the constant run position.

SAFETY RELIEF VALVE: This

valve is designed to prevent

system failures by relieving

pressure from the system when

the compressed air reaches a

predetermined level. The valve

is preset by the manufacturer

and must not be modified in any

way. Toverifythevalveisworking

properly, pull on the ring. Air

pressure should escape. When

the ring is released, it will reseat.

AIR TANK DRAIN VALVE: The

drain valve is used to

remove moisture from the air

tank(s) after the air compressor

is shut off. NEVER attempt to

openthedrainvalvewhenmore

than10 PSI of airpressureis in

the air tank! To open the drain

valve,turntheknobcounterclock-

wise.

AIRTANKPRESSUREGAUGE:

The air tank pressure gauge

indicates the reserve air pres-

sure in the air tank (s).

PRESSUREREGULATOR: The

air pressure coming from the air

tankiscontrolledbytheregulator

knob. Turn the pressure regula-

tion knob clockwise to increase

discharge pressure, and coun-

terclockwise to decrease dis-

charge pressure.

OUTLET PRESSURE GAUGE:

The outlet pressure gauge indi-

cates the air pressure available

at the outlet side of the regulator.

This pressure is controlled by

the regulator and is always less

or equal to the air tank pressure.

OIL DIPSTICK: The dipstick will

register the amount of oil in the

pump. Oil level should be

checked on a daily basis to en-

sureitdoes not exceedthe maxi-

mumnotch orfall below the mini-

mum notch on the dipstick

PC2016 FEATURES REVIEW