Sencon 487 Series User manual

1

© 2020

Sencon’s 11-487-00 Short Can Sensor can be used to replace the following sensors: 9-287-03, 11-287-63, 11-287-33,

11-287-53, 9H-387-56, 11-387-S1.

The 11-487-00 is a direct replacement for some of the sensors above while others will require a wiring change in the

bodymaker.

Current Sensor

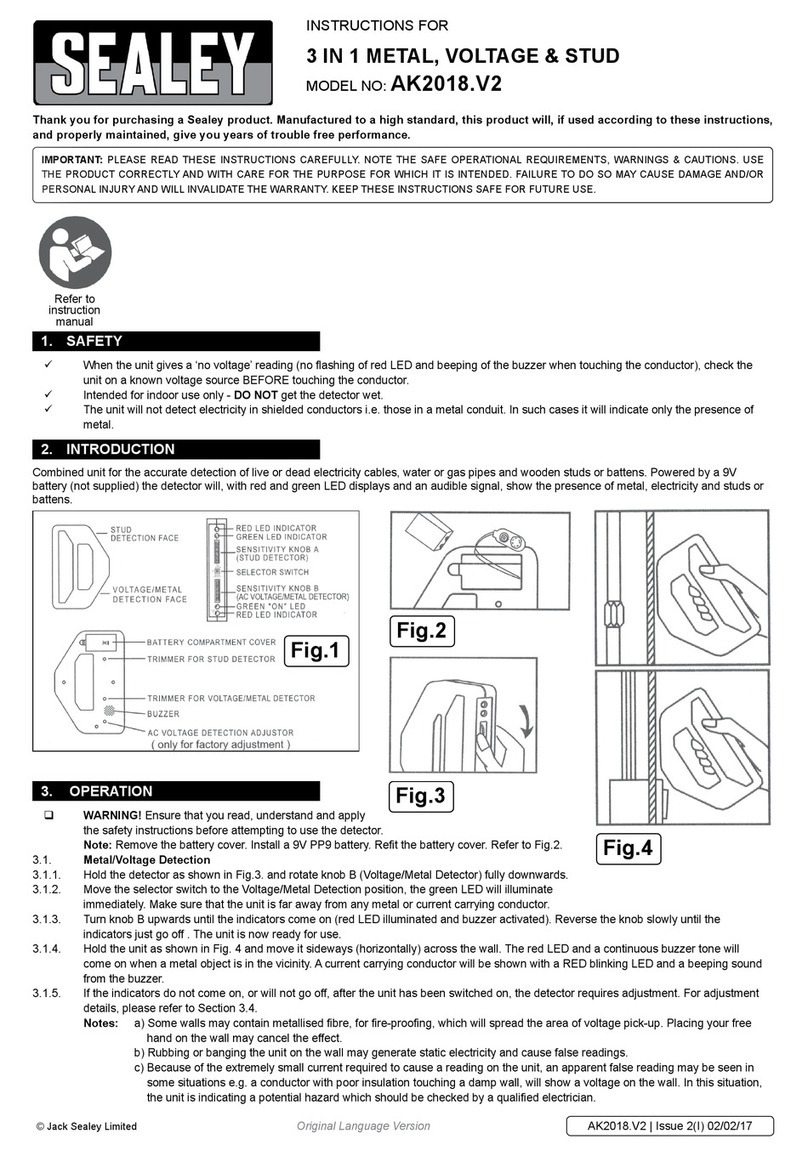

9-287-03 or 11-287-63 Direct swap -See wiring diagram Fig:1 or Fig:2 22-487-03/63 (default)

11-287-33 or 11-287-53 Direct swap -See wiring diagram Fig: 1 or Fig:2

387 Sensor interfaced to a

BCM387 module

Remove BCM387 module,

Wire 487 directly to bodymaker’s PLC Fig: 1 or Fig:2

Depends on the type of punch

being used see punch chart below.

387 Sensor interfaced to a

BCM500 module

Wire 487 sensor to BCM500

module as per diagram Fig:3

Depends on the type of punch

being used see punch chart below.

The SENCON 11-487-00 is a self-contained metal

discriminator proximity switch; an excellent choice for

can line machine control. The sensor detects wall-ironed

aluminum over carbide tooling and is designed to act as

“short can” detector to protect the tooling in wall ironing

machines.

The integral electronics interface directly with

discrete logic or computer controlled systems and

are encapsulated inside an all metal housing. This

humidity. Thermal stability and repeatability provide reliable

performance over a wide temperature range.

current punch types.

487 Short Can Sensor guide

Short Can Timing Window

The short can window dictates when the sensor’s output is

sensor is 100% covered by the punch at around 1350

the top of the can just starts to uncover the sensor at 1550

this depends on the height of the can body, and is typically

between 1550and 1650.

displayed from the control system.

Contents

....1

.......1

Punch Assessment ..............2

...........3

.............5

Introduction to the 487 sensor

PC Client Interface ..............6

...........7

................9

.....................9

.......10

2

© 2020

These punches use various binder materials (most

commonly nickel and cobalt) as well as other elements

such as chromium and iron to obtain the desired

carbide punches requires loading the appropriate Punch

materials.

unknown, a common hobby or kitchen magnet can also be

strength.

binder carbides such as Vista VM-NM12, Sandvik C9M/385 are

The 22-487-33/53 is the correct PDP for this material.

22-487-33/53 PDP is the correct choice for this material.

The 22-487-03/63 is the correct PDP for this material.

•

•

•

* PDP SELECTION TO MATCH PUNCH TYPE

22-487-03/63 (Default PDP)

22-487-33/53

22-487-33/53

Punch Assessment

3

© 2020

Push Button Operation

•

•

• The next available PDP in memory will be selected.

•

PDP memory number that was switched to.

i.e. 2 blinks equals memory 2.

•

•

•

•

•

•

•

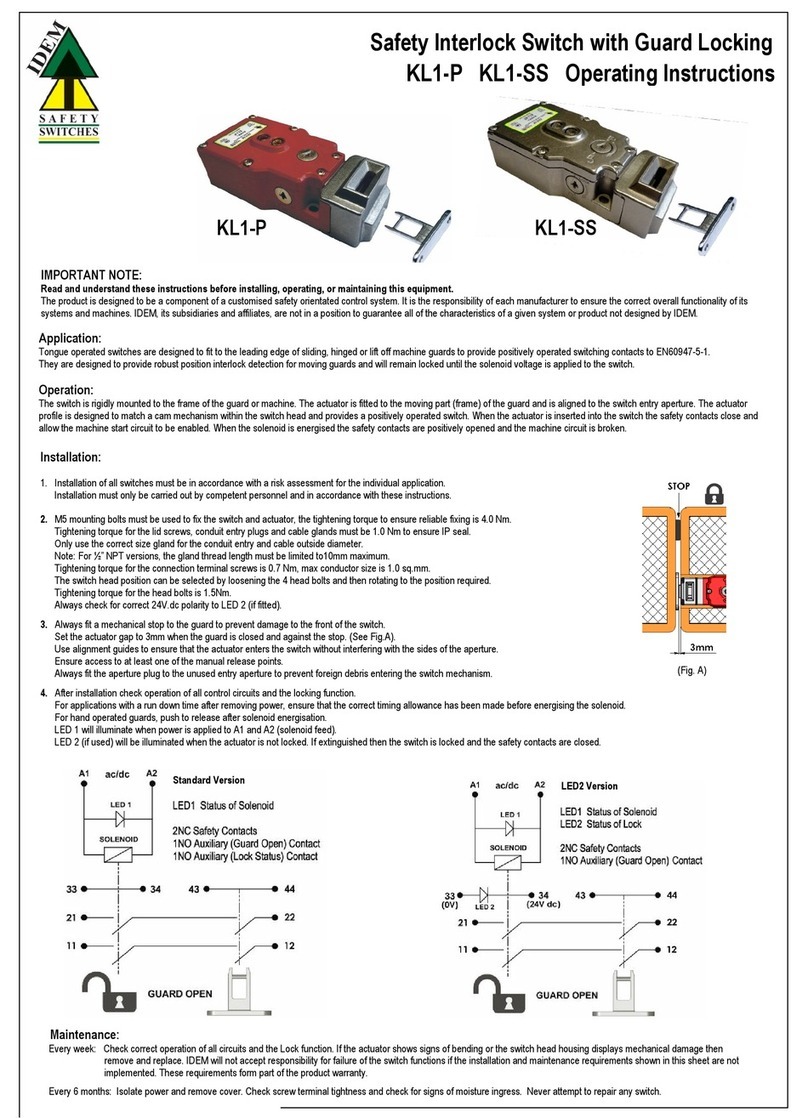

While the switch contacts SS-1, PB-1 could be physical switches they

could also be PLC outputs. Bear in mind these PLC outputs would

Fig: 1

4

© 2020

11-487-00 Sensor wiring to a

Fig: 2

Fig: 3

Murrelektronik

54040

Murrelektronik

54040

to 2x7 mode.

Techinfo.

5

© 2020

The Sencon PC software can achieve the following:

•

•

•

• Show which PDPs are stored in the sensor’s memory.

•

•

Installation and set up of the PC Client software

•

• Double click on the setup.exe

•

PC Client Installation

• You will also need to install

converter you are using. This

will be available on the CD

that came with the converter.

•

converter to the PC you need

to change the default driver

• Select Windows Device

Manager (via Control Panel –

• Change is Latency Timer from

16mS to 1mS.

• Note which COM port is

selected as this needs to

be entered into the Client

•

double clicking on the desktop

icon Sensor487.exe

• When the Client starts you

need to select the same COM

above.

6

© 2020

Activate a PDP

•

•

•

window.

•

window.

•

Punch Optimization

punch in front of the sensor.

•

distance from the punch. 0.060-0.080” [1.52-2.03 mm]

• Bar the press to the point where the punch is in front

window.

0 and ends at 1550,

bar the press to 1450.

•

Adding PDP

• PDPs can only be added to the sensor via the Windows

•

•

•

Change PDP via Windows PC software

• PDPs may also be selected by using the Windows

• To switch to a loaded PDP simply press the “Play”

This is shown below.

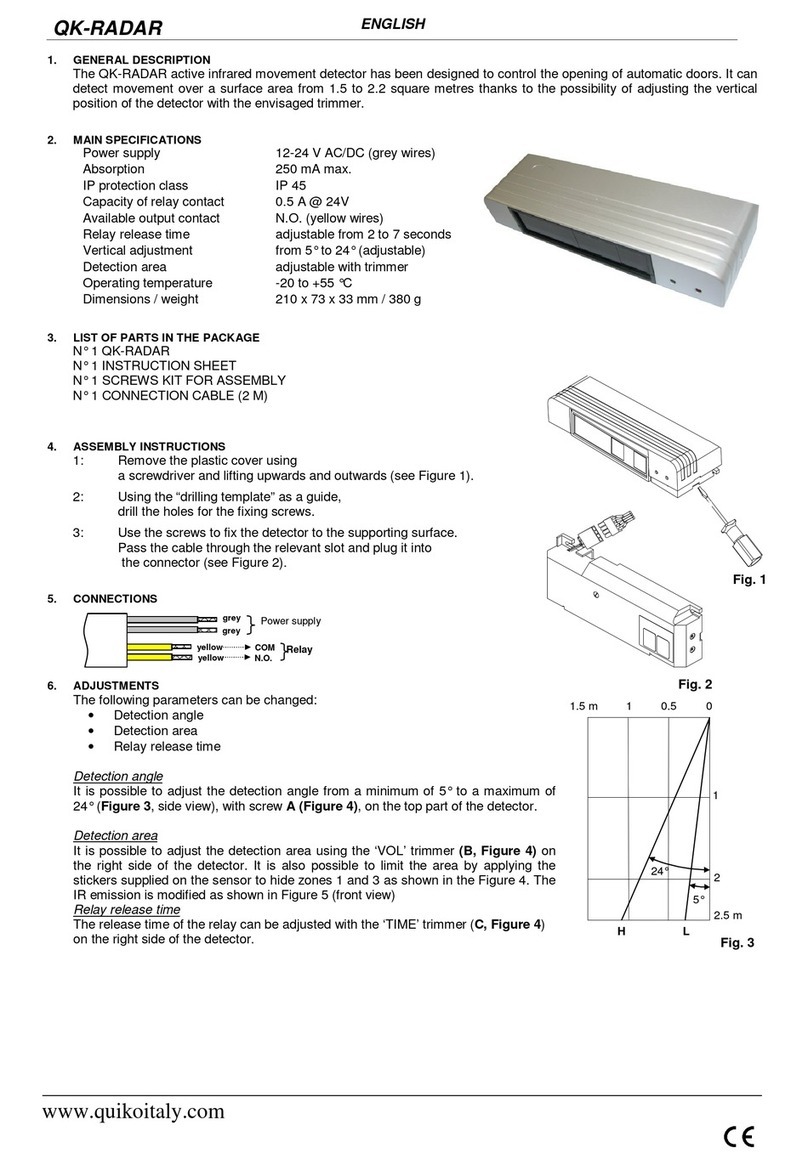

Sensor PDPs

This area shows which

PDPs are available for

Local PDPs

This area shows which

PDP’s are stored on

the PC folder

“C:/Sencon/Packages”

PC Client Interface

This area shows which PDPs

are installed in the sensor.

Sensor status area

7

© 2020

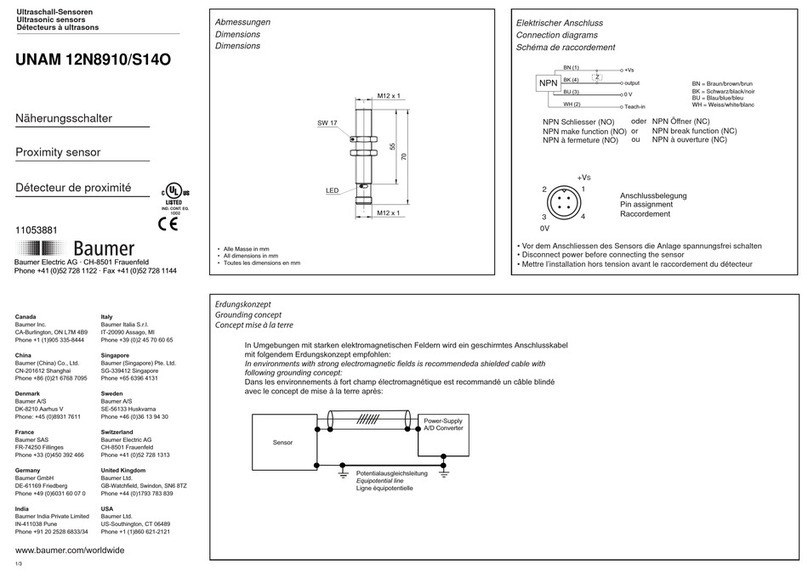

The graph trace will look something like the graph below.

Diagnostics - Graphing

T-on - Orange threshold lines – these indicate the sensor’s hysteresis.

gain to give 1.4 volts when it sees the bare punch.

8

© 2020

1. The sensor is seeing fresh air

2. The nose of the punch arrives with a can body over

3. The side wall area – lower signal due to the thinner side wall material

4. The trim line of the can – higher signal due to the thicker trim line material

5. The bare punch without can material over.

9

© 2020

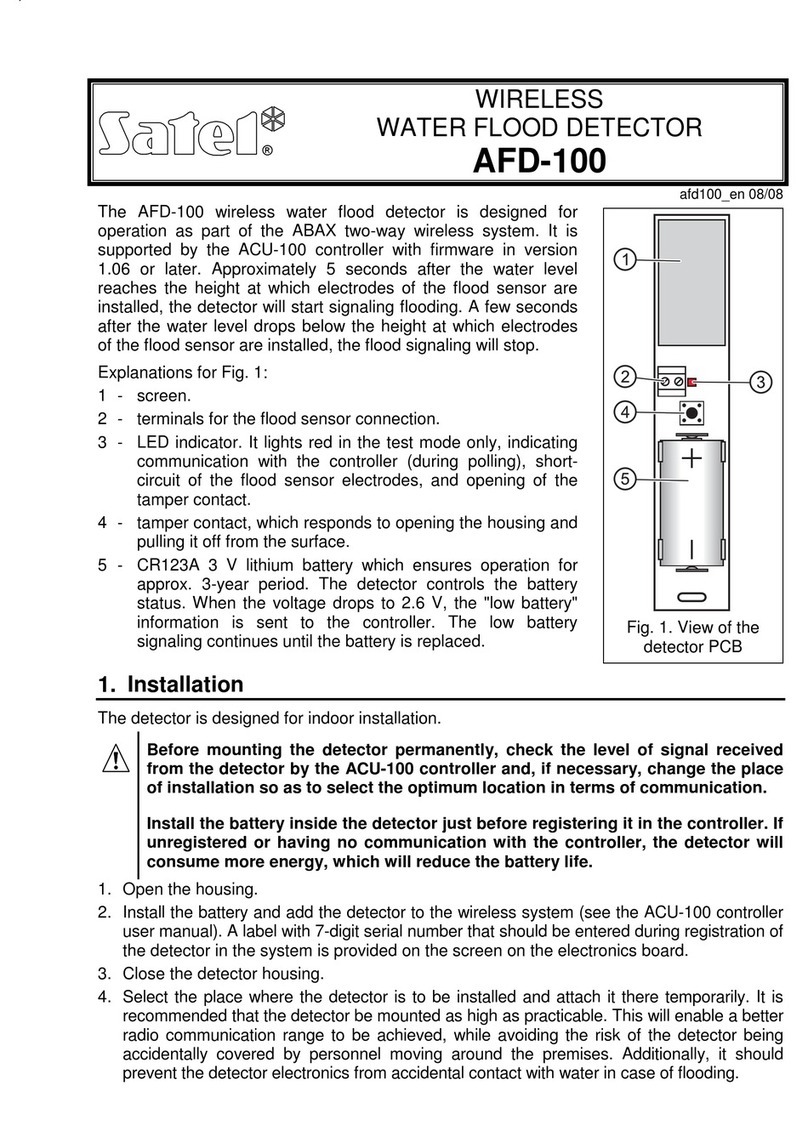

The trigger level, trigger delay and trigger slope are used to give a stable image on the graph.

They work in the way the same way as the controls on an oscilloscope.

The trigger level determins the signal level

needed to start the data display.

This is controlled by the Trigger Level

slider and is shown on the graph by the

The trigger delay allows some data already

collected to be shown prior to the trigger point.

Tp line.

The trigger slope determines whether the graph

or slope and the angle of the slope (V/ms) as the

voltage changes.

There are three modes:

• Append - free running trace. This shows the live signal from the sensor

• Overwrite - The trace starts at a predetermined trigger point. Only one trace

will be displayed.

•

Graphing modes

Triggering

read/write access. C:\Program Files (x86)\Sencon\487SensorClient

You will need administrator rights to make these changes.

10

© 2020

An example of Append mode, which shows two press

strokes.

Example of Overwrite mode, the return stroke appears

can strips and the punch clears the sensor at around

12.95ms

next.

Graphing mode examples

11

© 2020

Copyright © 2020 Sencon . - All Rights Reserved

NORTH, CENTRAL & SOUTH AMERICA

Sencon Incorporated

6385 W.74th Street, Bedford Park,

IL 60638

Tel: +1 708 496 3100

Fax: +1 708 496 3105

www.sencon.com

EUROPE - MIDDLE EAST - ASIA

Stonebridge Cross Business Park,

Droitwich WR9 0LW

Tel: +44 1905 827800

Fax: +44 1905 795876

This manual suits for next models

2

Table of contents

Popular Security Sensor manuals by other brands

Rokonet

Rokonet Zodiac Quad RK-410RQ installation instructions

PCB Piezotronics

PCB Piezotronics PCB-234B Installation and operating manual

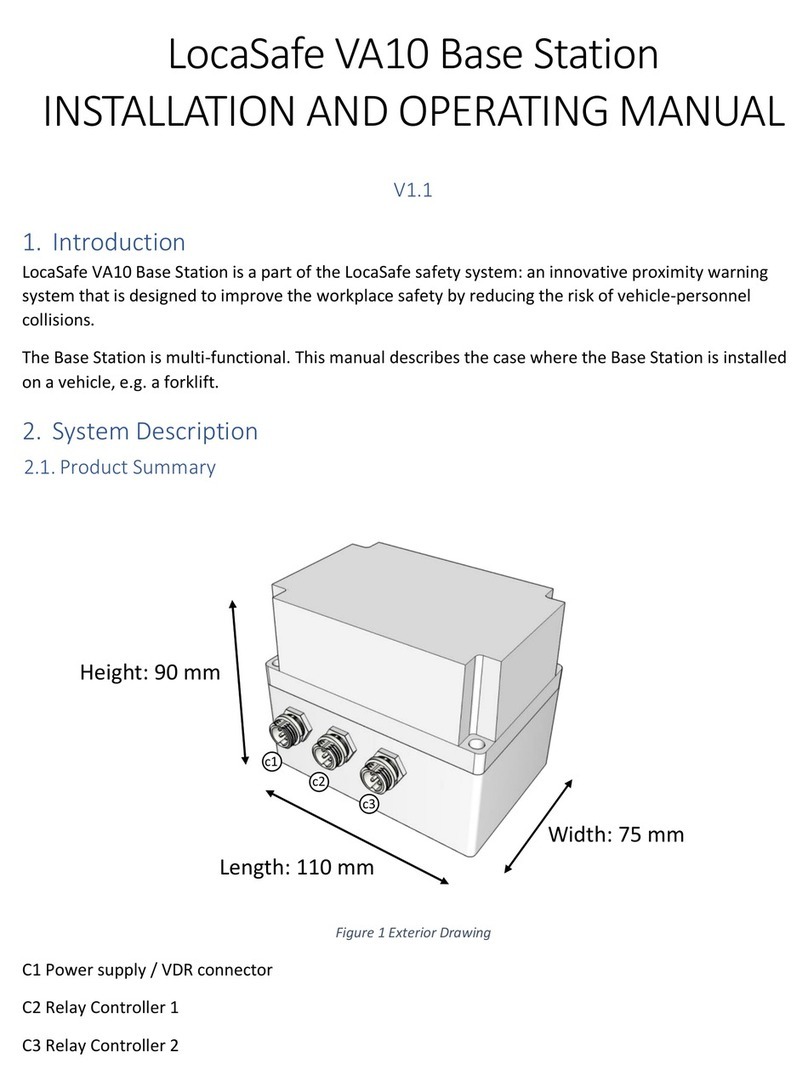

Locatechs

Locatechs LocaSafe VA10 Base Station Installation and operating manual

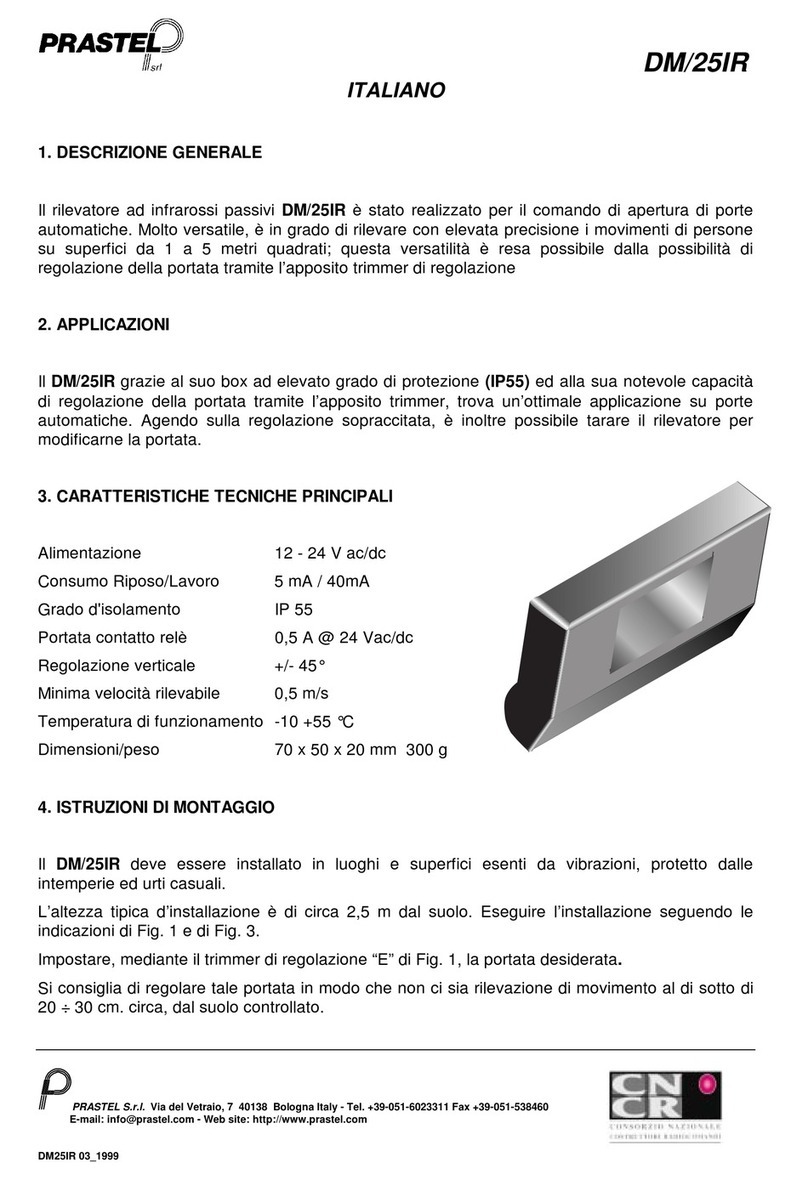

PRASTEL

PRASTEL DM/25IR quick start guide

IFM

IFM OY95 S Series Original operating instructions

TAKATA

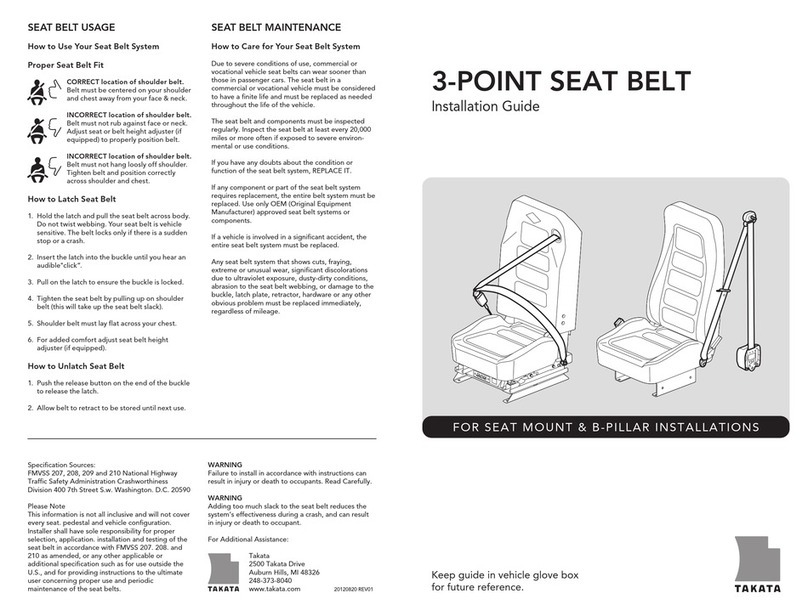

TAKATA 3-POINT SEAT BELT installation guide