Sendix PROFI BUS Singleturn 5858 Series User manual

T

Te

ec

ch

hn

ni

ic

ca

al

l

M

Ma

an

nu

ua

al

l

AbsoluteSingle/Multiturn

Encoders

SingleturnSeries5858,5878

MultiturnSeries5868,5888

P

Pr

ro

of

fi

ib

bu

us

s

D

DP

P‐

‐D

DI

IN

N

1

19

92

24

45

5‐

‐3

3

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 1-2 of 22

CopyrightProtection

Liabilitytomodificationwithoutnotice

As a result of ongoing efforts to improve our products, we reserve the right to make changes at any time to

technicalinformationcontainedinthedocumenttohand.

WarrantyDisclaimer

Their is noprovidenoguarantee,neithertacitnorexpress,inrespectofthewholemanual(whetherthisappliesto

theoriginalGermantextortotheEnglishtranslation)andassumesnoliabilityforanydamage,neitherdirectnor

indirect,howevercaused.

Documentinformation

Revised 09‐2011

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 1-3 of 22

TableofContents

1GENERAL.........................................................................................................1‐4

PROFIBUS‐DPBASICS.............................................................................................................................................................................1‐4

THEPROFILEREQUIRED..............................................................................................................................................................................1‐4

CHARACTERISTICS.....................................................................................................................................................................................1‐4

PROTECTIVEFUNCTIONS.............................................................................................................................................................................1‐4

2START‐UP........................................................................................................2‐5

3GENERALWIRINGINSTRUCTIONS....................................................................3‐5

INSTALLATIONINSTRUCTIONSFORRS‐485......................................................................................................................................................3‐5

4CABLESHIELDING............................................................................................4‐6

5CHARACTERISTICSOFTHEMULTITURNENCODERONTHEPROFIBUS..............5‐7

PNO‐IDENT‐NUMBER...............................................................................................................................................................................5‐7

STARTPHASEOFTHEENCODERONTHEPROFIBUS..........................................................................................................................................5‐7

CONFIGURATIONANDPARAMETERISATION.....................................................................................................................................................5‐7

CONFIGURATION......................................................................................................................................................................................5‐7

6DEVICEPROFILE‐PROFILEFORENCODERV1.1...............................................6‐8

CONFIGURATION......................................................................................................................................................................................6‐8

7PROFIBUSENCODERPROFILE3062(VERSION1.1)...........................................7‐9

PRESETSETTING.......................................................................................................................................................................................7‐9

SPEEDVALUES.........................................................................................................................................................................................7‐9

8EXTENDEDDIAGNOSTICS................................................................................8‐10

1.DEVICEPROFILEFORENCODERS..............................................................................................................................................................8‐10

Class1MandatoryforallDPencoders..........................................................................................................................................8‐10

Class2OptionalFunctionality.......................................................................................................................................................8‐10

9INITIALSTART‐UP‐GENERALDEVICESETTINGS..............................................9‐11

Nodenumber(Deviceaddress)......................................................................................................................................................9‐11

10SETSTATIONADDRESS(SSA)*....................................................................10‐11

11EXTERNALPOSITIONRESET..........................................................................11‐11

12PROFIBUSCONNECTIONPG.........................................................................12‐12

SUPPLYVOLTAGE..................................................................................................................................................................................12‐12

13PROFIBUSCONNECTIONM12.......................................................................13‐12

Bustermination..........................................................................................................................................................................13‐13

14INSTALLATIONNOTESWHENUSINGHOUSINGSWITHCABLEGLANDS:........14‐13

15PARAMETERISATION....................................................................................15‐14

16SCALING.......................................................................................................16‐15

17DEFAULTSETTINGSONDELIVERY.................................................................17‐19

ENCODERPROFILE................................................................................................................................................................................17‐19

18GENERALRESETOFTHEDEVICE....................................................................18‐19

19LEDMONITORINGDURINGOPERATION.......................................................19‐20

REDLED=DIAGNOSTICS......................................................................................................................................................................19‐20

YELLOWLED=BUS.............................................................................................................................................................................19‐20

GREENLED=PWRBUSVOLTAGE..........................................................................................................................................................19‐20

LEDCOMBINATIONSDURINGOPERATION...................................................................................................................................................19‐20

GENERALRESET‐SWITCHINGTHEDEVICEONWITHTHESETKEYPRESSED........................................................................................................19‐21

20DEFINITIONS................................................................................................20‐21

21DECIMAL‐HEXADECIMALCONVERSIONTABLE..............................................21‐22

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 1-4 of 22

1

1

General

General

PROFIBUS‐DPbasics

ThisdescriptionprovidesinformationconcerningtheimplementationofthePROFIBUS‐DPtransmissionprotocolintheslave

modeinourdevices.Itshouldbenotedthattheextentofthefunctionsdescribedmightbelimitedaccordingtothedeviceor

application.Withprotocolconversionsinparticular,asarulefewerfunctionsareused!

Theprofilerequired

Thelinkbetweenthedecentralizedprocessoperationandthecentralcontrolviathecommunicationsystemtakesplacein

thelowesthierarchylevelonthefiledorprocessbus.Atthislevel,themainrequirementsareasimpleprotocoloperation

andshortdatatransmissiontimesforthecommunication.Thisensuresthefastestsystemreactiontimetothedynamic

statesoftheperipherals.Inadditiontotheclassicdataexchange,theacyclictransmissionofparameter,diagnosticand

configurationdatamustbepossible,withoutradicallyimpedingthereal‐timecapabilityofthebus.Thisistheonlywayto

guaranteetheachievementofgooddiagnosticsandsafeoperation.

Characteristics

ThemaintaskofPROFIBUS‐DPisthecyclictransmissionoftheprocessdatafromthecontrolsystemtotheperipheral

equipmentandviceversa.TheaccessprocedureusestheMaster‐Slaveprinciple.HereinthepollingoperationaMaster

communicateswithitsassignedslavedevicesoneaftertheotheronthebus.Adataexchangeisinitiatedbyarequest

telegramandendedbyanacknowledgementtelegramfromtheSlaveconcerned.So,eachSlaveonlybecomesactiveaftera

callfromtheMaster.Thisavoidsasimultaneousbusaccess.ThehybridaccessprocedureofPROFIBUSallowsacombined

operationofseveralbusmastersandevenamixedoperationofPROFIBUS‐DPandPROFIBUS‐FMSwithinabussection.

Howeverthepre‐requisitionforthisisthecorrectconfigurationofthebussystemandtheunambiguousassignmentofthe

SlavedevicestotheMasters.PROFIBUS‐DPdistinguishestwotypesofMaster.TheClass1Mastercarriesoutthecyclic

transmissionoftheoperatingdataandsuppliestheuserdata.TheClass1MastercanbeaddressedbyaClass2Masterusing

certainfunctions.DirectaccesstotheSlavesisnotpermitted.Thefunctionsarelimitedtosupportservicessuchasreading

thediagnosticinformationoftheslaves.AClass2Masteristhusalsounderstoodasaprogrammingordiagnosticdevice.

Protectivefunctions

PROFIBUS‐DPisequippedwithmanyprotectivefunctions.Theseensuresafefault‐freecommunicationnotonlyintheharsh

environmentofthedecentralisedperipheralequipment,butalsointhecaseofexternalinterferenceorthefailureofoneor

morestations.Wrongparametersettingsarerecognizeddirectly,inthatstationshavingthewrongparametersarenot

integratedintheoperatingdataexchange.

TheMasterrecordsthefailureofanystationandindicatesthistotheuserbymeansofageneraldiagnosticmessage.

AnybreakdowninthetransmissionpathisdetectedbytheSlavebymeansoftimemonitoringandleadstotheoutputsbeing

switchedoff.

EMVdisturbancesarevirtuallyfilteredoutbymeansofthedifferencesignal,thankstotheparticularlynoise‐immuneRS485

transmissionsystem.

Datatransmissionerrorsarerecognizedthankstoframeandcheck‐sumcontrolsandleadtotheretransmissionofthe

telegram.

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 3-5 of 22

2

2

Start-up

Start-up

BeforeaPROFIBUS‐DPsystemcanbestartedup,uniquebusaddressesmustbeassignedtoallconnectedstations,including

theMastersystem.Thisistheonlywaytoensureunambiguousaddressingonthebus.Asanoption,thestationaddresses

canalsobeassignedviathebus.

ThephysicalsystemsettingsaremadeusingtheparametersetoftheMaster.InadditiontothebusaddressoftheMaster,

thissetincludes,forexample,thebaudrate,thetime‐outdelaysandthenumberofrepetitionsofthetransmission.Along

withtheMasterparameterset,aSlavedatasetmustbesavedforeachSlavetobeactivated.Adatasetcontainsthe

parameterassignmentandconfigurationdataoftheSlaveandtheaddressindicatorforthelogicalstorageoftheI/Odata.If

theparametersetsarepresent,theneitherattherequestoftheuserorautomaticallytheMastersystembeginstostartthe

Slavesup,oneaftertheother.Thefirstso‐calleddiagnosticcyclesareabletoshow,whichslaveispresentonthebus.Only

thoseSlaves,whichsentacorrectfeedbackduringthediagnosticcycle,willsubsequentlybeparameterizedintheparameter

cycleswiththecorrespondingdatastoredintheMaster.Ifthishasbeencorrectlycarriedout,thenconfigurationcycles

follow,duringwhichacomparisonismadebetweentherequiredconfigurationdatastoredintheMasterandtheactual

configurationdataoftheSlave.Afterthelastdiagnosticcycle,eachSlaveforwhichnoerrorwasdetectedduringthe

comparisonisreadyforoperation.EachoftheseSlavesisthenintegratedautomaticallybytheMasterintheoperatingdata

transfer.

Fordiagnosticpurposes,theMasterprovidesadiagnosticbufferforeachSlave,whichcanbereadbytheuserforother

purposes.Tosimplifythediagnostics,ageneraldiagnosticfieldiskeptsimultaneously,whichshowsbitwisewhetheraSlave

hasdiagnosticdatareadyornot.

3

3

General

wiring

instructions

General wiring instructions

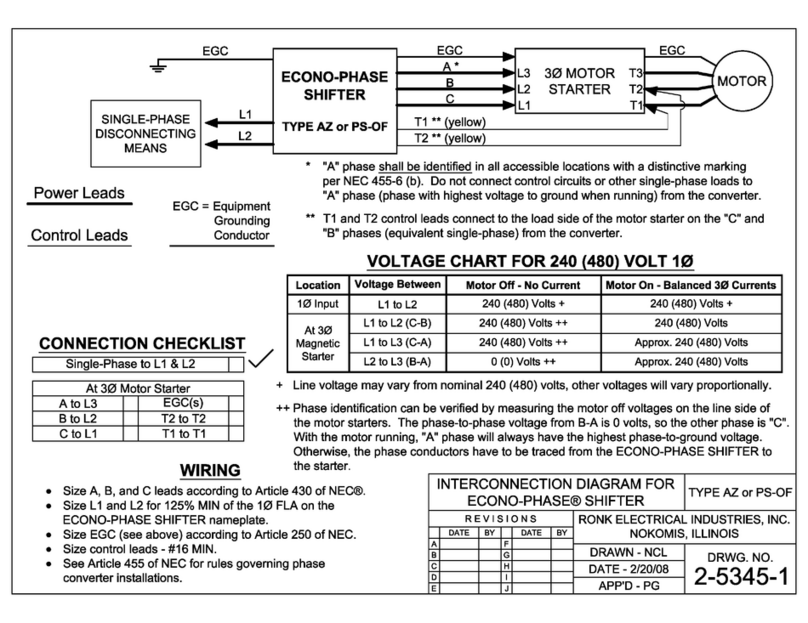

InstallationinstructionsforRS‐485

Alldevicesareconnectedwithinabusstructure(line).Upto32stations(MasterorSlaves)canbelinkedtogetherinone

segment.Thebusisterminatedatthebeginningandattheendofeachsegmentbyanactivebustermination(termination

resistors).Toensuredisturbance‐freeoperationbothbusterminationsmustalwaysremainpowered.Thebusterminationis

providedready‐to‐activateinthedeviceofintheconnector.

Whentherearemorethan32stationsonthebus,repeatersmustbeinsertedtoconnecttheindividualbussegments.

Themaximumlinelengthisdependentonthetransmissionspeed–refertoTable2.

Thelinelengthindicatedcanbeincreasedusingrepeaters.Itisrecommendednottoconnectmorethan3repeatersin

succession.

Baudrate(kBit/s)9.619.2 93.75 187.5 500150012000

Range/Segment1200m 1200m 1200m 1000m 400m200m100m

Table2:RangedependingonthetransmissionspeedforA‐typecable

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 4-6 of 22

4

4

Cable

shielding

Cable shielding

EN50170leavesituptotheusertodecide,whethertouseshieldedorunshieldedcable.Unshieldedcableisallowedin

interference‐freeenvironments.However,thefollowingpointsargueforsystematicuseofshieldedcable:

a) Anareafreefrominterferenceexistsatbestinsideshieldedcabinets.Butassoonasthiscontainsotherelectronic

devicessuchasrelaysandcontactors,thenthisisnolongerguaranteed.

b) Theuseofunshieldedcablesrequiresadditionalprotectivemeasuresagainstovervoltageatthebussignalinputs.

Thisiswhywerecommendonprincipletheuseofshieldedcablesforthebuslines.Thisrecommendationextendsalsotothe

possibleuseofpower‐supplycablescomingfromexternalpowersourcestothePROFIBUSdevices,e.g.forrepeaters.

Double‐shieldedcablesareparticularlysuitableforenvironmentswithstrongEMCinterference.Inthiscase,inorderto

ensureoptimalprotection,thewholesurfaceoftheexternalshielding(braidedshield)andtheinnershielding(foilshield)

mustbeconnectedatbothcableendstotheprotectiveearthbymeansofanearthclip.

Shieldingrules

Whenusingashieldedbuscable,itisrecommendedtoconnecttheshieldatbothendstotheprotectiveearthusinglow‐

inductionconnections.Thisensuresthehighestpossibleelectromagneticcompatibility(EMC).Oneexceptionconcerns

separatedpotentials(e.g.inrefineries):generally,intheseplants,earthingispermittedatoneendonly.

Theconnectionbetweenthecableshieldingandtheprotectiveearthisbestdoneusingthemetallicdevicehousingandthe

screwterminaloftheplugconnector.Hereitshouldbenotedthatdischargeviathepindoesnotrepresentanoptimal

solution.ToachievethebestEMC,itisbettertoexposethecableshieldingatasuitablelocationandtoconnectittothe

protectiveearth(e.g.themetalliccabinetframe)usingalow‐inductioncablelinkthatshouldbekeptasshortaspossible.

Thiscanbedoneforexamplewithashieldingclipbeforethebusplug.

Cablespecification:A‐typecableforPROFIBUS–DP

Surgeimpedance:135to165Ohm,forameasurementfrequencyof3to20MHz.

Cablecapacitance:<30pFpermetre

Conductorsection:>0.34mm²,correspondstoAWG22

Cabletype:twistedpair,1x2or2x2or

1x4conductors

Loopresistance:<110Ohmperkm

Signaldamping:max.9dBoverthewholelengthofthecablesection

Shielding:Copperbraidshieldingorbraidshieldingandfoilshielding

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 5-7 of 22

5

5

Characteristics

of

the

Multiturn

Encoder

on

the

Profibus

Characteristics of the Multiturn Encoder on the Profibus

PNO‐Ident‐Number

TheSendixAbsoluteSingleturn/MultiturnEncoderhasthePNO‐Ident‐Number5868(Hex).Thisnumberisregisteredatthe

PNO(ProfibusUserOrganization)asanuniqueidentification.TheaccordingGSD‐Filesarenamedasfollows:

•MultiturnSeries5868,5888 KUEB5868.GSD

•SingleturnSeries5858,5878 KUEB5868ST.GSD

StartphaseoftheencoderonthePROFIBUS

Whentheencoderstartsupitisinthe‘Baud‐Search’state.Oncethebaudratehasbeenrecognized,itswitchestothe

WAIT_PRMstateandwaitsfortheparameterdatafromtheDP‐Master.Theparameterisationoccursautomaticallywhenthe

DP‐Masterstartsup.Thefollowingparametersaretransmittedtotheencoder:countdirectionandthemeasuringlengthin

steps(formoredetails,seetheEncoderProfilefromthePNO).Whenthecorrectparameterdatahavebeensuccessfully

transferred,theencoderswitchestotheWAIT_CFGstate.ThePROFIBUSMasterthensendsaconfigurationbyteto

determinethenumberofinputs/outputs.Iftheconfigurationbyteiscorrect,theencoderswitchestothestate

DATA_EXCHANGE.

ConfigurationandParameterisation

Theparameterisation,i.e.thetransferoftheparametersforcountdirection,encoderresolutionetc.,normallyoccurswithin

theconfigurationprogrammeforthePROFIBUSMasterused.Todothis,thetypefileorGSD(devicefile)shouldbecopiedto

therespectivedirectoryfortypeorGSDfiles.WithsomeprogrammessuchasCOMPROFIBUSorSTEP7Manager,anupdate

oftheinternaldevicelist(hardwarecatalogue)mustbecarriedoutwithinthesoftware.Formoreinformationabout

integratingfielddevices,pleaserefertothedocumentationforthesoftwareyouareusing.

ThetwostepsdescribedbelowarenormallynecessaryforintegratingandparameterisingtheencoderinaMastersystem.

Configuration

Forconfigurationpurposes,i.e.toinputthelengthandtypeoftheI/OonthePROFIBUS,theconfigurationprogramme

normallyprovidesaninputmask(screen),inwhich–independentlyofthedesiredconfiguration–theidentifierhasnormally

alreadybeensetasadefault,sothatonlytheI/Oaddressesremaintobeentered.Dependingontherequiredconfiguration

thatisdesired,theencoderallocatesavaryingnumberofinputandoutputwordsonthePROFIBUS.

Thefollowingparametersdescribedarealsodependentontherequiredconfiguration.TheGSDdevicefile(e.g.

KUEB5868.GSD)containsfiverequiredconfigurationsforPNOClass1and2,eachwith16‐and32Bitresolution.

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 6-8 of 22

6

6

Device

Profile

-

Profile

for

Encoder

V1.1

Device Profile - Profile for Encoder V1.1

Thisprofiledescribesamanufacturer‐independentandmandatorydeterminationoftheinterfaceforencoders.Itisdefined

intheprotocol,whichProfibusfunctionsareusedaswellashowtheyaretobeused.Thisstandardpermitsanopen

manufacturer‐independentbussystem.

Thedeviceprofileisdividedintotwoobjectclasses:

•ClassC1describesallthebasicfunctions,whichthe

encodershouldcontain.

•ClassC2containsanumberofextendedfunctions,which

musteitherbesupportedbyencodersofthisclass

(Mandatory)orwhichareoptional.ClassC2devicesthus

containalltheC1andC2mandatoryfunctions,aswellas

additionalmanufacturer‐dependentoptionalfunctions.An

addressareaisalsodefinedintheprofile,whichcanbe

reservedforamanufacturer’sownproprietaryspecial

functions.

Configuration

Theconfigurationprogrammenormallyprovidesaninputmask(screen)forparameterisationpurposes,i.e.forenteringthe

dataforresolution,countdirectionetc.Theindividualmodulesarelistedbelow:

7configurationsareavailablefortheregularoperationoftheencoder:

-32BitInput/Output,consistent

-32BitInput,consistent

-16BitInput/Output,consistent

-16BitInput,consistent

-MUR=13BitandTMR=25Bit(32BitInput/Output,consistent)

‐allcancombinedwithSpeed(RPM)16BitconsistentorSpeed(Units/s)32Bitconsistent

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 7-9 of 22

7

7

Profibus

Encoder

Profile

3062

(Version

1.1).

Profibus Encoder Profile 3062 (Version 1.1).

Class232‐Bitresolution,Input/Outputconsistent:

Theencoderuses2inputwordsand2outputwords,whichareeachconsistentlytransmittedoverthebus.

Class232‐Bitresolution,Inputconsistent:

Theencoderuses2inputwords,whichareeachconsistentlytransmittedoverthebus.

Class116‐Bitresolution,Input/Outputconsistent:

Theencoderuses1inputwordand1outputword,whichareeachconsistentlytransmittedoverthebus.

Class116‐Bitresolution,Inputconsistent:

Theencoderuses1inputword,whichisconsistentlytransmittedoverthebus.

Combinationwith:

Class232‐Bitresolution,InputconsistentSpeedin(units/s)or

Class216‐Bitresolution,InputconsistentSpeedin(rpm)

Theencoderusesmax.2inputwords,whichareeachconsistentlytransmittedoverthebus.

DefaultsettingScalingon,25Bittotalresolution

Class232‐BitresolutionMUR=13Bit,TMR=25Bit:

Presetsetting

Inthemode‘Class2’theencodercanbeadjustedoverthePROFIBUStoanypositionvalueinthevaluerangeof27Bitor15

Bit.

Thisoccursbysettingthemostsignificantbit(MSB)oftheoutputdata(2^31for

configurationClass2‐32Bitor2^15forconfigurationClass2‐16Bit).

ThePresetValuethatistransmittedinthedatabytes0‐3isacceptedasthepositionvaluewiththerisingedgeofBit32

(=Bit7ofdatabyte3).Theencoderthencontinuescountingfromthisposition.Anewadjustmentisthenonlypossibleafter

thecontrolbithasbeenreset.Thereisnoacknowledgmentofthisactionviatheinputs.

Speedvalues

AllmodulescanbecombinedwiththeconfigurationofanadditionalSpeedvalue.Theinputwordsareincreasedtoa

maximumlengthof8Bytes(64Bit)dependingontheconfigurationofthespeedvalue.TheSpeedvalueissignedand

dependsonthecountdirection.

PositivevaluesinCW,negativeinCCWdirection.

Formatisin“BigEndian”:

Inputword Inputword

Byte0Byte1Byte2Byte3FormatMax.

00RPM0

1770 RPM6000

E890 RPM ‐6000

0063FF9C Units/s6553500

FF9C0064 Units/s‐6553500

Speedlimits:

SingleturnEncoder: 600rpmhigherspeedshowsffffhasvalue

Multiturnencoder: 12000rpmhigherspeedshowsffffhasvalue

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 8-10 of 22

8

8

Extended

Diagnostics

Extended Diagnostics

1. Deviceprofileforencoders

C

Cl

la

as

ss

s

1

1

M

Ma

an

nd

da

at

to

or

ry

y

f

fo

or

r

a

al

ll

l

D

DP

P

e

en

nc

co

od

de

er

rs

s

FunctionOctetN°.DataTypeName

Data_Exchange1‐4Unsigned32PositionValue(input)

Data_Exchange1‐4Unsigned32PresetValue(output)

Data_Exchange1‐4Unsigned32SpeedValue(input)(units/s)

Data_Exchange1‐4Unsigned16SpeedValue(input)(rpm)

RD_inp1‐4Unsigned32PositionValue

RD_inp1‐4Unsigned32SpeedValue

Slave_Diag7OctetStringExternalDiagnosticHeader

Slave_Diag8OctetStringAlarms

Slave_Diag9OctetStringOperatingStatus

Slave_Diag10OctetStringEncoderType

Slave_Diag11‐14Unsigned32SingleturnResolution

Slave_Diag15,16Unsigned16NumberofRevolution

Set_prm9OctetStringOperatingParameters

C

Cl

la

as

ss

s

2

2

O

Op

pt

ti

io

on

na

al

l

F

Fu

un

nc

ct

ti

io

on

na

al

li

it

ty

y

FunctionOctetN°.DataTypeName

Slave_Diag17OctetStringAdditionalAlarms

Slave_Diag18,19OctetStringSupportedAlarms

Slave_Diag20,21OctetStringWarnings

Slave_Diag22,23OctetStringSupportedWarnings

Slave_Diag24,25OctetStringProfileVersion

Slave_Diag26,27OctetStringSoftwareVersion

Slave_Diag28‐31Unsigned32OperatingTime

Slave_Diag32‐35Signed32OffsetValue

Slave_Diag36‐39Signed32ManufacturerOffsetValue

Slave_Diag40‐43Unsigned32MeasuringUnitsperRevolution

Slave_Diag44‐47Unsigned32Totalmeasuringrangeinmeasuringunits

Slave_Diag48‐57ASCIIStringSerialNumber

Set_prm10‐13Unsigned32MeasuringUnitsperrevolution

Set_prm 14‐17 Unsigned32Totalmeasuringrangeinmeasuringunits

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 11-11 of 22

9

9

I

In

ni

it

ti

ia

al

l

S

St

ta

ar

rt

t-

-u

up

p

-

-

G

Ge

en

ne

er

ra

al

l

D

De

ev

vi

ic

ce

e

S

Se

et

tt

ti

in

ng

gs

s

N

No

od

de

e

n

nu

um

mb

be

er

r

(

(D

De

ev

vi

ic

ce

e

a

ad

dd

dr

re

es

ss

s)

)

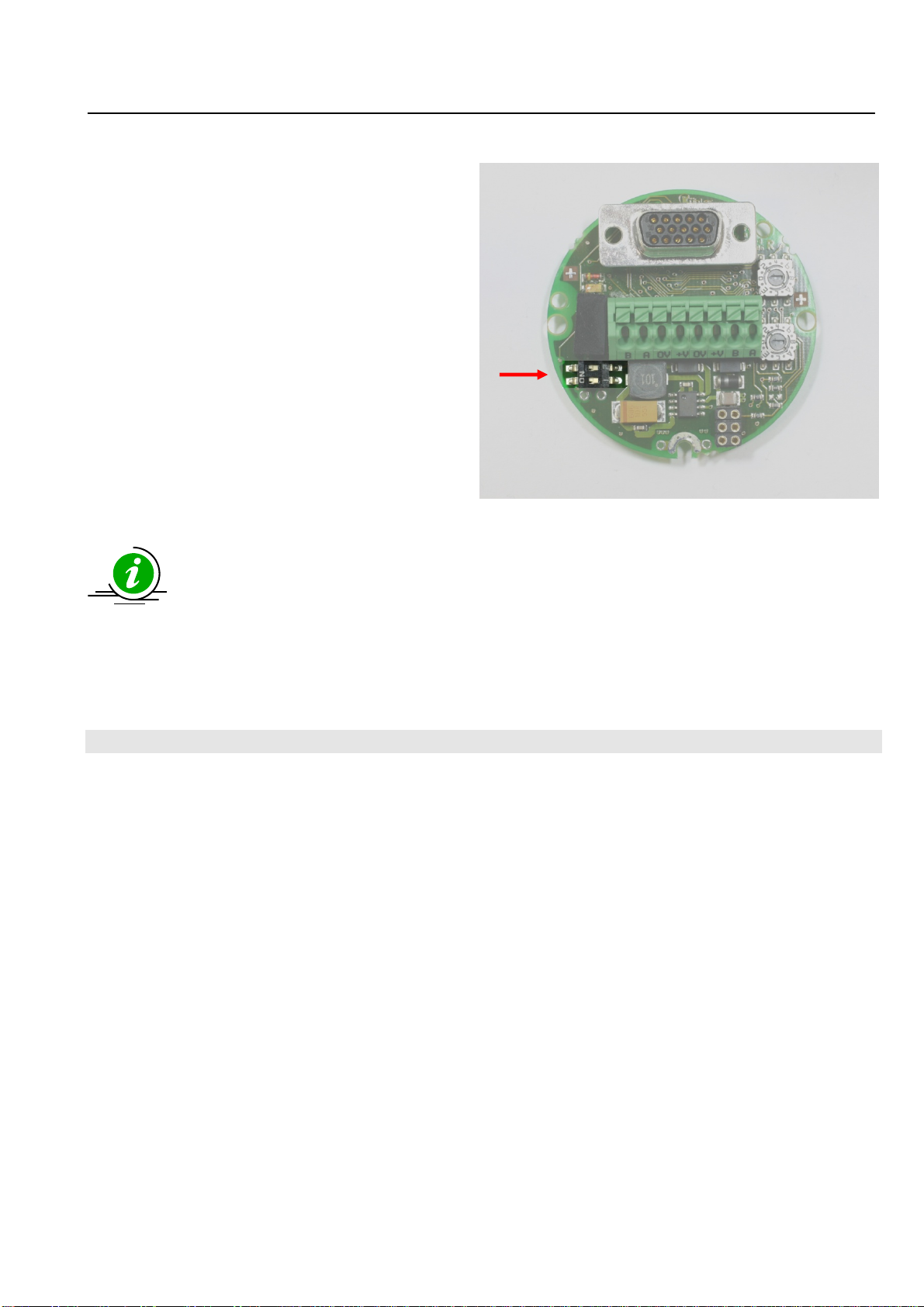

Settingthenodenumberfortheaddress,usingbothrotaryswitchesandadjustthenumbertotheaccording

address.R1fortheloworderaddresses,R2forthehighordervalue.

View:intotheopenedbuscover

RotaryswitchforloworderR1

Rangeofvalues1..F*

RotaryswitchforhighorderaddressR2

Rangeofvalues1..7*

²

Example:

R1settoF,R2setto3

3Fhcorrespondsto63decimal

1

10

Set

Station

address

(SSA)

*

0 Set Station address (SSA) *

*AdjustbothrotaryswitchestopositionFforSoftware“setstationaddress”supportwithaClass2Master.

TheSoftware“setstationaddress”supportcanonlybecarriedoutwithaClass2Master.

DefaultsettingsafteraPower‐onistheaddress125(0x7D)forSSA_Support.

Onlyvalidaddresseswillbestoredinanon‐volatilememoryandareactivebynow.

TheNodenumber0isreservedandmustnotbeusedbyanynode.

Theresultingnodenumberslieintherange1...7Dhhexadecimal(1...125decimal).

11

1

External

Position

Reset

1 External Position Reset

Thedevicecanbesettoaresetpositionbymeansofthe

built‐inSETkey.Theresultingpositionis0.

Theresultingoffsetbetweenthephysicalzeroposition

ofthediscandtheelectroniczeropositioncanbe

interrogatedviatheextendeddiagnosticsheader.

Position:0

Asperillustration

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 13-12 of 22

1

12

2

P

Pr

ro

of

fi

ib

bu

us

s

c

co

on

nn

ne

ec

ct

ti

io

on

n

P

PG

G

BusconnectionwithseparatepowersupplyandPGcableglandconnection

Undobothscrewsonthebuscoverandremovethebuscoverfromtheencoder.

Feedtheincomingbuscablethroughtheleftcableglandandconnectittotheleftterminal(B)andterminal(A).

Placethecableshieldontothecablegland.Iffurtherdevicesfollowinthebussegment:

Runcontinuingcablethroughtherightcableglandandconnecttoterminal(B)andterminal(A).

Supplyvoltage

Runthesupplyvoltagefortheencoderthroughthecentralcableglandandconnectittotheterminalsontheleft

(+V)and(0V).Placethecableshieldontothecablegland.

(seewiringdiagram)

View:intotheopenedbuscover

Descriptionfromlefttoright

Abbreviation DescriptionDirection

BProfibusOut

AProfibusOut

0V0VoltSupplyOut

+V+UBSupplyOut

0V0VoltSupplyIn

+V+UBSupplyIn

BProfibus In

AProfibusIN

1

13

3

P

Pr

ro

of

fi

ib

bu

us

s

C

Co

on

nn

ne

ec

ct

ti

io

on

n

M

M1

12

2

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 14-13 of 22

B

Bu

us

s

t

te

er

rm

mi

in

na

at

ti

io

on

n

Thebusterminationissetviahardwareusingboth

DIPswitchesonthebuscoverontherearofthe

encoder.

Whentheswitchissetto‘ON‐>theterminationis

active

Ifthedevicerepresentsthefinalstationonthebus,

thenthelooped‐throughProfibusmustbeactively

terminatedatbothendswithabustermination

resistorbetweenAandB.

Atclosedhousingsitisnecessarytoorderwithterminationadjustedtherightway,otherwiseit

ismandatorytoadaptanexternalresistor.

14

4

Installation

notes

when

using

housings

with

cable

glands:

1 Installation notes when using housings with cable glands:

Asbusorconnectioncable,useonlyapprovedProfibuscablewithsuitableshielding.

•Placethecableshieldonthecablegland

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 15-14 of 22

1

15

5

P

Pa

ar

ra

am

me

et

te

er

ri

is

sa

at

ti

io

on

n

Inordertocarryoutageneralparameterisationofthedevice,itisnecessaryfirsttoselectamodulefromtheGSDfile

(KUEB5868.GSD).

Example:

Withtheparametertelegram(exceptforthe25‐Bitconfiguration)thefollowingcanbedefined:

-CodeSequence(Octet9,Bit0)

o0=clockwise

o1=counterclockwise

-Class2functionality(Octet9,Bit1)

o0=no

o1=yes

-Scalingenabled(Octet9,Bit3)

o0=no

o1=yes

-Scalingtype(Octet9,Bit7)

o0=Standard(MUR+TMR)

o1=Alternative(NDR+TMR)

-ScalingparameterMURorNDR(Octets10‐13)

oMUR=MeasuringUnitsperRevolution

oNDR=NumberofDistinguishedRevolutions

-ScalingparameterTMR(Octets14‐17)

oTMR=TotalMeasuringRange

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 16-15 of 22

1

16

Scaling

6 Scaling

WithStandardScaling,scalingwillbedoneasfollows:

oWithMURandTMR

oOnerevolutionisequivalentexactlytoMUR=TMRvalues

Positionscaled=((Positionunscaled/Singleturn‐resolution)*MUR)%TMR

WithAlternativeScaling,scalingwillbedoneasfollows:

oWithNDRandTMR

oNDRrevolutionsareequivalentexactlytotheTMRvalues

Positionscaled=((Positionunscaled/(NDR*Singleturn‐resolution))*TMR)%TMR

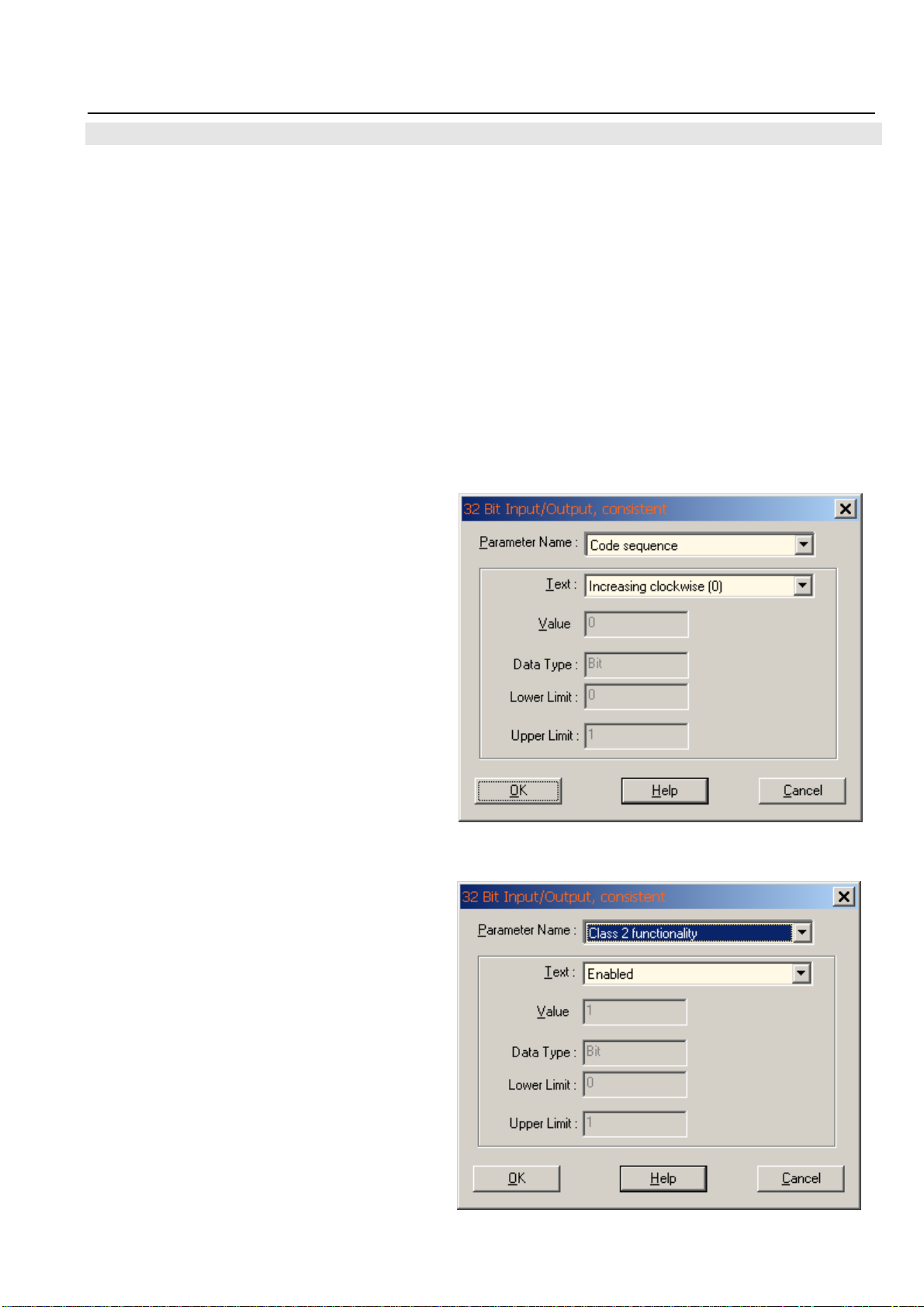

1. CodesequenceCW

Possiblesettings:

Increasingclockwise(0)(CW)

Increasingcounter‐clockwise(1)(CCW)

2. Class2functionalityon

Class2mustbeturnedonwhenscalingisactive.

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 16-16 of 22

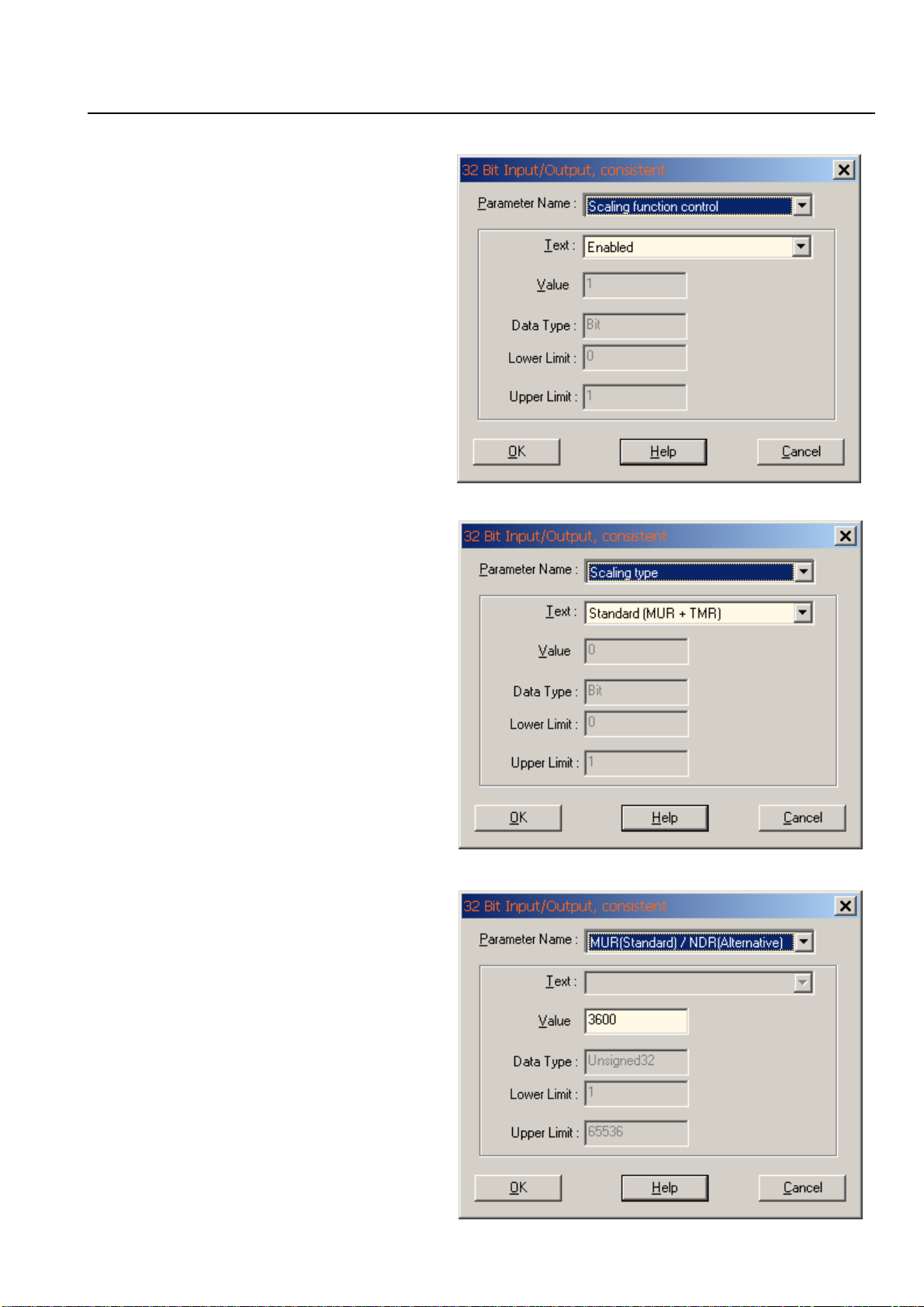

3. Scalingfunctioncontrolon

Whenscalingisturnedon–Position

dependsonthevaluesMURandTMR.

4. Scalingtype

MUR+TMR

Scalingtype(MUR+TMR)

5. ValueforResolutionper

RevolutionMUR

Example:3600Stepsperrevolution

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 16-17 of 22

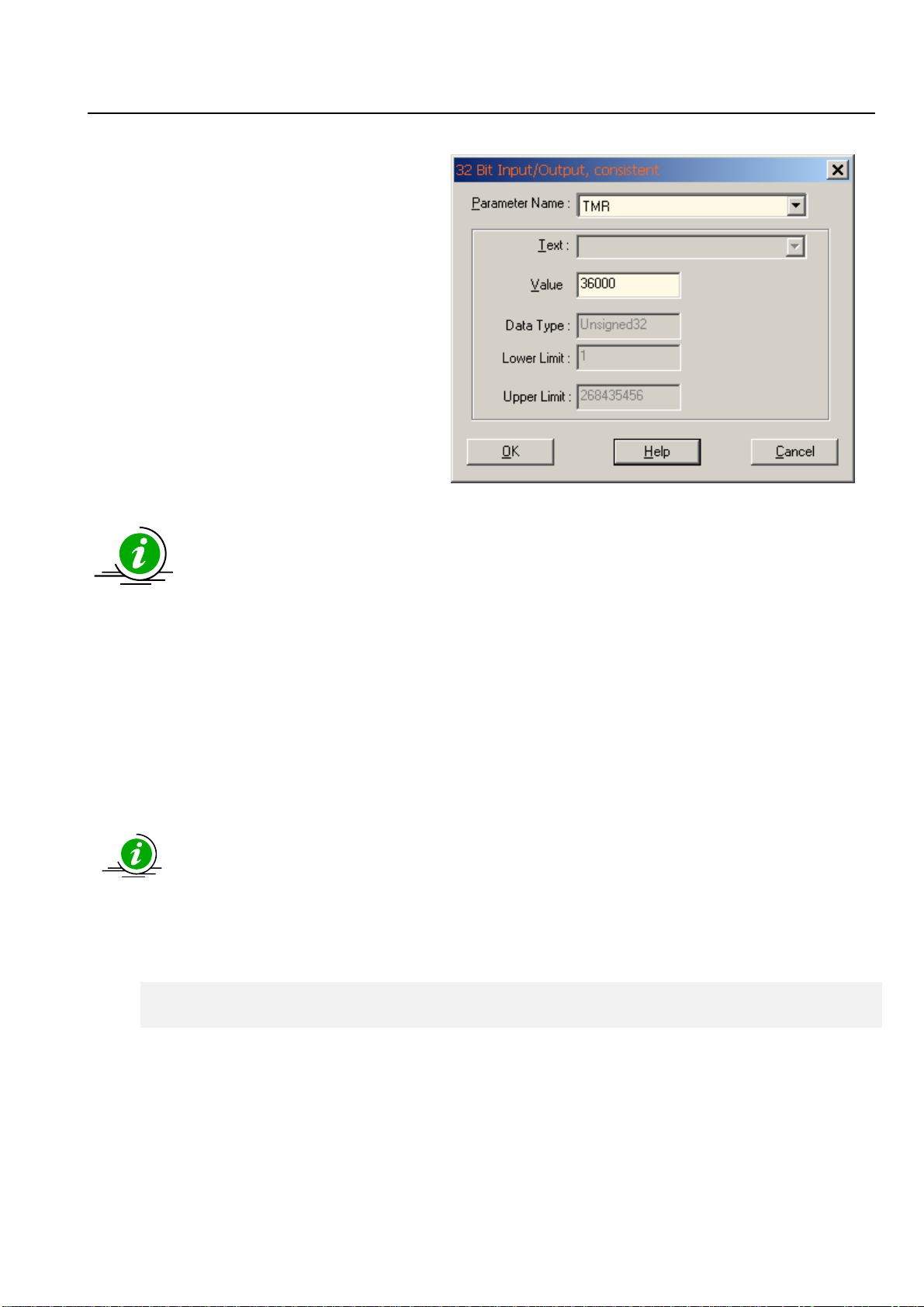

6. ValueforTotalResolution

Example:Valuefortotalresolution36000

Positionrange:0…36000

Revolutions10

WithStandardScaling,scalingwillbedoneasfollows:

oWithMURandTMR

oOnerevolutionisequivalentexactlytoMUR=TMRvalues

Positionscaled=((Positionunscaled/Singleturn‐resolution)*MUR)%TMR

Ifthescalingvalues(TMR/MUR)cannotbedividedwithoutaresttherewillbeanerroratthelimitsofthe

positionvalues(value<0and<maximumposition).ThiscanbeavoidwithamultiplevalueofMURtoTMR.

*Limitations

ThecalculatedfactorGP_U/TMRshouldalwaysbeanintegernumber

k=GP_U/TMRk=Integernumber

Example

InputObject6001hMUR=65000

InputObject6002hTMR=65.000.000

Calculatednumberofrevolutions=1000(MT)

k=GP_U/TMRk=Integernumber

Fault k=228/65.000.000=4,1297

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 16-18 of 22

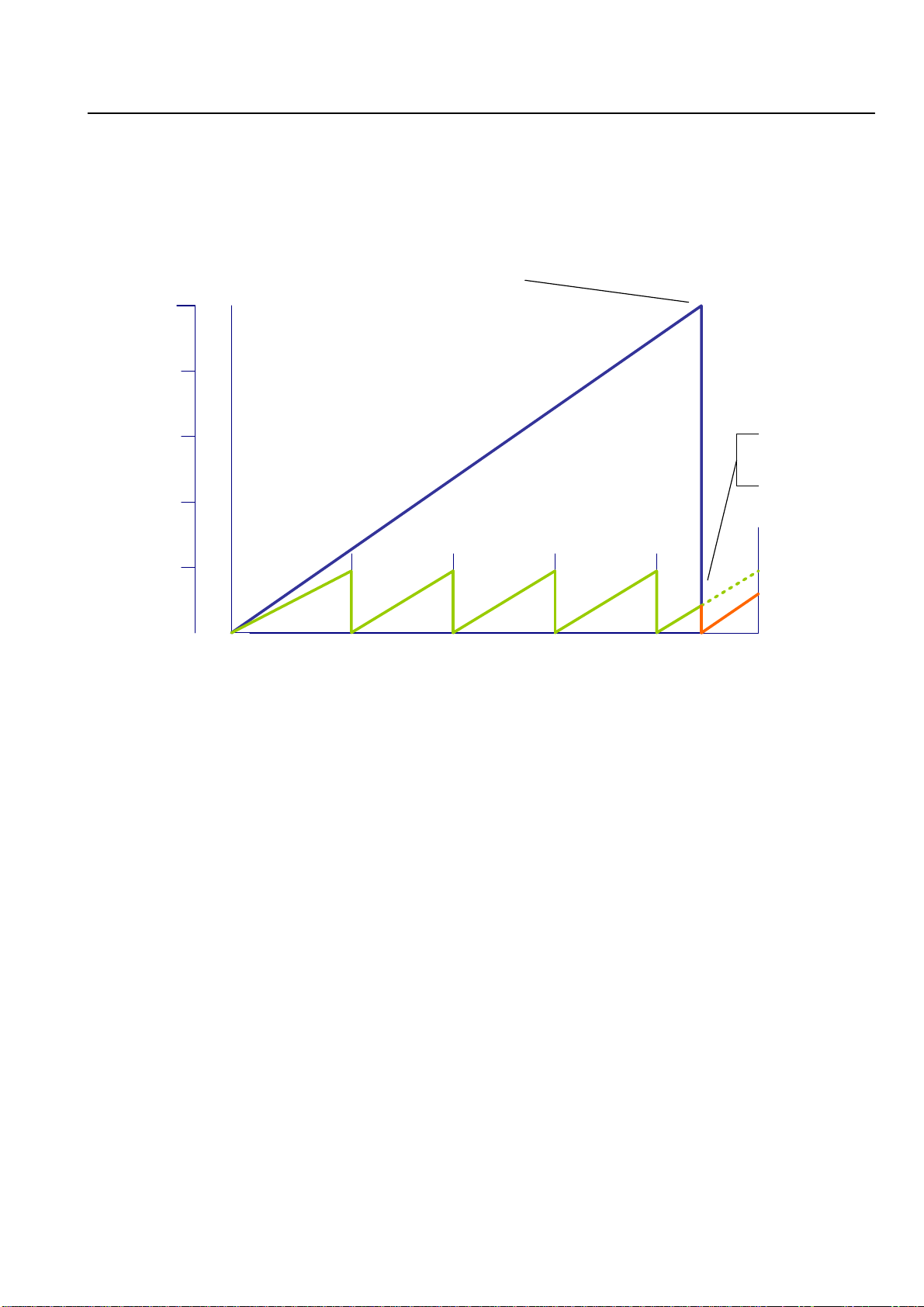

Positiondiagram

Total Measuring Range (TMR)

0 Number of Revolutions

Max

4000 0 1 2

2000 U

Error behavior

MT resets the

position value

4000 U

Max.physical Resolution 2^28 Bit

Singleturn Resolution (MUR) * 4096

= TMR

Attheendoftthephysicalresolution(GP_U)itcomestoafault,becausetheinputofkisno

integernumber.TheEncoderresetsthepositionattheendoftheMultiturntoZero.Thesame

faultoccursimmediatelywhenafterapresettozerothemaximumvalueoftheMultiturn(4095)

willbeadjusted.

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 18-19 of 22

1

17

7

D

De

ef

fa

au

ul

lt

t

s

se

et

tt

ti

in

ng

gs

s

o

on

n

d

de

el

li

iv

ve

er

ry

y

Ondeliverythefollowingparametershavebeenfactoryset.

DescriptionSettingSwitch

BaudrateautomaticNotavailable

Nodeaddress63Switchsetting3Fh(63)*

*Atclosedhousingstheswitchissettothepreordednode

addressorto0xFFfor“setstationaddress”withsoftware

TerminationOFFSwitchsettingof

f

Index(hex)NameStandardvalue

EncoderProfile

Set_prm9OperatingParameter Bit3Scalingon

Class2on/CW

Set_prm10‐13MeasuringUnitsperRevolution 8192(13Bit)

Set_prm14‐17TotalMeasuringRange 33554432(25Bit)

TheoriginalStandardValues(Defaultvaluesondelivery)canbereloadedbypressingthebutton

ontherearwhenswitchingon(Restoreparameters).

Iferrorshaveoccurredduringprogrammingoftheobjectsandiftheseparametershavebeen

savedintheEEPROM,itwillnotbepossibletoaddresstheencodernexttimeitisswitchedon;

thiserrorcanbeclearedonlybymeansofageneralResetoftheencoder.

18

8

General

Reset

of

the

device

1 General Reset of the device

Pleasenotethatallprogrammedparameterswillbelost.

•Switchtheencoderoff.

•Turntheencoderbackon,keepingtheSET‐Key*pressedforapprox.3sec.

untiltheDIAGLEDflashes

•Switchthedeviceoffagain

Whentheencoderisrebootedallvalueswillberesettotheirdefault

settings.(SSA‐addressis125)

*onlyfordeviceswithanexternalSET‐Key;inothercasesthedeviceshouldbe

returnedtothefactory.

Technical Manual

Absolute Single/Multiturn Encoders Profibus

R.000.000 19-20 of 22

1

19

9

L

LE

ED

D

M

Mo

on

ni

it

to

or

ri

in

ng

g

d

du

ur

ri

in

ng

g

o

op

pe

er

ra

at

ti

io

on

n

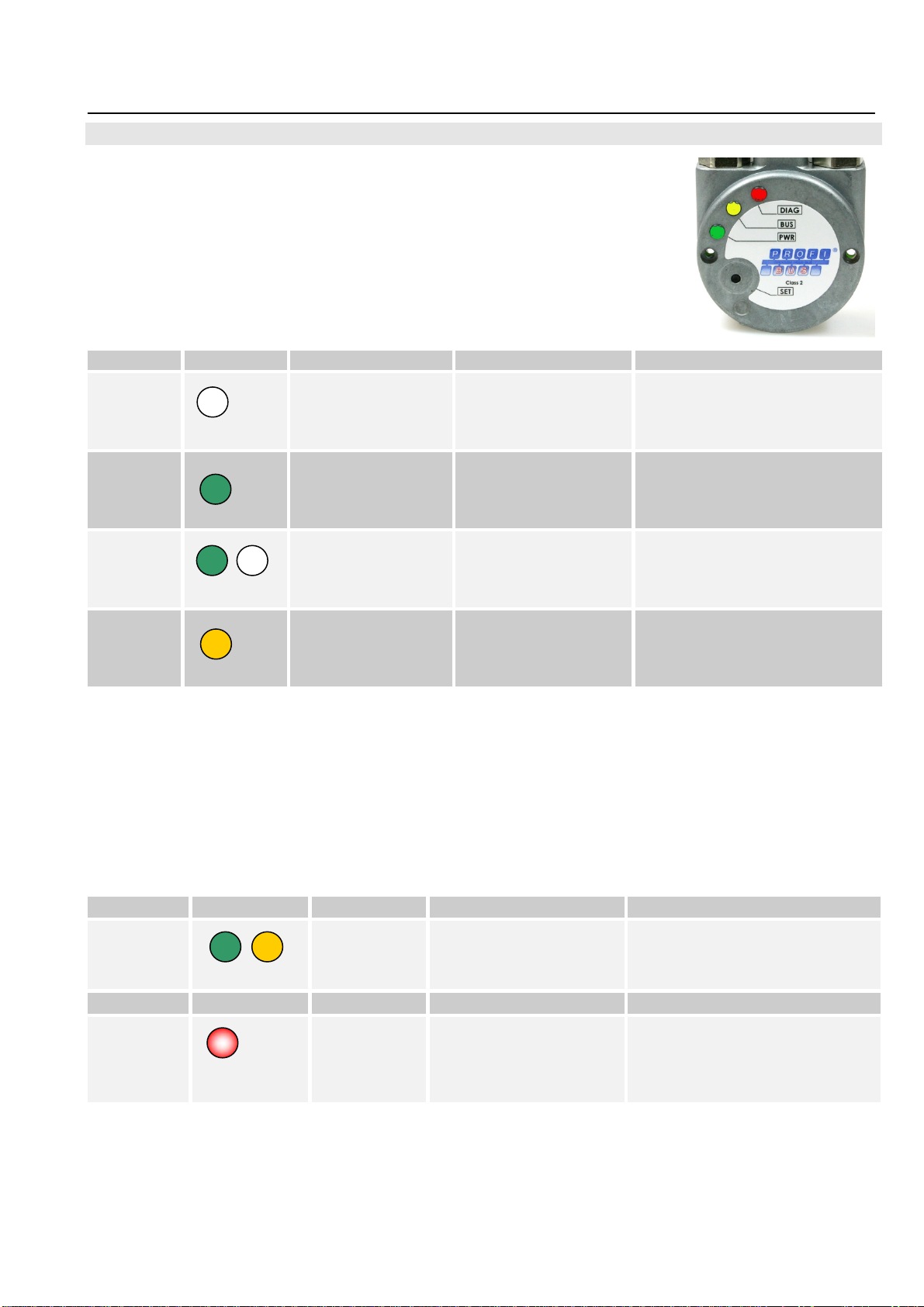

redLED=DIAGnostics

yellowLED=BUS

greenLED=PWRBusvoltage

AnnunciatorLEDDescriptionCauseoferror Addendum

PWR

OFF

Nobusvoltage

present

Nopowertodevice

Powersupplyunit

defective

Checkpowersupply³

PWR

ON

Busvoltagepresent.

Devicereadyfor

operation

Deviceisinconfiguration

mode

BUS

OFF

Deviceiswaitingfor

configurationor

parameterisation

GSDmodulemustbe

loadedandsenttothe

encoder

ObservecombinationwithDIAG

LED

BUS

ON

ConnectiontoMaster

established

DATA_ExchangeMode

Exchangeofprocessdata

TheindividualLEDannunciatorscanofcoursealsooccurincombinations.

²MastercanbeeitheraPLCorasecondcommunicationpartner

³Operatingvoltage

LEDcombinationsduringoperation

AnnunciatorLEDDescriptionCauseoferrorAddendum

PWR+BUS

ON

Data_Exchange

Mode

Devicewillexchangepositiondata

Diag

flashing

RedLEDflashingOver‐temperature

Sensormonitoring

Singlebitfunctionerror

Sensorcurrentmonitoring

ConnectiontoMasterinterrupted+

additionalcausesoferror(Diagnostic

headerisrequested)

This manual suits for next models

3

Table of contents