Senect FILTER CONTROL Series User manual

Product type

2

Product type

Product name:

SENECT®FILTER|CONTROL

Versions:

FILTER|CONTROL (150 W)

FILTER|CONTROL (300 W)

Type:

FC-A1-333-150

FC-A1-333-300

Producer:

SENECT GmbH & Co. KG

An 44 –No. 11

76829 Landau / Germany

Important note:

Please read this manual carefully and store it so that you can use it later. Read the warning and safety

notes attentive.

Further information and latest software releases or documents can be downloaded from:

www.senect.de

© SENECT GmbH & Co. KG - FW 00.80

Table of contents

3

Table of contents

Product type............................................................................................................................................ 2

Table of contents..................................................................................................................................... 3

Used symbols and wording ..................................................................................................................... 4

General Security Notes............................................................................................................................ 4

Intended use ........................................................................................................................................... 5

General theory of operation ................................................................................................................... 5

Getting started ........................................................................................................................................ 6

Scope of delivery................................................................................................................................. 6

Note..................................................................................................................................................... 6

Installation and start-up...................................................................................................................... 6

Operation .............................................................................................................................................. 14

Display and symbols.......................................................................................................................... 14

Buttons and menu............................................................................................................................. 15

Accessoires for the SENECT FILTER|CONTROL...................................................................................... 33

Connecting a solenoid valve to refill water....................................................................................... 33

Troubleshooting: What if… ................................................................................................................... 33

Technical Data...................................................................................................................................... 34

Information about the correct disposal ................................................................................................ 34

Guarantee ............................................................................................................................................. 35

Used symbols and wording

4

Used symbols and wording

DANGER!

Warning of life threatening dangers.

WARNING!

Warning of possible life threatening and / or severe irreversible

injuries.

ATTENTION!

Warning of possible medium or slight injury.

ATTENTION!

Follow the notes to avoid damage of equipment.

NOTE!

Further information for the use of the device.

NOTE!

Further information for the use of the device.

General Security Notes

The SENECT® FILTER|CONTROL is an electronic control unit developed for controlling drum

and belt filters.

Since it is an electric product the common prerequisites for a safe instrument usage

must be fulfilled. The device must be operatated with 230 V AC (~50 Hz). Ensure

that all cables are installed safely so that no obstacles for persons are built and all.

Mount all cables and electric devices protected against direct environmental

impacts like overheating by direct sunlight and water. Even if the product is

protected against spray water, the product´s lifetime will be elongated, if it is

mounted on a protected place.

For many applications a ground fault circuit interruper (interrupting current <= 30 mA) is

required by law. Inform yourself about the valid legislation. If the mains plug cable is damaged,

only the producer or a qualified person designated by the producer is allowed to repair the

damage.

Intended use

5

The operating temperature of the device must be between 0°C and +40°C. It is not allowed to

modify the FILTER|CONTROL, to open the housing or to insert anything into the housing.

If the power cable is damaged, it must be replaced by the producer or a qualified person

designated by the producer to avoid potential dangers.

The device is designed to be operated by professional users. It can be also operated by

children over the age of 8 years and persons with limited physical, sensorial or cognitive ability,

if they are supervised, trained in the operation of the device, able to operate the device safely

and if they understand potential risks resulting from the operation. It is for children or persons

with limited physical, sensorial or cognitive ability not allowed to perform any maintenance

works.

Please store this manual. We suggest the storage a copy of the manual in the vicinity of the

drum filter.

Technical and optical changes of this manual are subject to alterations.

Warning: Before doing any maintenance work switch off all electric devices or unplug

the mains plug.

Intended use

The SENECT® FILTER|CONTROL is an electronic control unit developed for

controlling drum and belt filter in industrial applications. It can be combined with

maximal two water level sensors (SENECT PS-300-MA or EPS-250-MA), one filter

case switch, one solenoid valve (MVW-M12-SC) and one further actuator (e.g. alarm lamp VIS-

LED).

On the three 230 V AC plugs, one spray pump, one UVC lamp or a 230 V AC filter motor and

one circulation pump can be connected.

The direct control of drum or belt filters is only possible for filter with a 24 V DC filter

motor with max. 5 A (FC-A1-333-150) or 10 A (FC-A1-333-300) or with a 230 V AC

filter motor. The spray pump must be operated with 230 V AC with a maximal

current of 8 A.

General theory of operation

Drum and belt filter (terms were used interchangeably) remove suspended particles in

aqueous solutions. Therefore, the water flows through a filter mesh and the particles stick to

the mesh. The FILTER|CONTROL can detect if the filter mesh is clogged by measuring the water

level in front of or behind the filter (only with the optional PS-300-MA or EPS-250-MA). If the

Getting started

6

filter mesh is clogged, the FILTER|CONTROL starts the filter motor so that the drum starts to

rotate or the belt starts to move and the spray pump will be activated. The filter mesh will be

flushed and all dirt particles will be washed to the outlet.

Alternatively, if the is no water level sensor connected to the FILTER|CONTROL, a time

controlled operation of the filter is also possible.

With the FILTER|CONTROL, many parameters can be set by the user so that many different

types of filter can be operated with the FILTER|CONTROL.

With its 230 V AC circulation pump plug, one pump with a maximum power of 900 W can be

connected and is therefore implemented in the control algorithm. This enables for example

the emergency switch-off of this pump in case of water level below the alarming threshold. If

you want to use a pump with a power of over 900 W, the optional Power Switch (PWS-24230-

SC) can be used.

Besides the operation of the filter, the FILTER|CONTROL can regulate the water level (PS-300-MA or

EPS-250-MA plus solenoid valve MVW-M12-SC necessary) by measuring the water level and

activating a solenoid valve.

Getting started

Scope of delivery

o1 x FILTER|CONTROL unit with 3 m power cable

o1 x Motor cable

o1 x Wall mount set

o1 x Manual

Note

Please check directly after delivery, that the package is not destroyed or damaged

or was opened before. Please check also, that all parts as listed above are included.

If anything is missing or broken, please contact us as soon as possible within 14 days.

Unfortunately, we cannot accept later information of damage, which happened during the

transport.

Installation and start-up

Choose a place for your FILTER|CONTROL which is clean, dry and protected from

direct sunlight. Ensure that all cables are placed safely and all regulations are

fulfilled.

To mount the FILTER|CONTROL, place the delivered wall mounting parts on the back of the

device. Tight the parts with the delivered screws (3 x 10 mm, see Fig. 1). Afterwards, you can

use the wall mounting parts of the FILTER|CONTROL to attach the device to its place, e.g. on

a wall.

Getting started

7

Fig. 1: Connecting an open channel drum filter and a boxed drum filter. Please note that the filter motors here are

controlled by the high-power acuator output port OUT 3.

Getting started

8

Fig. 1: Wall mounting parts and dimensions of the drill holes of the FILTER|CONTROL.

Plug the 230 V power plug of the FILTER|CONTROL in a spray water protected plug (IPx4 or

higher) but do not switch FILTER|CONTROL on yet.

1.) Water level sensor installation

If you do not have a water level sensor, please continue with 2.).

The optimal location of the water level sensor (PS-300-MA or EPS-250-MA) is where

a control over the proper functioning of the circulation pump is. In a gravity system,

this location is usually behind the filter while in pumped systems, this is typically

before the filter or in the pre-chamber of the filter.

Please do not insert the water level sensor deeper than 2.5 m and ensure that it is well fixed

and at a place with low direct currents. Read also the instructions of the level sensor manual.

Fig. 2: Sensor and actuator ports of the FILTER|CONTROL.

Getting started

9

Connect the water level probe PS for the filter control with SENSOR 1 (see Fig. 2). If you are

using a second water level probe PS, connect the 2nd probe with SENSOR 2.

If you are using two water level sensors EPS-250-MA, connect the sensor in the filter chamber

with SENSOR 1 and the sensor in the pre chamber with SENSOR 2 (for water refill).

2.) Case switch

If your filter is equipped with a case or cover proximity switch, you can connect it to SENSOR 3.

If you do not have a suitable plug at your switch, you can order the proper plug from SENECT

or your dealer.

The function of the case switch is to switch off the drum motor and a connected UVC lamp

(which are often located inside the drum filter), when the cover is opened (mode: drum filter).

In the mode “belt filter” is selected, then only the UVC lamp is switched off.

Please consider that the case or cover switch does not fulfil all requirements to be an

emergency stop switch according to EN ISO 13850:2015-10.

3.) Filter motor

24 V DC Filter motors:

Ensure that the filter motor is correctly installed at your filter and check in the technical

documentation, if the motor can be operated with 24 V DC (max. current 5 or 10 A). If yes,

you can connect the motor with the delivered cable (polarity: red = +, black = -). Connect the

motor cable plug to OUT 3 (motor).

Fig. 3: View at the lower side of the FILTER|CONTROL.

Getting started

10

230 V AC Filter motors:

If your filter is equipped with a 230 V AC motor, connect its plug at the 230 V plug UVC /

MOTOR. Please consider that only motors with a power of max. 500 W can be connected

directly. Motors with a higher power consumption can be connected via the optional Power

Switch 24-230.

Note here, that all functions where the motor speed is controlled by the FILTER|CONTROL do

not work, because there is just an on / off switching of the filter motor possible. These

functions are:

Intensive cleaning programme

Soft motor start

High-pressure cleaning mode

If you want to use these functions with AC motors, you need a variable frequency drive to

control the motor speed.

230 V / 400 V AC Filter motors connected via variable frequency drive (VFD):

For changing the rotation speed of AC filter motors, which allows to use all functions which

change the motor speed, a variable frequency drive between the FILTER|CONTROL and the

filter motor is necessary.

SENECT offers fully configurated, parametrized and wired VFDs. The green labelled actuator

cable from the VFD must be connected to one the actuator output ports, e.g. OUT 1.

Note: Select the function “filter motor” for the corresponding actuator output port

(here OUT 1) and select the additional function “variable frequency drive”.

Getting started

11

4.) Connecting the spray and circulation pump

If the pumps are correctly installed, arrange all cables safely to your FILTER|CONTROL. Check

on the data sheets of your pumps, if they fit to the specifications of the FILTER|CONTROL

(spray pump: 230 V AC, max. 1800 W, circulation pump: 230 V AC, max. 900 W). Plug the spray

pump connector into the plug „SPRAY PUMP“ and the connector of the circulation pump to

the plug „CIRULATION PUMP“ (see Fig. 3).

To operate a drum or beltfilter correctly, it is necessary to connect the filter motor

and spray pump according to the specifications of the filter producer.

Every drum or belt filter consumes water. Therefore, it is absolutely necessary

that the lost water is refilled. Ensure that either the water is replenished

automatically or if manually, that the water level in your tanks or ponds is

constant.

Fig. 4: Sketch showing the general two hydraulic systems in which drum filter are operated.

Getting started

12

STARTING THE SYSTEM

Switch the FILTER|CONTROL on with the ON/OFF Switch at the bottom (Fig. 3).

Note: Changing languages can be easiliy done in the menu. Press the button MENU and

select under „System Einstellungen / Sprache“ the language „English“.

By pressing the button MENU, you can configure all necessary settings. With the cursor

buttons and , you can choose the desired menu item and to confirm your selection, press

OK. The button BACK brings you alway one hierachical level down, while HOME displays the

normal screen and exits the menu.

If your filter is used in a pumped system, select in the Filter Settings as Filter Mode „Pumped

System“. If you are operating the filter in gravity mode, select “Gravity System”.

If you are using a 230 V AC filter motor select in the menu at 230 V Plug / 230 V Plu 2 the

function „Filter Motor”. If you are using a 230 V AC filter motor connected via a variable

frequency drive to an actuator output port, select in the menu at Output ports / Plug 1 the

function „Filter Motor” and the additional function “Var. Frequency Dri”.

Select the proper type of water level sensor connected to your FILTER|CONTROL. If you are

using the water level probe PS, select Sensors / Sensor backwashing / Sensor Type the type:

„PS-300-MA” while if you use the water level sensor EPS, select „EPS-250-MA“.

Switch on your circulation pump by pressing the button „PUMP ON/OFF“. You can now also

switch off (and on) the filter operation (incl. circulation pump) by pressing the button „STOP“.

Clean the filter by pressing the button „CLEAN FILTER“. After the cleaning process, check the

water level in your system. If the water level is correct, you have to set the water level

sensor(s) to zero (referencing). Press the button „SENSOR REF.“ and confirm with yes.

Now, your system is ready for operation.

To achieve the most efficient operation, you have to set all settings so that they fit to your

filter, for example the cleaning duration, etc. You´ll find more information in the chapter

“Operation”.

Getting started –Short version

1. Mount the FILTER|CONTROL at a protected place.

2. Mount the water level sensor PS submerged in the filter chamber (gravity system) or in

the pre chamber (pumped system).

Getting started

13

3. Connect the filter motor cable, the spray pump, the water level sensor, the cover switch

and the circulation pump with your FILTER|CONTROL.

a. If you are using a VFD, connect the motor to the VFD, connect the green marked

actuator cable of the VFD to the FILTER|CONTROL to OUT 1 and plug the VFD

power plug into a power supply mains plug.

4. Switch the FILTER|CONTROL on.

a. If you are using a VFD, select in the MENU the function “filter motor” for the

corresponding actuator output port (e.g. Plug 1) and the additional function

“variable frequency drive”.

5. Set the correct backwash settings in the MENU under Filter Settings.

6. Switch on the circulation pump (button PUMP ON/OFF) and clean the filter (button

CLEAN FILTER).

7. Check the water level. If the water level is correct, set with the button SENSOR REF the

water level to zero.

Now, your system is ready for operation.

Please note that the filter backwash water levels refer to the referenced water level

while the alarm settings of the sensor refer to the absolute water level.

Fig. 2: Relative water level vs. absolute water level.

reference zero level

absolute water level

(used for alarming,

e.g. +48 cm)

relative water level

(used for filter

operation, e.g. -5 cm)

Operation

14

Operation

Display and symbols

On the display, you´ll find information about

current measurement and the status of the

instrument.

The upper row shows you action symbols,

which display the current running actions or

modes of operation.

The action symbols are:

Alarm active

Pause, release with “STOP”

Pin code active, unit blocked

Circulation pump on

Filter cleaning

Water refill

WLAN: Not connected

WLAN connected, but not internet access

WLAN: Connected with network

WLAN: Configuration mode active

WLAN: Update available

Fig. 5: The display of the FILTER|CONTROL.

Operation

15

Buttons and menu

The FILTER|CONTROL is operated by

the user via the buttons on the front.

With the navigation buttons (, ,

, , BACK and HOME) you can

navigate through the menu and

change the displayed view (e.g.

showing the water level or the

barometric pressure).

Cursors: With the cursor

buttons you can move

through the menu and

change settings..

OK: With OK you confirm your selection.

BACK: The button BACK brings you one level back in the menu.

HOME: By pressing home, the home screen will be displayed and you exit the menu.

MENU: The menu is opened by pressing MENU.

INFO: The button INFO shows you information about the filter operation like the

history of actions.

Lock: By pressing the buttons MENU and HOME simulatanously, the lock is active. To

unlock the keypad, you have to enter the Pin Code. The Pin Code is 0000 unless

you have changed it in the menu.

STOP: By pressing STOP all actions are stopped immedeately and the device is in the

break mode. By pressing STOP again, the device starts again.

CLEAN FILTER: By pressing CLEAN FILTER you start a cleaning process. If you press longer than

3 s, the intensive cleaning mode is started.

ROTATE/MOVE: To move the belt or rotate the drum manually, press ROTATE/MOVE. If you

release the button, the motor stopps.

SENSOR REF: To reference the water level sensors, press SENSOR REF. If you confirm then

with ok, the water level is set to 0.

WATER: If there is a SENECT soleonoid valve connected, pressing WATER leads you

directly to the water refill menu. If you press WATER longer than 3 s, the

solenoid valve is opended until you release the button.

PUMP ON/OFF: With the button PUMP you can switch the circulation pump on and off.

Fig. 6: Buttons of the FILTER|CONTROL.

Operation

16

All settings and parameters can be set in the menu. The following overview shows the menu

exemplarily. Please consider that some parts of the menu are dynamic, which means that they

only appear in certain constellation or with certain equipment.

Table 1: Description of the history entries.

Entry

Description

System Start

Start of the control unit

Man. Backwash

Backwashing started manually (by pressing the button)

Sens. Backwash

Backwashing started by sensor measurements

Sens. Forced B.

Forced backwashing started by sensor

Time contr. Bw.

Time-controlled backwashing

Abort backwash

Manual interruption of backwashing

Modus changed

Operating mode of filter settings changed (automatic vs. time-contr.)

Intensive cleaning

Intensive backwash

Drive error 1

Error on high-power OUT 3: no current measureable

Drive error 2

Error on high-power OUT 3: overload

Drive error 3

Error on high-power OUT 3: short circuit

Break active

Break mode is active (e.g. by pressing STOP)

Break deact.

Break mode was deactivated

Dry run prot.

Dry run protection mode was started

Reset dry run.

Dry run protection mode was manually stopped

Man. Pump off

Pump was switched off manually

Man. Pump on

Pump was switched on manually

Power fail

Power failure or control unit switched off

Factory setting

Factory settings loaded

Man. Refill.

Water refill was started manually

End of refill

End of water refilling

Timer refill

Start of time-controlled refilling

Sensor refill

Start of sensor-controlled refilling (time table)

Interv. refill

Start of time-controlled refilling (interval)

Abort sensorc.

Abort of sensor-controlled water refill (exceeding max. time)

Timer on

Timer controlled output was switched on

Timer off

Timer controlled output was switched off

Sen.Reg.on

Sensor controlled output was switched on

Sen.Reg.off

Sensor controlled output was switched off

Feeding

Feeder active

No Feeding

Feeding cancelled due to environmental parameters e.g. O2, temp.

Cover opened

Cover switch recognizes open cover

Cover closed

Cover switch detects closing of cover

Output Alarm

Alarm on output

Output Ok

Alarm on output cleared

Sensor Error

Error at sensor

Sensor Alarm

Sensor measurements above or below alarm thresholds

Sensor Ok

Sensor values again in normal range

Operation

17

Filter Settings

Filter Mode

Gravity System

Pumped System

Operating Mode

Deactivate

Automatic Mode

Time-controlled

High-Press. Cleaner

Extras

Deactivate

Dynamic|Mode

Eco|Mode

Cover Sw. DF

Cover Sw. EBF

Dry run Prot. Off

Dry run pro. pump sump.

Water Level

Flush Level

Dry run Protection 1

Dry run Protection 2 (only pumped system)

Backwash Parameter

Backwash Duration

Pre-flushing time

Post-flushing time

Cleaning Pause

Forced Clean. Cycle

Intensive Cleaning

Interval

Duration

Motor Speed

Motor Speed

Eco|Mode

Dauer Eco|Mode

Alarm

Mode

Deactivate

Forced Clean. Cycl

Service Interval

Service Interval

Filter Menu

continued on next page

Selection:

selected (factorysettings)

not selected

123

123

123

Input value:

Numerical

123

123

123

123

123

123

123

123

123

123

123

123

Filter settings

18

Filter settings

Here you can configure all relevant settings for the filter operation.

Filter Mode

Select here, if you are using your filter in a gravity or pumped system. The selection here

means that the filters backwashing is triggered by an decrease of the water level (typically

for gravity mode, where the sensor is installed behind the filter) or by an increase (when

the sensor is installed before the filter).

Operating Mode

Without a water level sensor, the filter is operated time-controlled. In this menu point, you

can choose the operation mode. „Automatic mode“ means that based on the clogging of

the filter mesh, indicated by the measurements of the water level sensor, the cleaning is

initiated. In the „Time-controlled mode“, the filter is cleaned in regular time intervals. The

“High-Press. Cleaner” mode lets the filter motor run continuously, but slow without

activating the spray pump. This mode is handy, when the filter mesh is cleaned manually

with a high-pressure cleaner.

Filter settings

19

Extras

Here you can select the activation of extra functions.

1. Dynamic|Mode:

The Dynamic|Mode is a special algorithm which leads to a more stable clogging-induced

control of the backwashing. With this mode, the backwash water level is continuously

corrected for changes in the water level. Please note, that the backwashing is then not at

exactly the specified backwash water level. Instead it starts when the “corrected”

backwash level is reached.

2. Eco|Mode

With the Eco-Mode you can decrease the water consumption of your filter. When the water

level sensor initiates the cleaning, only the filter motor is activated for a short time to bring

the until then unused filter mesh into the water. By monitoring the water level, the

FILTER|CONTROL will decide when the next full cleaning is necessary.

3. Cover Sw. DF

If the cover switch is defined as “Cover Sw. DF” where DF stands for drum filter, the

backwashing will be stopped, if the cover is opened. Additionally, when the 230 V plug 2 is

defined as “UVC lamp”, it will be also switched off immediately.

4. Cover Sw. EBF

In case the cover switch is set to EBF, which means “Endlosbandfilter” or continuous belt

filter, a backwashing will not be interrupted when the cover is opened. The UVC on 230 V

plug 2 however will be switched off.

Water level

All water level related parameters are system-specific. In this menu item, you can configure

the cleaning-related water level settings.

Flush Level

The flush level is the water level threshold, under (gravity system) or over (pumped system)

which the cleaning is initiated. It is always displayed positive as a difference.

Dry run Protection

The Dry run Protection level is the water level at which the circulation pump is deactivated

and the system stopped. If the water level is below this level, the FILTER|CONTROL tries

several times to reactivate the filter. Only if the operation can be safely continued, the

FILTER|CONTROL goes back into the normal operation mode.

You will see this as a message in the display. The symbol “Pause” will also appear. To restart

the operation manually, press “STOP”.

Filter settings

20

Backwash Parameter

Here you can set all relevant parameters for the filter cleaning.

Backwash Duration

The backwash duration defines the time of one cleaning cycle. Choose the flush time so

that the drum is rotated at least one time completely.

Pre-flushing time

With the pre-flushing time, you can define how long the spray pump is activated before the

filter motor starts.

Post-flushing time

To discharge also the last rest of particles from the flush tray, you can set with the post-

flushing time the duration, how long the spray pump should stay activated after the filter

motor stops.

Cleaning pause

The cleaning pause defines the minimal temporal distance between two filter cleaning

events. This break prevents from water loss associated from too man cleaning events. But

in case the water level drops further towards the emergency level, the filter flushes despite

there is a cleaning pause. This function disables the cleaning pause in situations, when

urgent cleaning is necessary.

Forced Clean. Cycle

Here, you can specify how often the filter should be backwashed even when the sensor

does not detect the necessity of backwashing. This means that you can set here the

maximum time where the filer is not flushed.

This manual suits for next models

2

Table of contents

Other Senect Control Unit manuals

Popular Control Unit manuals by other brands

IEI Technology

IEI Technology IVC-168G Quick installation guide

Trueline Distribution

Trueline Distribution Fig.652 Installation & Maintenance Manua

Leviton

Leviton VIZIA RF PLUS VRC0P-1LW installation instructions

Texas Instruments

Texas Instruments TPA0142 user guide

SUPPO

SUPPO OSD V3.71 manual

TLV

TLV JA3D instruction manual

AB Quality

AB Quality CompactLogix 1768-CNB installation instructions

Tekmar

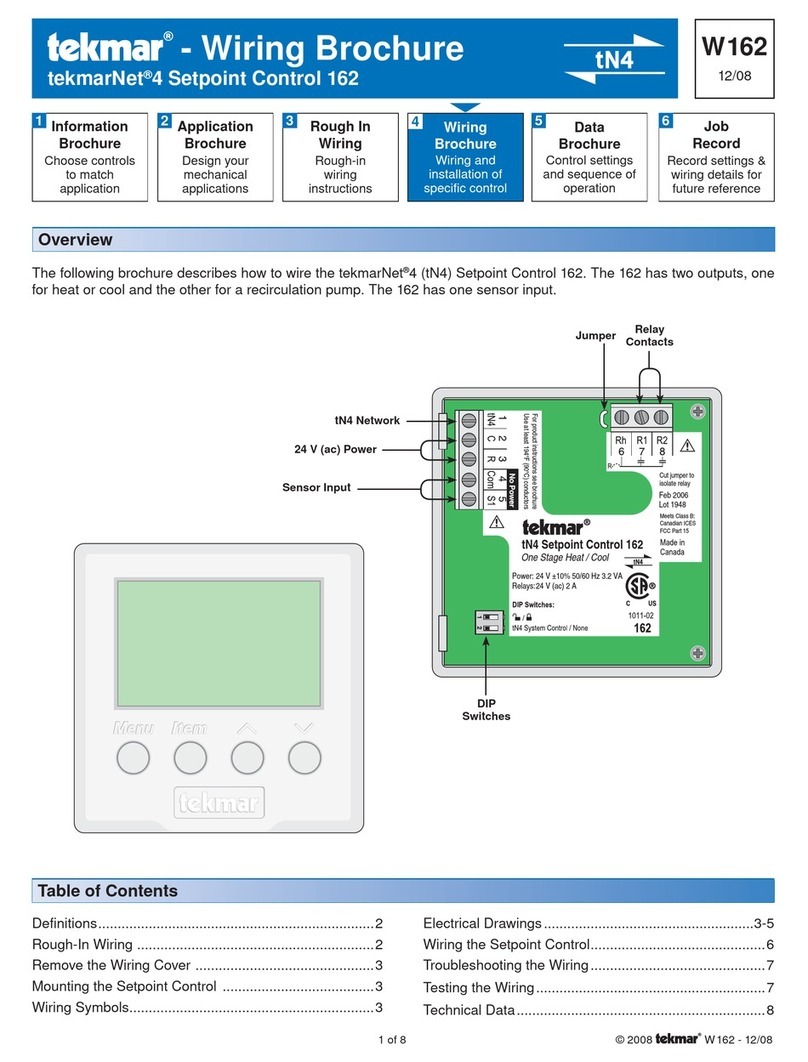

Tekmar tekmarNet4 Setpoint Control 162 Wiring Brochure

Leviton

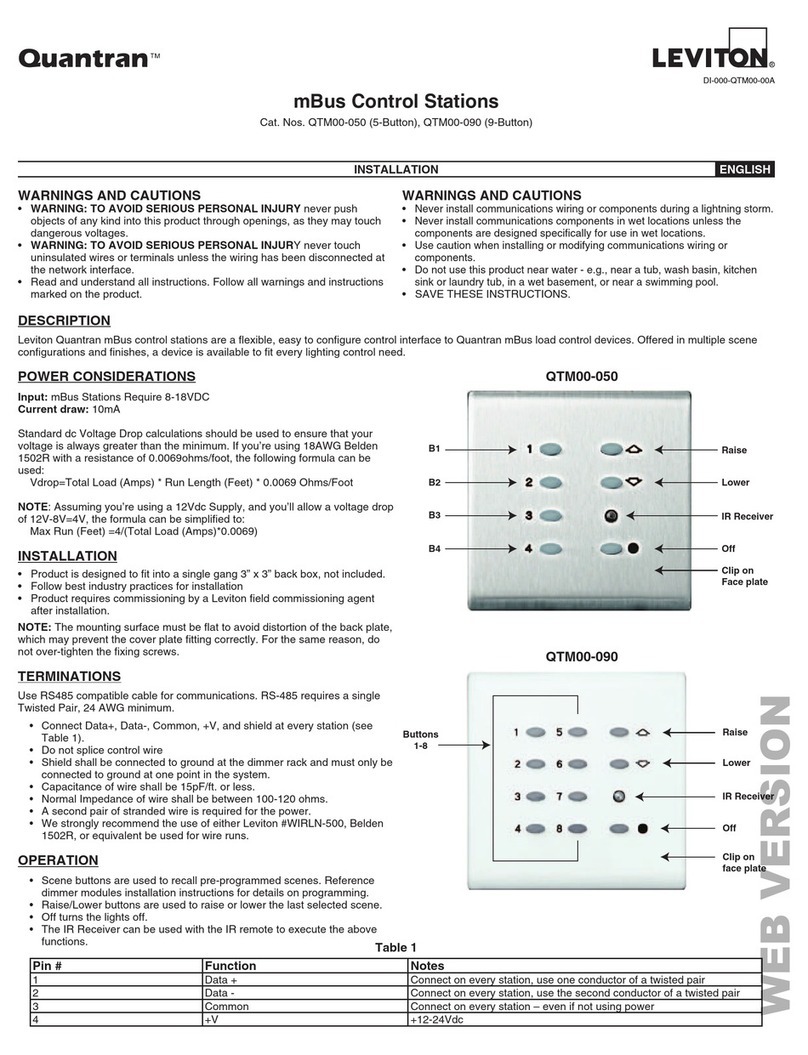

Leviton Quantran QTM00-050 quick guide

Rotex

Rotex 31123 Mounting, Operating, Testing & Maintenance Instructions

Duali

Duali DE-ABCM6 user manual

Aprimatic

Aprimatic WING NK Mechanical installation instructions