Trueline Distribution Fig.652 Instruction Manual

Fig.652 Installation & Maintenance Manual

1

Trueline Distribution

20201 Clark Graham, Baie D’Urfé,

H9X 3T5 CANADA

P. : (514) 457-5777 T.F. : (800) 667-4819

F. : (514) 457-1348

General Information:

•Toprovideanoptimumservicelife,thevalveshouldbeoperatedonlyinitsfully

openorfullycloseposition.Ifthevalveisusedinpartlyopen(throttled)

position,seatlifemaybereduced.

•Extendingthehandleleverisconsideredmisuseandcandamagethevalveor

causeinjuries.

•Thevalvebodyratingcanbehigherthantheseatrating.

•Highviscousorabrasivemedia,frequentoperationandtemperature

fluctuationscouldcauseanincreaseinvalvetorque.

•Valvepressurevariesunderdifferentmodels,sizes,workingtemperaturesand

materials.Pleaseverifytheapplicationwithinthelimitsspecifiedhereinandas

describedonmetalplatespotweldedonvalvebody.Referencescontainedin

thisdocumentstothe‘PED”areinregardstoEuropeanPressureEquipment

Directive97/23EC.

•AlwaysuseTruelinerecommendedsparepartsformaintenanceand

replacement.

Shipping and Storage:

Allvalvesarepackedinstrongcardboardsandplasticbagstoavoidanypossible

damageduringtransportation.Allthevalvesmustbeexaminedonreception,toensure

thattheyhavenotsufferedanydamagesduringtransport,andthesuppliermustbe

informedofanydamagesobserved.Iftheitemsarenotforimmediateuse,please

followthefollowinginstructions:

1. Leavethevalvesinfullyopenposition.Neverleavethevalveinapartiallyopen

position.

2. Alwayskeeptheprotectivecoversinplaceuntilthevalveisreadyfor

installation.

3. Thevalvesshouldnotbeunpackeduntiltheyaretobedefinitivelyinstalled,

exceptforpurposeofinspection.Afterinspectiontheywillbepackedagain.

4. Thevalvesshouldbestoredundercoverandprotectedfromsevereweather

conditionsandforeignbodies.

5. Stainlesssteelballvalvesdonotneedanyadditionalprotectioncoatingsonce

theyareinstalled.

6. ValvestobestoredforalongperiodoftimeshouldbeinspectedbyQC

personneleverysixmonthsandeverythreemonthsforautomatedvalves.

Fig.652 Installation & Maintenance Manual

2

Trueline Distribution

20201 Clark Graham, Baie D’Urfé,

H9X 3T5 CANADA

P. : (514) 457-5777 T.F. : (800) 667-4819

F. : (514) 457-1348

General Installation Step:

Thehandlingandtransportingofthevalvesmustbecarriedoutwithextreme

precautionandusingthenecessary&adequatemeansonthebasisoftheirsizeand

weight,avoidinganyriskstothepersonthathandlethem.

1. Valvepressurevariesunderdifferentvalveseries,sizes,applicationtemperature

andthematerialofthemainparts.Pleaseverifytheapplicationwithinthelimits

andasdescribedonthevalvebody.

2. Priortoinstallation,pleasemakesurethevalveisfreefromdirtandother

foreignmaterialsthatcoulddamagethevalveseats,asthesepartsare

fundamentaltothecorrectoperationofthevalve.

3. Itmightbenecessarytoflushtheballvalve,valvecavityandthepipestoremove

theaccumulateddirtandburrs.

4. Valvesshouldbeoperatedforatleasttwocompletecyclesbeforethe

installationtothepipe.Allthemultiportballvalveshaveavisualindicator

engravedonthevalvestem.Makesurethevalveportconfigurationcomplywith

theflowarrangementofthepipe.

5. Useanypipesealantsuitableforthematerialandtheprocessthatthevalveis

installedin.Don’tusethesealanttooexcessivelytoavoidtheobstructionin

valveoperation.

6. Alwaysleaktestthesystembeforeusing.

Installation Step for Screwed End:

1. Keepthevalveinopenposition.

2. Checkthevalvethreadsandthethreadsoftheconnectingpipeandmakesure

thesearefreefromdirt,gritorburrs.

3. Useananti‐seizethreadsealanttosealandpreventgalling.Taperthreaded

fittingsshouldnotbeovertightened.

4. Whentighteningvalve,useawrenchontheendnearesttothepipe.

Installation Step for SW/BW End:

1. Tackweldthevalve(inopenposition)endcapstothepipesatthreepoints.

2. Loosen&separatetheendcapsfromthebody.Removetheseatandsealand

setasideinthecleanandsecuredareaforreassemblylater.

3. Weldcompletelytheendcapstothepipes.Allowenoughtimeforcoolingthe

weldedjoints.Removetheremnantfromtheendcapsandpipes.

4. Putbacktheseatsandreassembletheendcapstothebodyaccordingtothe

BoltTorqueSpecifications.

Fig.652 Installation & Maintenance Manual

3

Trueline Distribution

20201 Clark Graham, Baie D’Urfé,

H9X 3T5 CANADA

P. : (514) 457-5777 T.F. : (800) 667-4819

F. : (514) 457-1348

Preventive Maintenance:

Preventivemaintenanceoperationsessentiallyconsistofperiodicinspectionsto

ensurethatthevalveisworkingproperly.

1. Thevalvemustbeopenedandclosedatleastonceeverysixmonths.Theuser

willberesponsibleforestablishingopeningandclosingplansthatareadequate

fortheworkingconditionsandfluidsused.

2. Beforemakingthemaintenance,alwaysmakesurethepressureisreleasedand

thelinehasbeenclosed.

3. Wearprotectiveclothingadequateforthecirculatingfluid.(Complywiththe

safetyguidelineslaiddownbythecompany).

4. Ifleakagehappensatthestem,tightenthestemnutaquarterturnasaroutine

maintenanceprocedure.Thiswillcompensateforanywearingorsettlingofthe

glandpacking.

5. Don’tovertightenthestemnut.Itwillcauseinexcessiveoperatingtorqueand

shortenthelifeofthepackingservice.Ifleakagepersists,depressurizethevalve

andreplacethestempacking.

6. Ifleakageisdetectedinthebodyseal,tightenthebodyconnectorbolts.Ifthe

leakagestilloccurs,thiswillbeduetothedamagedseal.Thevalveneedstobe

dismantledforrepairs.

Disassembly:

1. Makesuretheinstallationisnotunderpressure.

2. Loosenallbodyboltsorscrewsandremovethebodyfromtheline.Ifthe

circulatingfluidisnoxiousorinflammableprecautionsmustbetakentoavoid

accidents.

3. Removeanddiscardtheseatsandbodyseals.Removetheballandcheckthe

exteriorsurfaceoftheball,particularlytheareaincontactwiththeseatandthe

radiusortransitionbetweentheexteriorsurfaceandthebore.Iftheball’s

surfaceisdamagedreplaceitwithanewone.

4. Removethehandlesubassembly(handlenut,handle,stemnut,tabwasher,and

glandbushing).Placeallcomponentsincleanandsecuredarea.

5. Pushdownthestemintostuffingboxanddiscardthestempacking,O‐Ring,

thrustwasher.Becarefulnottoscratchornickthestempackingareaofthe

stuffingboxarea.

Fig.652 Installation & Maintenance Manual

4

Trueline Distribution

20201 Clark Graham, Baie D’Urfé,

H9X 3T5 CANADA

P. : (514) 457-5777 T.F. : (800) 667-4819

F. : (514) 457-1348

Assembly:

1. Cleaneachcomponentwithacleancloth.

2. Lubricatethethrustwasherandstempacking.Insertthestemintothestemport

ofthevalvebody.Placethethreadedendperpendiculartocenterlineofthe

body.

3. Holdthestemupandinsertthethrustwasher,O‐Ring,Stempacking,gland

packing,tabwasherandgland(stem)nut.

4. Tightenthestemnutaccordingtothetorquespecificationstatedinthismanual.

5. Inserttabwasher,handleandhandlenut.Tightenthehandlenut.

6. Bringthehandletoclosepositionandinserttheballandmakesureitengages

withthestem.

7. Movethehandleinopenpositiontopreventballfromfallingout.

8. Placetheballseatandbodysealintothebodyandinstallthebodyboltsand

nuts.Tightenthebodyboltsaccordingtothetorquespecifications.

9. Cyclethevalveseveraltimestoverifythefreeoperationofthevalve.

Table of contents

Popular Control Unit manuals by other brands

Spirax Sarco

Spirax Sarco DCV4 Installation and maintenance instructions

urmet domus

urmet domus Sinthesi 1148 manual

Tash

Tash SICARE Pilot user manual

Jinmuyu Electronics

Jinmuyu Electronics JMY601H user manual

Victaulic

Victaulic FireLock NXT 769 Series manual

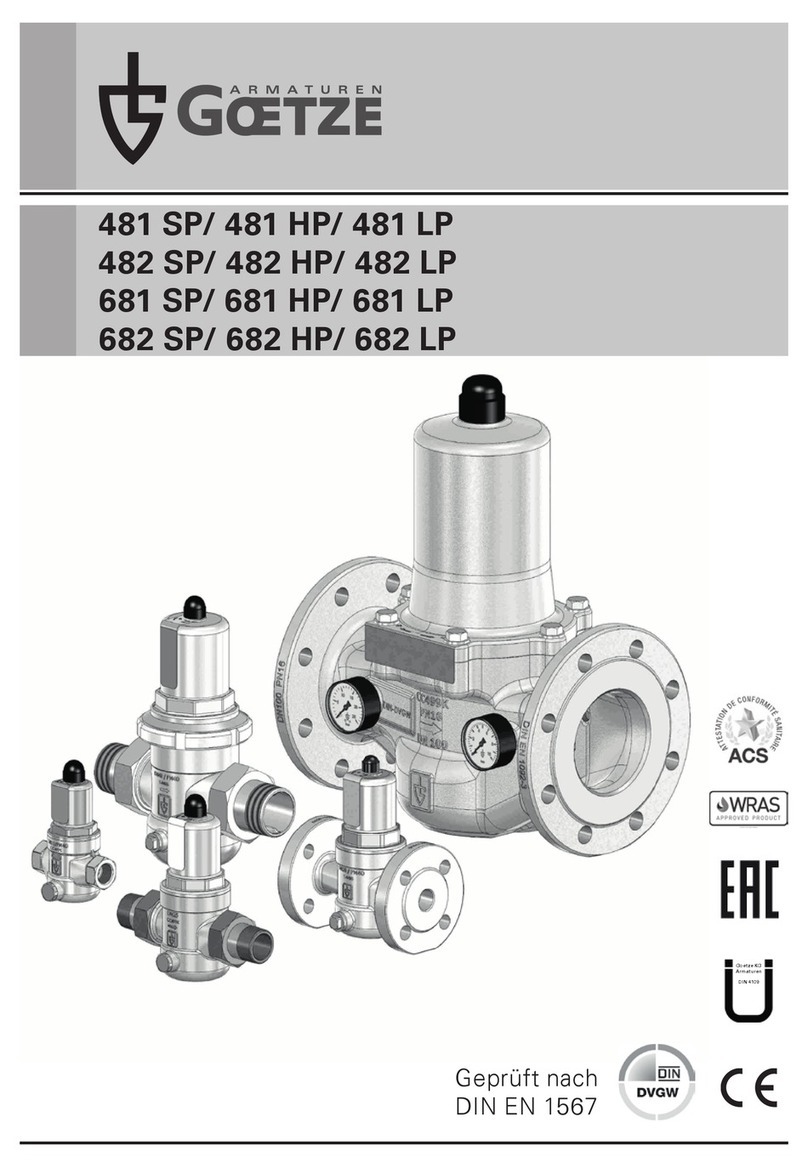

Goetze

Goetze 481 SP Assembly and maintenance instructions