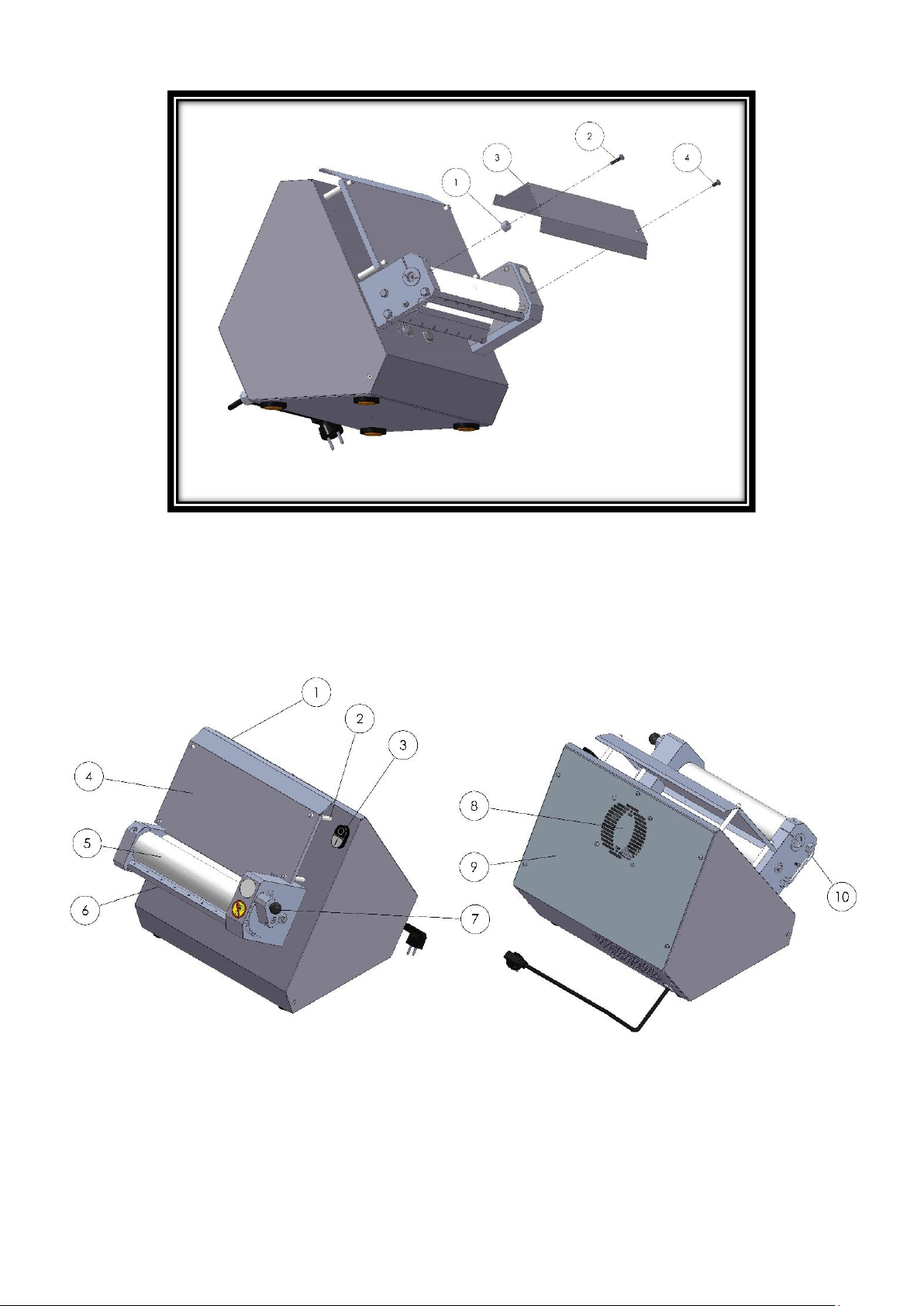

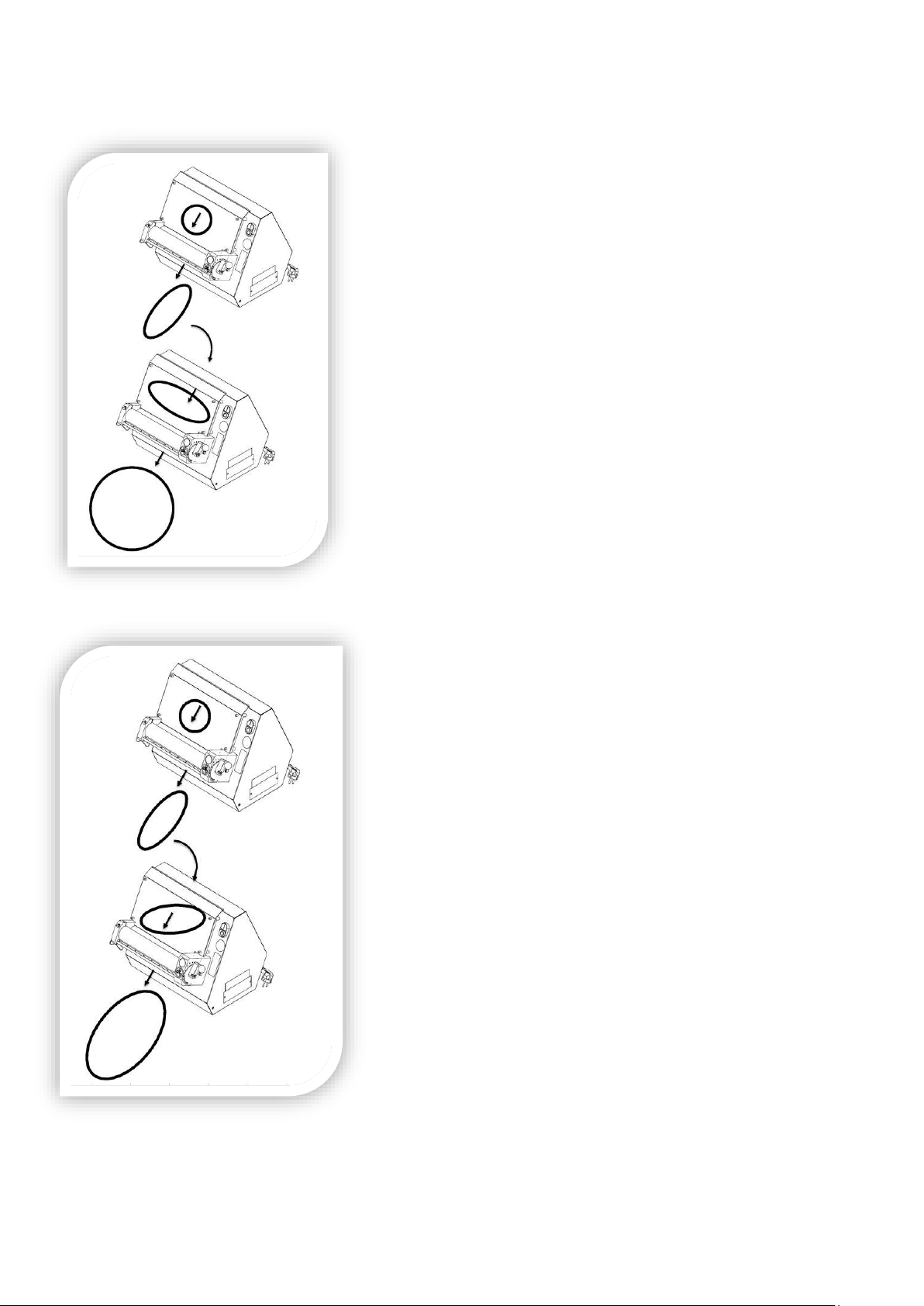

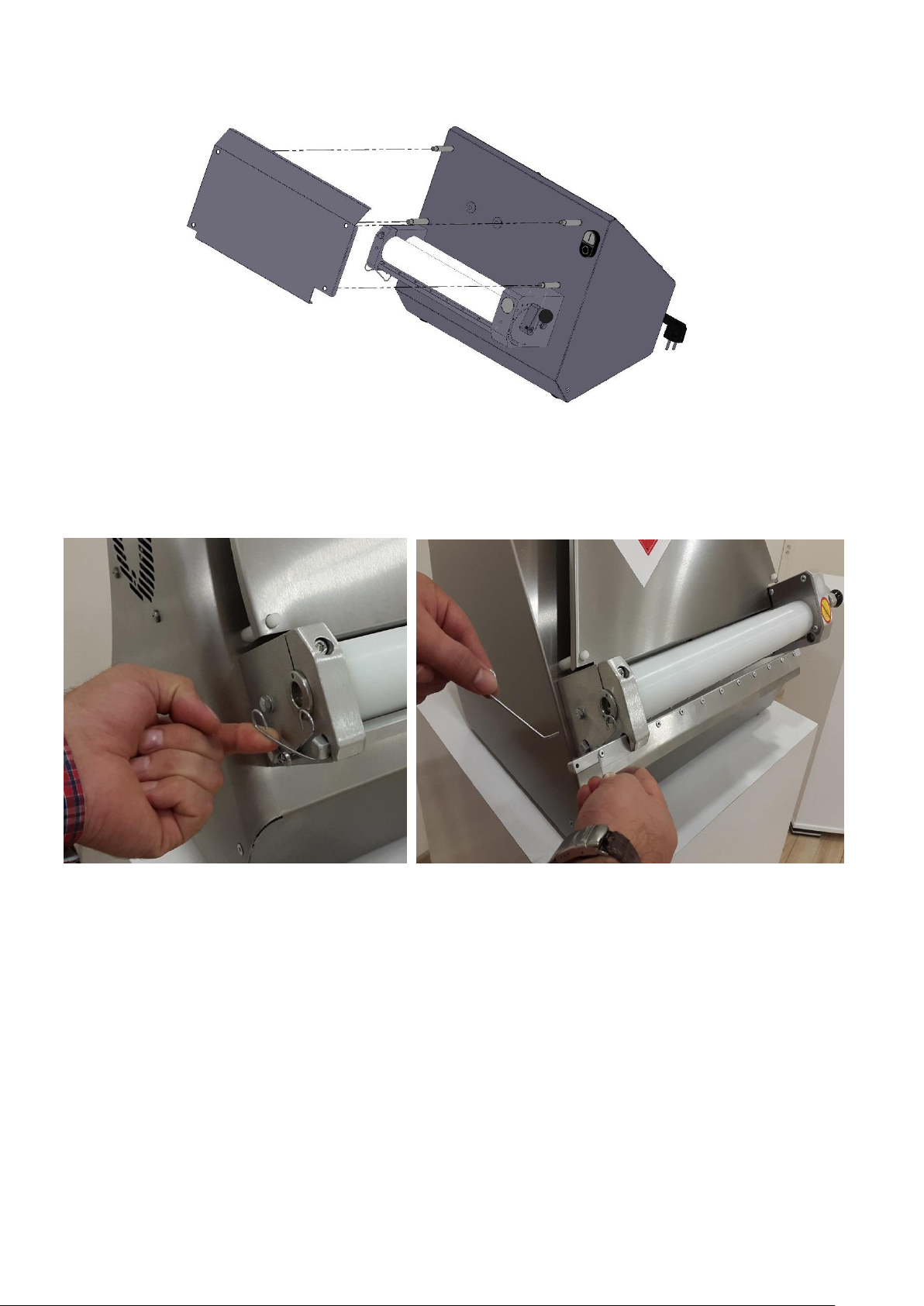

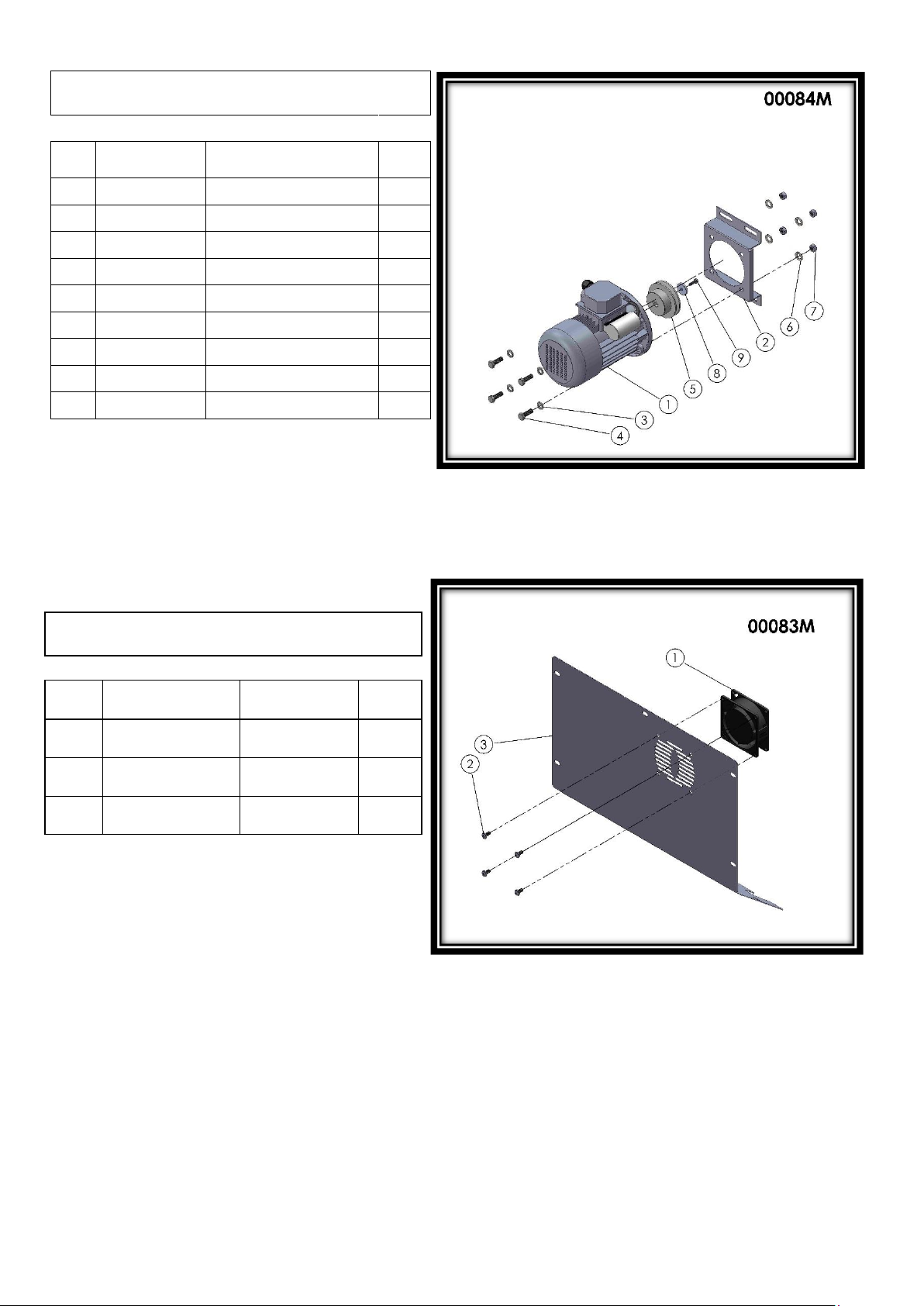

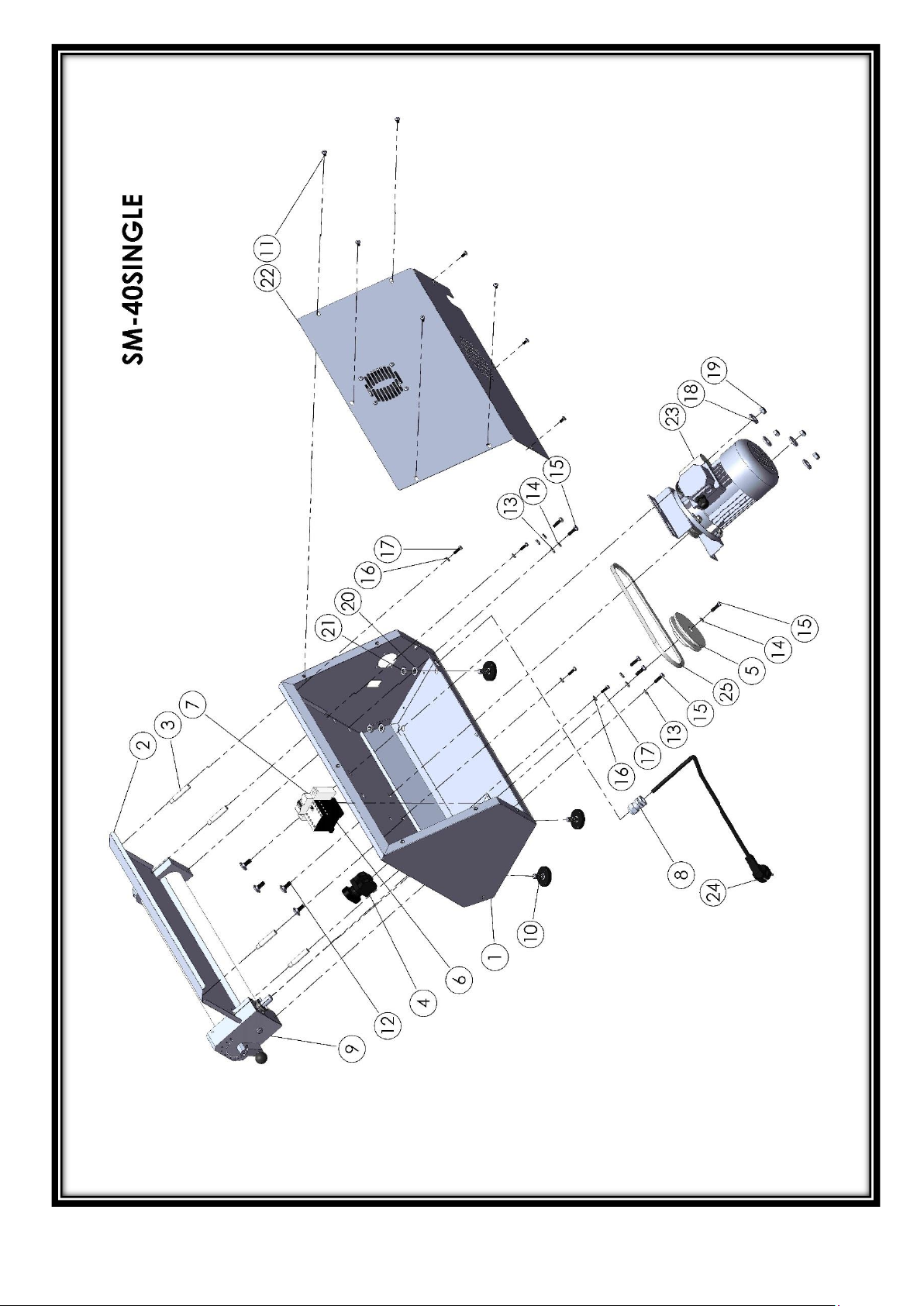

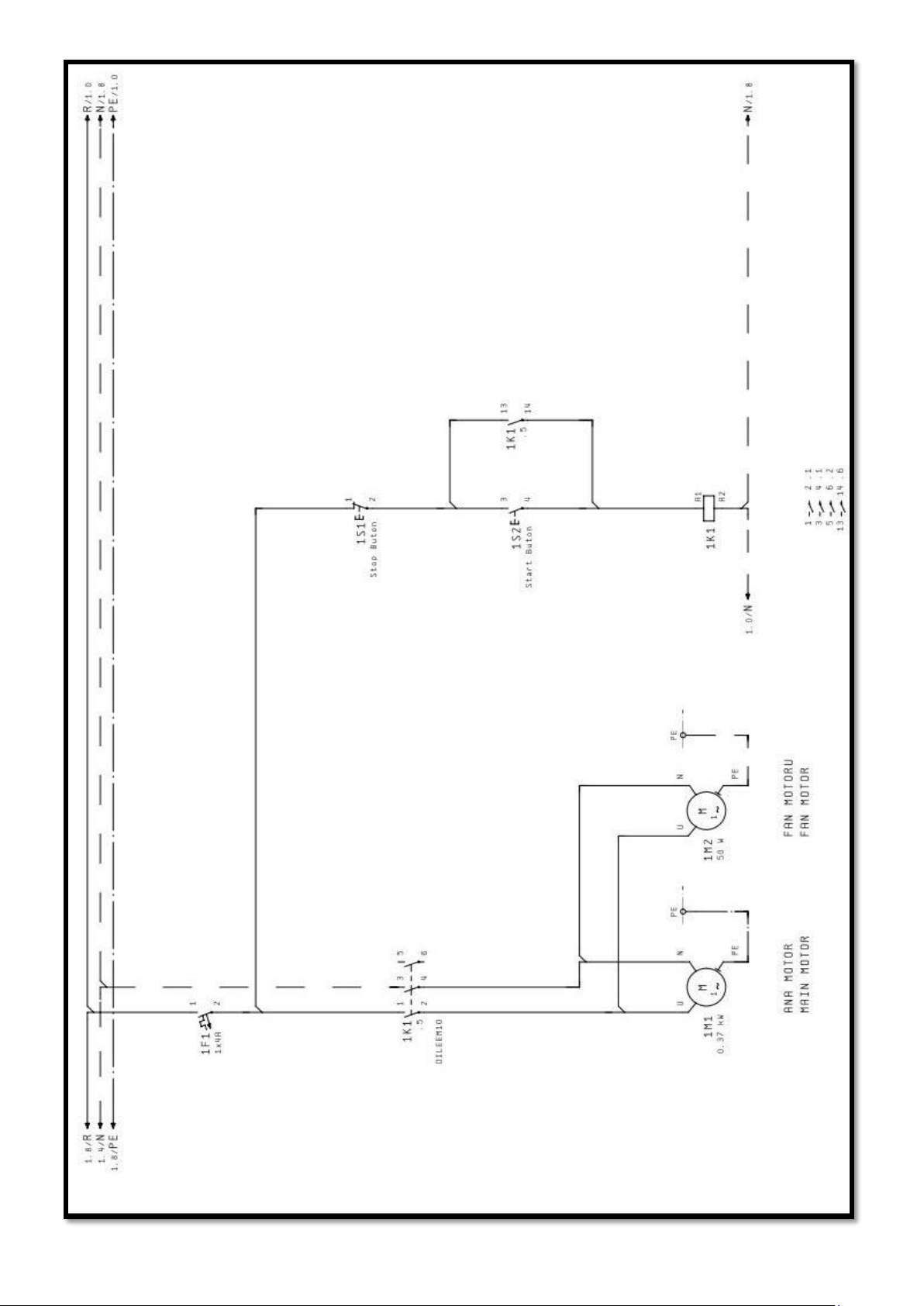

Sengun Makina SM-30 Single Operating instructions

This manual suits for next models

1

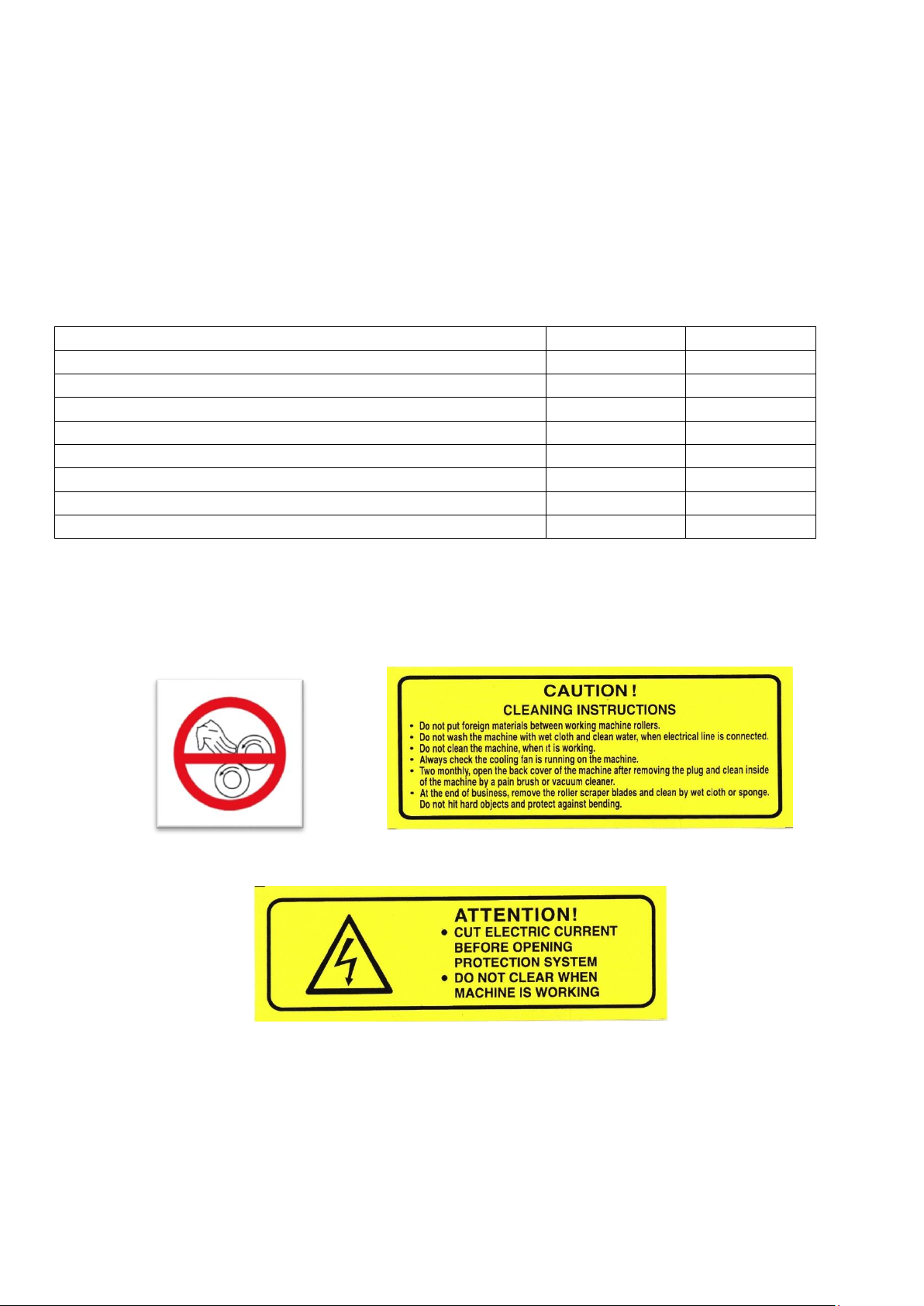

Table of contents

Other Sengun Makina Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Flavor Burst

Flavor Burst CTP 80CBB Equipment, Maintenance and Operations Manual

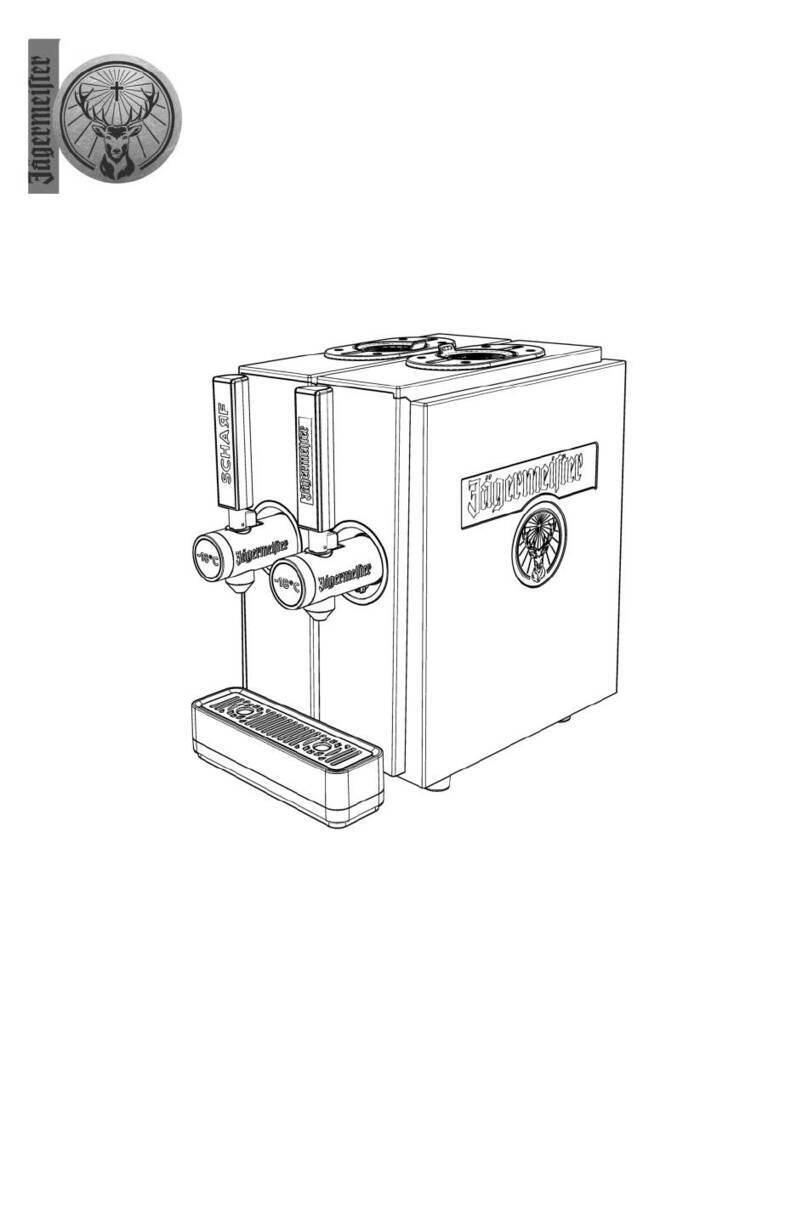

Jägermeister

Jägermeister DTM-EU Instructions for use

Wells

Wells WVAE-30F Supplemental service instructions

Rational

Rational SelfCooking Center Combi Master Training manual

Rühle

Rühle MPR 500 Translation of the original instructions

Hendi

Hendi 211502 user manual

Blanco

Blanco BLANCOTHERM 320 KB operating instructions

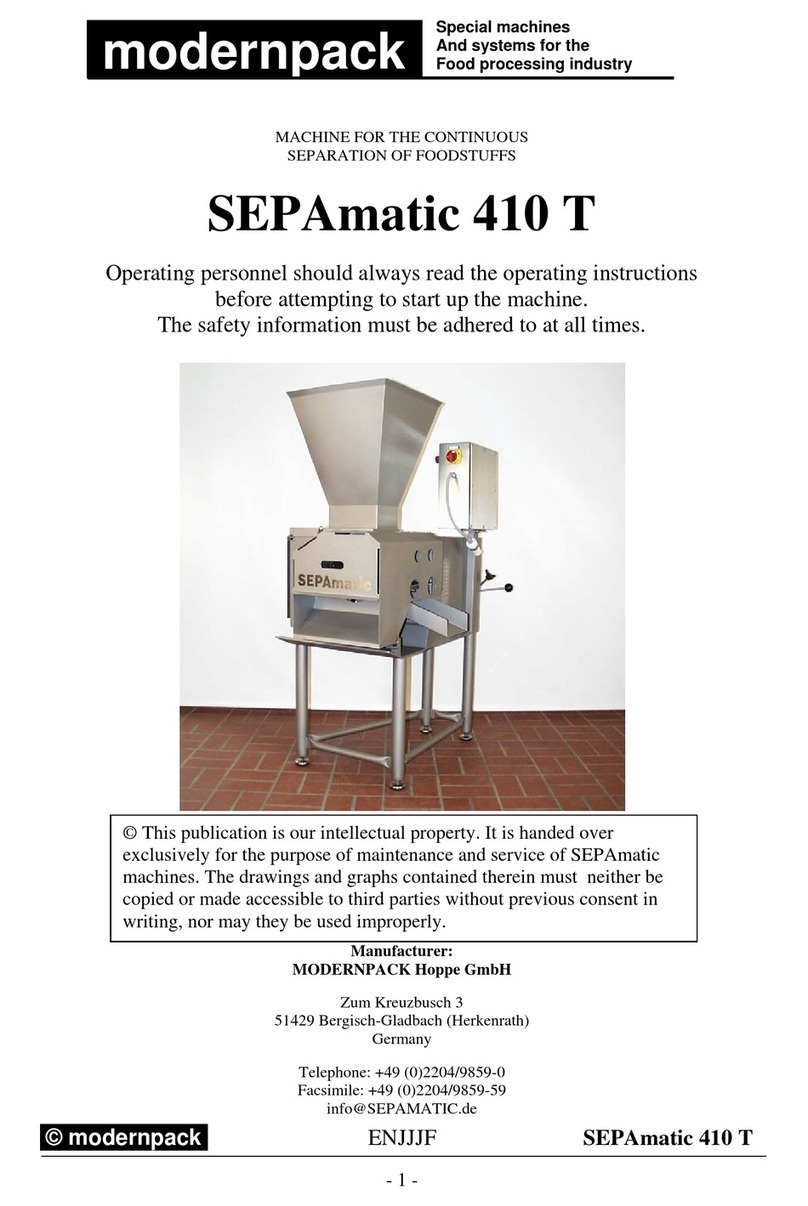

Modernpack

Modernpack EPAmatic 410 T manual

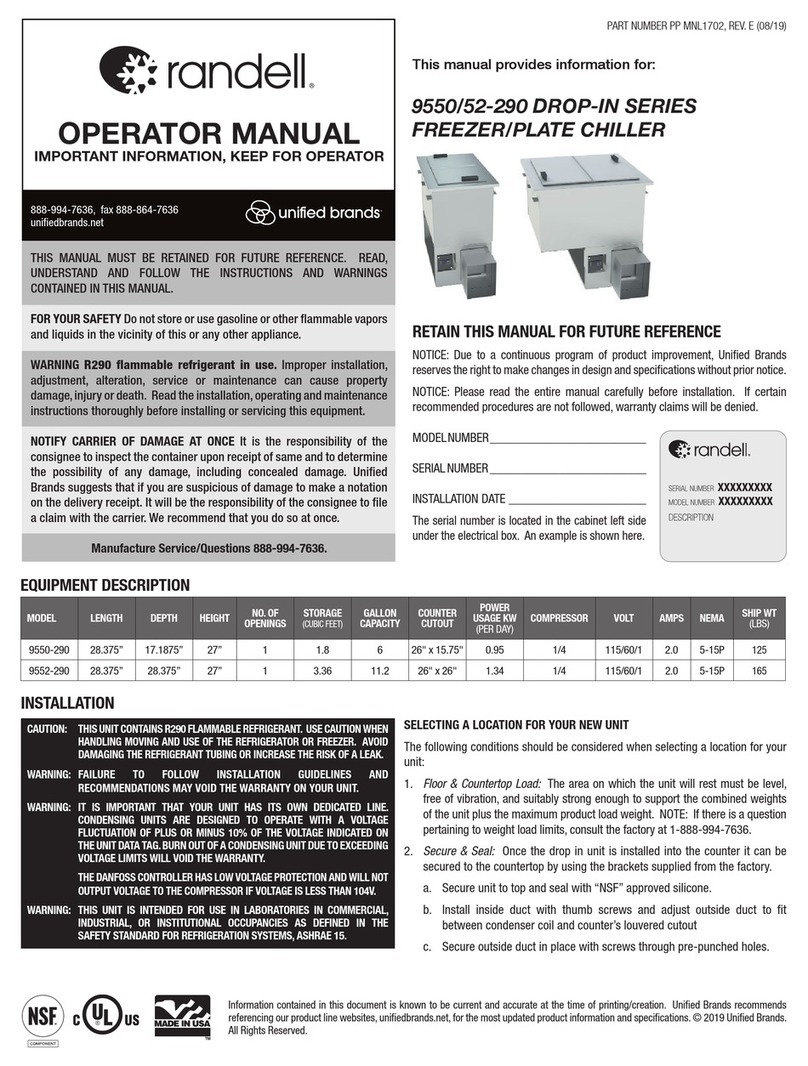

Unified Brands

Unified Brands Randell DROP-IN 9550-290 Operator's manual

ASBER

ASBER AESB-36 instruction manual

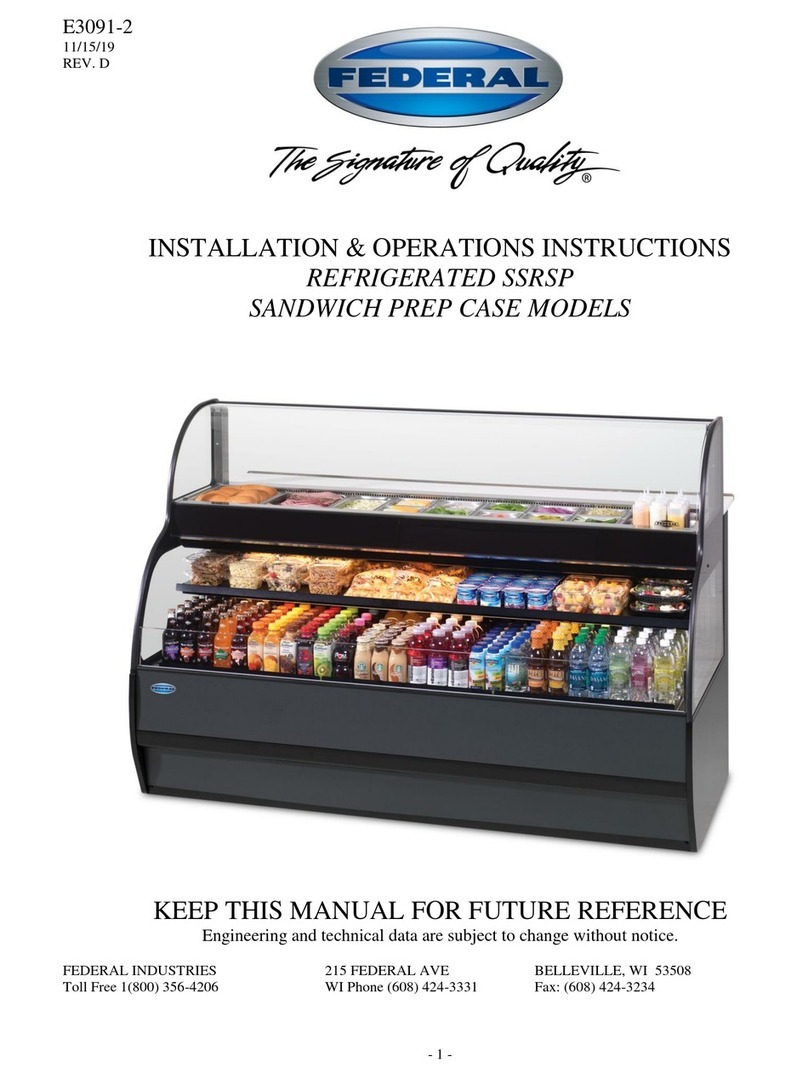

Federal

Federal SSRSP Series Installation & operation instructions

Rondo

Rondo COSTAN User instructions

Henny Penny

Henny Penny FlexFusion SpaceSaver Plus FSE-610 installation instructions

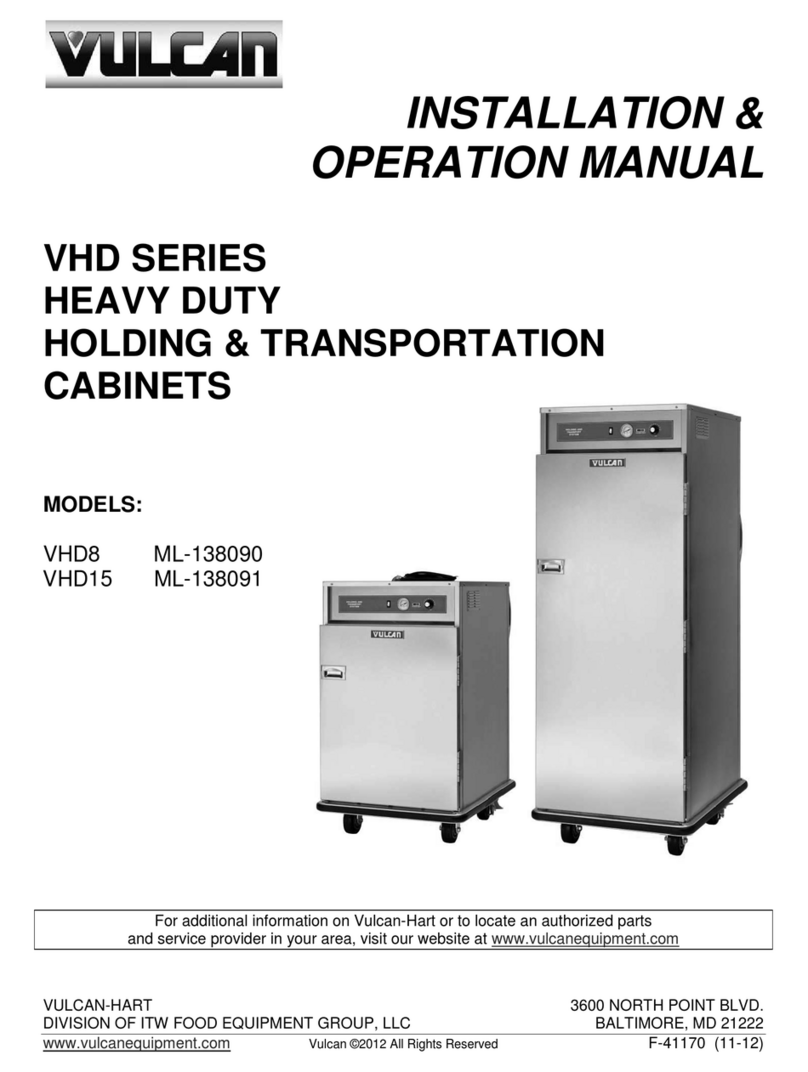

Vulcan-Hart

Vulcan-Hart VHD Series Installation & operation manual

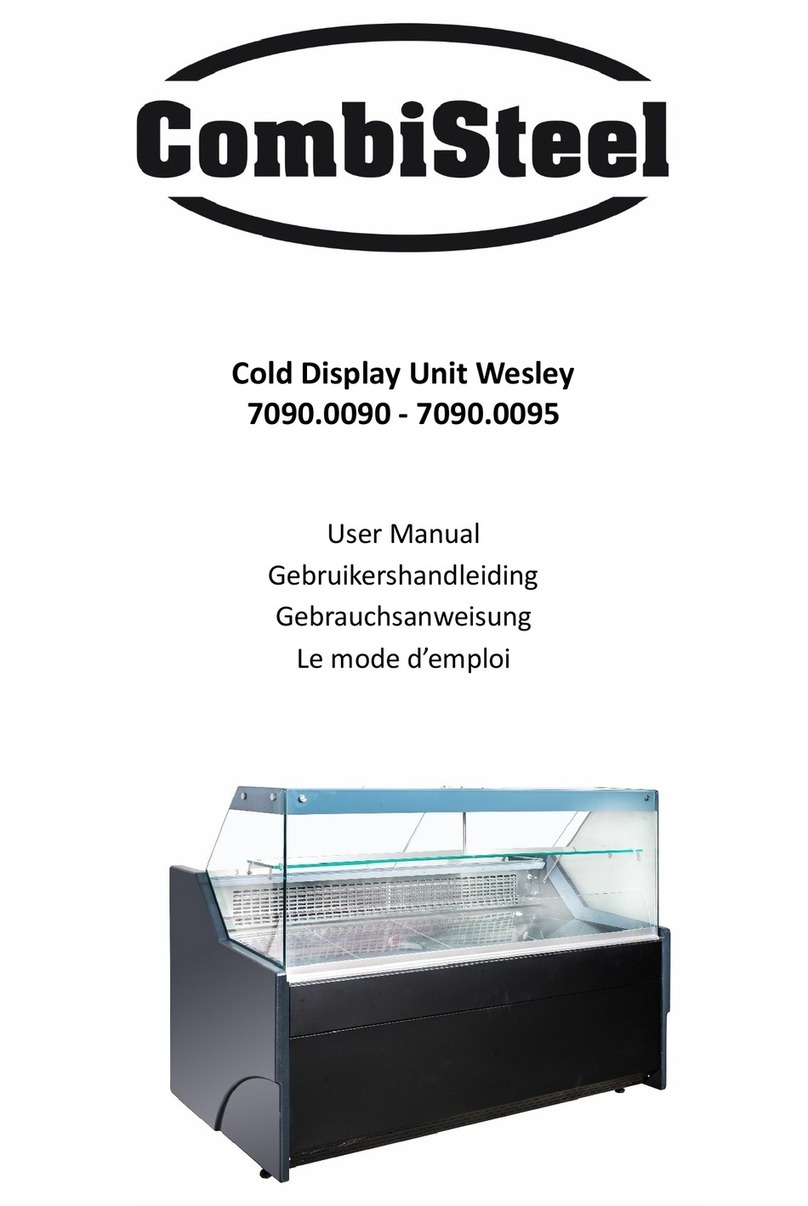

CombiSteel

CombiSteel Wesley user manual

Nordcap

Nordcap 437010313 INSTALLATION AND USE BOOKLET

Univex

Univex VS9 Operator's manual

Nuttall

Nuttall Flexeserve Zone FXZNA10S3C51 Operation manual