Sengun Makina MODEL-30 Operating instructions

MODEL-30, MODEL-40 MODEL -50

DOUGH ROLLING MACHINE

USER & MAINTENANCE MANUAL

1

WARRANTY CERTIFICATE

SERIAL NUMBER:

SALE DATE:

Sold at the above date MODEL- ..........DOUGH ROLLING MACHINE is guaranteed against production failures

for ..… Year by manufacturer.

Warranty Terms;

- Warranty terms start after the product delivery for ….. year.

- Recommended daily working time is 10 hours. The scope of warranty is assessed by year or by working

hours.

- The product is under warranty except plastic rollers (included plastic rollers if it is a manufacturing defect).

- Documents are invalid, if haven’t sale date and confirm signature of company. You have to show the

warranty certificate to benefit from the warranty.

- Device is guaranteed against defects if mount and use as described in the use and maintenance manual.

- Detection the location of defects, and elimination of the problems are responsibilities of the manufacturer.

- Warranty terms include only one device. You can’t claim any rights or compensation for another device.

- If Changes are made at the type, model and serial numbers, the warranty eliminates.

- If material, worker or assembly defects appear, repaired free by manufacturer at the product warranty

period (Transportation cost is not included).

- Failures are only repaired by manufacturer personal. The intervention of unauthorized person cancel the

appliance of warranty.

- Installation have to be done by manufacturer personal. İf usage place changes, customer must give

information to manufacturer

- In the event of failure service must be informed.

- The failures and damages given by external factors are out of the warranty terms.

- Any failure of the product warranty period is added to the product warranty time. The repair time is until

20 working days.

AUTHORIZED PERSON

STAMP –SIGNATURE

2

PRESENTATION

Please read the manuel carefully before installing the machine.

The machine will be out of warranty when your operate the machine with at read.

Please read carefully the manual that gives you information on the installation is prepared in

accordance with the legal regulations before arriving at the machine installation.

For information you coonot understand, ask your nearest out horized service

Please note that if the technical service personnel is kept waiting you will be billed for each hour.

3

CONTENTS

WARRANTY CERTIFICATE

PRESANTATION

SECTION 1: INTRODUCTION

1.1 General Introduction of Dough Rolling Machine Model: 30/40

1.2 Technical Specifications Table

1.3 Safety Warnings Labels

SECTION 2: INTRODUCTION OF MACHINE BODY COMPONENTS

2.1 Body Components

SECTION 3: INSTRUCTIONS FOR USE

3.1 Usage Recommendations

3.2 Safety Warnings

3.3 Operating and Starting Instructions

3.4 Operation On Optional Pedal Models

SECTION 4: MAINTENANCE

4.1 Exterior Body Maintenance

4.2 Scraping Knife Maintenance

SECTION 5: MACHINE SPARE PARTS MANUAL

SECTION 6: PLATEN PROTECTION SHEET ASSEMBLY

SECTION 7: ELECTRICAL DIAGRAM

7.1 Model 30/40, Model 30/40 Flat Electrical Diagram

7.2 Model 30/40/50 Pedal, Model 30/40/50 Flat Pedal Electrical Diagram

4

SECTION 1: INTRODUCTION

1.1 General Introduction of Dough Rolling Machine Model-30 / Model-40:

Uses at lahmacun, pizza and other dough rolling processes. Dough thickness and diameter get easy with

roller gap adjustment system. Dough rolling process perform in min. 3, max. 5 seconds with fast and

easy using feature.

1.2 Technical Specifications Table:

Technical Specifications Table

MODEL-30

MODEL-30 FLAT

MODEL-40

MODEL-40 FLAT

MODEL -50 FLAT

Machine Length (cm)

45

45

48

48

61

Machine Width (cm)

41

41

51

51

48

Machine Height (cm)

60

65

72

75

75

Machine Weight (Kg)

31,8

31,8

39

39

46

Engine Power (kW)

0.37

0.37

0.37

0.37

0,37

Electrical Connection (V-HZ)

230V 1N

50/60HZ

230V 1N

50/60HZ

230V 1N

50/60HZ

230V 1N

50/60HZ

230V 1N

50/60HZ

Dough Weight (gr)

80-210

80-210

80-500

80-500

80-500

Dough Diameter (cm)

19-29

19-29

26-40

26-40

26-40

Roller Range (mm)

0-4,1

0-4,1

0-4,1

0-4,1

0-4,1

Hourly Production Quantity

720-1200

720-1200

720-1200

720-1200

720-1200

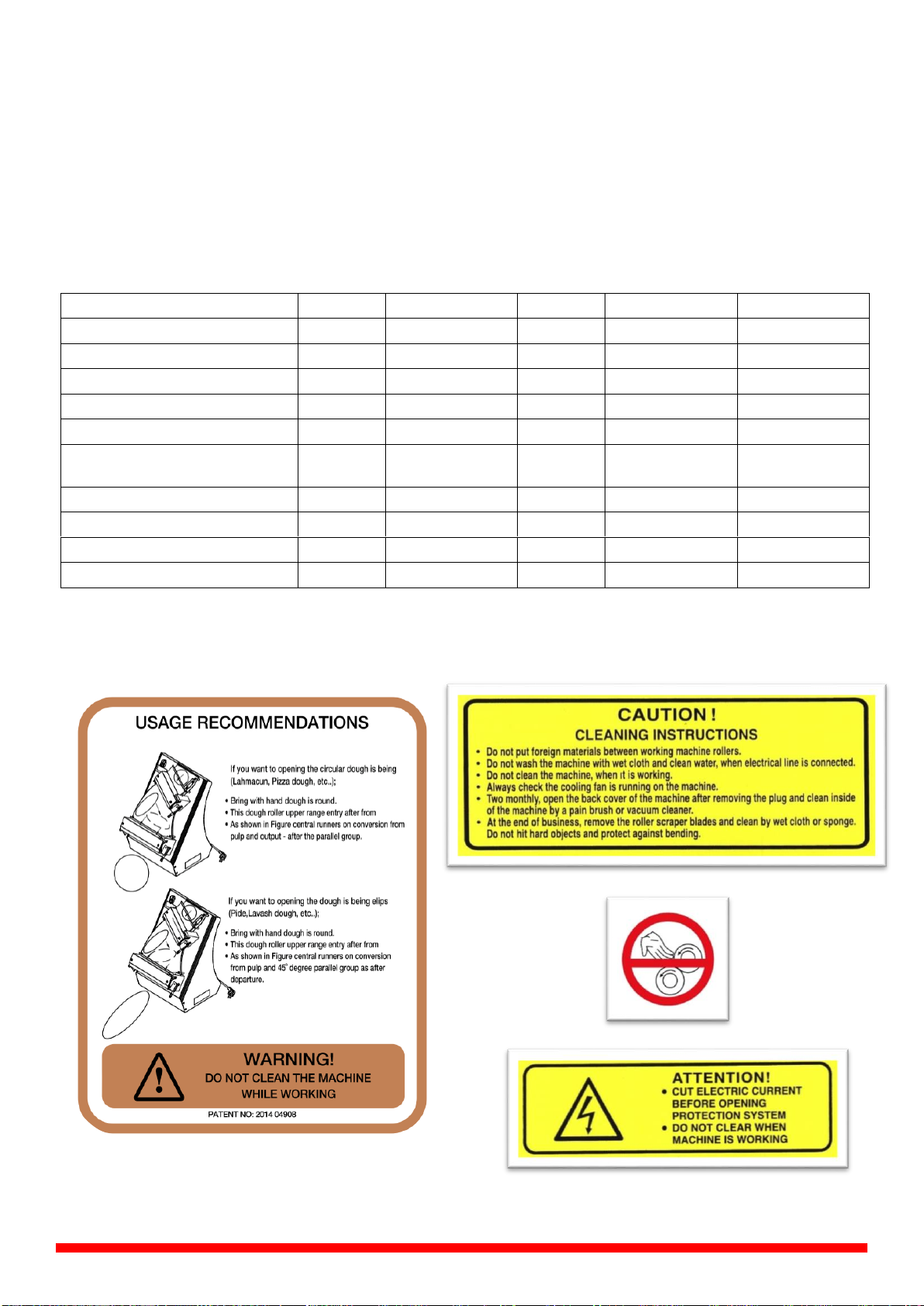

1.3 Safety Warnings Labels:

LABELS

5

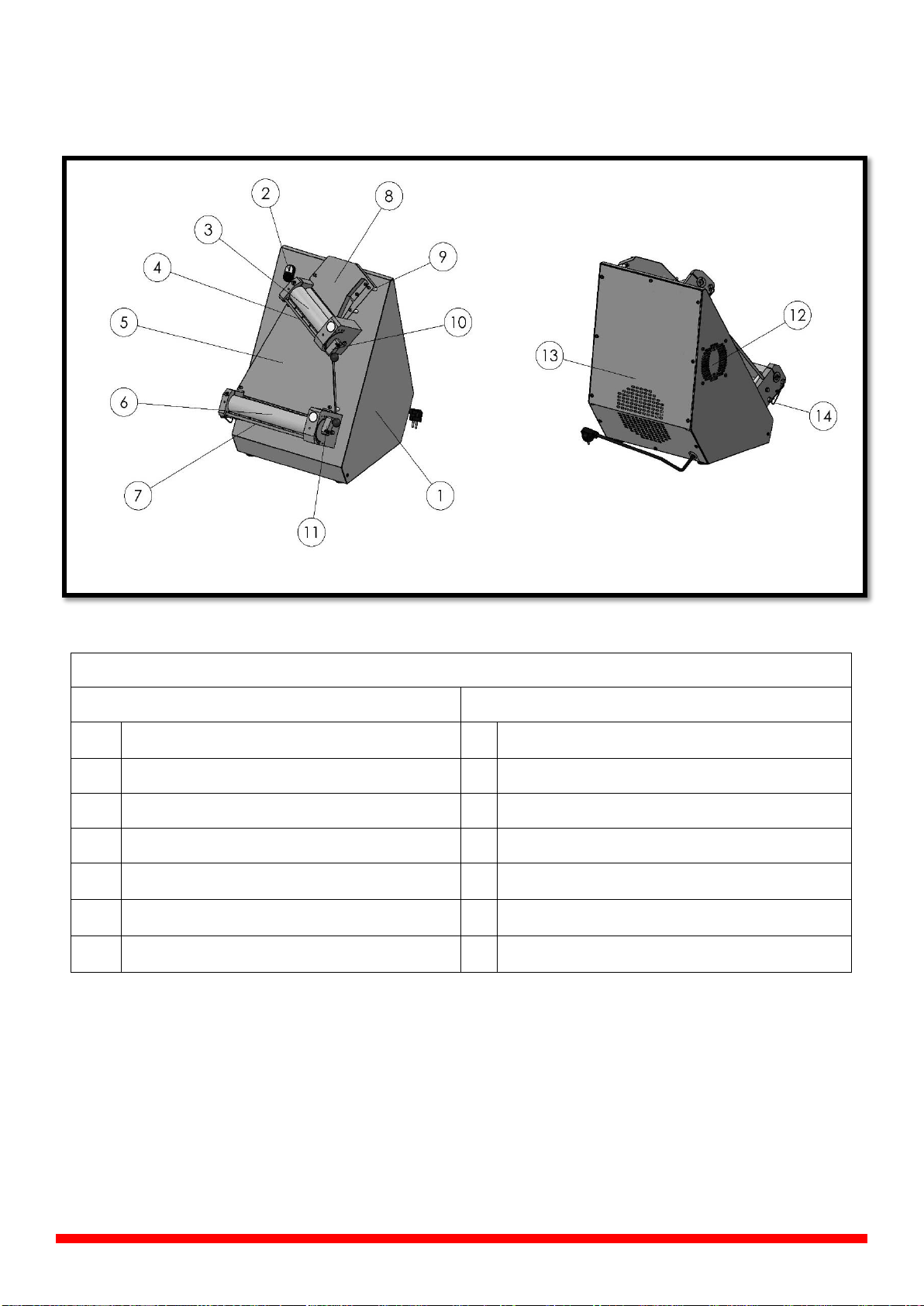

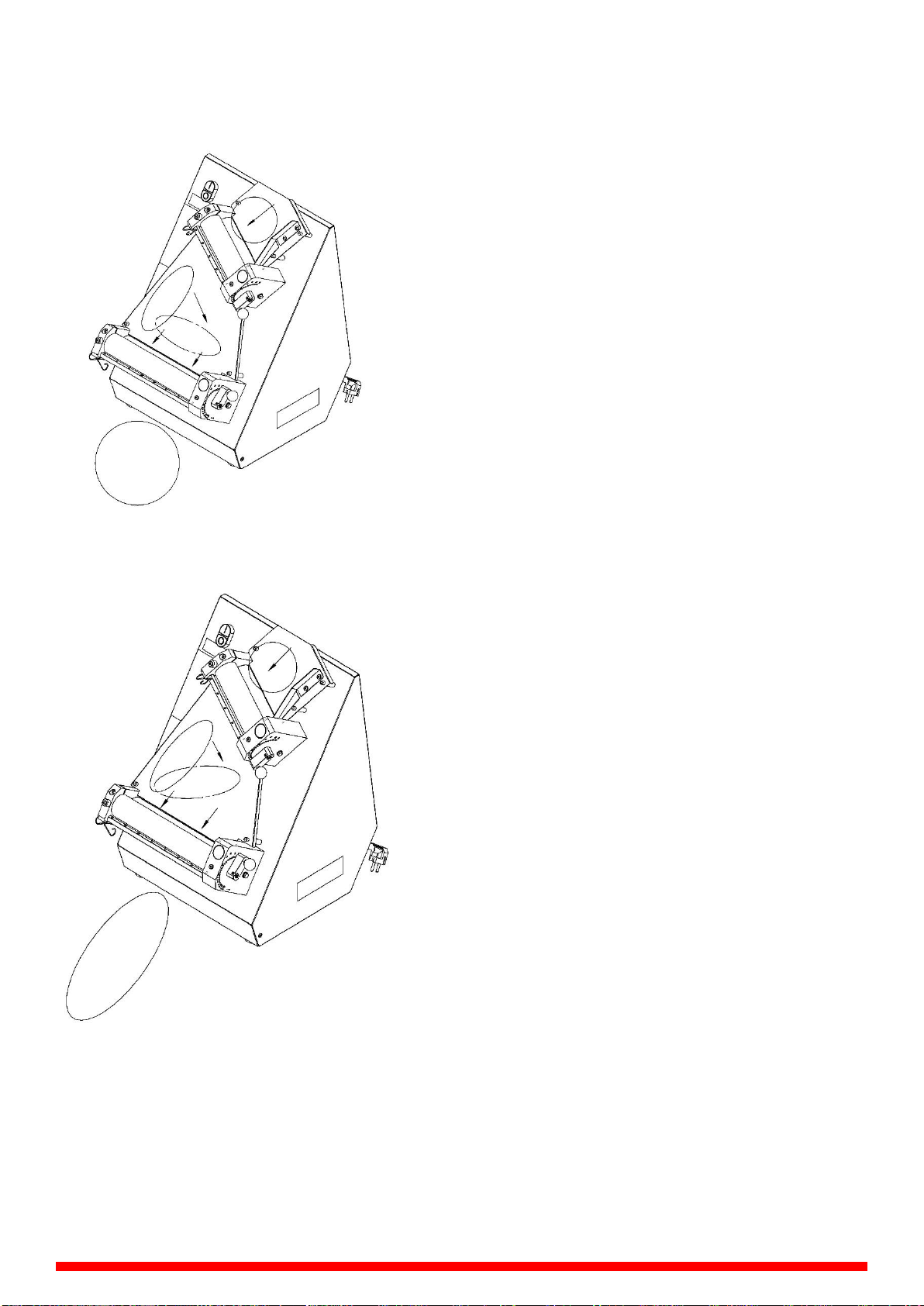

SECTION 2: INTRODUCTION OF MACHINE BODY COMPONENTS

2.1 Body Components:

PART DESCRIPTION

FRONT VIEW

BACK VIEW

1

BODY

8

TOP ROAD SHEET

2

START/STOP SWITCH

9

SHEET HOLDER PIN

3

TOP ROLLER GROUP

10

TOP ROLLER RANGE ADJUSTMENT HANDLE

4

TOP ROLLER SCRAPERS

11

UNDER ROLLER RANGE ADJUSTMENT HANDLE

5

MIDDLE ROAD SHEET

12

VENTILATION FAN

6

BOTTOM ROLER GROUP

13

BACK COVER

7

BOTTOM ROLER SCRAPERS

14

ROLLER SCRAPERS WİRE

6

SECTION 3: INSTRUCTIONS FOR USE

3.1 Usage Recommendations:

For Rolling Circular Dough (Lahmacun Dough Etc.);

- Compress the dough and make it circular.

- Pass through the dough to the upper roller gap.

Rotate the dough (shown in figure) then pass through the

dough in parallel to the bottom roller gap.

For Rolling Ellipse Dough (Pide Dough);

- Compress the dough and make it circular.

- Pass through the dough to the upper roller gap.

- Rotate the dough (shown in figure) then pass through the

dough in 45° to the bottom roller gap.

3.2 Safety Warnings:

1. Secure voltage is between 230 V and 240 V

2. Set up on a straight floor.

3. Single phase on operating.

4. Don’t wipe the machine with a wet cloth when

connect to plug.

5. Cut electric current before opening protection system.

6. Check the air intake of the cooling fan daily.

7

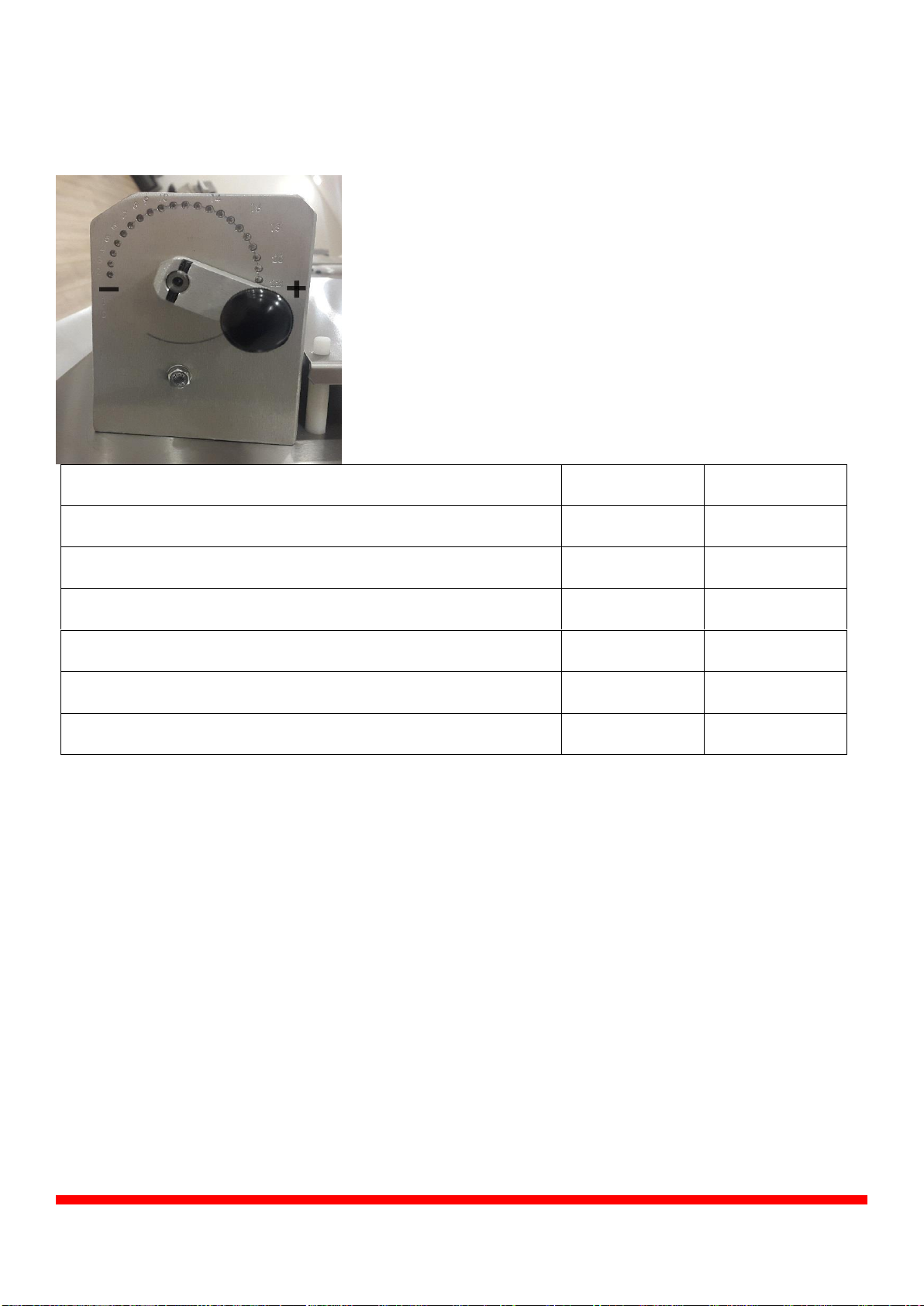

3.3 Operating and Starting Instructions:

1. Connect to monophase electrical supply.

2. Push the “1” button.

3. Adjust the roller space shown in picture. (This procedure adjusts the dough thickness and diameter)

Adjust the dough thickness from “0” to “20” shown in figure.

- Pull the bakelite knob and rotate the knob to “+” or “-” direction.

- Rotate the knob to “+” direction for enlarge the dough thickness.

Rotate the knob to “-” direction for reduce the dough thickness.

- Push the bakelite knob when the intended roller gap adjusted.

NOTE = Entrance roller gap advice to be bigger than the exit roller gap.

DESIRED PRODUCT

UPPER

BOTTOM

LAHMACUN

PİDE

PİZZA

NAIL PIDE

TORTILLA BREAD

BOREK DOUGH

NOTE: Write down the values of the input and output (upper and lower) roller adjustment lever which are

specified by the user in the table.

NOTE: For roller scrapers to work properly, scraper springs need to be stretched.

8

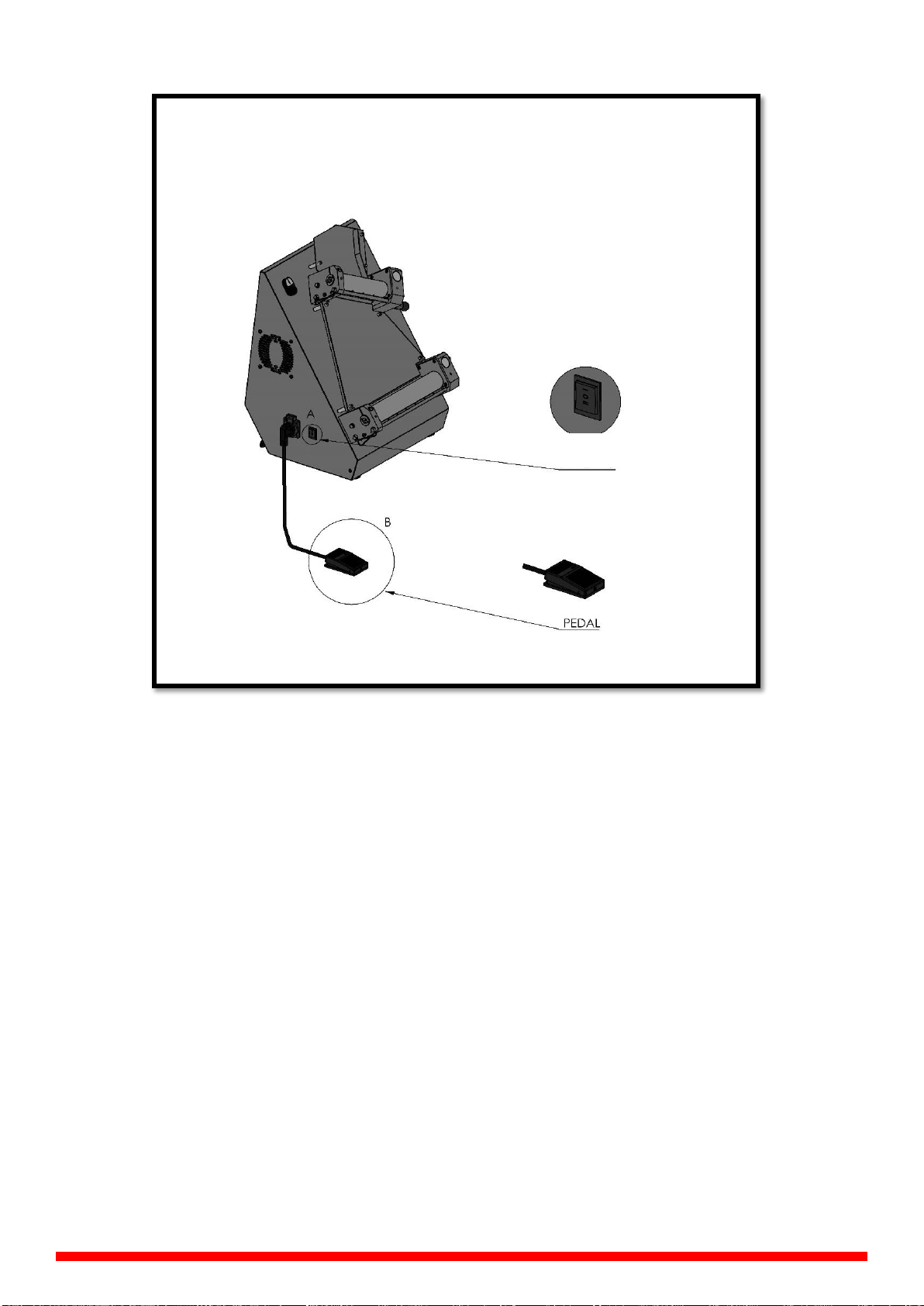

3.4 Operation On Optional Pedal Models:

Plug in the Pedal.

If you turn switch as “0”, the rolling machine doesn’t work.

If you turn switch as “I”, you can control the machine with the 0-I switch at the top of Rolling machine.

If you turn switch as “II” you can control the machine with the pedal. If you press the pedal once, machine

works, if you press again machine stops.

If you don’t want to use pedal unplug the pedal and turn switch as “I” position.

SWITCH

9

SECTION 4: MAINTENANCE

4.1 Exterior Body Maintenance:

Pull up the entrance and central sheets shown in picture then clean the flour and crumbs. Stop the machine

and unplug the electrical supply then clean with wet cloth. Don’t plug the electrical supply before the machine

dry.

NOTE: The pins on the road sheet are inserted into their slots on the body and assembled. Pins must be free.

4.2 Scrapers Maintenance:

Push up scrapers wire as shown in the figure

Remove the scrapers from the hole as shown in the figure and clean the scrapers daily.

10

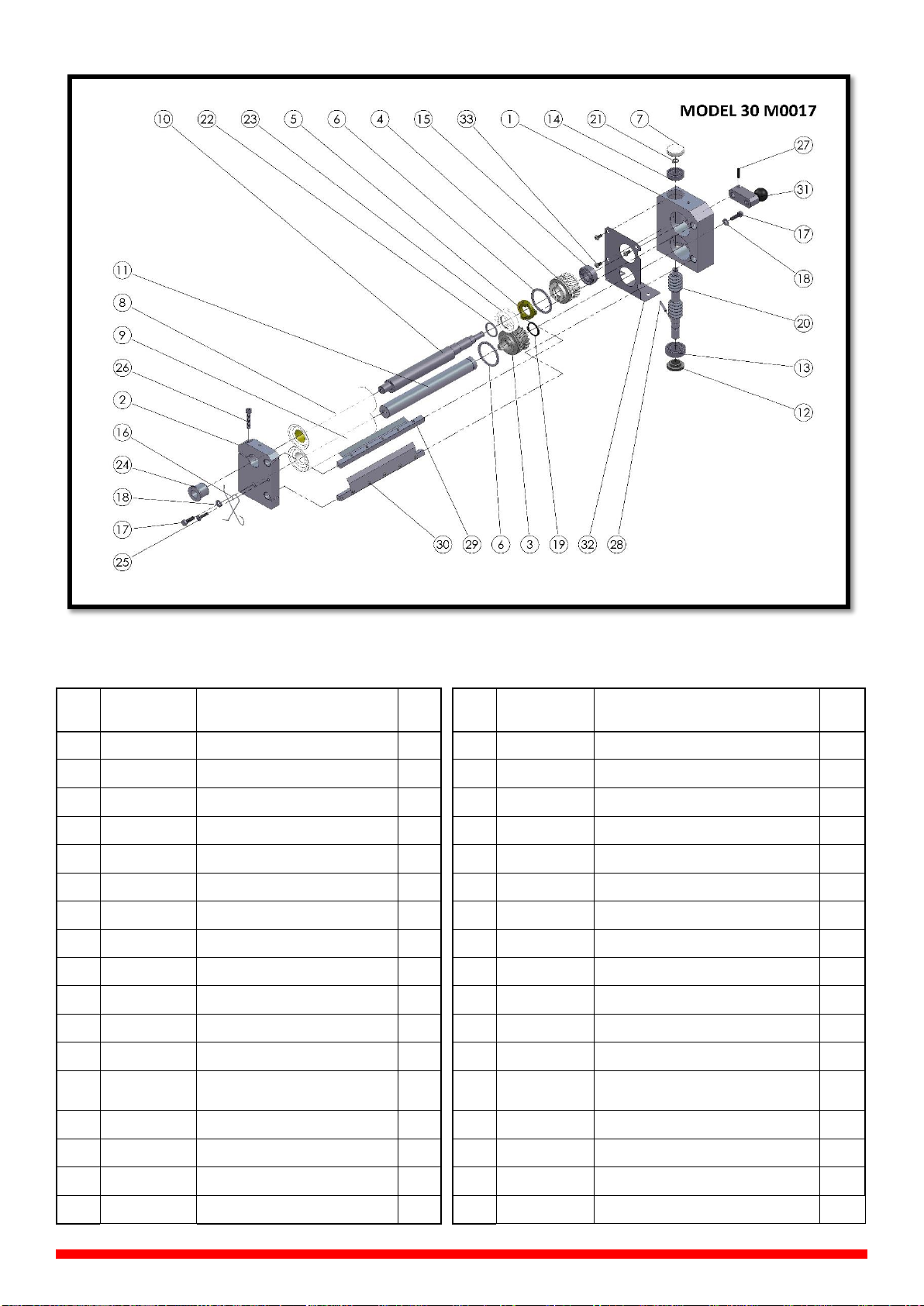

SECTION 5: SPARE PARTS MANUAL

MODEL-30 M0017 (TOP ROLLER GROUP) SPARE PART LIST

ITEM

NO.

SPARE PART

NUMBER

DESCRIPTION OF THE SPARE

PART

UNIT

ITEM

NO.

SPARE PART

NUMBER

DESCRIPTION OF THE SPARE

PART

UNIT

1

00372

GEARBOX

1

18

00050

WASHER

2

2

00001

ROLLER BEARING

1

19

00089

RING

1

3

00338

GEAR

1

20

00011

WORM

1

4

00007

GEAR

1

21

00027

RING

1

5

00010

CLUTCH

1

22

00092

O-RİNG

1

6

00009

RING

2

23

00088

CLUTCH

1

7

00013

COVER

1

24

00086

THIMBLE

1

8

00014

ROLLER

1

25

00047

BOLT

1

9

00015

ROLLER

1

26

00054

BOLT

1

10

00018

SHAFT

1

27

00095

PIN

1

11

00019

SHAFT

1

28

00096

PIN

1

12

00022

THIMBLE

1

29

00333M

TOP ROLLER SCRAPPERS (TOP)

1

13

00024

BEARING

1

30

00334M

TOP ROLLER SCRAPPERS

(BOTTOM)

1

14

00025

BEARING

1

31

00335M

ADJUSTING LEVER

1

15

00026

BEARING

1

32

00385

ROLLER GUARD SHEET

1

16

00038

SCRAPERS WIRE

2

33

00340

BOLT

3

17

00041

BOLT

2

11

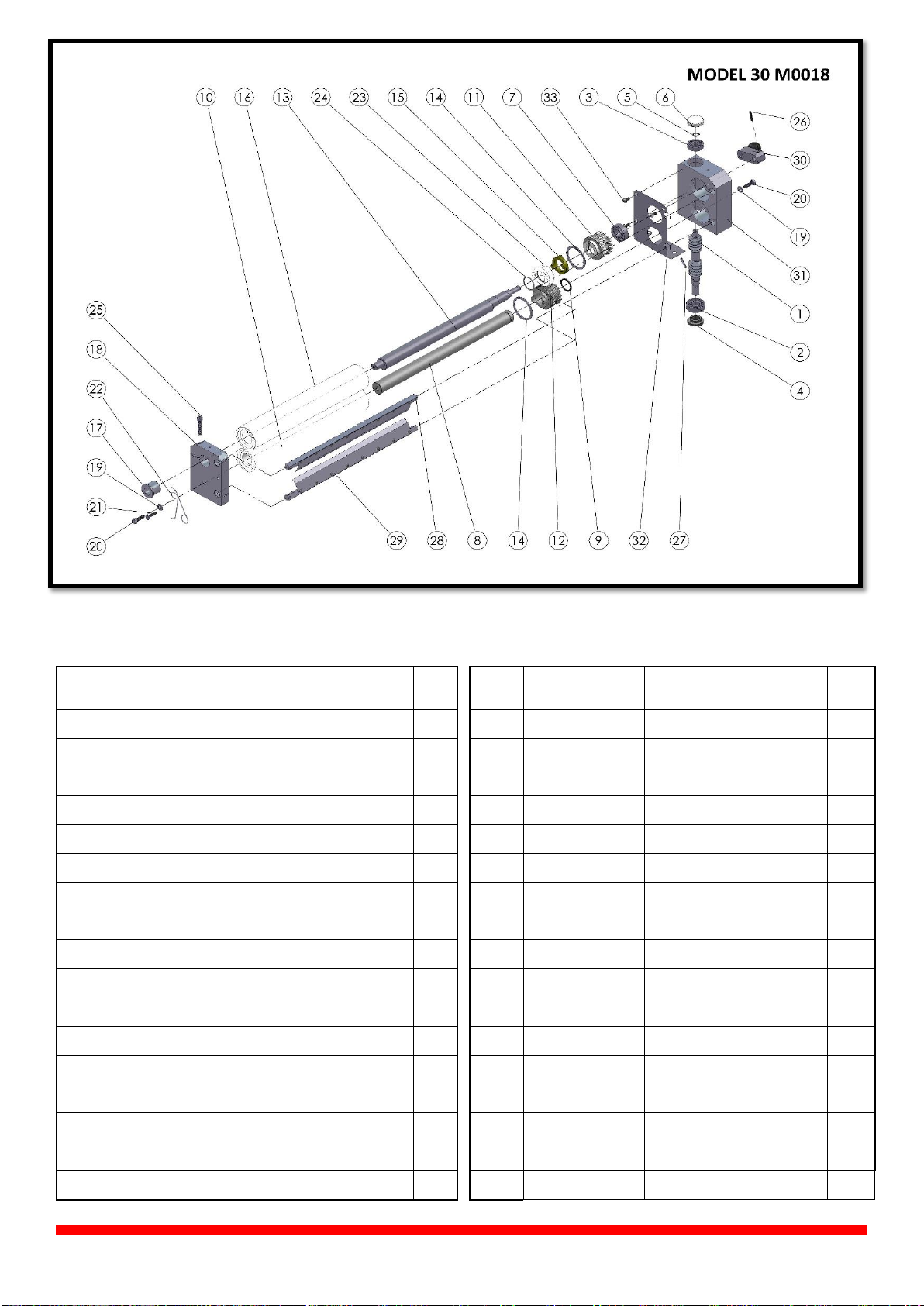

MODEL-30 M0018 (BOTTOM ROLLER GROUP) SPARE PARTS LIST

ITEM

NO.

SPARE PART

NUMBER

DESCRIPTION OF THE SPARE

PART

UNIT

ITEM

NO.

SPARE PART

NUMBER

DESCRIPTION OF THE

SPARE PART

UNIT

1

00011

WORM

1

18

00001

ROLLER BEARING

1

2

00024

BEARING

1

19

00050

WASHER

2

3

00025

BEARING

1

20

00041

BOLT

2

4

00022

THIMBLE

1

21

00047

BOLT

1

5

00027

RING

1

22

00038

SCRAPERS WIRE

2

6

00013

COVER

1

23

00088

CLUTCH

1

7

00026

BEARING

1

24

00092

O-RİNG

1

8

00021

SHAFT (BOTTOM)

1

25

00054

BOLT

1

9

00089

RING

1

26

00095

PIM

1

10

00017

ROLLER (BOTTOM)

1

27

00096

PIM

1

11

00007

GEAR (FEMALE)

1

28

00336M

SCRAPERS (TOP)

1

12

00338

GEAR (MALE)

1

29

00337M

SCRAPERS (BOTTOM)

1

13

00020

SHAFT (TOP)

1

30

00335M

ADJUSTING LEVER

1

14

00009

RING

2

31

00372

GEARBOX

1

15

00010

CLUTCH

1

32

00385

ROLLER GUARD SHEET

1

16

00016

ROLLER (TOP)

1

33

00340

BOLT

3

17

00086

THIMBLE

1

12

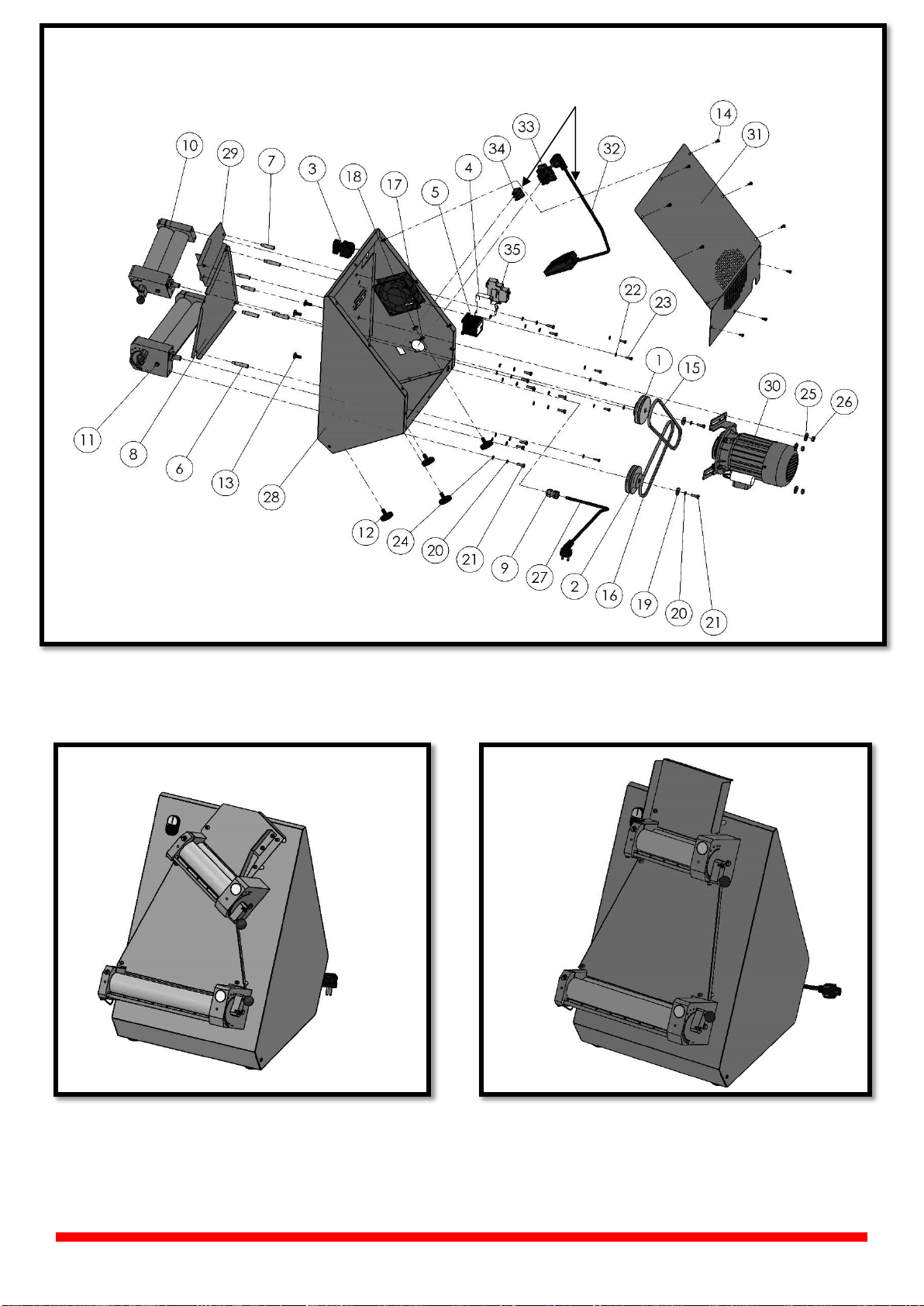

Model -30 Model -30 Flat

NOTE: Parts 32, 33, 34, 35 are optional on all models.

MODEL-30/ MODEL-30

FLAT BODY

Optional

13

MODEL-30/ MODEL 30 FLAT BODY SPARE PARTS LIST

ITEM

NO.

SPARE PART NUMBER

DESCRIPTION OF THE SPARE PART

UNIT

1

00085

PULLEY

1

2

00005

PULLEY

1

3

00055

BUTTON

1

4

00057

FUSE

1

5

00056

CONTAKTOR

1

6

00132

MIDDLE ROAD SHEET PIN

(UZUN)

4

7

00133

TOP ROAD SHEET PIN (SHORT)

3

8

00067

MIDDLE ROAD SHEET

1

9

00097

RECORD

1

10

M0017

TOP ROLLER

(KOMPLE)

1

11

M0018

BOTTOM ROLLER

(KOMPLE)

1

12

00354

LEG

4

13

00476

BOLT

3

14

00046

BOLT

10

15

00138

V BELT

1

16

00028

V BELT

1

17

01960

WASHER

4

18

00298

NUT

4

19

00006

WASHER

2

20

00042

WASHER

12

21

00041

BOLT

12

22

00051

WASHER

7

23

00049

BOLT

7

24

00050

WASHER

10

25

01258

WASHER

3

26

01959

NUT

3

27

00355

ELECTRIC CABLE

1

28

00070M

BODY

1

29

00338M

TOP ROAD SHEET

1

30

00058M

ENGINE

1

31

00505

BACK COVER

1

32

00034M

PEDAL (OPTIONAL)

1

33

00357

SOCKET (OPTIONAL)

1

34

00369

I0II SWITCH (OPTIONAL)

1

35

00367

CIRCUIT BREAKER (OPTIONAL)

1

Model-30 Flat: The Different Parts

ITEM

NO.

SPARE PART

NUMBER

DESCRIPTION OF THE SPARE PART

UNIT

8

00127

MIDDLE ROAD SHEET

1

15

00458

V BELT

1

28

00068M

BODY

1

29

00068

TOP ROAD SHEET

1

30

00363M

ENGINE

14

00058M SPARE PART LIST

ITEM

SPARE PART NUMBER

DESCRIPTION OF THE SPARE PART

UNIT

1

00347

ENGINE SHEET

1

2

01963

WASHER

4

3

04072

BOLT

4

4

01961

WASHER

4

5

01959

NUT

4

6

00094

PULLEY

1

7

00098

PULLEY WASHER

1

8

00049

BOLT

1

9

00023

ENGINE

1

15

MODEL-40 M0011 (TOP ROLLER COMPLETE) SPARE PARTS LIST

ITEM

SPARE PART

NUMBER

DESCRIPTION OF THE

SPARE PART

UNIT

ITE

M

SPARE PART

NUMBER

DESCRIPTION OF THE SPARE PART

UNIT

1

00372

GEAR BOX

1

18

00103

SHAFT

1

2

00013

COVER

1

19

00105

SHAFT

1

3

00022

THIMBLE

1

20

00338

GEAR

1

4

00024

BEARING

1

21

00007

GEAR

1

5

00025

BEARING

1

22

00009

RING

2

6

00026

BEARING

1

23

00134

ROLLER

1

7

00011

WORM

1

24

00135

ROLLER

1

8

00027

RING

1

25

00038

SCRAPERS WIRE

2

9

00001

ROLLER BEARING

1

26

00092

O-RİNG

1

10

00086

THIMBLE

1

27

00095

PIN

1

11

00047

BOLT

1

28

00096

PIN

1

12

00041

BOLT

2

29

00339M

TOP ROLLER SCRAPER (TOP)

1

13

00050

WASHER

2

30

00340M

TOP ROLLER SCRAPER (BOTTOM)

1

14

00054

BOLT

1

31

00335M

ROLLER ADJUSTING LEVER

1

15

00010

CLUTCH

1

32

00385

ROLLER GUARD SHEET

1

16

00088

CLUTCH

1

33

00340

BOLT

3

17

00089

RING

1

16

MODEL-40 M0012 (BOTTOM ROLLER COMPLETE) SPARE PARTS LIST

ITEM

NO.

SPARE PART

NUMBER

DESCRIPTION OF THE

SPARE PART

UNIT

ITE

M

NO.

SPARE PART

NUMBER

DESCRIPTION OF THE SPARE PART

UNIT

1

00372

GEAR BOX

1

18

00054

BOLT

1

2

00011

WORM

1

19

00088

CLUTCH

1

3

00024

BEARING

1

20

00010

CLUTCH

1

4

00025

BEARING

1

21

00007

GEAR (FEMALE)

1

5

00022

THIMBLE

1

22

00102

ROLLER SHAFT (TOP)

1

6

00027

RING

1

23

00104

ROLLER SHAFT (BOTTOM)

1

7

00013

COVER

1

24

00089

RING

1

8

00026

ROLLER

1

25

00136

ROLLER

1

9

00338

GEAR (MALE)

1

26

00137

ROLLER

1

10

00009

RING

2

27

00095

PIN

1

11

00092

O-RİNG

1

28

00096

PIN

1

12

00038

SCRAPERS WIRE

2

29

00341M

SCRAPER (TOP)

1

13

00047

BOLT

1

30

00342M

SCRAPER (BOTTOM)

1

14

00086

THIMBLE

1

31

00335M

ADJUSTING LEVER

1

15

00041

BOLT

2

32

00385

ROLLER GUARD SHEET

1

16

00050

WASHER

2

33

00340

BOLT

3

17

00001

ROLLER BEARING

1

17

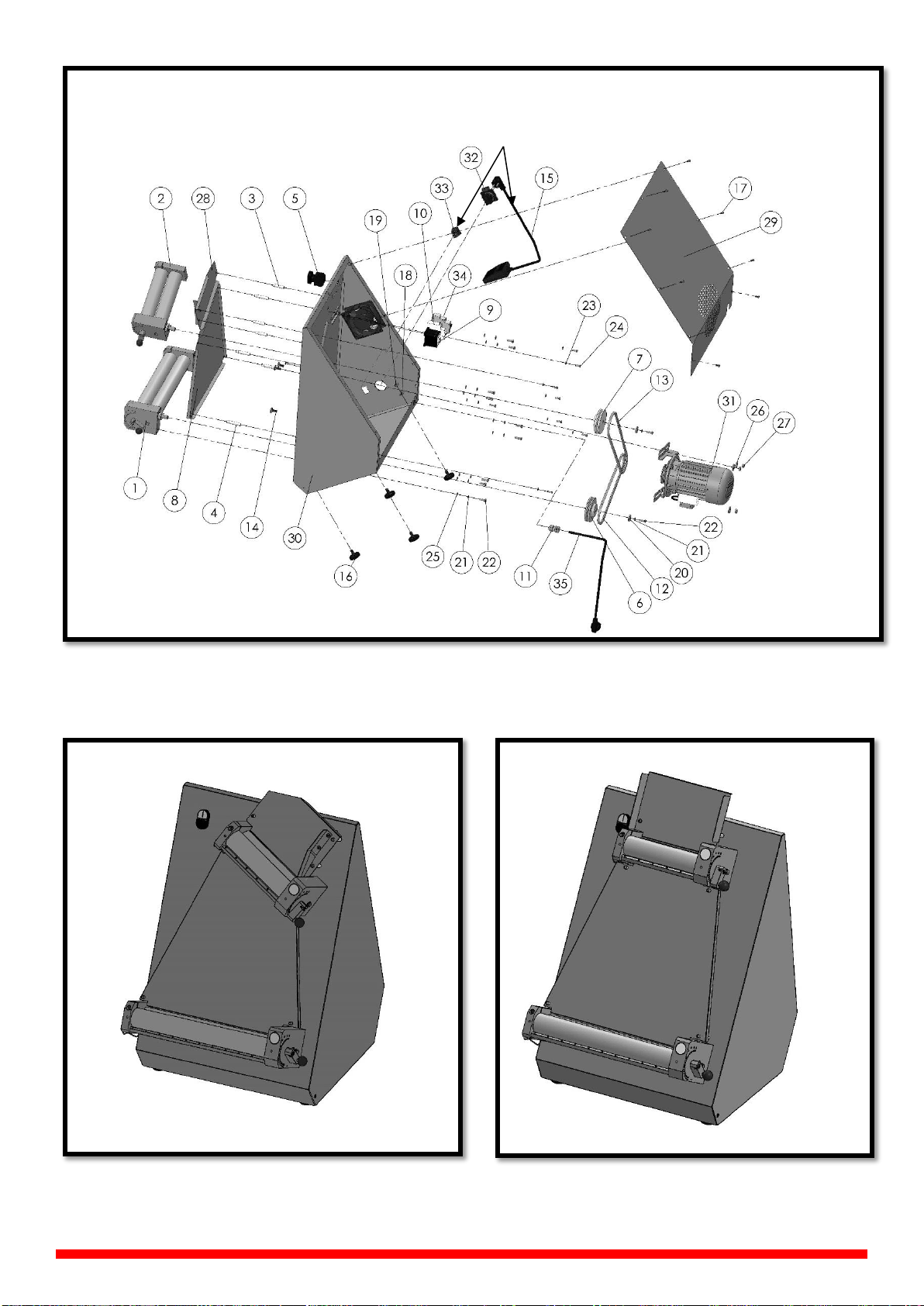

Model-40 Model-40 Flat

NOTE: Parts 15, 32, 33, 34 are optional on all models.

Optional

MODEL-40/ MODEL-40 FLAT

BODY

18

MODEL-40/ MODEL 40 FLAT BODY SPARE PARTS LIST

Model-40 Flat: The Different Parts

ITEM

NO.

SPARE PART NUMBER

DESCRIPTION OF THE SPARE PART

UNIT

1

M0012

BOTTOM ROLER (COMPLETE)

1

2

M0011

TOP ROLLER (COMPLETE)

(KOMPLE)

1

3

00133

TOP ROAD SHEET PIN (SHORT)

3

4

00132

MIDDLE ROAD SHEET PIN

(UZUN)

4

5

00055

BUTTON

1

6

00005

PULLEY

1

7

00085

PULLEY

1

8

00110

MIDDLE ROAD SHEET

1

9

00056

KONTAKTÖR 3kw

400v

CONTACTOR

1

10

00057

1x4A C

FUSE

1

11

00097

RECORD

1

12

00424

8X700

V BELT

1

13

00426

8X950

V BELT

1

14

00476

M8X19 YB K

BOLT

3

15

00034M

PEDAL (OPTIONAL)

1

16

00354

LEG

4

17

00046

M5x10 YB İ

BOLT

10

18

01960

RONDELA M10 K

WASHER

4

19

00298

SOMUN

NUT

4

20

00006

WASHER

2

21

00042

RONDELA M6 K

WASHER

12

22

00041

M6x20 AKB K

BOLT

12

23

00051

K

WASHER

7

24

00049

M5x16 AKB K

BOLT

7

25

00050

K

WASHER

10

26

01258

WASHER

3

27

01959

M8 K

NUT

3

28

00343M

TOP ROAD SHEET

1

29

00061M

BACK COVER

1

30

00075M

BODY

1

31

00058M

ENGINE

1

32

00357

SOCKET (OPTIONAL)

1

33

00369

I0II SWITCH (OPTIONAL)

1

34

00367

ANAHTARI

CIRCUIT BREAKER (OPTIONAL)

1

35

00355

ELECTRIC CABLE

1

ITEM

NO.

SPARE PART

NUMBER

DESCRIPTION OF THE SPARE PART

UNIT

8

00130

MIDDLE ROAD SHEET

1

28

00131

TOP ROAD SHEET

1

30

0069M

BODY

1

19

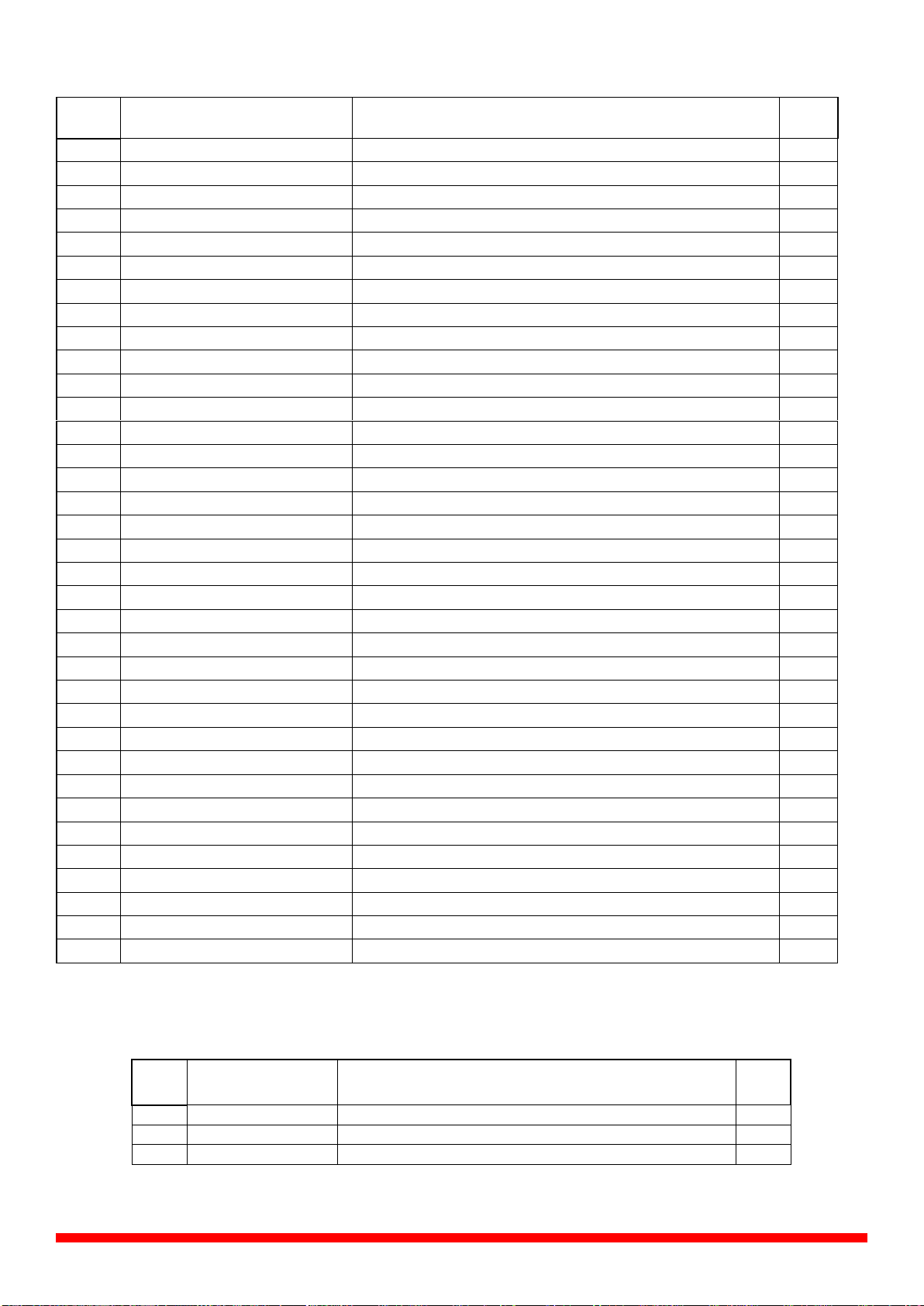

SECTION 6: ROLLER PROTECTION SHEET ASSEMBLY

PART DESCRIPTION

1

STAY BOLT (LEFT)

2

GUARD SHEET THIMBLE

3

BOARDING HANDLE

4

STAY BOLT (RIGHT)

5

GUARD SHEET (TOP ROLLER)

6

GUARD SHEET (BOTTOM ROLLER)

DETAIL A

SCALE 1: 4

DETAIL B

SCALE 1: 4

This manual suits for next models

3

Table of contents

Other Sengun Makina Commercial Food Equipment manuals