Sensata M700 Series User manual

| M700

HYDRAULIC PUMP MOTOR CONTROLLER

INTERFACE MANUAL

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

2

Copyright © 2021 Sensata Technologies, Inc.

CONTENTS

OVERVIEW ........................................................................................................................................3

INSTALLATION AND WIRING.............................................................................................................5

MOUNTING THE CONTROLLER.....................................................................................................5

CONNECTIONS ..............................................................................................................................7

High current connections.............................................................................................................8

Low current connections..............................................................................................................8

CONTROLLER WIRING: TYPICAL CONFIGURATION...................................................................9

KSI Wiring ...................................................................................................................................10

Main Contactor...........................................................................................................................10

Interlock Switch..........................................................................................................................11

Circuitry Protection Devices.......................................................................................................11

Throttle Wiring ...........................................................................................................................11

PROGRAMMABLE PARAMETERS....................................................................................................16

VOLTAGE MENU..........................................................................................................................17

CURRENT MENU .........................................................................................................................18

SPEED MENU...............................................................................................................................18

THROTTLE MENU........................................................................................................................19

MISCELLANEOUS PARAMETERS .................................................................................................23

MONITOR MENU............................................................................................................................24

DIAGNOSTICS AND TROUBLESHOOTING .......................................................................................25

PC APP DIAGNOSTICS.................................................................................................................25

LED DIAGNOSTICS.......................................................................................................................27

MAINTENANCE .......................................................................................................................28

CLEANING....................................................................................................................................28

FAULT HISTORY ...........................................................................................................................29

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

3

Copyright © 2021 Sensata Technologies, Inc.

OVERVIEW

M700 is a high-power hydraulic pump controller that provides

fully programmable control of DC series wound motors. It

features microprocessor-based logic with programmable

parameters and offers maximum flexibility for minimum cost.

This means the controller can be tailored to the needs of

specific applications. In addition to configuration flexibility,

use of the programmer offers diagnostics and test capability. It

is the ideal solution for hydraulic pump motor control on

aerial work platform (AWP) equipment.

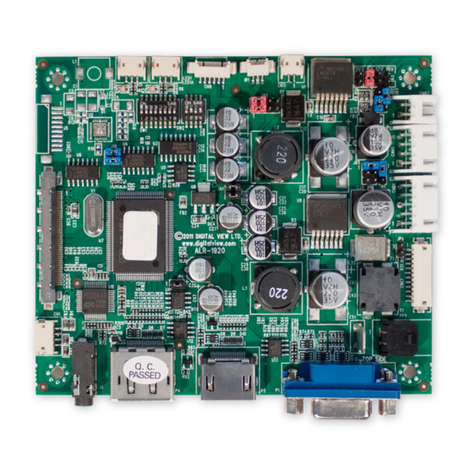

Fig. 1 M700-VR1

hydraulic pump motor

controller.

The M700 controller offers superior operator control of motor

speed and torque.

Controllable Power

➢Pulse Width Modulation (PWM) control with programmable

speed, acceleration rate, and current limit.

➢Short duration boost capability (10 sec, 110% of 2 min current

rating). Allows clearing of obstacles, climbing ramps.

➢16 kHz PWM frequency for near silent operation.

➢High efficiency, silent operation. Operating costs, heat-sinking

requirements, motor and battery losses reduced. Low-end

torque, range, and battery life maximized.

1

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

4

Copyright © 2021 Sensata Technologies, Inc.

Programmable and Flexible

➢Fully programmable via Sensata PC programming software.

➢Supports multiple throttle types and High Pedal Disable (HPD)

options.

➢LED output for easy system troubleshooting via flash codes.

➢Fully programmable analog throttle input for precise speed

control with a variety of signal sources.

➢Programmable under voltage cutback caters to different

battery types.

➢CAN type input for throttle function

➢Interlock function with a digital signal input that can be easily

disabled/enabled by setting.

➢Two-driver output with max 2A.

Robust Safety and Reliability

➢Redundant hardware and software watchdog timers.

➢MOSFET short-circuit protection functions.

➢Programmable HPD function prevents controller operation if

throttle is applied before key is turned on.

➢Contactor fault detection: controller shuts down safety if the

main contactor opens.

➢Contactor protection functions minimize high current arcing to

prevent contact pitting and thus prevent contactor weld

failures.

➢Undervoltage cutback and shutdown functions protect against

low battery voltage, including low voltage caused by external

loads.

➢Electrical isolation to heat sink: 500VAC.

➢Rugged housing meets IP54 environmental ratings.

➢Full power operation over -40°C to 50°C environment

temperature range.

Familiarity with the controller will help you install and operate it

properly. We encourage you to read this manual carefully. If you have

questions, please contact the Sensata service office nearest you.

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

5

Copyright © 2021 Sensata Technologies, Inc.

INSTALLATION AND WIRING

MOUNTING THE CONTROLLER

The M700 controller can be oriented in any position and meets

the IP54 ratings for environmental protection against dust and

water. However, the location should be carefully chosen to

keep the controller clean and dry. If a clean and dry mounting

location cannot be found, a cover must be used to shield the

controller from water and contaminants.

The controller’s outline and mounting hole dimensions are

shown in Figure 2. When selecting the mounting position, be

sure to also take into consideration that access is needed at the

end of the controller to plug the programming cable into its

connector. To ensure full rated power, the controller should be

fastened to a clean, flat metal surface with four 6 mm (1/4")

diameter screws, using the holes provided. Although not

usually necessary, a thermal joint compound can be used to

improve heat conduction from the controller heatsink to the

mounting surface. You will need to take steps during the design

and development of your application product to ensure that its

EMC performance complies with applicable regulations;

suggestions are presented in Appendix A.

2

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

6

Copyright © 2021 Sensata Technologies, Inc.

Fig 2 Mounting dimensions,

M700-VR1 controller

.

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

7

Copyright © 2021 Sensata Technologies, Inc.

caution

CONNECTIONS

The controller’s connectors are all conveniently located on one end:

Working on electrical systems is potentially dangerous. You should

protect yourself against uncontrolled operation, high current arcs, and

outgassing from lead acid batteries.

UNCONTROLLED OPERATION — Some conditions could cause the

hydraulic pump system to run out of control. Disconnect the motor or

make sure the pump system has enough room to operate before

attempting any work on the motor control circuitry. Note: If the wrong

throttle input signal type is selected with the programming device, the

pump system may suddenly begin to operate.

HIGH CURRENT ARCS — Batteries can supply very high power, and arcs

can occur if they are short circuited. Always open the battery circuit

before working on the motor control circuit. Wear safety glasses and

use properly insulated tools to prevent shorts.

LEAD ACID BATTERIES — Charging or discharging generates hydrogen

gas, which can build up in and around the batteries. Follow the battery

manufacturer’s safety recommendations. Wear safety glasses.

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

8

Copyright © 2021 Sensata Technologies, Inc.

High current connections

This controller has three high-current busbars: B+, B- and M-. The

busbars are tin-plated solid copper.

Cables used for the battery and motor connections must be heavy

enough to carry the high current required. A minimum size of 25 mm2 (#4

AWG) is recommended.

Connections to the controller busbars should be made with lugs

suitable for the cable used, fastened by M8 bolts and nuts. When

tightening the bolts, two opposing wrenches should be used. Failure to

use the double-wrench technique could cause undue strain to be placed

on the internal connections, and could also result in cracked seals around

the busbars.

Low current connections

This controller has six low-current connections: four 6.35 mm push-on

terminals (J1, J2, J3, and J5), and two 4-pin connectors (J4 and J6).

Table 2 Low Current Connections

J1

Keyswitch

J2

Wire 1 of 2-wire throttle; Pot High of 3-wire.

J3

Wire 2 of 2-wire throttle; Pot Wiper of 3-wire throttle.

J4

4-pin connector: see Table 3.

J5

Reverse signal output / main contactor coil driver.

J6

4-pin connector: see Table 4.

For the control wiring, 0.75 mm2 (#18 AWG) vinyl insulated stranded wire

is recommended.

The mating connector for J4 is a 4-pin Molex Mini-fit Jr. or equivalent.

Either an external Status LED or a USB2UART programmer can be

connected to J4. The pinout is as follows.

Table 1 High Current Connections

B+

Battery+ and motor armature

B-

B-

M-

Motor field (controller output)

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

9

Copyright © 2021 Sensata Technologies, Inc.

Note: When J4 is used for a Status LED, a jumper must be added between

pins J4-1 and J4-4 as shown in the basic wiring diagram (Figure 3).

The mating connector for J6 is a 4-pin TE Mini-Universal MATE-N-LOK or

equivalent. The pinout is as follows.

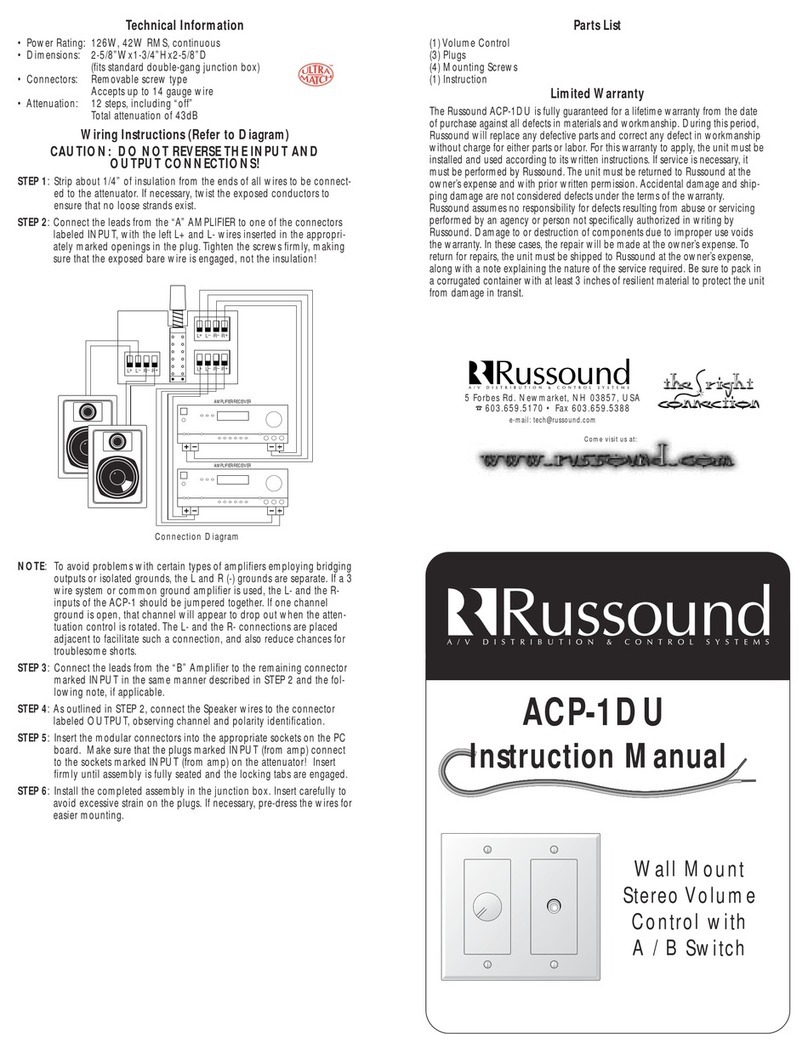

CONTROLLER WIRING: TYPICAL CONFIGURATION

Figure 3 shows the typical wiring configuration for most applications. The

interlock switch is typically a seat switch, tiller switch, or foot switch, the

interlock function can be disable in the setting. The throttle shown is a 3-

wire pot; other types of throttles can also be used.

PIN PROGRAMMER STATUS LED

J4-1 Data input from programmer (Rx). Status LED enable.

J4-2 GND GND

J4-3 Data output to programmer (Tx). Status LED output.

J4-4 +12.7V +12.7V

Table 3 J4 connector pinout

Table 4 J6 connector pinout

PIN

PROGRAMMER

J6-1

Driver output

J6-2

Interlock

J6-3

CANL

J6-4

CANH

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

10

Copyright © 2021 Sensata Technologies, Inc.

KSI

J1

THROTTLE POT

WIPER

J2

J3 THROTTLE POT

LOW

+12V

TX

RX

GND

CANH

CANL

INTERLOCK

Reserved

B+

M-

B-

Main Contactor

Driver J5

A1

A2

S1

S2

MAIN

PRECHARGE RESISTOR

J6-4

J6-3

J6-2

J6-1

1

2

3

4

J4

MAIN CONTACTOR

POLARITY

PROTECTION

DIODE

FUSE

FUSE

THROTTLE POT

Fig.3 Typical wring diagram

KSI Wiring

The keyswitch input (KSI) circuit includes input from the keyswitch and from

the various interlocks. The controller KSI is used to turn the controller on and

off. KSI is turned on by connecting it to battery B+. Any positive voltage greater

than about 16 volts will turn on the controller, but usually the full vehicle battery

voltage is used. KSI draws up to 120 mA with the programmer connected.

In its simplest form, KSI is operated by a keyswitch that turns the vehicle off and

prevents unauthorized use. The keyswitch should also turn off the main contactor

This will act as a safety feature by removing power from the motor control system

when the keyswitch is turned off.

Main Contactor

A main contactor should be used with the controller. Otherwise, the controller’s

fault detection will not be able to fully protect the controller and hydraulic system

from damage in a fault condition. The main contactor allows the controller and

motor to be disconnected from the battery. This provides a significant safety

feature, because it means the battery power can be removed from the hydraulic

system if a controller or wiring fault results in battery power being applied to the

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

11

Copyright © 2021 Sensata Technologies, Inc.

motor inappropriately.

The controller provides a low-side contactor coil driver (at J5) for the main

contactor. The driver output is rated at 1 amp and is short-circuit protected.

It is recommended that a coil suppression diode be included, as shown in the

wiring diagrams. This protects the contactor coil driver from inductive voltage

kickback spikes when the contactor is turned off.

Interlock Switch

The interlock switch, which is typically implemented as a seatswitch or a

hand/foot activated deadman switch, provides a safety interlock to ensure that

an operator is present in order for the system to run.

Circuitry Protection Devices

To protect the control circuitry from accidental shorts, a low current fuse (ap-

propriate for the maximum current draw) should be connected in series with

the battery feed to the keyswitch. Additionally, a high current fuse should be

wired in series with the main contactor to protect the motor, controller, and

batteries from accidental shorts in the power system. The appropriate fuse for

each application should be selected with the help of a reputable fuse

manufacturer or dealer. The standard wiring diagrams (Figure 3) show the

recommended location for each fuse.

Throttle Wiring

Four throttle types can be used with this controller:

TABLE 5 WIPER INPUT: THROTTLE THRESHOLD VALUES

THROTTLE

TYPE

PARAMETER

MINIMUM

THROTTLE FAULT

MAXIMUM

THROTTLE FAULT

0

0-5kΩ

2-wire potentiometer

-

5.5kΩ

1

5kΩ-0

2-wire potentiometer

-

5.5kΩ

2

0-5V

Single-ended input

-

5.5V

3

CANOPEN command

-

1023

Throttle Type 0

Wiring for Type 0 throttles is simple: just connect the two wires to

the J2 and J3 push-on terminals; it doesn’t matter which wire goes

on which terminal. With Type 0 throttles, resistance increases as

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

12

Copyright © 2021 Sensata Technologies, Inc.

the applied throttle is increased. Mechanical pot boxes and foot

pedals are Type 0 throttles. It doesn’t matter which wire goes on

which terminal, and the wires can be extended as required.

Fig 4 Wiring for

0–5kΩ

throttle (“Type

0”).

Some pot boxes have a built-in microswitch, eliminating the need to

install a separate pedal actuated microswitch. It is important that a

pedal microswitch be included in the circuit as shown in Figure 3 to

allow the microcontroller a few milliseconds to boot up, run

diagnostics and safety checks, and then be ready in standby before

receiving the throttle signal.

Any pot box that can provide a nominal 0–5kΩ output will

work as a Type 0 throttle input.

If a pot box is used, it must be mounted so as to allow

connection be-tween the pot box lever arm and the vehicle

accelerator linkage. Use of a second return spring on the pedal, in

addition to the pot box return spring, is required to prevent an

uncontrollable full-on throttle input (which could happen if there

was a single spring, and it broke). If the self-contained pot box

spring is insufficient to return the pedal by itself, two additional

pedal return springs must be used. It is also required that the

accelerator pedal hit a mechanical stop at its full-on position just

before (≈1 mm) the pot box lever hits its own full-on stop. This

mechanical stop will prevent the pot box lever arm from bending if

undue force is put on the pedal. Protection of the pot box from

water and dirt will help avoid problems of corrosion and electrical

leakage. After the pot box has been mounted, operation of the pot

can be tested by measuring the resistance between the two wires

with an ohmmeter. With the pedal not applied, the resistance

should be less than 50 ohms. As the pedal is applied, the resistance

should rise smoothly until it reaches a value between 4500 and

5500 ohms. Values below 4500 ohms may cause a reduction in

efficiency and top speed; however, you still can get top speed by

lowering the Throttle Max setting. Values above 5500 ohms indicate

a defective pot box and will cause controller shutdown.

Throttle Type 1

Wiring for Type 1 throttles is the same as for Type 0 throttle; again,

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

13

Copyright © 2021 Sensata Technologies, Inc.

it doesn’t matter which wire goes on which terminal. With these

throttles, resistance is in an inverse relationship to applied throttle;

that is, resistance decreases as applied throttle is increased.

Fig 4 Wiring for

5k–0Ω

throttle (“Type

0”).

Throttle Type 2

With Type 2 throttles, the controller looks for a voltage signal at J3. Zero

throttle request corresponds to 0 V and full throttle request to 5 V. A

variety of devices can be used with this throttle input type, including voltage

sources, current sources, and electronic throttles. The wiring for each is

slightly different, as shown in Figure 10, and they have varying levels of

throttle fault protection.

When a voltage source is used as a throttle, it is the responsibility of the

OEM to provide appropriate throttle fault detection. For ground referenced

0–5V throttles, the controller will detect open breaks in the wiper input but

cannot provide full throttle fault protection. To use a current source as a

throttle, a resistor must be added to the circuit to convert the current source

value to a voltage; the resistor should be sized to provide a 0–5V signal

variation over the full current range. It is the responsibility of the OEM to

provide appropriate throttle fault detection.

There are many electronic foot pedals on the market; for wiring, consult

the instructions that are provided with the foot pedal.

Fig 5 Wiring for type 2

throttle

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

14

Copyright © 2021 Sensata Technologies, Inc.

Throttle Type 3

Communicates with ECU and other devices via CAN. Main microcontroller of

this controller can send controller’s state and the measure values to other devices.

The communication protocol should follow CANOpen protocol.

M700-VR1 will set as slave station, and support NMT, PDO and Emergency message.

1. Common

Baud rate: Configurable, default value is 250kbps (Max speed), and it

is adjustable.

ID format: Standard ID (11bit).

Node type: M700-VR1 is a slave node.

Node ID: Configurable, default value is 1.

2. PDO

TPDO1 (SlaveMaster, COB-ID=0x180+Node-ID, length=8)

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Status

word 1

Lo

Status

word 1

Hi

Throttle

Lo

Throttle

Hi

Battery

Lo

Battery

Hi

Heatsink

temperature

Lo

Heatsink

temperature

Hi

Unsigned 16

Bit 0: interlock input status

Bit 1: drive 1 output status

Bit 2: drive 2 output status

Bit 3-15: reserved

Unsigned 16

0-1023: 0-100%

Unsigned 16

0-3600: 0-36.0V

Unsigned 16

0-150: --25-+125°C

RPDO1 (MasterSlave, COB-ID=0x200+Node-ID, length=8)

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Control

word Lo

Control

word Hi

Throttle

reference

Lo

Throttle

reference

Hi

reserved

reserved

reserved

Reserved

Unsigned 16

Bit 0: interlock enable

Bit 1: drive 1 enable

Bit 2-15: reserved

Unsigned 16

0-1023: 0-100%

3. NMT

NMT Module Control (MasterSlave, COB-ID=0x000, length=2)

Byte 0

Byte 1

NMT type

Node ID

0x01: start node

0x02: stop node

0x80: enter pre-operational

0x81: reset node

0x82: reset communication

0: broadcast

>0: special node

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

15

Copyright © 2021 Sensata Technologies, Inc.

NMT Node Guarding Request (MasterSlave, COB-ID=0x700+Node-

ID, remote frame)

NMT Node Guarding Response (SlaveMaster, COB-ID=0x700+

Node-ID, length=1)

Byte 0

Node Status

Bit 0-6: 0-boot up, 4-stopped, 5-operational, 127-pre-operational

Bit 7: toggle bit

4. Emergency Object

Emergency Object (SlaveMaster, COB-ID=0x080+Node-ID, length=8)

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Error code

Hi

Error code

Lo

reserved

reserved

reserved

reserved

reserved

reserved

Unsigned 8

High digit of

error code

Unsigned 8

low digit of error

code

5. Sequence

M700-VR1 should design 4 states for CANOpen communication:

Initializing, Pre-operational, Operational, Stopped. State machine of

CANOpen communication is shown as below:

M700-VR1 changes state after received NMT Module Control frame.

When M700-VR1 change state from initializing to pre-operational, it

should send NMT Node Guarding Request frame actively. (node

status is 0)

In all states, M700-VR1 send NMT Node Guarding Response frame

after received NMT Node Guarding Request frame. (Toggle bit 7 every

time)

In all states, M700-VR1 send Emergency Object once when any fault

happened.

Only in Operational state, M700-VR1 executes command in RPDO1,

and send TPDO1 frame after received RPDO1 frame.

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

16

Copyright © 2021 Sensata Technologies, Inc.

Fig 6 CANopen

communication

sequence

6. Error Handle

In operational state, if M700-VR1 not receive RPDO1 for 200ms, it will

return to pre-operational state and clear all command.

PROGRAMMABLE PARAMETERS

The M700-VR1 programmable parameters allow the pump system’s

performance characteristics to be customized to fit the needs of

individual applications or system operators. Programming can be

done with a UART2USB adapter and PC APP.

Voltage

Rating Voltage

Under Voltage Cutback

Under Voltage Cutback Rate

Under Voltage Cutback Off

Over Voltage

Current

Max Current Limitation

Continue Current Limitation

Speed

Accel Rate

3

Initializing

Pre-

operational

Operational

Stopped

Initialized

NMT Cmd

0x01

NMT Cmd

0x01

NMT Cmd 0x80

Or comm. lost

NMT Cmd

0x02

NMT Cmd

0x02

NMT Cmd

0x80

NMT Cmd

0x81 or 0x82

NMT Cmd

0x81 or 0x82

NMT Cmd

0x81 or 0x82

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

17

Copyright © 2021 Sensata Technologies, Inc.

Quick Start

Max Speed

Throttle

Throttle Type

Throttle Deadband

Throttle Max

Throttle Map

Misc

HPD

Boost

Main Contactor Driver

Contactor Pull In

Contactor Holding

Contactor Protection

Contactor Open Delay

Interlock

CAN

CAN ID

CAN Baud Rate

The individual parameters are presented as follows in the

parameter charts:

VOLTAGE MENU

PARAMETER

ALLOWABLE

RANGE

DEFAULT VALUE

DESCRIPTION

Rating Voltage

24V

36V

24

Set this parameter to match the battery pack of your

vehicle

Under Voltage Cutback

50-100(%)

80

The controller’s circuitry requires a minimum battery

voltage to function properly. When battery voltage drops,

reducing the controller’s output to the motor allows the

battery to recover. The parameter sets the threshold

voltage below which controller output will start to be

reduced. The programmed value is a percentage of the

battery voltage.

Under Voltage Cutback

Rate

0-50(A/0.1V)

5

This is a proportional value. Use the current voltage minus

the cutoff voltage and then the ratio to the current output

current

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

18

Copyright © 2021 Sensata Technologies, Inc.

Under Voltage Cutback Off

50-100(%)

75

The Under Voltage Cutoff parameter sets the voltage at

which controller

output will be cut off completely. The programmed

value is a percentage of the battery voltage. The

Under Voltage Cutoff parameter can only be set to values

smaller (lower) than the programmed Under Voltage

Cutback.

Over Voltage

2500-3000

(Battery

Voltage*100)

2800

The Over Voltage parameter sets the voltage at which

controller will stop run to protect the circuit from

high voltage. It is the highest voltage at that rating voltage.

CURRENT MENU

PARAMETER

ALLOWABLE

RANGE

DEFAULT

VALUE

DESCRIPTION

Max Current Limitation

0-3000(setting

current*10)

1500

Max Current Limitation parameter sets the

max current that the software allows the

controller's output

SPEED MENU

PARAMETER

ALLOWABLE

RANGE

DEFAULT

VALUE

DESCRIPTION

Accel Rate

2-30(100ms)

10

The Accel Rate defines the time it takes the

controller to accelerate from 0%

output to 100% output when full throttle is

applied.

Larger values represent a longer

acceleration time and therefore a gentler

start. For faster starts, adjust the Accel Rate to

a smaller value.

Quick Start

2-30(100ms)

10

When the throttle is moved from zero rapidly,

the quick start feature is activated.

The Quick Start acceleration rate then replaces

the normal acceleration rate as

set by the Accel Rate parameter).

The Quick Start parameter can only be set to

values smaller (faster) than

the programmed Accel Rate.

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

19

Copyright © 2021 Sensata Technologies, Inc.

Max Speed

0-1000(percentage*10)

1000

Defines the maximum requested motor

speed at full forward throttle, as %

PWM. Partially-applied throttle is scaled

proportionately; e.g., 40% applied

throttle corresponds to a request for 40% of

the programmed Max Speed

value. Example: if Max Speed is set to 80%, a

40% applied forward throttle

corresponds to a 32% request

(0.80*0.40=0.32).

THROTTLE MENU

PARAMETER

ALLOWABLE

RANGE

DEFAULT VALUE

DESCRIPTION

Throttle Type

0:0-5K

1:5K-0

2:0-5V

3:CANOPEN

0:0-5k

The M700-VR1 controllers accepts a variety of throttle

inputs. The Throttle Type parameter can be programmed

as follows:

0: 2-wire potentiometer, 0–5kΩ input

1: 2-wire potentiometer, 5kΩ–0 input

2: single-ended 0–5V input

Throttle Deadband

10-500

(percentage*10)

200

The Throttle Deadband parameter defines the neutral

deadband as a per-centage of the full throttle range.

Increasing the Throttle Deadband setting will increase the

neutral range. This parameter is especially useful with

throttle assemblies that do not reliably return to a well-

defined neutral point, because it allows the deadband to

be defined wide enough to ensure that the controller goes

into neutral when the throttle mechanism is released.

Throttle Max

100-1000

(percentage*10)

800

The Throttle Max parameter defines the percentage of

throttle movement at which 100% output is requested.

Decreasing the Throttle Max setting reduces the full stroke

necessary to produce full controller output. This

parameter allows reduced-range throttle assemblies to be

accommodated.

www.sensata.com

| M700 SERIES

HYDRAULIC PUMP MOTOR CONTROLLER

20

Copyright © 2021 Sensata Technologies, Inc.

Throttle Map

0-100(%)

50

The Throttle Map parameter modifies the vehicle’s

response to the throttle input. Setting Throttle Map at

50% provides a linear output response to throttle position.

Values below 50% reduce the controller output at low

throttle settings, providing enhanced slow speed

maneuverability. Values above 50% give the vehicle a

faster, more responsive feel at low throttle settings. The

Throttle Map value is the controller output at half throttle,

as a percentage of the Max Speed. Half throttle is the mid

point of the throttle’s active range, which is the range

from zero output (at the Deadband setting) to 100%

output (at the Throttle Max setting).

THRTL DEADBAND

The Throttle Deadband parameter defines the pot wiper voltage

range the controller interprets as neutral. Increasing the throttle

deadband setting increases the neutral range. This parameter is

especially useful with throttle assemblies that do not reliably return

to a well-defined neutral point, because it allows the deadband to be

defined wide enough to ensure that the controller goes into neutral

when the throttle mechanism is released.

Examples of deadband settings (30%, 10%, 0%) are shown in

Figure 6 for throttle types 0 through 3, using a nominal 5kΩ–0

potentiometer (where applicable).

The programmer displays the throttle deadband parameter as

a percentage of the nominal wiper voltage range and is adjustable

from 4% to 90%, in 1% increments. The default deadband setting is

10%. The nominal wiper voltage range depends on the throttle type

selected.

This manual suits for next models

1

Table of contents