© Martin Engineering GmbH 2 M3776UK-05/10

Table of contents

1 Introduction ................................................................................ 3

1.1 Important notes............................................................................. 3

1.2 Safety instructions, safety at work................................................ 5

1.3 Symbols in these instructions ....................................................... 6

1.4 References .................................................................................... 7

2 Description of the product ......................................................... 8

2.1 General description....................................................................... 8

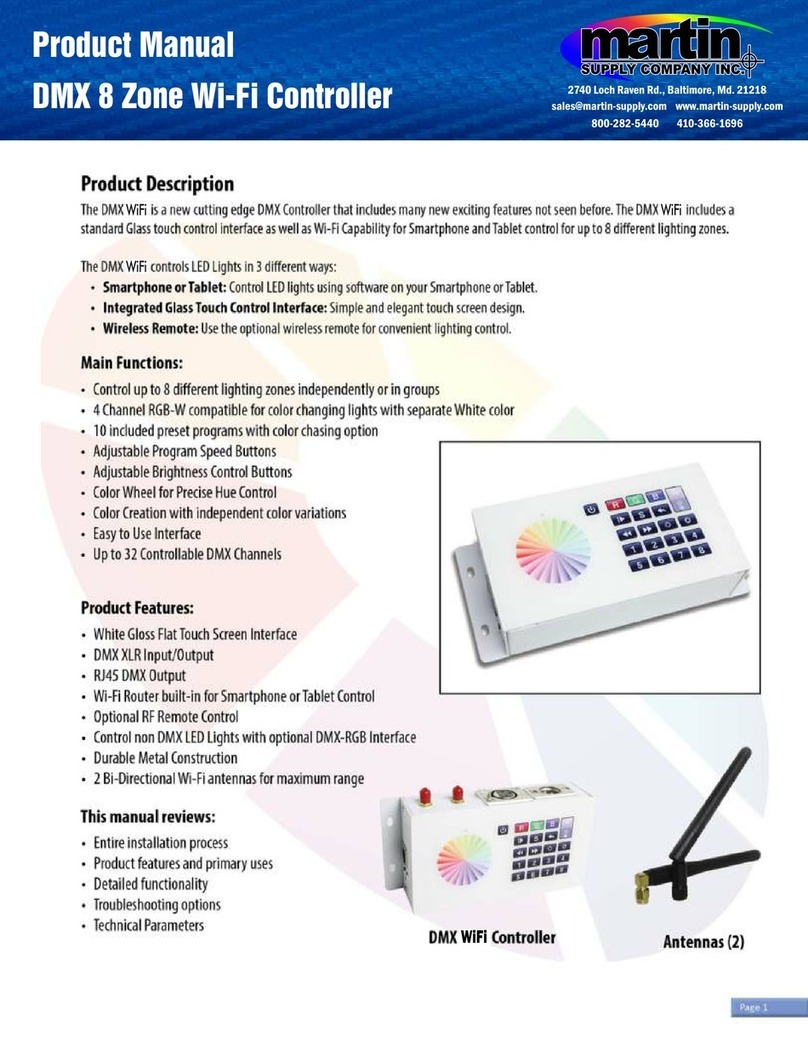

2.2 Control and display elements ....................................................... 8

2.3 Serial and model number.............................................................. 9

2.4 Structure of the product numbers ................................................. 9

3 Before installation..................................................................... 10

4 Installing controller .................................................................. 11

4.1 Assembly of the controller ......................................................... 11

4.2 Connection of the controller....................................................... 12

4.3 Programming controller.............................................................. 13

5 Operation of the controller ...................................................... 17

5.1 Imminent danger when discharging air cannons ........................ 17

5.2 Measures for avoiding risks........................................................ 17

5.3 Discharging ports........................................................................ 18

6 Part numbers ............................................................................ 21

6.1 MARTIN®MultiPort Air Cannon Controller ............................ 21

6.2 Accessories ................................................................................. 21

6.3 Parts list ...................................................................................... 22

6.4 Part number explanation............................................................. 23

7 Appendix A................................................................................ 24

8 EU Manufacturer´s declaration .............................................. 26

List of tables

1MARTIN

®MultiPort air cannon controller ................................ 23

List of figures

1 Control and display elements ......................................................... 8

2 Type plate; parts no. 21313-MCG.................................................. 9

3 Dimensions of the controller ........................................................ 11

4 Connection diagram...................................................................... 12

5 Programme sequence.................................................................... 13

6 Controller operator device............................................................ 14

7 Selection of the parameter ............................................................ 14

8 Changing parameter...................................................................... 14

9 Operational controls cabinet......................................................... 18

10 MARTIN®MultiPort air cannon controller ................................. 22

11 Terminal connections diagram ..................................................... 24