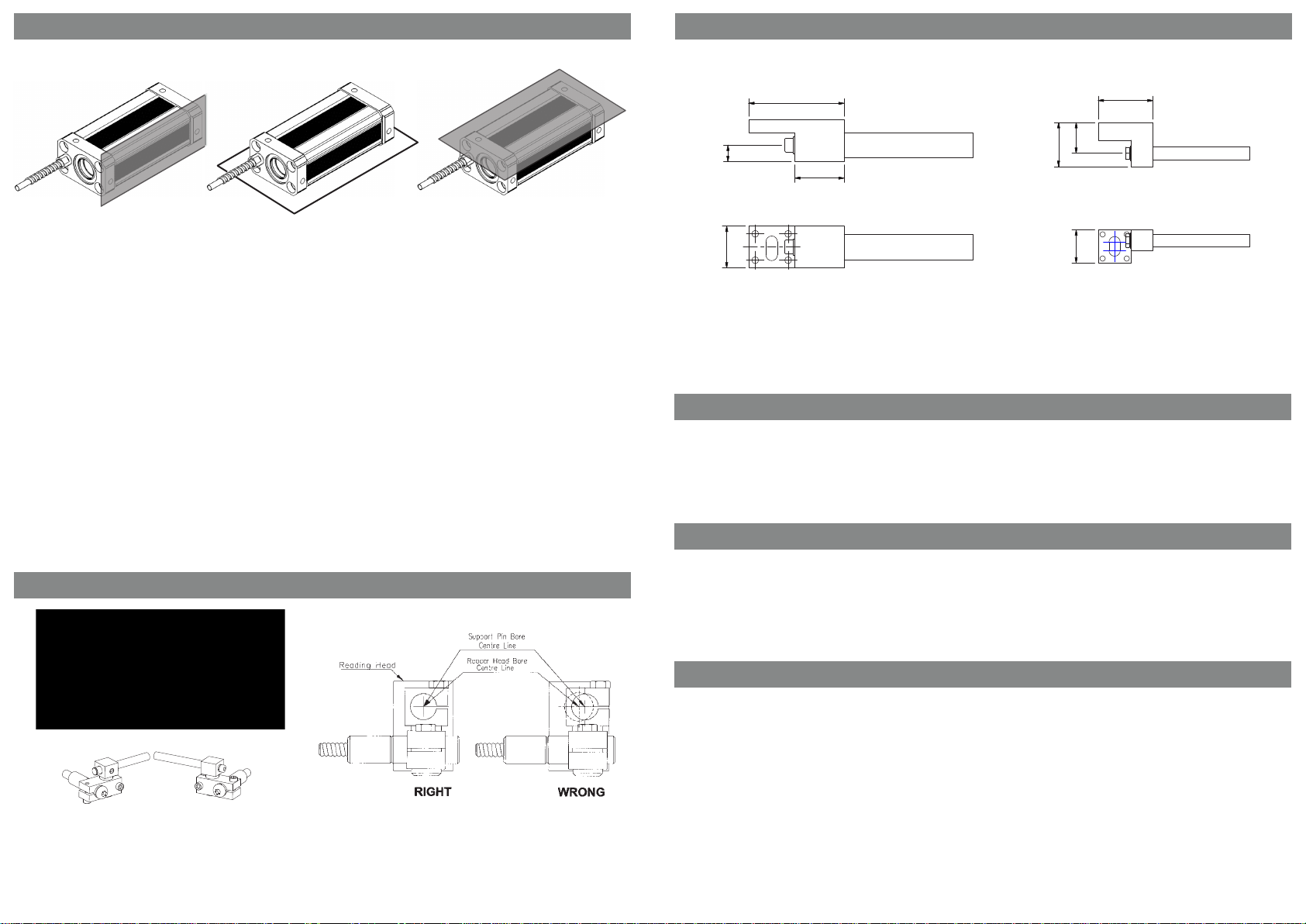

Reader head alignment

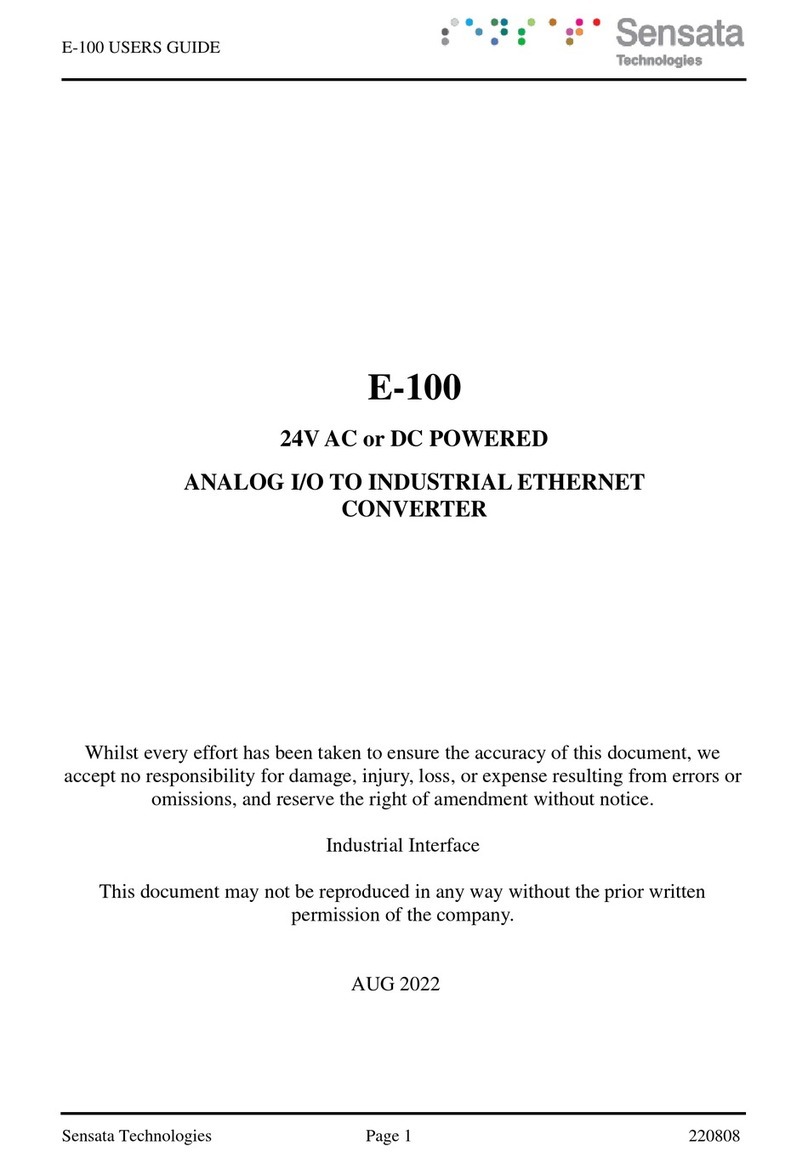

Scale mounting - double ended

Scale mounting - single end (300mm (12”) travel or less)

Mounting faces

The reader head can be mounted on any 3 of the faces shown in g 3.

Alignment tolerance to machine

The reader head should be mounted with both planes parallel to the axis of travel within ± 0.05mm (0.002”).

See g 4 and 5.

SIZE

A4

DRAWING

NUMBER

316-81880

REV.

ISS.

0

DO NOT SCALE

THIRD ANGLE PROJECTION

IF IN DOUBT ASK

UNLESS OTHERWISE TOLERANCES: - 0 DECIMAL PLACES

0.5

STATED: - 1 DECIMAL PLACES

0.2

2 DECIMAL PLACES

0.1

DIMENSIONS ARE IN M.M ANGULAR

1

DRAWING

NUMBER

REV.

ISS.

316-81880

0

SCALE

SHEET

1 OF 1

MATERIAL/FINISH

THIS DRAWING IS THE PROPERTY OF

NEWALL MEASUREMENT SYSTEMS LTD.

THE INFORMATION THERON MAY NOT BE COPIED OR USED

WITHOUT WRITTEN PERMISSION

N

Leicester England

TITLE

DRAWN

DATE chris.w

08/02/2006

REV.ISS.

DATE

C.N.No

ALTERATION

1=1

Spherosyn300

Microsyn300

Traverse the machine to its maximum position towards the non cable entry side of the reader head. Slide the

scale through reader head and t assembly (g 6 & 7) onto end of scale. Mark the position of the pillar.

Drill & tap to suit pillar (g 1 & 2). Loosely t assembly to pillar, pass scale through, slide scale forwards and

back whilst tightening the screws until it passes smoothly through head and bracket. Once aligned repeat at the

other end.

Spherosyn300 Microsyn300

SIZE

A4

DRAWING

NUMBER

316-83070

REV.

ISS.

0

DO NOT SCALE

THIRD ANGLE PROJECTION

IF IN DOUBT ASK

UNLESS OTHERWISE TOLERANCES: - 0 DECIMAL PLACES

0.5

STATED: - 1 DECIMAL PLACES

0.2

2 DECIMAL PLACES

0.1

DIMENSIONS ARE IN M.M ANGULAR

1

DRAWING

NUMBER

REV.

ISS.

316-83070

0

SCALE

SHEET

1 OF 1

MATERIAL/FINISH

THIS DRAWING IS THE PROPERTY OF

NEWALL MEASUREMENT SYSTEMS LTD.

THE INFORMATION THERON MAY NOT BE COPIED OR USED

WITHOUT WRITTEN PERMISSION

N

Leicester England

TITLE

SINGLE END DEATILS FOR BROCHURES

DRAWN

DATE chris.w

19/01/2006

REV.ISS.

DATE

C.N.No

ALTERATION

NTS

For Spherosyn300 remove the white nylon snap rivet from end of the scale.

Once reader head is aligned, slide the scale through and into the single end support and secure into place.

Position the block in the correct position, mark the slot. Drill & tap to suit xing (g 8 & 9). Once secured check

alignment by gently sliding scale in and out through head and block. Grub screws are available for adjustment.

You can single end mount with the standard link, pillar brackets or with the optional single end mount brackets

shown above.

Fitting the scale guard

Cable routing

Final check

Care should be taken to ensure that all cables are routed and secured to the machine avoiding any mechanical

interference with any part of the machine or encoder movement. Routing should also avoid sources of electrical

noise and interference. Cable clamps are supplied.

Note: The armoured cable is an integrated part of the reader head. If the cable becomes damaged this will

require a replacement reader head. Ensure all connectors are located in a position to avoid uid contamination.

Each Encoder includes a protective guard. The guard can be attached to the machine casting or by means of

the scale support pins via the button head screws provided.

For single end mounting use machine faces.

After the guard is attached, move the machine axis to both extents of its travel ensuring that the guard does not

interfere with or rub against the Reader Head.

Prior to putting the linear encoder system into operation after installation, slowly traverse the machine axis to

ensure that all cable routings are correct and machine over-travel cannot occur.

30.00

10.00

58.00

25.40

25.00

14.00

8.00

15.00