sensl J series User manual

USER MANUAL

J-Series High PDE and Timing Resolution, TSV Package

SensL © 2015 1

Overview

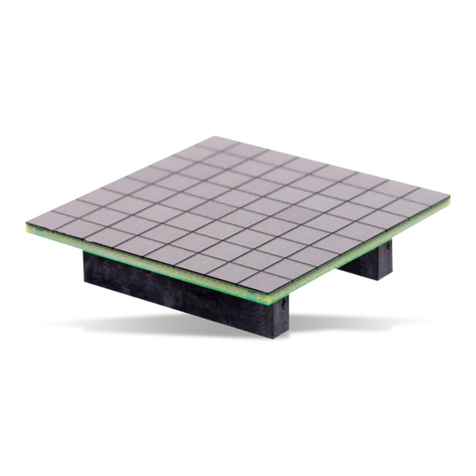

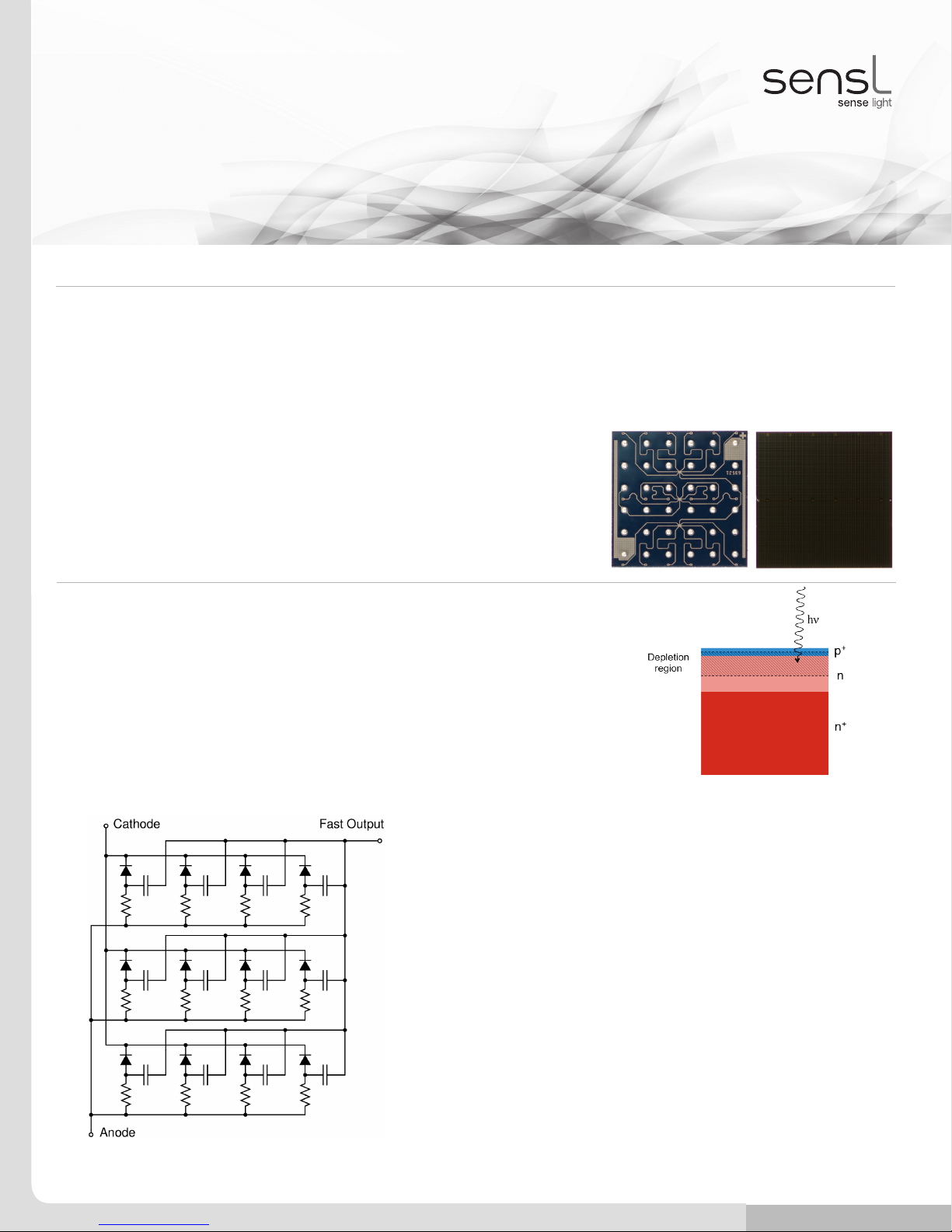

J-Series SiPM sensors from SensL are based on a P-on-N diode structure

(Figure 1), which provides optimized PDE at the blue end of the visible

spectrum, and feature a number of signicant performance upgrades:

PDE: J-Series sensors feature increased microcell density, giving an overall

improvement to PDE (with a peak at 50%), along with other optimizations

that extend the sensitivity into the UV, (>5% PDE at 250nm). This PDE

improvement is achieved while keeping the dark count rate low.

High-Density Fill Factor Silicon Photomultipliers

Figure 1, P-on-N sensor structure

J-Series

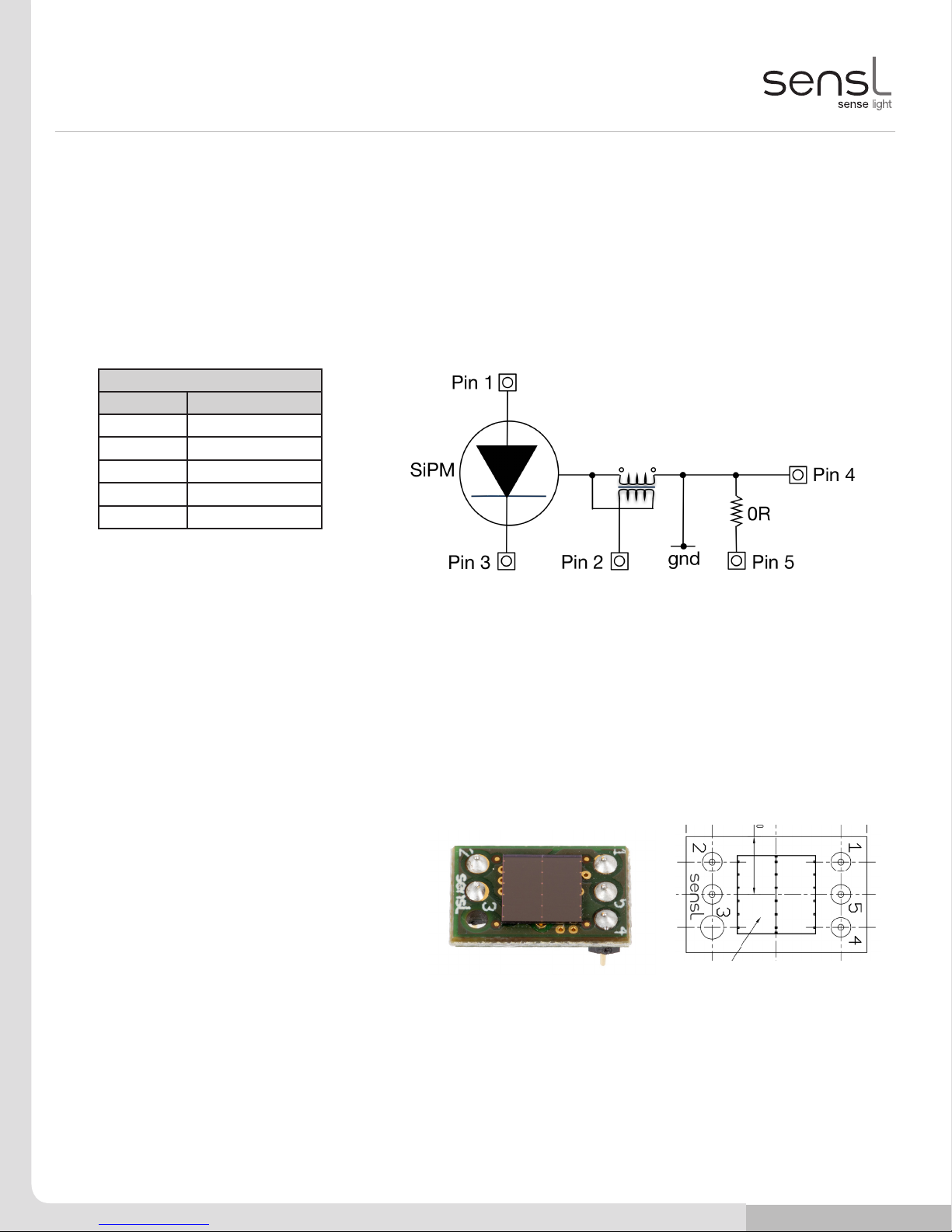

Figure 2, Simplied microcell level schematic of

the J-Series SiPM.

Timing: J-Series sensors feature reduced microcell recovery time

and standard signal rise time. All J-Series sensors also feature

SensL’s proprietary fast output terminal (Figure 2), which is the

derivative of the internal fast switching of the microcell in response

to the detection of a single photon, which has sub-nanosecond

rise times and pulse-widths.

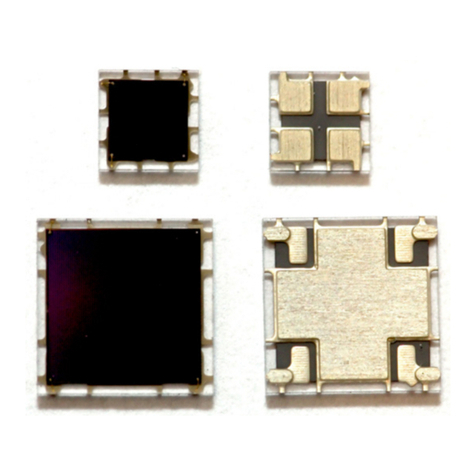

Package: J-Series sensors are available as either a 3mm or 6mm

chip packaged using a TSV (through-silicon via) process to create

a CSP (Chip Scale Package) with minimal deadspace. The TSV

sensors have a number of ball contacts on the reverse, giving

access to the fast output as well as the anode and cathode.

SensL’s J-Series low-light sensors feature an industry-leading low dark count rate and a high PDE that extends

much further into the blue part of the spectrum using a high-volume, P-on-N silicon process. Improvements have

been made to both the standard (anode-cathode) rise time and the recovery time, in addition to the inclusion of

SensL’s unique fast output that offers sub-nanosecond pulse widths. J-Series sensors are available in different sizes

(3mm and 6mm) and use TSV (Through Silicon Via) technology to create a CSP (Chip Scale Package) with minimal

deadspace, that is compatible with industry standard, lead-free, reow soldering processes.

The J-Series Silicon Photomultipliers (SiPM) form a range of high gain,

single-photon sensitive, UV-to-visible light sensors. They have performance

characteristics similar to a conventional PMT, while beneting from the

practical advantages of solid-state technology: low operating voltage,

excellent temperature stability, robustness, compactness, output uniformity,

and low cost. For more information on the J-Series sensors please refer to

the datasheet.

SensL © 2015 2

USER MANUAL

J-Series High PDE and Timing Resolution, TSV Package

SensL © 2015 2

Contents

Overview ............................................................................................................................................................ 1

Biasing and Readout .......................................................................................................................................... 3

Recommended Biasing ............................................................................................................................... 3

Recommended Readout and Amplication .................................................................................................. 3

Readout of the Fast Output ......................................................................................................................... 3

J-Series Mounted Sensors ................................................................................................................................. 4

MicroFJ-SMA .............................................................................................................................................. 4

MicroFJ-SMTPA .......................................................................................................................................... 5

Handling and Soldering ...................................................................................................................................... 6

Safe Handling of Sensors ............................................................................................................................ 6

Product Packaging ...................................................................................................................................... 6

Cleaning ...................................................................................................................................................... 6

Solder Reow Conditions ............................................................................................................................ 7

CAD and Solder Footprint Files........................................................................................................................... 8

Further Help ....................................................................................................................................................... 9

Appendix A - Biasing Alternatives & Signal Polarity ........................................................................................... 10

SensL © 2015 3

USER MANUAL

J-Series High PDE and Timing Resolution, TSV Package

SensL © 2015 3

Biasing and Readout

Recommended Biasing

The cathode needs to be held at a positive bias with respect to the anode, as in Figure 3. It is recommended that

bias voltage decoupling, such as the examples shown in Figure 4, is used to provide a stable operating condition.

Please refer to the Appendix for further information on biasing schemes and the resulting signal polarities.

Recommended Readout and Amplication

Figure 5 shows how the J-Series sensors can be connected to a standard high-speed amplier, such as the

OPA656, to convert the standard output signal current to a voltage. This particular arrangement is suitable for

either the 3mm or 6mm sensors.

Readout of the Fast Output

For extensive information about the fast output and its readout, please consult pages 4-8 of the C-Series User

Manual. In addition, Appendix A of this document shows the resulting signal polarities when various biasing

schemes are used.

Figure 4, Generic biasing set-up with decoupling capacitors.

Figure 5, Example circuit for readout of individual sensors.

Figure 3, Recommended biasing

SensL © 2015 4

USER MANUAL

J-Series High PDE and Timing Resolution, TSV Package

SensL © 2015 4

J-Series Mounted Sensors

MicroFJ-SMA

J-Series sensors are available ready-mounted on test boards, to allow for easy evaluation. The MicroFJ-SMA-XXXXX

sensors (Figure 6) feature the TSV-packaged SiPM sensor reow-soldered onto a small PCB. The board is simple to

use, having just three SMA (female) connectors: one delivers the bias voltage (Vbias) and the other two provide the

output signals: standard output from the anode (Sout) and the fast output (Fout). The SMA board requires a positive

bias, which allows the standard output to be referenced to ground rather than the bias. For the complete circuit

schematic, please consult the TSV Board Reference Design document.

Output Connector Function Comments

Vbias Standard female

SMA connector

bias input (cathode) positive bias input

Fout fast output if unused can be left open

Sout standard output (anode) if unused can be left open

Table 1, SMA Connections

The MicroFJ-SMA board is for users who require a plug-and-play set-up to quickly evaluate the TSV sensors with

optimal timing performance. The board provides outputs which can be connected directly to a 50W-terminated

oscilloscope for viewing signals. The board also allows the standard output from the anode to be observed at the

same time as the fast output. Table 1 summarizes the connections to the SMA board. Each board has two mounting

holes to allow secure placement during testing.

For more discussion regarding the readout of the fast output signals, please consult pages 4-8 of the C-Series User

Manual. In addition Appendix A of this document shows the signal output polarities when various biasing schemes

are used.

Figure 6, The MicroFJ-SMA-300XX board.

Bias

Fast

output

TSV

sensor

Mounting

holes

Standard

output

SensL © 2015 5

USER MANUAL

J-Series High PDE and Timing Resolution, TSV Package

SensL © 2015 5

MicroFJ-SMTPA

The TSV Pin Adapter board (SMTPA) is a small PCB board that houses the TSV sensor and has 5 through-hole pins

to allow its use with standard sockets or probe clips. This product is useful for those needing a quick way to evaluate

the TSV package without the need for specialist surface-mount soldering. While this is a ‘quick x’ suitable for many

evaluations, it should be noted that the timing performance from this board will not be optimized and if the best

possible timing performance is required, the MicroFJ-SMA-XXXXX is recommended. The SMTPA circuit schematic is

shown below in Figure 7. Please consult Appendix A for further information on biasing. The SMTPA board electrical

schematics are available to download in the TSV Board Reference Design document.

MicroFJ-SMTPA-XXXXX

Pin No. Connection

1 anode

2 fast output

3 cathode

4 ground

5 no connect

The SMTPA board does not include any on-board decoupling on the bias line. Therefore, bias decoupling, such as

that in Figure 4, should be included on the bias line at the relevant pin (see Table 2). The standard output can be

connected directly to an amplier or 50Wload oscilloscope. If the standard output is not used, then that pin should

be connected to zero Volts.

Due to the presence of the pins on the SMTPA board, it is not optimal for evaluation testing where timing with the

fast output signal is critical. For evaluations where the timing performance of the fast output is critical, the use of the

SMA board is recommended.

The connectors from Samtec used are:

BBL-103-G-E

BBL-102-G-E

Compatible sockets from Samtec are:

SL-103-G-10

SL-102-G-10

For more discussion regarding the readout of the fast output signals, please consult pages 4-8 of the C-Series

User Manual. In addition Appendix A of this document shows the signal output polarities when various biasing

schemes are used.

Figure 8, The top view of the SMTPA board, showing the

numbering of the pins

Table 2, Pin assignments for the

MicroFJ-SMTPA board

Figure 7, SMTPA circuit schematic

SensL © 2015 6

USER MANUAL

J-Series High PDE and Timing Resolution, TSV Package

SensL © 2015 6

Handling and Soldering

Safe Handling of Sensors

• When unpacking, care should be taken to prevent dropping or misorienting the sensors. The specic items

contained in the package and the type of packaging will depend on the parts ordered.

• Remember that the SiPM is a sensitive optoelectronic instrument; always handle the sensor as carefully as

possible.

• The sensor should be disconnected from the bias supply when not in use.

• SiPM sensors are ESD sensitive. The following precautions are recommended:

• Ensure that personal grounding, environmental controls and work surfaces are compliant with

recommendations in JESD625.

• Ensure that all personnel handling these devices are trained according to the recommendations in

JESD625.

• Devices must be placed in an ESD approved carrier during transport through an uncontrolled area.

• Complete handling information can be found in the TSV Handling and Soldering guide.

Product Packaging

The sensors are shipped in moisture barrier bags (MBBs) according to J-STD 033 standard. An unopened MBB

should be stored at a temperature below 40OC and relative humidity <90%. After the MBB has been opened, the

devices must be reow soldered within a period of time depending on the moisture sensitivity level (MSL), which is

MSL3 for sensors delivered on tape and reel and MSL4 for sensors on cut tape. See Table 3 for details.

Delivery format MSL Exposure time Condition

Tape and reel 3 168 hours

≤30 °C/60% RH

Cut tape 4 72 hours

Table 3, MSL denitions applicable to the J-Series sensors (reference J-STD 020).

Cleaning

The parts can be cleaned using Isopropyl alcohol.

SensL © 2015 7

USER MANUAL

J-Series High PDE and Timing Resolution, TSV Package

SensL © 2015 7

Solder Reow Conditions

The J-Series sensors must be mounted according to specied soldering pad patterns as given in the CAD les (see

links on the following page). The ‘No Connect’ pins are electrically isolated and should be soldered to a ground (or

bias) plane to help with heat dissipation.

Solder paste must be evenly applied to each soldering pad to insure proper bonding and positioning of the

component. After soldering, allow at least three minutes for the component to cool to room temperature before

further operations.

Solder reow conditions must be in compliance with J-STD-20, table 5.2. This is summarized in Figure 9. The

number of passes shall not be more than 2.

Complete soldering information can be found in the TSV Handling and Soldering guide.

0

50

100

150

200

250

300

0 50 100 150 200 250 300

Temperature (OC)

Time (sec)

Solder Reflow Profile

Max 4OC/sec

60 to 120 sec

Max 260OC

217OC

180OC60~100sec

Max 10sec at 260OC

Figure 9, Reow solder prole for use with J-Series sensors.

SensL © 2015 8

USER MANUAL

J-Series High PDE and Timing Resolution, TSV Package

SensL © 2015 8

CAD and Solder Footprint Files

• MicroFJ-60035-TSV-A2 sensor CAD, including tape and reel, and solder footprint.

• MicroFJ-30020-TSV-A1 sensor CAD, including tape and reel, and solder footprint.

• MicroFJ-30035-TSV-A2 sensor CAD, including tape and reel, and solder footprint.

(This PCN describes the changes to the tape and reel between revisions A1 and A2.)

• MicroFJ-SMA-300XX CAD

• MicroFJ-SMA-60035 CAD

• MicroFJ-SMTPA-300XX CAD

• MicroFJ-SMTPA-60035 CAD

SensL © 2015 9

USER MANUAL

J-Series High PDE and Timing Resolution, TSV Package

SensL © 2015 9

Further Help

If more help is required in the set-up or operation of J-Series sensors, there are several SensL resources that can

help.

• The J-Series Datasheet contains more detailed information on the physical and performance characteristics of the

sensors.

• A variety of Tech Notes are available on the website, www.sensl.com, such as:

• The TSV Handling and Soldering guide.

• The TSV Board Reference Design document.

• A guide on creating arrays of close-packed sensors.

• An extensive library of technical and scientic papers on the use of SensL SiPM sensors.

SensL © 2015 10

SensL © 2015 10

USER MANUAL

J-Series High PDE and Timing Resolution, TSV Package

Rev. 1.0, December 2016

www.sensl.com

+353 21 240 7110 (International)

+1 650 641 3278 (North America)

SensL © 2015 10

All specications are subject to change without notice

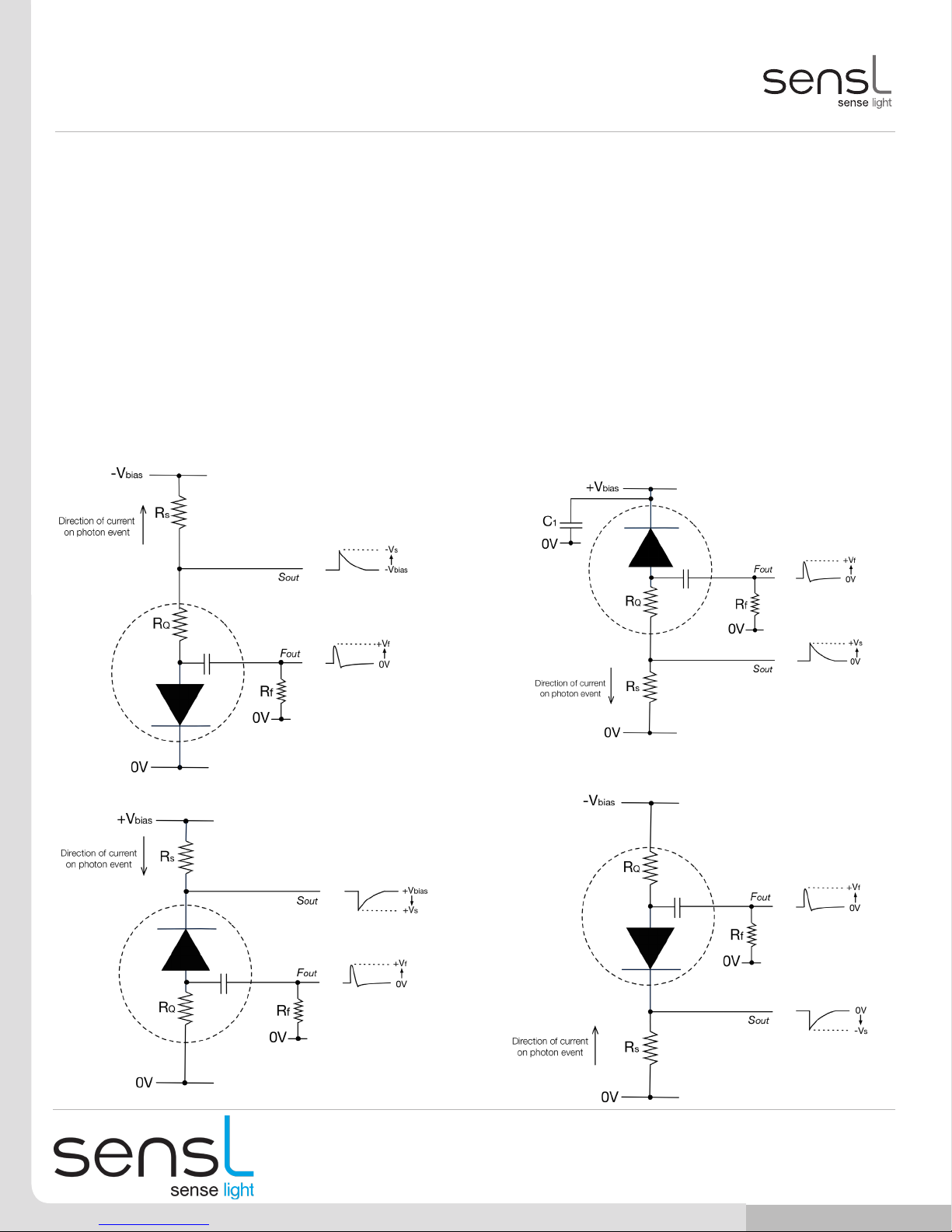

Appendix A - Biasing Alternatives & Signal Polarity

This Appendix lists all of the possible ways in which a J-Series SiPM can be biased. For each biasing arrangement,

the standard and fast signal polarities are given. Aand B are the recommended congurations. Cand Dwill work,

but are not recommended for use with the fast output. The following abbreviations are used throughout:

Vbias = bias voltage

Sout = standard output

Fout = fast output

Rs= load resistor for the standard output

Rf= load resistor for the fast output

Vs= standard output voltage

Vf= fast output voltage

RQ= quench resistor (included on the SiPM die)

C1 = decoupling capacitor 10nF (50V), low ESR, ceramic

AB

CD

Other manuals for J series

1

Table of contents

Other sensl Accessories manuals

Popular Accessories manuals by other brands

Gleason Reel

Gleason Reel Dual Hose Reel-Direct Drive K-28 Installation and maintenance instructions

ALERTON

ALERTON MICROSET 4 Installation & operation guide

Panasonic

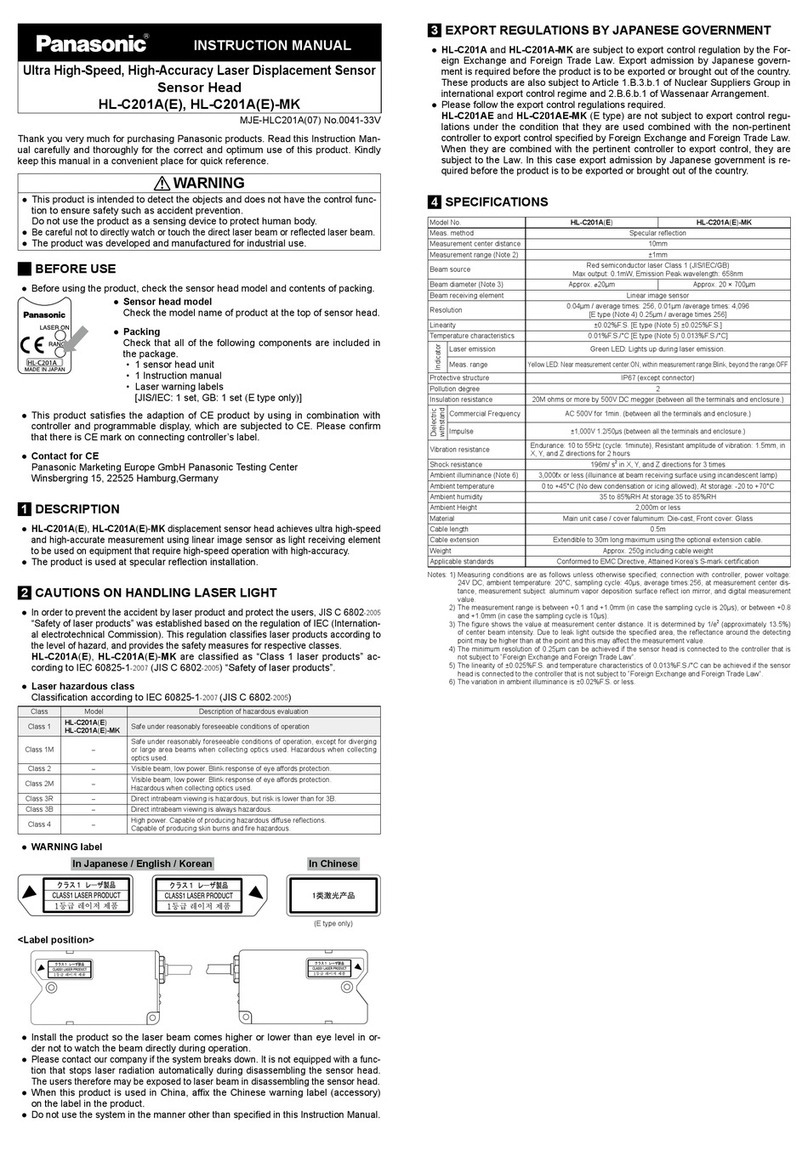

Panasonic HL-C201A instruction manual

Rice Lake

Rice Lake 380 Synergy Technical manual

Xantech

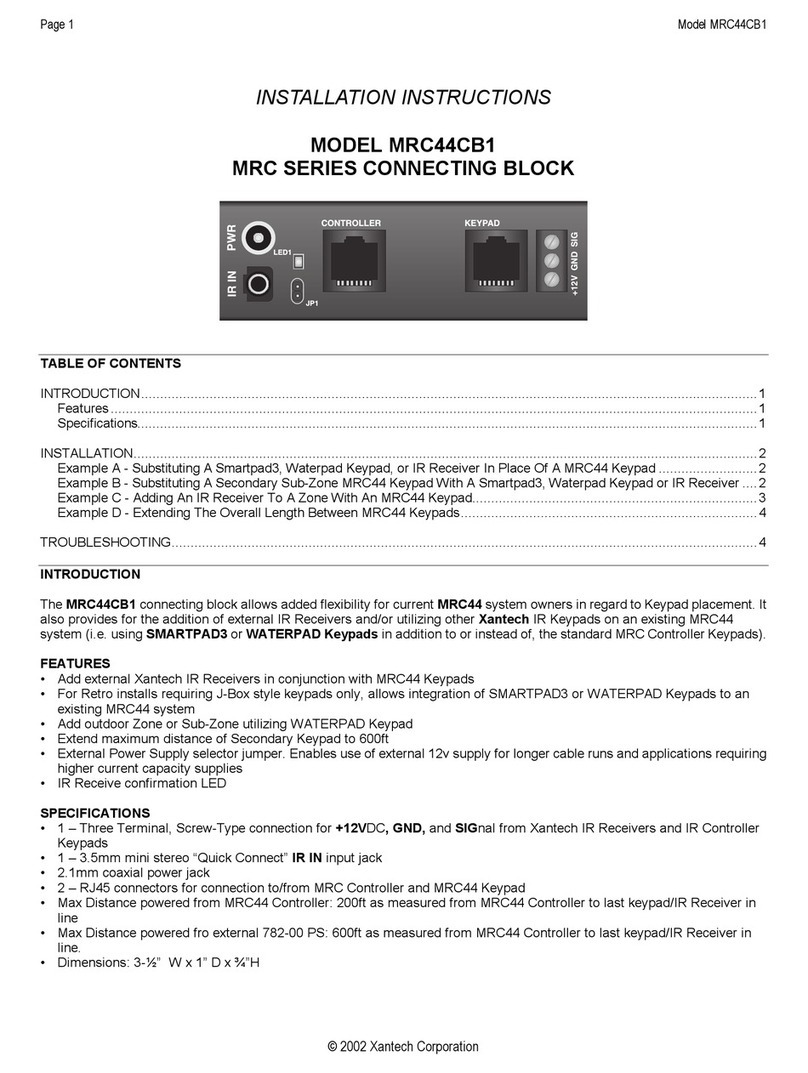

Xantech MRC44CB1 installation instructions

Omron

Omron E3ZM - datasheet