Sensor Electronics SEC Millenium Series Manual

Sensor Electronics Corporation

12730 Creek View Avenue

Savage, Minnesota 55378

Gas Detection Systems

Training Manual

August 2017

SEC 3000 Gas Detector

© 09/13

• Compact low cost design

• No field gas calibration required

• Intrinsically safe & explosion proof

• Universal control board

• Interchangeable sensor modules for oxygen and toxic gases

• Temperature compensated sensor

• Stand alone gas detector with 4-20 mA output

• Corrosion resistant 316 stainless steel housing construction

• Long life electrochemical sensors

• Can be mated with SEC 3100 Transmitter

• Optional heater with closed loop temperature control ensures accuracy in

low temperature applications

Features

• Petrochemical • LNG & LPG Processing

• Medical • Waste Water

• Semi Conductor • Water Treatment

• Mining • Chemical

• Pulp and Paper • Automotive

• Offshore • Pharmaceutical

• Fertilizer • Refrigeration

Industries

Operation

The SEC 3000 gas detector is a unique design combining intrinsically safe and explosion proof

approved standards. This allows for quick and simple field installation of a calibrated sensor module into

the gas detector in hazardous locations with power applied.

The SEC 3000 sensor module retains operating parameters and calibration settings. Once the sensor

module is plugged into the gas detector, the sensor module automatically uploads current information to

the control board in the SEC 3000. Changing to a different type of gas sensor is accomplished by only

changing the sensor module board. The existing housing and wiring remains intact.

An industry standard 4-20 mA analog output provides remote alarm, fault and calibration signals. The

entire unit utilizes self-diagnostics, identifies problems and continuously transmits status.

The SEC 3000 can be used inconjunction with the SEC 3100 explosion proof transmitter. The SEC 3100

has a backlit LCD display, non-intrusive local calibration, 4-20 mA output, non-intrusive local configura-

tion, optional relays, RS485 interface and intrinsic barrier.

Sensor Electronics Corporation

12730 Creek View Avenue, Savage, MN 55378 U.S.A. • (800) 285-3651 • (952) 938-9486 • FAX: (952) 938-9617

www.sensorelectronic.com • [email protected]

© 09/13

Detection Method:

Electrochemical or Galvanic

Sampling Method:

Diffusion

Optional sample draw (requires 1 liter per

minute sample flow rate)

Output (Analog):

4-20 mA (source type), max. 1000 Ohm load

at 24 VDC supply voltage

Output (Digital):

Interactive Interface Available On The

Calibration (White) Wire

Construction:

316 Stainless Steel Explosion Proof

Accuracy:

+/- 5%

Lower Detectable Limit:

1% of Full Scale (Under Ideal Conditions)

Recommended Minimum Alarm Setting:

10% of Full Scale

Temperature Rating:

Toxic gas sensors temperature range may vary.

Please consult with Sensor Electronics.

Operating Voltage:

24 VDC ______ Operating range: 8 to 32 VDC

measured at the detector head

Power Consumption

1-2 Watt Max.

Max. Current Draw

50 mA (at 24 VDC)

Approvals:

CSA: Class 1, Div 1, Groups B,C,D, T6

CSA: Intrinsically Safe, Groups A,B,C,D,T4

Installation Category:

Cat. I, Pollution Degree 2

SEC 3000 Gas Detector

Specifications

Current Output Status

0.0 mA Unit Fault

0.8 mA Unit warm up

1.2 mA Zero drift fault

1.6 mA Calibration fault

2.0 mA Unit spanning

2.2 mA Unit zeroing

4-20 mA Normal measuring mode

4.0 mA Zero gas level

5.6 mA 10% Full Scale

8.0 mA 25% Full Scale

12 mA 50% Full Scale

16 mA 75% Full Scale

20 mA Full scale

>20 mA Over-range

Partial Gas List

Oxygen (O2) Carbon Monoxide (CO)

Hydrogen (H2) Germane (GeH4)

Ammonia (NH3) Silane (SiH4)

Nitric Oxide (NO) Phosphine (PH3)

Bromine (Br2) Sulfur Dioxide (SO2)

Fluorine (F2) Nitrogen Dioxide (NO2)

Arsine (AsH3) Chlorine Dioxide (ClO2)

Ozone (O3) Hydrogen Sulfide (H2S)

Chlorine (Cl2) Hydrogen Fluoride (HF)

Phosgene (COCl2) Hydrogen Chloride (HCl)

Diborane (B2H6) Hydrogen Cyanide (HCN)

Formaldehyde (HCHO) Hydrogen Selenide (H2Se)

Ethylene Oxide (ETO) Hydrogen Peroxide (H2O2)

_ _ _

Doc#: 1460003, Rev A Operation Manual, SEC 3000 Electro-Chemical Gas Sensor Page 2of 13

Commitment

Our quality and service are uncompromising. We back each of our products with a two-year warranty on all

materials and workmanship. We offer technical support, user training and on-site service and maintenance

of equipment to meet the needs of our customers.

Gas Detection Service

Individually designed maintenance packages are available for specific customer needs. Service begins with

verification of the system installation that includes an initial system check and calibration. We then offer

customer training programs (on-site and at factory) to insure that technical personnel fully understand

operation and maintenance procedures. When on-the-spot assistance is required, service representatives

are available to handle any questions or problems immediately.

Warranty

Sensor Electronics Corporation (SEC) warrants products manufactured by SEC to be free from defects in

workmanship and materials for a period of two (2) years from date of shipment from the factory. Any parts

returned freight pre-paid to the factory and found defective within the warranty would be repaired or

replaced, at SEC's option. SEC will return repaired or replaced equipment pre-paid lowest cost freight. This

warranty does not apply to items, which by their nature are subject to deterioration or consumption in normal

service. Such items may include:

Fuses and Batteries

Warranty is voided by abuse including rough handling, mechanical damage, alteration or repair. This

warranty covers the full extent of SEC liability and SEC is not responsible for removal, replacement costs,

local repair costs, transportation costs or contingent expenses incurred without prior written approval.

Sensor Electronics Corporation's obligation under this warranty shall be limited to repair or replacement of

any product that has been returned to Sensor Electronics Corporation for warranty consideration. This

warranty is expressly in lieu of any and all other warranties expressed or implied, and all other obligations or

liabilities on the part of Sensor Electronics Corporation including but not limited to, the fitness for a particular

purpose. In no event shall Sensor Electronics Corporation be liable for direct, incidental, or consequential

loss or damage of any kind connected with the use of its products or failure to function or operate properly.

WARNING: READ AND UNDERSTAND THE USER’S MANUAL BEFORE OPERATING

OR SERVICING

WARNING: KEEP COVER TIGHT WHILE CIRCUITS ARE LIVE

CAUTION: FOR SAFETY REASONS THIS EQUIPMENT MUST BE OPERATED AND

SERVICED BY QUALIFIED PERSONEL ONLY

Doc#: 1460003, Rev A Operation Manual, SEC 3000 Electro-Chemical Gas Sensor Page 3of 13

Revision History

Rev

Date

Description of Change

Page

A

Aug 2015

Assign new part number, place under ECO control

All (footer)

Correct Temp Specifications to align with certifications

4

Add Caution and Warning Statements

2

Remove Y2K Disclaimer (obsolete)

1

31015

Oct 2013

Part Number 75-3000

Update Company Address

Cover

091404

Sep 2004

Revision History Undocumented

Table of Contents

Revision History........................................................................................................3

I. SPECIFICATIONS................................................................................................4

II GENERAL DESCRIPTION ..................................................................................5

III. OPERATION ......................................................................................................6

IV. CALIBRATION..................................................................................................8

V. MAINTENANCE.................................................................................................9

VI. Parts List .............................................................................................................9

Cross Sensitivity Table............................................................................................10

VII. Drawing Section...............................................................................................11

Part Number Construction.......................................................................................13

Doc#: 1460003, Rev A Operation Manual, SEC 3000 Electro-Chemical Gas Sensor Page 4of 13

I. SPECIFICATIONS

Model: SEC 3000 Gas Detector

Model Number: SEC3000

Available gases:

Ammonia Carbon Monoxide Hydrogen

Nitric Oxide Oxygen Phosgene

Bromine Chlorine Chlorine Dioxide

Fluorine Hydrogen Peroxide Ozone

Hydrogen Chloride Hydrogen Cyanide Hydrogen Fluoride

Hydrogen Sulfide Nitrogen Dioxide Sulfur Dioxide

Arsine Diborane Germane

Hydrogen Selenide Phosphine Silane

Formaldehyde

Please note that this list is not all-inclusive. The SEC 3000 sensors can be calibrated for other toxic gases

provided a calibration gas is available. For more please contact Sensor Electronics Corporation.

Detection Method: Electrochemical or Galvanic

Aspiration:

Diffusion

Optional Sample Draw (requires 1 liter per minute sample flow rate)

Output (Analog): 4-20 mA (Source type), max. 1000 Ohm load at 24 VDC supply voltage

Output (Digital) Interactive Interface Available On The Calibration (White) Wire

Response Time: Varies for type of sensing element

Construction: 316 Stainless Steel Explosion Proof

Accuracy: +/- 5%

Operating Temperature Rating:

-40to +50C at 0 to 99% RH (non-condensing)

Operating Voltage:

8 to 32 VDC measured at the detector head

Power Consumption: 1 Watt Max.

Max. Current Draw: 40 mA (at 24 VDC)

Approvals:

Explosion Proof CSA c,us: Class I, Division 1, Groups B,C,D T6

IECEx CSA 13.00xx: Ex d IIB+H2 T4 Gb

Intrinsically Safe CSAc,us: Cl I, Division 1, Groups Vmax Imax Pmax Ci Li T-Code

ABCD 10.4V 148mA 1.2W 2.51uF 22.5uH T4

CD 16.4V 148mA 1.2W 2.51uF 22.5uH T4

D 26.3V 148mA 1.2W 2.51uF 22.5uH T4

IECEx CSA 13.00xx: Ex ia IIC T4 Ga

Installation Category: Cat. I, Pollution Degree 2

Doc#: 1460003, Rev A Operation Manual, SEC 3000 Electro-Chemical Gas Sensor Page 5of 13

II GENERAL DESCRIPTION

CONVENTIONS

The following conventions are used in this manual.

Warning Statement

VDC (DC Voltage)

SEC 3000

The SEC 3000 toxic gas detector is a microprocessor based intelligent gas detector that continuously

monitors toxic gases and vapors ideally suited for use in harsh environments.

The SEC 3000 is a stand-alone device providing a continuous 4 to 20 mA output.

Intrinsically Safe and Explosion Proof versions are available.

When operated with the appropriate Intrinsic Barrier, the IS SEC3000 allows cover removal and sensor

replacement without declassifying the area.

Each sensor comes calibrated and carries all operating parameters. Simply plugging the sensor board into

any SEC3000 base results in a calibrated fully functional unit.

WARNING: SUBSTITUTION OF COMPONENTS MAY IMPAIR INTRINSIC SAFETY

AVERTISSEMENT: LA SUBSTITUTION DE COMPOSANTS PEUT

COMPROMETTRE LA SECURITE INTRINSEQUE

Features

Compact low cost design

No field gas calibration required

Intrinsically Safe and explosion proof

Universal control board

Interchangeable sensor modules for oxygen and toxic gases

Temperature compensated sensor

Stand alone gas detector with 4-20 mA sourced output

Corrosion resistant 316 stainless steel housing construction

Long life electrochemical sensors

Optional heater with closed loop temperature control ensures accuracy in low temperature applications

Can Be Coupled With SEC3100 Transmitter to Provide

Alarm and Fault Relays

Isolated RS485 Modbus Interface

Lighted LCD Display

Magnetic Switches For Unit Calibration Configuration

Doc#: 1460003, Rev A Operation Manual, SEC 3000 Electro-Chemical Gas Sensor Page 6of 13

III. OPERATION

Installation and Startup

Warning: The user shall be made aware that if the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be impaired.

The first step in the installation process is to establish a mounting location for the SEC 3000. Select a

location that is typical of the atmosphere to be monitored or close to the anticipated source of a dangerous

gas.

It is very important that the SEC 3000 be properly located to enable it to provide maximum protection. The

most effective number and placement of sensors vary depending on the conditions of the application. When

determining where to locate sensors the following factors should be considered.

What are the characteristics of the gas that is to be detected? Is it lighter or heavier than air? If it is

lighter than air the sensor should be placed above the potential gas leak. Place the sensor close to the

floor for gases that are heavier than air or for vapors resulting from liquid spills. Note that air currents

can cause a gas that is heavier than air to rise. In addition, if the temperature of the gas is hotter than

ambient air or mixed with gases that are lighter than air, it could also rise.

How rapidly will the gas diffuse into the ambient air? Select a location for the sensor that is close to the

anticipated source of a gas leak.

Wind or ventilation characteristics of the immediate area must also be considered. Movement of air may

cause gas to accumulate more heavily in one area than in another. The detector should be placed in the

areas where the most concentrated accumulation of gas is anticipated. For outdoor applications with

strong wind conditions, it may require the sensors to be mounted closer together and on the down wind

side, to the anticipated area of a gas leak. Also take into consideration for indoor applications, the fact

that many ventilation systems do not operate continuously.

The sensor should be accessible for maintenance.

Excessive heat or vibration can cause premature failure of any electronic device and should be avoided

if possible.

Follow all national and local installation codes and practices.

The SEC 3000 has a ¾” NPT threaded connector for mounting the detector to a junction box. SEC can

provide a junction box with terminals for this purpose.

A user-supplied junction box can be used providing it has the appropriate sized NPT conduit entries. The

junction box must be suitable for use in the application and location in which it is being installed. After the

device has been installed, a calibration is required. Refer to the Calibration section of this manual.

Wiring connections

Red wire: 8 to 32 VDC

Black wire: DC Common

Blue wire: 4 to 20 mA output

White wire: Smart Calibration Wire (data wire)

Earth Ground: Two (2) grounding screws on SEC 3000 housing.

Wire sizing:

0 to 500 feet, recommended wire gauge size 16 AWG

501 to 1000 feet, recommended wire gauge size 14 AWG

Doc#: 1460003, Rev A Operation Manual, SEC 3000 Electro-Chemical Gas Sensor Page 7of 13

Shielded cable is recommended. Wiring should be installed in medal conduit with no other cabling in the

same conduit.

Warm-up

When power is applied to the detector, it enters a one (1) minute warm-up mode. The output current will be

0.8 mA during the warm up time period. At the end of the warm-up period with no faults present, the

detector automatically enters the normal operating mode (4 mA). If a fault is present after warm-up, the

detector current output will indicate a fault. See the following chart for fault code status. Some

electrochemical sensors will take up to 24 hours to stabilize. Newly installed sensors should be calibrated

after they have been allowed to stabilize.

Normal

In the normal operating mode, the 4 to 20 mA signal levels correspond to the detected gas concentration.

The detector continuously checks for system faults or initiation of calibration and automatically changes to

the appropriate mode.

The 4 to 20 mA output of the SEC 3000 is a non-isolated current source.

Current Output and Corresponding Status

Once the fault is cleared the SEC 3000 will automatically resume normal operation.

Current Output Status.

0-20 mA Normal measuring mode

0.0 mA Unit Fault

0.8 mA Unit warm up

1.2 mA Zero drift fault

1.6 mA Calibration fault

2.0 mA Unit spanning

2.2 mA Unit zeroing

4-20 mA Normal measuring mode

4.0 mA Zero gas level

5.6 mA 10% Full Scale

8.0 mA 25% Full Scale

12 mA 50% Full Scale

16 mA 75% Full Scale

20 mA Full scale

>20 mA Over-range

Doc#: 1460003, Rev A Operation Manual, SEC 3000 Electro-Chemical Gas Sensor Page 8of 13

IV. CALIBRATION

The SEC 3000 is factory calibrated, zeroed and spanned with calibration gas. After the SEC 3000 is

installed under power for 24 hours it should be calibrated (zeroed and spanned) with calibration gas.

Calibration frequency is dependent on the application and installation requirements. Typical calibration of

the gas sensors should be done on a quarterly basis.

The SEC 3000 sensor board is factory programmed with the following parameters. The parameters can be

changed using the SEC 3000 PC Link software package. Refer the SEC 3000 PC Link Instruction Manual

for additional information.

Gas Type

Range

Calibration Gas

Calibration Date

Sensor Bias Voltage (Not Adjustable)

If the calibration gas concentration is known, the SEC 3000 sensor can be zeroed and spanned in the field.

The SEC 3000 can also be calibrated using the SEC 3000 PC Link software package. Refer the SEC 3000

PC Link Instruction Manual for additional information.

Hardwire Calibration Method (For declassified areas)

Before beginning calibration attach the SEC 3000 Calibration Adaptor (PN 1421468) to the SEC 3000

sensor housing. The zero and span gas flow should be regulated to 1.0 liter per minute (LPM).

Zeroing the SEC 3000

Apply clean air or zero air (nitrogen for oxygen sensor).

Connect calibration wire (white wire on SEC 3000) to negative (black wire of SEC 3000, common of the

power supply) for ten (10) seconds, upon release the sensor will automatically enter the zero calibration

routine. The electronics will automatically adjust the sensor’s signal to the new zero reference level. During

the zero calibration routine, the current output of the SEC 3000 will briefly go to 2.2 mA. Although this can

be accomplished manually, installation of a switch (contact closure) can accomplish the zeroing procedure.

It is recommended that this switch be a momentary type switch to prevent it from inadvertently being left in

the calibrate position. If after 20 seconds the calibration lead has not been removed from common, the SEC

3000 will ignore the signal and continue operation as normal.

Spanning the SEC 3000

Apply the correct span gas concentration to the sensor (20.9% volume of O2 for oxygen sensor).

Connect calibration wire (white wire on SEC 3000) to positive (red wire of SEC 3000, +24 VDC of the power

supply) for ten (10) seconds; upon release the sensor will automatically enter the span calibration routine.

The electronics will automatically adjust the sensor’s signal to the new span reference level. During the span

calibration routine, the current output of the SEC 3000 will briefly go to 2.0 mA. Although this can be

accomplished manually, installation of a switch (contact closure) can accomplish the spanning procedure. It

is recommended that this switch be a momentary type switch to prevent it from inadvertently being left in the

calibrate position. If after 20 seconds the calibration lead has not been removed from +24 VDC, the SEC

3000 will ignore the signal and continue operation as normal.

Doc#: 1460003, Rev A Operation Manual, SEC 3000 Electro-Chemical Gas Sensor Page 9of 13

V. MAINTENANCE

The SEC 3000 does not normally require routine maintenance other than calibration. The only consumable

item on the SEC 3000 is the sensing element. The toxic gas sensing element will typically last for 2 years of

operation.

VI. Parts List

Part Number Description

1420636 SEC 3000 PC Link software package

1091000 Sensor Separation Kit

1421468 Cal Adapter

1421467 Splash Guard

1421467 Sample Draw Adapter

Doc#: 1460003, Rev A Operation Manual, SEC 3000 Electro-Chemical Gas Sensor Page 10 of 13

Cross sensitivity data was developed by exposure of sensors to gas concentrations below 100 PPM. Sensors may show either

transient or continuous responses different from those listed above if exposed to very high concentrations of gas. The values

shown are the equivalent signal generated by the sensor when exposed to 1 PPM of the indicated gas. For instance, exposure

of a chlorine (oxidant) sensor to 1 PPM of nitrogen dioxide would produce a sensor signal equivalent to 0.2 PPM chlorine.

Negative numbers indicate gases that can cause low readings when present with the target gas

* Indicates a three electrode sensor that requires a minimum of 5% oxygen for proper operation.

** Data shown for the chlorine sensor refers to the sensor used for bromine, chlorine, chlorine dioxide, fluorine or ozone.

Oxygen sensors will respond to halogen gases at % levels but are unaffected by low PPM levels.

Oxygen sensor response will be affected by % levels of CO2 but unaffected by low PPM levels.

NH3

Cl2**

HF

HCl

HCN

H2S

SO2

CO

H2

O2

NO

NO2

Hydride

SiH4

COCl2

Form.

ETO

NH3

-

N

0.05

N

N

N

N

N

N

N

N

N

N

N

N

N

N

CO

0.05

N

N

0.005

N

0.002

N

-

0.1

N

N

0.001

N

N

N

0.5

0.5

H2

0.02

N

N

0.01

0.01

0.001

0.005

0.1

-

N

0.001

0.001

0.00002

0.001

N

0.05

0.05

NO

N

N

N

1.5

3

0.4

0.04

0.1

N

N

-

N

N

0.3

0.1

0.8

0.8

O2

*

N

N

*

*

*

*

*

*

-

*

*

*

*

N

N

N

Cl2**

-0.1

-

1

N

N

N

-0.1

N

N

(1)

N

0.5

N

N

0.1

N

N

HCl

N

N

0.5

-

N

N

N

N

N

N

N

-0.3

N

N

0.05

0.2

0.2

HCN

N

-0.08

-0.1

0.01

-

N

0.15

0.1

N

N

N

-0.07

N

N

0.5

0.1

0.1

HF

N

N

-

N

N

N

N

N

N

N

N

N

N

N

N

N

N

H2S

0.3

-0.1

-0.3

3

N

-

N

N

N

N

N

-2.5

N

N

N

2

2

NO2

N

0.2

0.2

0.2

0.5

0.1

-0.8

N

N

N

N

-

N

N

-1

0.1

0.1

SO2

N

-0.01

1

0.5

2.0

0.1

-

N

N

N

N

-1

N

N

0.2

0.4

0.4

Hydri

de

0.5

N

N

1.5

4.0

0.5

2

N

N

N

1

-2

-

1

N

2

2

SiH4

0.5

N

N

1.5

4.0

0.5

2

N

N

N

1

-2

1

-

N

2

2

CO2

N

N

N

N

N

N

N

N

N

(2)

N

N

N

N

N

N

N

CH4

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

CH3SH

N

-0.04

-0.1

1

N

0.3

N

N

N

N

N

-0.8

N

N

N

1

1

C2H2

0.03

N

N

N

0.04

-0.01

0.02

0.1

0.1

N

0.05

N

0.00005

0.005

N

1.2

1.2

C2H4

N

N

N

N

N

N

N

0.1

0.1

N

N

N

N

N

N

1

1

C2H6O

0.01

N

N

0.01

0.02

0.005

0.05

N

N

N

0.001

0.001

0.00001

0.01

N

2

2

Interferring Gas

Cross Sensitivity Table

Gas Sensor

Type

Doc#: 1460003, Rev A Operation Manual, SEC 3000 Electro-Chemical Gas Sensor Page 11 of 13

VII. Drawing Section

Figure # Title

Figure 1 Wiring Diagram, SEC 3000

Figure 2 SEC Sensor Separation Kit

Figure 1

Doc#: 1460003, Rev A Operation Manual, SEC 3000 Electro-Chemical Gas Sensor Page 12 of 13

Doc#: 1460003, Rev A Operation Manual, SEC 3000 Electro-Chemical Gas Sensor Page 13 of 13

Part Number Construction

Gas Type Range Units Wire/Cable Wire Length

30 XX XXXX X X XXX

Range Value (4 Places)

M: PPM

0: Wires

Inches Length

Or

S: Standard Length

(24”)

B: PPB

1: Cable

V: %Vol

L: %LEL

B2H6: 32

AsH3: 32

BCl3: 21

BF3: 23

Cl2: 11

ClF3: 23

CO: 16

DCS: 21

F2: 13

H2: 18

H2S: 24

HBr: 23

HCl: 21

HF: 23

NH3: 15

O2: 19

PH3: 32

SiH4: 33

SO2: 27

TiCl4: 21

WF6: 23

Example: 0-100PPM Carbon Monoxide with 36 inches of wire

P/N: 30160100M036

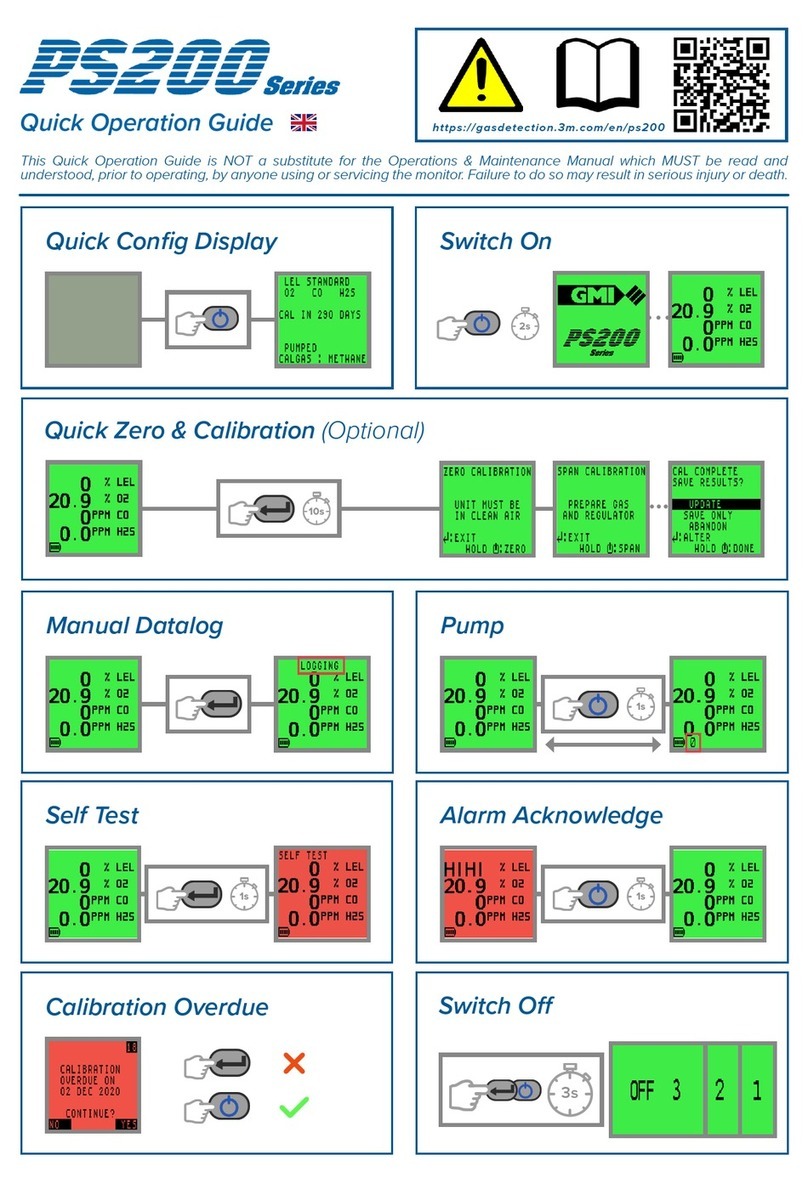

Operation

The SEC3100 provides interface capabilities for the SEC3000 Gas Detector and SEC Millenium

Infrared Gas Detectors.

The SEC3100 features:

• Back lit LCD for Gas Level/Unit Parameter display

• Four (4) configurable Alarm/Fault Relays

• An isolated RS485 Modbus interface provides reliable communication in noisy

environments and eliminates “Ground Loop” problems.

• Three push button switches for local configuration and calibration

• Time stamped Data logging using a removable non-volatile memory stick module. Module

can be removed from the unit to allow remote data downloading and data archiving.

Features • DIN rail mount

• Backlit LCD Display

• Low Cost

• Plug and play toxic, oxygen and combustible gas sensors

• Self-check system

• 4-20 mA output

• RS-485 Interface (Isolated)

• Optional alarm and fault relays

• Push button programming

• Non-intrusive calibration

• Removable, non-volatile, time stamped data logging

• Digital communication link to SEC 3000 and SEC Millenium Gas Detectors

SEC 3100 DIN

Digital Gas Transmitter

© 02/15

Applications • Petrochemical Refineries • LNG & LPG Facilities

• Compost Facilities • Sewage Industry

• Semi-Conductor Industry • Water Treatment Plants

• Mining • Parking Garages

• Pulp and Paper Mills • Chemical Industry

• Oil Rig Platforms • Nuclear Industry

• Buildings • Fertilizer Industry

• Automotive Industry • Tunnels

• Engine Test Rooms • Medical Facilities

SEC 3100 DIN Digital Gas Transmitter

SPECIFICATIONS

Detection Method Power Consumption (SEC3100 & Sensor)

Toxic Gases – Electrochemical Toxic Gases and Oxygen (SEC 3000) – 4W Max

Combustible - Infrared Combustible and CO2 (SEC Millenium) – 9W Max

Gas Sensor Compatibility Temperature Rating

SEC 3000 & SEC Millenium -40°C to +70°C

Output (digital) Humidity

RS-485 LAN (Isolated) 0-99% RH (Non-condensing)

Output (analog) Housing Construction

4-20 mA (source type), max. 1000 ohm load ABS Plastic

at 24 VDC supply voltage

Certification

Output (optional relays) CSA/NRTL Pending

(3) Alarm and (1) Fault

Housing Dimensions

Display 3.54 (W) x 4.17 (L) x 2.28 (H) inches

Back Lit LCD 90 (W) x 106 (L) x 58 (H) mm

LEDs for alarm/status indication

Weight

Operating Voltage Approximately 1 lb. {0.9 Kg.}

18-32 VDC

Operating Current (No Sensor)

125mA Max @ 24VDC

Partial Gas List

Oxygen (O2) Carbon Monoxide (CO)

Hydrogen (H2) Germane (GeH4)

Ammonia (NH3) Silane (SiH4)

Nitric Oxide (NO) Phosphine (PH3)

Bromine (Br2) Sulfur Dioxide (SO2)

Fluorine (F2) Nitrogen Dioxide (NO2)

Arsine (AsH3) Chlorine Dioxide (ClO2)

Ozone (O3) Hydrogen Sulfide (H2S)

Chlorine (Cl2) Hydrogen Fluoride (HF)

Phosgene (COCl2) Hydrogen Chloride (HCl)

Diborane (B2H6) Hydrogen Cyanide (HCN)

Formaldehyde (HCHO) Hydrogen Selenide (H2Se)

Ethylene Oxide (ETO) Hydrogen Peroxide (H2O2)

Combustible (HC) Carbon Dioxide (CO2)

Methyl Mercaptan (CH4S) Ethyl Mercaptan (C2H6S)

Current Output Status

0.0 mA Unit Fault

0.8 mA Unit warm up

1.2 mA Zero drift fault

1.6 mA Calibration fault

2.0 mA Unit spanning

2.2 mA Unit zeroing

4-20 mA Normal measuring mode

4.0 mA Zero gas level

5.6 mA 10% Full Scale

8.0 mA 25% Full Scale

12 mA 50% Full Scale

16 mA 75% Full Scale

20 mA Full scale

>20 mA Over-range

TB1 (J1) TB2 (J2)

TB5 (J5) TB6 (J6)

Sensor Electronics Corporation

12730 Creek View Avenue, Savage, MN 55378 U.S.A. • (800) 285-3651 • (952) 938-9486 • FAX: (952) 938-9617

Applications • Petrochemical Refineries • LNG & LPG Facilities

• Compost Facilities • Sewage Industry

• Semi-Conductor Industry • Water Treatment Plants

• Mining • Parking Garages

• Pulp and Paper Mills • Chemical Industry

• Oil Rig Platforms • Nuclear Industry

• Buildings • Fertilizer Industry

• Automotive Industry • Tunnels

• Engine Test Rooms • Medical Facilities

Operation / Description

The SEC 3100 provides interface capabilities for the SEC 3000 Gas Detector and SEC Millenium

Infrared Gas Detectors.

The SEC 3100 features:

• Back lighted LCD for Gas Level/Unit Parameter display

• Four (4) configurable Alarm/Fault Relays

• An isolated RS485 Modbus interface provides reliable communication in noisy environments and

eliminates “Ground Loop” problems.

• Three magnetic switches for local configuration and calibration

• Time stamped data logging using a removable non-volatile memory module. Module can be

removed from the unit to allow remote data downloading and data archiving.

An optional IS barrier allows “hot” sensor replacement in rated locations. This allows the user to install

pre-calibrated/pre-configured sensor boards without removing unit power while maintaining EX rating.

Removable circuit board stack and detachable connectors facilitate field-wiring installation.

Features • Explosion Proof

• Back lighted LCD Display

• Low Cost

• Plug and play toxic, oxygen and combustible gas sensors

• Self-Check system

• 4-20 mA output

• RS-485 Interface (Isolated)

• Alarm and fault relays

• Non-intrusive configuration

• Non-intrusive calibration

• Removable, non-volatile, time stamped data logging memory stick

• Optional IS barrier

• Digital communication link to SEC 3000 and SEC Millenium Gas Detectors

• Multi port housing for easy installation

SEC 3100

Digital Gas Transmitter

© REV 3, 2/15

SHOWN WITH SEC MILLENIUM SENSOR

LIT PART NUMBER: 3100DATASHEET © REV 3, 2/15

SEC 3100

Digital Gas Transmitter

SPECIFICATIONS

Detection Method Power Consumption SEC 3100 (Sensor)

Toxic Gases - Electrochemical Toxic & O2 (SEC 3000) - 4W Max

Combustible - Infrared HC & CO2 (SEC Millenium) - 9W Max

Gas Sensor Compatibility Temperature Rating

SEC 3000 & SEC Millenium -40˚C to +70˚C

Output (digital) Humidity

RS-485 LAN (Isolated) 0-99% RH (Non-condensing)

Output (optional relays) Housing Construction

4-20 mA (source type), max. 1000 ohm load Epoxy coated aluminum

at 24 VDC supply voltage Certification

Display CSA/NRTL: Cl I, Div 1, Groups B,C,D T5

Back Lighted LCD IECEx: Ex d IIB + H2 T5 Gb

LEDs for relay status Housing Dimensions

Operating Voltage 5.25 (W) x 5.30 (L) x 4.95 (H) inches

18-32 VDC {131 (W) x 132 (L) x 124 (H) mm}

Operating Current (No Sensor) Weight

125mA Max @ 24 VDC Approximately 6 lbs. {2.8 Kg.}

Sensor Electronics Corporation

12730 Creek View Avenue, Savage, MN 55378 U.S.A. • (800) 285-3651 • (952) 938-9486 • FAX: (952) 938-9617

www.sensorelectronic.com • [email protected]

Partial Gas List

Oxygen (O2) Carbon Monoxide (CO)

Hydrogen (H2) Germane (GeH4)

Ammonia (NH3) Silane (SiH4)

Nitric Oxide (NO) Phosphine (PH3)

Bromine (Br2) Sulfur Dioxide (SO2)

Fluorine (F2) Nitrogen Dioxide (NO2)

Arsine (AsH3) Chlorine Dioxide (ClO2)

Ozone (O3) Hydrogen Sulfide (H2S)

Chlorine (Cl2) Hydrogen Fluoride (HF)

Phosgene (COCl2) Hydrogen Chloride (HCl)

Diborane (B2H6) Hydrogen Cyanide (HCN)

Formaldehyde (HCHO) Hydrogen Selenide (H2Se)

Ethylene Oxide (ETO) Hydrogen Peroxide (H2O2)

Combustible (HC) Carbon Dioxide (CO2)

Current Output Status

0.0 mA Unit Fault

0.8 mA Unit warm up

1.2 mA Zero drift fault

1.6 mA Calibration fault

2.0 mA Unit spanning

2.2 mA Unit zeroing

4-20 mA Normal measuring mode

4.0 mA Zero gas level

5.6 mA 10% Full Scale

8.0 mA 25% Full Scale

12 mA 50% Full Scale

16 mA 75% Full Scale

20 mA Full scale

>20 mA Over-range

SEC 3100 shown with SEC 3000 Sensor

ISOLATED RS-485

MODBUS

ONE-PERSON

CALIBRATION

EXPLOSION-PROOF

INTRINSICALLY SAFE

SENSOR

REMOTE-MOUNT

2000+ FEET

DATA LOGGING

MEMORY CARD

RELAYS

4-20 mA OUTPUTS

INTERCHANGABLE

TOXIC GAS SENSOR

STAND-ALONE

GAS DETECTOR

This manual suits for next models

12

Table of contents

Other Sensor Electronics Gas Detector manuals