Contents

Chapter 1 | General Information ..............................................5

User Manual...............................................................................................5

Symbols used.............................................................................................5

Safety instructions......................................................................................6

Important information.................................................................................6

Liability limits..............................................................................................7

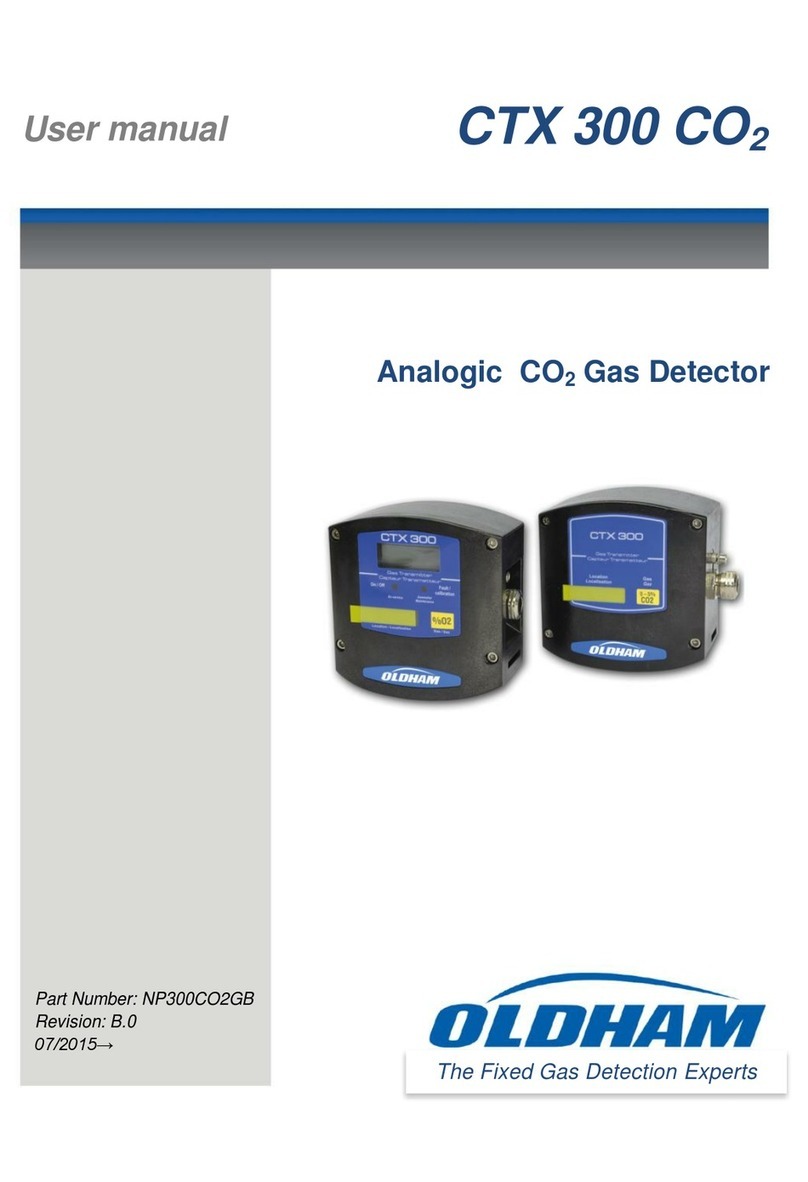

Chapter 2 | Introduction ...........................................................9

General Information ...................................................................................9

Composition .............................................................................................10

Chapter 3 | Installation and connection................................11

Installing the detectors .............................................................................11

Electrical connections ..............................................................................13

Chapter 4 | Powering up and use ..........................................19

Powering up .............................................................................................19

4-20 mA analog output.............................................................................20

Chapter 5 | Maintenance ........................................................21

Calibration................................................................................................21

Replacing a sensor ..................................................................................29

Disposal....................................................................................................29

Chapter 6 | Spare parts ..........................................................31

CTX/COX 300 toxic or oxygen sensors ...................................................31

CSC 300 semiconductor sensors.............................................................35

Chapter 7 | Certification .........................................................37

Chapter 8 Technical specifications.......................................41