Sensor SMT-200 User manual

Io SENSOR

SMT-200 Operations and Technical Manual 2.00/R1

SENSOR Nederland b.v.

SMT-200 v2.00

Operations and Technical

Manual

Io SENSOR

SMT-200 Operations and Technical Manual 2.00/R1

Page intentionally left blank

Io SENSOR Warranty

SMT-200 Operations and Technical Manual 2.00/R1 i

CERTIFICATION

SENSOR Nederland b.v. - INPUT/OUTPUT INC. certifies that this instrument meets it's published

specifications at the time of shipment from the factory.

WARRANTY AND ASSISTANCE

This INPUT/OUTPUT INC. product is warranted against defects in materials and workmanship for a period of

SIX months from the date of shipment. INPUT/OUTPUT INC. will, at it's option, repair or replace a product

which proved to be defective during the warranty period, provided it is returned to an INPUT/OUTPUT INC.

office and providing the proper preventative maintenance procedures as listed in this manual are followed.

Repairs necessitated by misuse of the product are not covered by this warranty.

NO OTHER WARRANTIES ARE EXPRESSED OR IMPLIED INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. IN

NO EVENT SHALL INPUT/OUTPUT INC. BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES RESULTING FROM THE USE OF THE PRODUCT OR CAUSED BY ANY DEFECT, FAILURE,

OR MALFUNCTION OF THE PRODUCT, WHETHER A CLAIM FOR SUCH DAMAGE IS BASED UPON

WARRANTY, CONTRACT, NEGLIGENCE OR OTHERWISE.

Software License Io SENSOR

ii SMT-200 Operations and Technical Manual 2.00/R1

SOFTWARE LICENSE

ATTENTION: USE OF THE SOFTWARE IS SUBJECT TO THE I/O SOFTWARE LICENSE TERMS SET

FORTH IN THE INPUT/OUTPUT MASTER SOFTWARE LICENSE AGREEMENT. USING THE

SOFTWARE INDICATES YOUR ACCEPTANCE OF THESE TERMS. IF YOU DO NOT ACCEPT THESE

TERMS, YOU MAY RETURN THE SOFTWARE FOR A FULL REFUND. IF THE SOFTWARE IS

SUPPLIED WITH ANOTHER PRODUCT, YOU MAY RETURN THE ENTIRE UNUSED PRODUCT FOR A

FULL REFUND. YOUR RIGHT TO RETURN AND REFUND EXPIRES 30 DAYS AFTER PURCHASE

FROM I/O OR AN I/O DISTRIBUTOR. THE RIGHT TO RETURN AND REFUND DOES NOT EXTEND TO

YOUR TRANSFEREE.

The following terms govern your use of the enclosed software unless you have a separate Input/Output

master software license agreement in place.

LICENSE Grant- I/O grants you a license to use one copy of the version of the software (identified in your

documentation) on any one hardware product. “You” means the company, entity or individual whose funds

are used to pay the license fee. “Use" means storing. loading, installing, executing or displaying the

software. You may not modify the software or disable any licensing or control features of the software

except as an intended part of the software's programming features

Ownership- The software is owned and copyrighted by I/O. Your license confers no title or ownership in the

software and should not be construed as a sale of any right in the software. I/O's third party suppliers may

protect their rights in the event of any violation of these terms.

Copies and Adaptations- You may only make copies or adaptations of the software for archival purposes

or when copying or adaptation is an essential step in the authorised use of the software. You must

reproduce all copyright notices in the original software on all authorised copies or adaptations. You may not

copy the Software onto any bulletin board or similar system.

No Disassembly or Decryption- You may not disassemble, decompile or decrypt the software unless I/O's

prior written consent is obtained. In some jurisdictions, I/O's consent may not be required for disassembly or

decompilation. Upon request, you will provide I/O with reasonable detailed information regarding any

disassembly or decompilation.

Transfer- Your license will automatically terminate upon any transfer of the software. Upon transfer, you

must deliver the original and all complete, partial or electronically stored copies of the software and related

documentation to the transferee. The transferee must accept these terms as a condition to the transfer.

Termination- I/O may terminate your license upon notice for failure to comply with any of these terms.

Upon termination, you must immediately destroy the software together with all copies, adaptations and

merged portions in any form.

Export Requirements-You may not export or re-export the software or any copy or adaptation in violation

of any applicable laws or regulations.

Io SENSOR Compliance

SMT-200 Operations and Technical Manual 2.00/R1 iii

Year 2000 Compliance

covering electronic equipment and software produced by

IOSENSOR

SMT-100

Transfer Program

Reader Program

The hardware and software used in the ‘SMT-100 Geophone Tester’ and

‘SMT-100 Fieldbox’ (model I and II) does not utilise a real-time clock and is

therefore immune from problems associated with the year 2000 issue. The

date (that can be manually set in the header of the printout) will accept the

year 2000 and higher. Also the associated ‘SMT-100 Module Reader’ and

RS232 data transfer ‘SMT-100 Xfer’ programs (both version 1.84 and higher)

will accept dates beyond 31 December 1999.

See Note

SMT-150

The SMT-150 hardware and associated ‘SMT-150 Geophone Tester’

program (version 1.84 and higher) will accept dates beyond 31 December

1999.

See Note

SMT-200

(Docking Station)

The SMT-200 hardware and software (version 1.89 and higher) and

associated ‘SMT-200DS Docking Station’ program (version 1.89 and

higher) are year 2000 compliant. Please note that during data transfer from or

to the PC and during updates of the SMT-200 program, the time and date of

the SMT-200 is synchronised with the time and date of the host PC.

* To prevent possible date conflicts it is strongly recommended to attach the

SMT-200 only to PC’s that are year 2000 compliant.

* To prevent possible update problems never update the SMT-200 software

from a PC that is not year 2000 compliant.

Note

The hardware and software has been tested on PC’s that are year 2000

compliant. Other than date and time stamp errors on files saved to PC’s that

are not year 2000 compliant, there are no other problems expected when

connected to PCs that are not year 2000 compliant.

IOSENSOR can not be held responsible for the malfunction of the

above programs or loss of data when used on PC’s that are not year 2000

compliant.

Please contact one of our sales offices in case you encounter any problem.

IOSENSOR has adopted the BSI-DISC definition of ‘Year 2000 Conformity’:

“Neither performance nor functionality is affected by dates prior to, during and after the year 2000”

Table of contents Io SENSOR

vi SMT-200 Operations and Technical Manual 2.00/R1

Table of Contents

Page

SECTION 1 INTRODUCTION 1

1.1 Introduction 3

1.2 Technical Support 3

1.3 Overview 4

1.4 Specifications 4

1.5 Packaging information 5

1.6 Before use... 6

1.6.1

Voltage selection 6

1.6.2

Battery charging 6

SECTION 2 SMT-200 OPERATIONS 7

2.1 SMT-200 Layout 9

2.2 Switching on the SMT-200 9

2.2.1

Post Mortem on Powering up 10

2.3 Navigating around the screens 10

2.4 Switching off the SMT-200 13

2.5 Battery level 14

2.6 Battery level Jumper setting 15

2.7 Menu flowchart 16

2.8 Main menu The main menu allows access to all functions of the SMT-200 19

2.9.1

Do a test Select this option to initiate a test sequence on a string 19

2.10.2 Setup menu Allows customisation of the SMT-200 operating and test parameters 20

2.11.2.1 String menu Set the string geometry and leader parameters 20

2.12.2.1.9 Limits menu Sets maximum allowable limits for various tests 21

2.13.2.2 Geophone menu Selects and modifies if required the type of geophone element used 21

2.14.2.2.1 Select menu Selects the type of geophone element used 22

2.15.2.2.2 Edit Edit the geophone parameters 22

2.16.2.2.3 Copy Copy existing element description to a new geophone type 22

2.16.2.2.4 Delete Deletes an existing element description 22

2.17.2.3 Operating menu General options for string testing 23

2.18.2.4 Tests Sequence Selects the tests to be performed on the string 24

2.19.2.5 Display menu Customises display, keypad and sound options 24

2.20.2.7 Power menu Selects the various power saving options 25

2.21.2.8 Date & Time Sets the SMT-200 clock 25

2.22.2.9 Diagnostics Runs the diagnostics and calibration routines 26

2.23.3 Temp. menu Read or set the external temperature and temperature options 28

2.24.4 File menu Internal file handling and data / code transfer options 30

2.25.4.1 Redisplay Last Shows the result of the last test run 30

2.26.4.2 Storage Status Indicates the internal memory storage 31

2.27.4.3 Dump data file Transfer contents of data file to COM port 31

2.28.4.4 List data file List contents of data file 32

2.29.4.5 Erase data Clears contents of data file 32

2.30.4.6 Read Config Loads the stored configuration file 33

2.31.4.7 Save Config Saves the configuration file 33

2.32.6 About Provides general information about the SMT-200 34

Io SENSOR Table of contents

SMT-200 Operations and Technical Manual 2.00/R1 vii

SECTION 3 DOCKING STATION & PC SOFTWARE OPERATIONS 35

3.1 Docking Station overview 37

3.2 Docking Station interconnection 37

3.2.1

Battery Charging 38

3.2.2

PC Interface 38

3.3 Docking Station PC software introduction 39

3.4 Software installation 39

3.5 Windows installation 39

3.5.1

Windows un-install 40

3.6 DOS installation 40

3.6.1

DOS un-install 40

3.7 Running the program 41

3.7.1

SMT-200DS menu 42

3.7.2

File menu 42

3.7.3

SMT-200 menu 42

3.8 Data Exchange 43

3.8.1

Instructions for File Transfer 43

3.8.2

Explanation of Data transfer sequence: 43

3.8.3

The SMT-200 During File Transfer 44

3.8.4

Failing Transfers 44

3.9 System Update 45

3.9.1

Instructions for System Update 45

3.9.2

Failing System Updates 45

3.10

The SMT-200 Geophone Specifications File 45

SECTION 4 RFID TAG READER 47

4.1 RFID Tag reader introduction 49

4.2 Principles of the RFID Tag reader 49

4.3 Working with the RFID Tag reader 50

4.3.1

Read tags 50

4.3.2

Test the strings 51

4.3.3

Transfer data file 52

4.4 Sorting the tag list 53

4.4.1

Download the tag list to the PC 53

4.4.2

Upload the tag list to the SMT-200 53

4.4.3

View the tag list on the SMT-200 55

4.4.4

View the tag list on the PC 55

4.5 Settings 57

4.5.1

COM settings 57

4.5.2

Autonumber 57

4.5.3

Tag menu visible 57

4.6 Internal storage 58

SECTION 5 GEOPHONE TESTING 59

5.1 Preparing the SMT-200 for use 61

5.2 Testing a string 63

5.3 Downloading data to a PC 64

5.3.1

Data File Test codes 65

5.3.2

Data File Reject codes 65

5.4 Basic Geophone Troubleshooting using the continuous impedance test 66

5.5 Isolation Table 69

Table of contents Io SENSOR

vi SMT-200 Operations and Technical Manual 2.00/R1

SECTION 6 SMT-200 TECHNICAL 71

6.1 SMT-200 Description 73

6.2 PC/104 Description 73

6.3 PC/104 Connector and Jumper Locations 74

6.4 SMT-200 Main Board block diagram 75

6.5 Power Supply 76

6.6 Address Decoder 76

6.7 Display 76

6.8 Keyboard 77

6.9 Digital to Analogue Converter 77

6.10

Filter 78

6.11

Geophone Circuit 78

6.12

Analogue to Digital Converter 78

6.13

SMT-200 Interconnection 79

SECTION 7 DOCKING STATION TECHNICAL 81

7.1 Docking Station Block Diagram 83

7.2 PC Interface 84

7.3 Battery Charging 84

APPENDIX A CONNECTOR PIN OUTS 87

A.1 SMT-200 Bendix Connector 89

A.2 Docking Station SMT-200 Connector 89

A.3 Docking Station External Smartec Connector 90

A.4 Docking Station PC Connector 90

A.5 Smartec Temperature Sensor 91

A.6 SMT-200 to Docking Station Cable 92

APPENDIX B TEST OVERVIEW 93

B.1 Geophone Basics 95

B.2 Polarity Test 95

B.3 Noise Test 96

B.4 Leakage Test 96

B.5 Resistance Test 97

B.6 Pulse Test 97

B.7 Distortion Test 99

B.8 Distortion test drive mode 100

B.9 Continuous Impedance 100

B.10

Low Drive Continuous Impedance 100

B.11

Geophone String Resistance Calculation 101

B.11.1 Series String 101

B.11.2 Series Parallel String 101

B.12

Damping Calculations 102

B.13

Temperature Compensation 102

APPENDIX C PARTS LIST 103

C.1 SMT-200 Geophone Tester 105

Io SENSOR Table of contents

SMT-200 Operations and Technical Manual 2.00/R1 vii

C.2 SMT-200 Battery Pack 109

C.3 SMT-200 Docking Station 110

C.4 SMT-200 Accessories and Cables 112

APPENDIX D SCHEMATICS & LAYOUTS 113

D.1

SMT-200 Schematics 115

D.1.1 SMT-200 Geophone Tester 115

D.1.2 SMT-200 ADC 116

D.1.3 SMT-200 Filter 117

D.1.4 SMT-200 Keyboard 118

D.1.5 SMT-200 DAC 119

D.1.6 SMT-200 Geophone Circuit 120

D.1.7 SMT-200 Power 121

D.1.8 SMT-200 Display 122

D.2 SMT-200 Component Layout (SMT-200.7 01/98) 123

D.3 SMT-200 Docking Station Schematics 124

D.3.1 SMT-200 Docking Station / Charger 124

D.3.2 UC3906-B1 125

D.3.3 UC3906-B2 126

D.4

SMT-200 Component Layout (SMT-200.7 CHARGER 01/98) 127

APPENDIX E QUICK REFERENCE 129

E.1

Quick Reference 131

APPENDIX F ADDENDUM 135

F.1

Addendum 137

INDEX 139

Table of terms Io SENSOR

viii SMT-200 Operations and Technical Manual 2.00/R1

Table of terms

Symbol Denotation

% Percent

Ω

ΩΩ

ΩOhm

ºC Degrees Centigrade

ºF Degrees Fahrenheit

Bo Open circuit damping

Bc Coil damping

Bt Total damping

FFT Fast Fourier Transfer

Fn Natural frequency

Go Open circuit sensitivity

Hz Hertz

Kg. Kilogram

Lbs. Pounds

M Suspended mass

mm Millimeters

m Meters

MB Mega byte

Rc Coil resistance

Rs Shunt resistance

Rt Total geophone resistance

V Volts

v Software version

V/in/s Volts per inch per second

V/m/s Volts per meter per second

VAC Volts alternating current

Io SENSOR Section 1 Introduction

SMT-200 Operations and Technical Manual 2.00/R1 1

Section 1

Introduction

Section 1 Introduction Io SENSOR

2SMT-200 Operations and Technical Manual 2.00/R1

Page intentionally left blank

Io SENSOR Section 1 Introduction

SMT-200 Operations and Technical Manual 2.00/R1 3

1.1 Introduction

These instructions are intended as a guideline for the operation of the SMT-200 Geophone Tester. Should

problems be found that cannot be answered by these notes please call your nearest I/O Sensor Technical

Support location for assistance.

The availability of future software upgrades will be made known to SMT-200 users via the i-o web site.

Your comments regarding the convenience of operation of the unit, its performance, any problems you have

experienced and any features that would be useful or are in your opinion essential, would be greatly

appreciated for the future development of this product.

The software provided with this tester is proprietary and may not be copied without prior consent having

been obtained from Sensor Nederland b.v.

1.2 Technical Support

Further information and assistance can be obtained by calling one of the following I/O SENSOR Technical

Support locations:

EUROPE

Sensor Nederland bv.

Rouwkooplaan 8

2251 AP Voorschoten

Holland

Tel. +31 (0)71 5601234

Fax. +31 (0)71 5617145

Contact and e-mail address:

Kees Faber (kfaber@i-o.com)

USA & CANADA

Input/Output

11104 West Airport

Stafford

Texas 77477 USA

Tel. +1 281 879 2130

Fax. +1 281 879 3500

Contact and e-mail address

Scott Williams (swilliam@i-o.com)

See our web site at www.i-o.com for SMT-200 updates, geophone specifications and information on other

I/O products.

Section 1 Introduction Io SENSOR

4SMT-200 Operations and Technical Manual 2.00/R1

1.3 Overview

The SMT-200 is the latest addition to the Sensor range of geophone testing equipment. Due to the

advanced technology used in the design it has all the features of previous generation testing

equipment in a smaller and more compact unit. Its easy to use menu system allows the SMT-200 to be

quickly configured to test virtually any type of geophone string. Internal automatic calibration

eliminates the need for regular maintenance.

The Docking station is provided to manage battery charging and communication between the

SMT-200 and the PC.

The SMT-200 can be operated from lead-acid gel batteries (2 supplied) or connected to the docking

station for file transfer. The battery pack will supply enough power for 4 hours heavy field use.

1.4 Specifications

Natural Frequency

Range 1 to 100Hz

Accuracy < 8Hz ± 2% of measured value or 0.1Hz whichever is the greater

8Hz - 14Hz ± 0.5% of measured value or 0.05Hz whichever is the greater

>14Hz ± 1% of measured value

Display Resolution 0.01Hz

Coil Resistance

Range 20 to 9999 ohm

Accuracy ± 1% or 1 ohm whichever is the greater

Display Resolution 1 ohm or 0.1 ohm when measured value is less than 100 ohm

Damping

Range 0.100 to 0.850

Accuracy ± 1% of measured value

Display Resolution 0.001

Sensitivity

Range 0 to 999 V/m/s

Accuracy ± 2% Calculated from other measured values

Display Resolution 0.1 V/m/s

Harmonic Distortion

Range 0 to 20 %

Accuracy ± 10% of measured value or 0.01% whichever is greater

Display Resolution 0.01%

Dynamic Resistance

Range 20 to 99999 ohm

Accuracy Not specified

Io SENSOR Section 1 Introduction

SMT-200 Operations and Technical Manual 2.00/R1 5

Leakage Test

Range 1M to 100M ohm (measured at 5V max)

Accuracy ± 5% of measured value (after calibration)

Test Storage

Capacity 2 MB FLASH disk typically storing 16000 records

Actual figure will depend on tests selected and tags stored

Physical Characteristics

Dimensions (Approx.) 270 x 110 x 60 mm (10.63 x 4.33 x 2.36 inches)

Weight (Approx.) 1.5 kg (3.30 lbs.)

Environmental Specifications

Operating temperature range -20 to 60 °C ( -4 to 140 °F)

Storage temperature range -40 to 70 ° C (-40 to 158 °F)

NOTE: All capabilities are measured at 20 °C.

1.5 Packaging information

Before getting started please check the package is complete with the following items:

• Transport case

• SMT-200 including carry strap

• Two Battery packs

• Docking Station

• Reference geophone SM4/U-B 10Hz 375 ohm

• Geophone cable Bendix to unterminated incl. temp sensor in Bendix connector

• Cable SMT-200 to Docking Station, Bendix-C24

• Serial cable D9 to D9

• Serial adaptor D9 - D25

• Mains cable (Euro / US / or UK)

• Leakage probe

• Temperature probe

• Spare fuse 500 mA 250V

• Software diskette SMT-200 v2.00 & Docking station programs

• Operations and Technical Manual (this Manual)

• Certificate of calibration

Section 1 Introduction Io SENSOR

6SMT-200 Operations and Technical Manual 2.00/R1

1.6 Before use...

1.6.1 Voltage selection

The docking station requires connection to a suitable power source. THE SELECTION OF 115 V OR

230 V MUST BE DONE MANUALLY.Moving a red switch on the rear of the docking station to the

appropriate position does this (Docking Station is always shipped with 230 V selected). The docking

station is designed to work between 50 Hz to 60 Hz AC so no switching for this is necessary.

Voltage Selector Switch 110 / 230 V

1.6.2 Battery charging

The battery supplied is a maintenance free 1.2 AH Lead Acid Gel Cell. This type of battery can be

used in any position and features a low ‘self discharge’ which means it can be left unused for some

time without requiring recharging. Due to the sealed nature of the battery it should only be recharged

on the supplied docking station. The battery could be destroyed if it is recharged with the incorrect

type of charging unit. To ensure maximum performance from the battery the following guidelines

should always be followed:

• Do not leave the battery discharged for extended periods

• Never short circuit the terminals

• If possible avoid charging battery pack at extreme ambient temperatures

Remove battery pack from the SMT-200 and store safely if the SMT-200 is not to be used for an

extended period of time

Io SENSOR Section 2 SMT-200 Operations

SMT-200 Operations and Technical Manual 2.00/R1 7

Section 2

SMT-200 Operations

Section 2 SMT-200 Operations Io SENSOR

8SMT-200 Operations and Technical Manual 2.00/R1

Page intentionally left blank

Io SENSOR Section 2 SMT-200 Operations

SMT-200 Operations and Technical Manual 2.00/R1 9

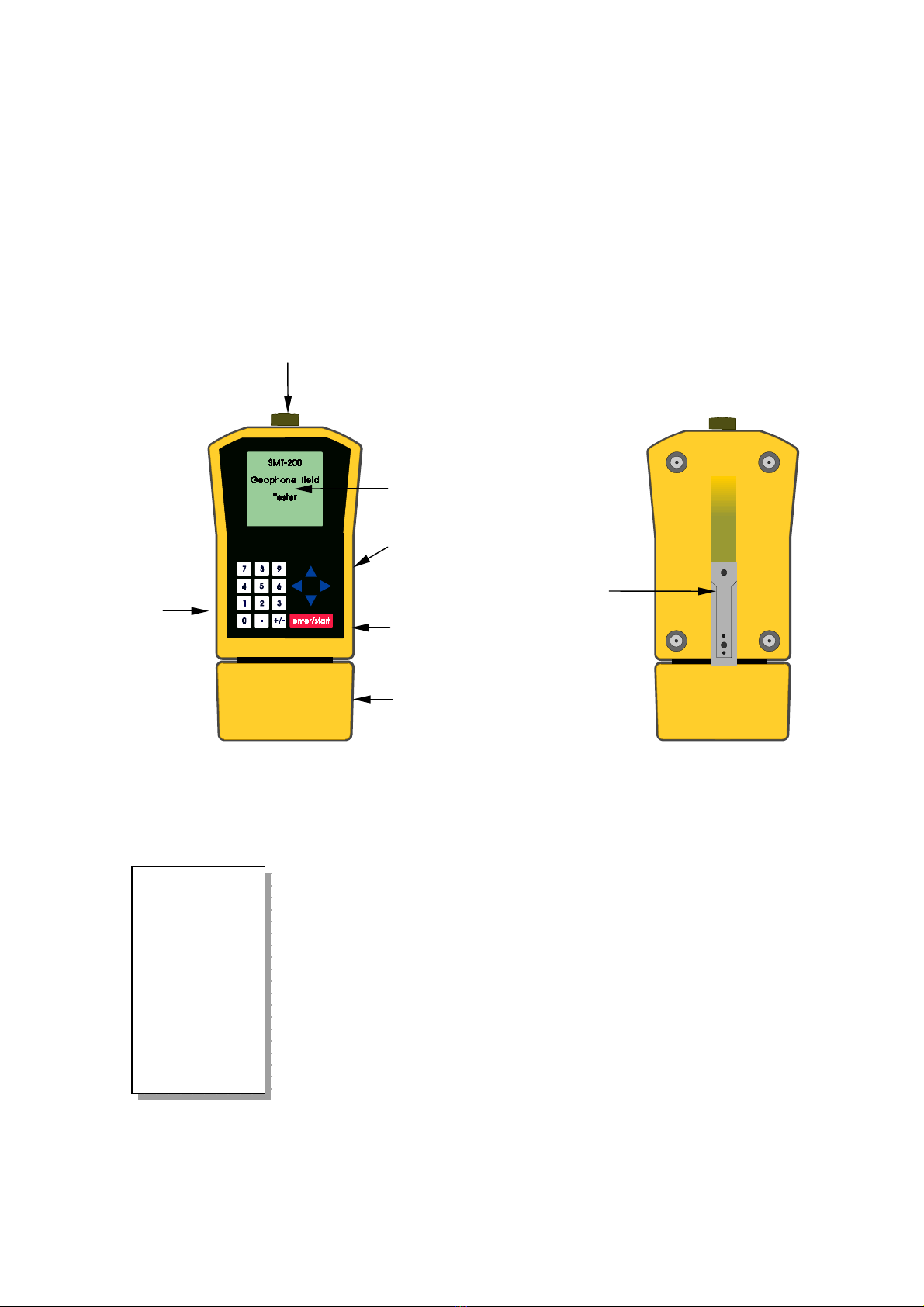

2.1 SMT-200 Layout

The SMT-200 consists of two parts, the main case and a removable battery pack. The battery pack

must be connected for mobile operation. Operation is still possible when connected to the supplied

docking station, in which case the battery does not need to be connected. If the battery pack is

attached to the main body the docking station will be monitoring the battery and will be automatically

charging the battery as required.

2.2 Switching on the SMT-200

To power up the SMT-200 simply push the ENTER/START key once. The unit

will beep to acknowledge the power up request. The start up screen will be

displayed while the system is going through a set of Power On Self Tests

(POST). This is a functional test of the CPU and its associated hardware.

After approximately 20 seconds the unit will beep once and the main menu

will appear after a further 20 seconds. The unit is now ready for operation. If

this is the first time the unit has been used it will need to be setup for the

particular strings to be tested. All settings are stored in non-volatile memory

and are retained even when the power is off.

SENSOR

SMT-200

GEOPHONE TESTER

Booting...

SENSOR

Nederland b.v.

SMT-200 Front View SMT-200 Rear View

Connector for Geophone string,

Docking Station or Tag reader

Backlit LCD Display

Cusor Keys

Power on &

Start/Enter Key

Battery Pack

Numeric

Keypad

Battery

Lever

Section 2 SMT-200 Operations Io SENSOR

10 SMT-200 Operations and Technical Manual 2.00/R1

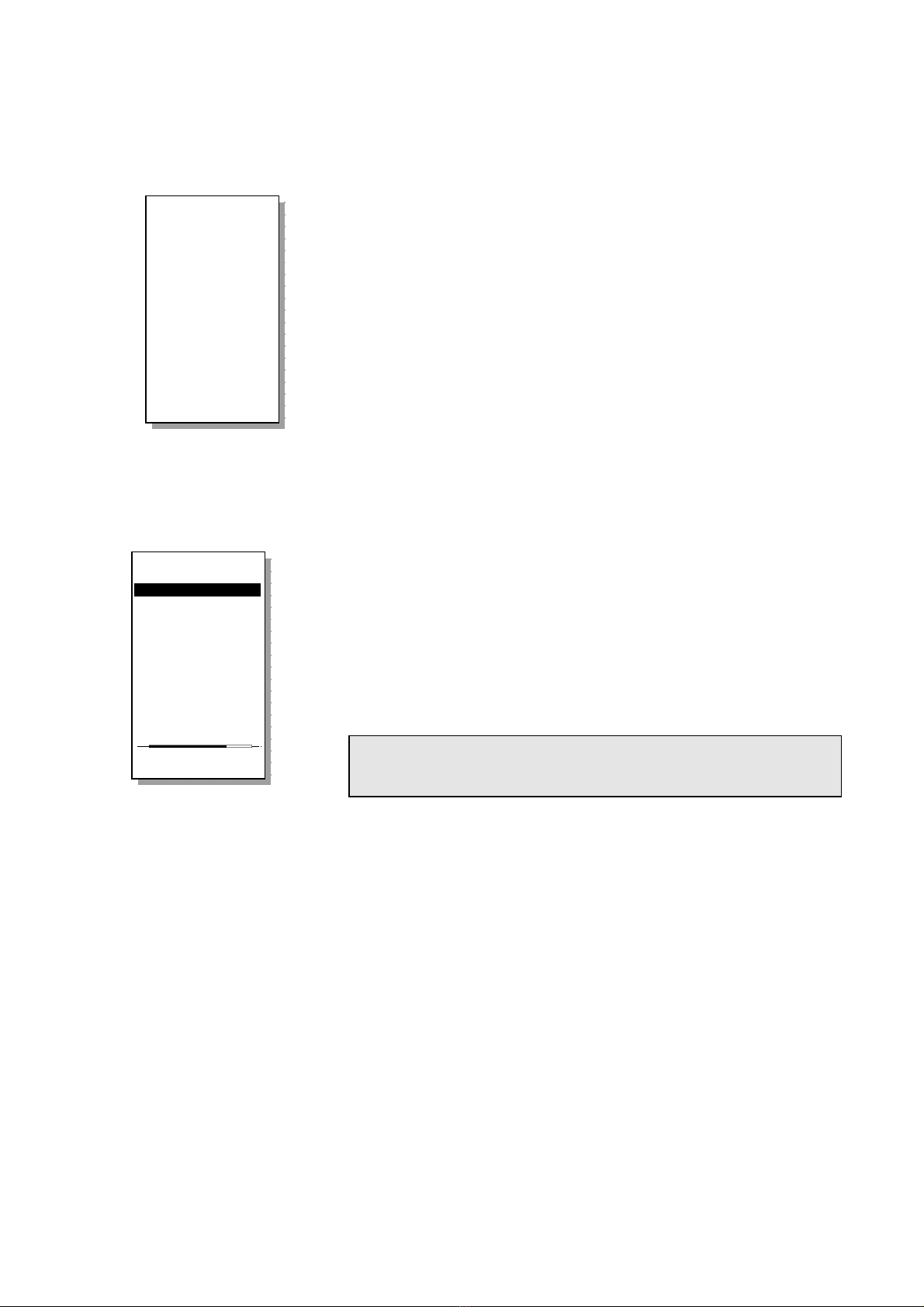

2.2.1 Post Mortem on Powering up

If the SMT-200 was last shutdown with one of the following errors, a

post mortem screen is displayed on the next power up sequence

to alert the operator.

Temperature High SMT-200 detected an internal temperature

greater than 80°C

Temperature Low SMT-200 detected an internal temperature

lower than -40°C

Battery Low SMT-200 detected a battery voltage less

than 10.7 V

Shut Down Error Abnormal shut down (e.g. battery removed)

2.3 Navigating around the screens

The SMT-200 operates on a simple menu system. There are two ways to access the sub-menus:

CURSOR CONTROL Use the cursor keys to move to the required sub-

menu. Once the cursor is next to the selected menu hit the

ENTER/START key to select the sub-menu. The down and right

cursors move down the screen and the up and left cursors move

up the screen.

DIRECT CONTROL Hit the number corresponding to the desired sub-

menu on the numeric keypad. This will take you directly to the

required menu.

NOTE: The Tag Reader 5is an SMT-200 optional extra. If not used all

menu items related to this feature can be removed from SMT-200

menu item display via the Docking Station Option screen.

For example Redisplay last is item 1 on the File menu. This particular option will display the last test

record that was recorded. From the Main menu press 4 to take you to the File menu. Press 1 to

directly enter the Redisplay last option. Press 0 to return to the File menu and 0 again to return you

to the Main menu. With a little practice this gives you a fast and powerful way of accessing the menu

items.

Main menu

----------------

1>Do a test...

2 Setup menu...

3 Temp. menu...

4 File menu...

5 Tag menu...

6 About...

0 Shut down

Enter test mode

!!!!!!!!!!!!!!!!

The SMT-200

was not properly

shut down

Shut Down ERROR!

18/11/99 12:35

Press any key

to continue

!!!!!!!!!!!!!!!!

Table of contents