RETRACT INTO

HOUSING UNTIL

YOU HEAR A

CLICK

TURN

COUNTER-

CLOCKWISE

BEFORE

RETRACTING

ROD

Mechanical Installation

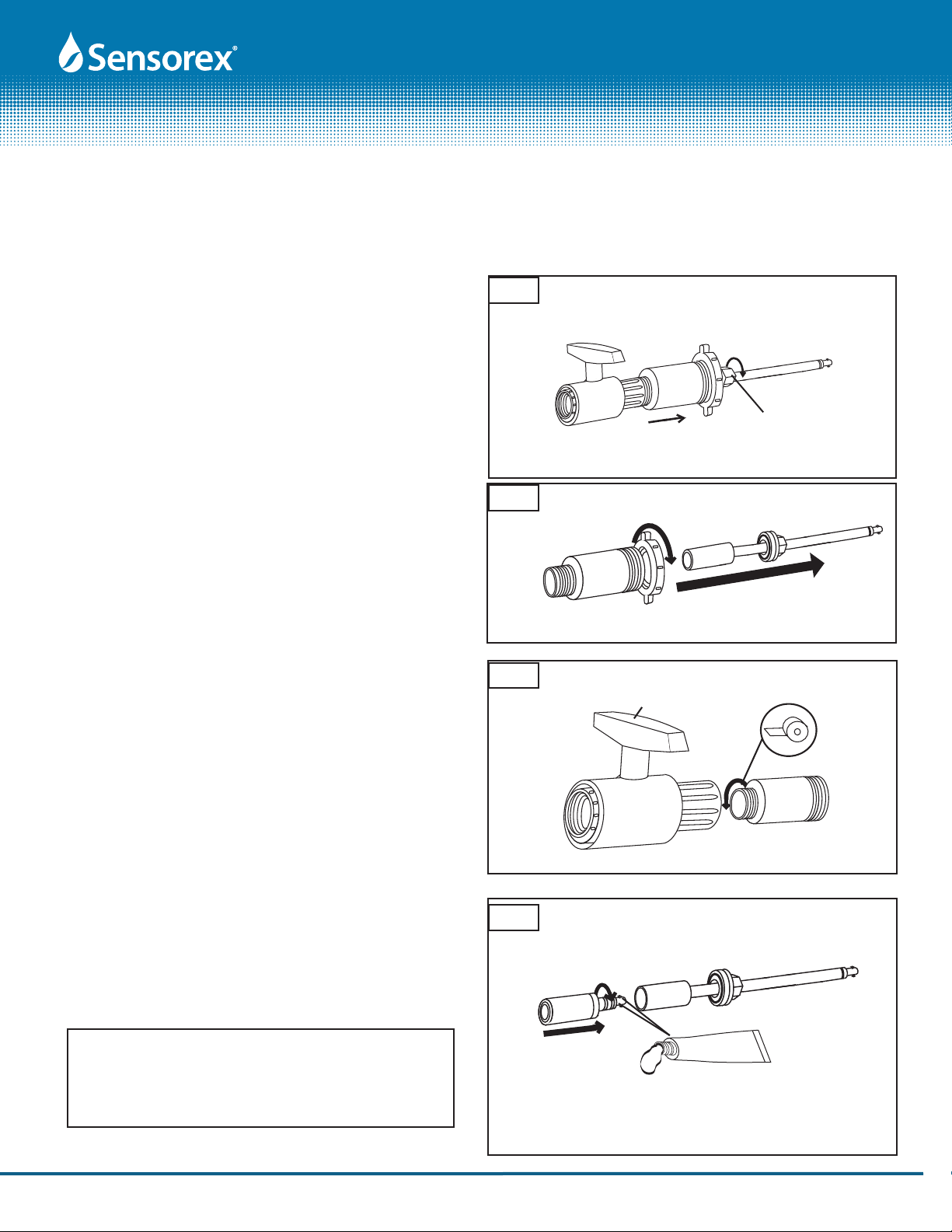

FIG. 1

FIG. 2

Description of Parts

S675 Insertion assembly with 12" insertion depth, 18" total length.

S676 Insertion assembly with 18" insertion depth, 24" total length.

S677 Insertion assembly with 24" insertion depth, 30" total length.

1. Unscrew the hex nut from the adapter body and retract rod

into body until you hear a“CLICK”(FIG 1)

2. Unscrew the white or black nut from the adapter body and

pull out the insertion tube and the parts mounted on it as

shown in FIG. 2.

3.Thread body assembly into 1”full-port ball-valve (user sup-

plied) as shown in FIG. 3. Be sure and seal threads with Pipe

Thread Sealing Tape.

4. Install electrode into rod assembly by pushing electrode

into large end of rod and rotate to align connector as shown

in FIG. 4. Apply liberal amount of 0-ring grease to o-rings on

electrode. After engaging connectors, rotate 1/4 run to lock

electrode in place. DO NOT INSERT INSERTION ROD

ASSEMBLY INTO SOLUTION WITHOUT ELECTRODE AT-

TACHED!!!

5. Insert rod into body assembly until o-ring face seal seals

against body. Then slide white nut over rod from back side

and tighten onto body. (FIG. 5)

6. Open ball valve then loosen hex nut and push rod into de-

sired position. Tighten nut to hold position.(FIG. 6)

7. Push cap cable assembly into insertion rod and rotate to

align tabs of BNC receptacle on rod with grooves of BNC in cap.

BALL

VALVE

CLOSED

THREAD

ASSEMBLY

INTO BALL

VALVE

CLOCKWISE

1/4 TURN

CLOCKWISE

AFTER PUSHING IN

ALIGN TABS

AND PRESS IN

TO ENGAGE

FIG. 3

FIG. 4

SILICONE O-RING GREASE

Grease all o-ring seals

before installation

HEX NUT

CAUTION: MAKE SURE ELECTRODE IS ORIENTED AS

SHOWN IN FIG 4. OR WITH GLASS POINTED DOWN-

WARD WHEN INSTALLING OR REMOVING SO THAT

LIQUID CANNOT FLOW BACK INTO THE INTERNAL

CONNECTOR!

Insertion/Wet-Tap pH and ORP Assembly (No ATC)

Product Instructions

PRODUCT INSTRUCTION SHEET

Page 1 of 3

Parts covered by this product data sheet include:

S675, S676, S677

Form: InstallInsert [Rev: 2012-05-16]

©2011 Sensorex Corporation