Important note regarding product liability

Due to the EU-Guidelines in force since 01.01.1990, the manufacturer is liable for his product only

if all parts originate from the manufacturer and the device was correctly assembled and operated. If

third-party accessories or replacement parts are used, the liability and the warranty may be comple-

tely or partially invalid. With original Carbon Cleaner 6 accessories and replacement parts you have a

guarantee that all safety requirements are fullled and you benet from ongoing further development.

Safety instructions

Safe working with the Cleaner 6 is only possible if you read the instruction manual and the safety ins-

tructions completely and strictly follow them.

1. The use of the Cleaner 6 is only permitted in the commercial and industrial area.

2. Keep your workplace tidy. Disorder in the work area promotes the risk of accidents.

3. Protect your eyes with tight-tting glasses or use face shield.

4. To avoid allergies (e.g. nickel), gloves made of latex, vinyl or similar should be worn.

5. Ensure sucient ventilation. If possible use an extraction system.

6. Take environmental inuences into account. Ensure good lighting. Do not use the Cleaner 6 near

by ammable substances (sparking).

7. Keep away from children. The chemicals contain partly toxic substances.

8. The operator must be at least 18 years old, trainees at least 16 year old, but only under supervision.

9. Eletromagnetic elds can aect pacemakers. Persons wearing these devices are not allowed to

work with the Cleaner 6.

10. Do not overload the Cleaner 6. Do not make short circuits. You will work better and safer in the

specied power range.

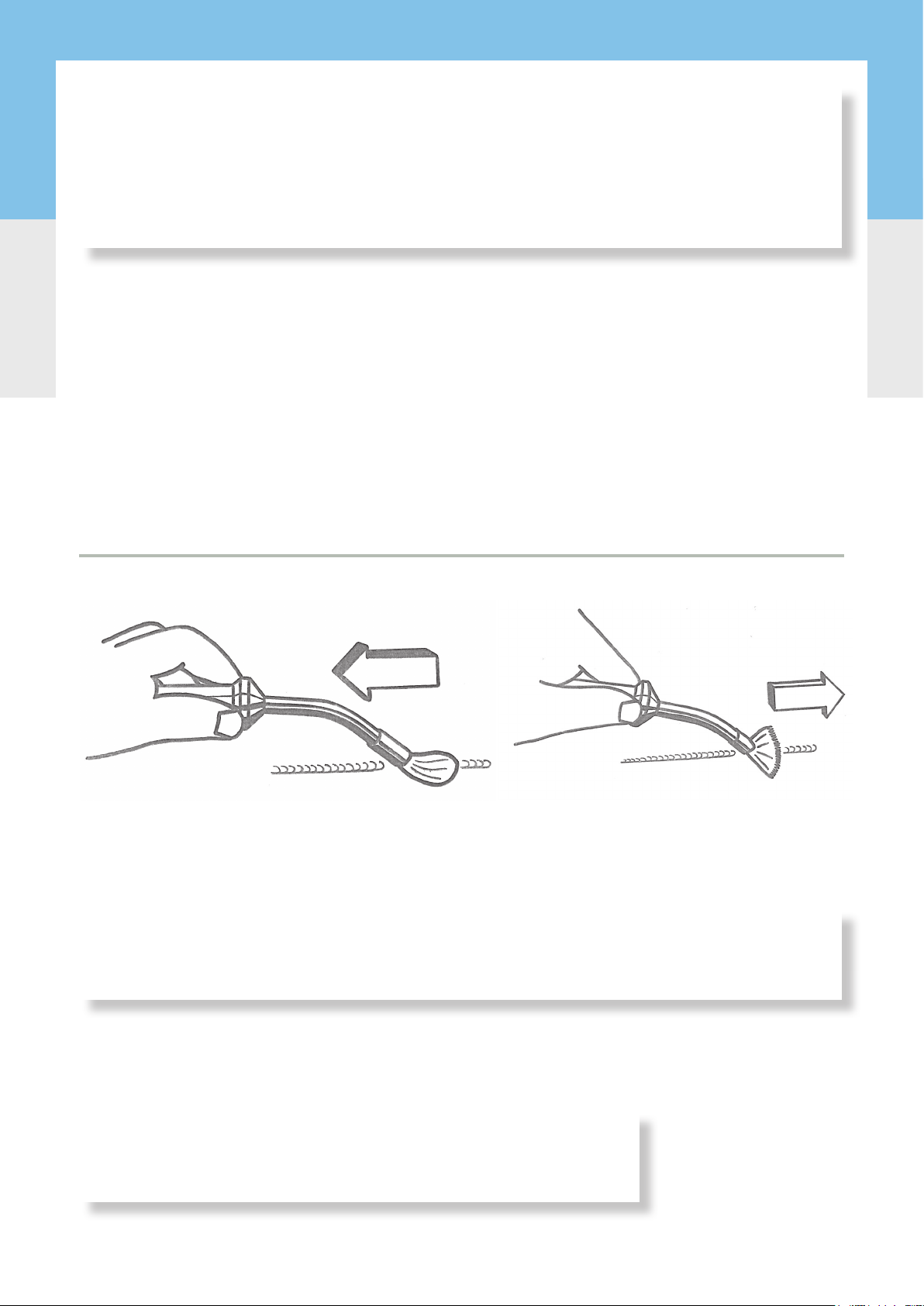

11. Use the correct tools. Use the attachments (carbon brush/electrode) appropriately.

12. Wear suitable clothing. The chemicals may cause discoloration on items of clothing.

13. Do not misuse the cables and hoses. Do not carry the Cleaner 6 by the cable. Check from time to

time wether the cables and hoses are damaged. Replace defective cables and hoses in good time.

14. Save the workpiece. Use holding devices to secure the tool, it is safer than being held by your

hand.

15. Do not overstretch your standing area. Avoid abnormal postures.

16. Ensure secure footing and maintain your balance at all times.

17. Take special care of your Cleaner 6.

18. Keep your device clean and clean it with soapy water or with SURFINOX N.

19. Unplug the power cord when not in use, maintenance etc.

20. Avoid unintended operation. Make sure that the Cleaner 6 is not damaged by tools, sheet metal,

welding tables etc.