SENSTAR MPS-4100 User manual

Product

MPS-4100

Microwave Protection System

Guide

E6DA0102-003, Rev C

Third Edition

April 27, 2009

Senstar Corporation

119 John Cavanaugh Drive

Carp, Ontario

Canada K0A 1L0

Tel: +1 (613) 839-5572

Fax: +1 (613) 839-5830

Website: www.senstar.com

Email: info@senstar.com

See back cover for regional offices.

E6DA0102-003, Rev C

April 27, 2009

Third edition

Senstar and Perimitrax are registered trademarks, and Silver Network, StarNeT 1000, Intelli-FLEX and the Senstar logo are

trademarks of Senstar Corporation. Product names and Company names used in this manual are included for identification

purposes only, and are the property of, and may be trademarks of, their respective owners. Copyright © 2009, 2008, 2005

Senstar Corporation. All rights reserved. Printed in Canada.

The information provided in this guide has been prepared by Senstar Corporation to the best of its ability. Senstar Corporation

is not responsible for any damage or accidents that may occur due to errors or omissions in this manual. Senstar Corporation is

not liable for any damages, or incidental consequences, arising from the use of, or the inability to use, the software and

equipment described in this guide. Senstar Corporation is not responsible for any damage or accidents that may occur due to

information about items of equipment or components manufactured by other companies. Features and specifications are

subject to change without notice. Any changes or modifications to the software or equipment that are not expressly approved

by Senstar Corporation void the manufacturer’s warranty, and could void the user’s authority to operate the equipment.

Senstar’s Quality Management System is IS0 9001:2000 registered.

Compliance:

USA: FCC Certification - This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver.

•Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

•Consult the dealer or an experienced radio/TV technician for help.

FCC Identification Number: I5TMPS4100

Canada: This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

MPS-4100productguide • • • toc-1

Table of contents

1Overview

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

General description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Antenna Pattern - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Operating frequencies and polarization - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Built-in AGC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

PLL circuit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Alarm output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Alignment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Audio output- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Self-test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

MPS-4100 Transmitter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

MPS-4100 Receiver - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

Coverage pattern - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

2 Installation

Installation planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Positioning the MPS-4100 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Terrain------------------------ - - - - - - - - - - - - - - - - - - - - - - - - - ------2-2

Microwavesignalconsiderations- - - - - - - - - - - - - - - - - - --------------------2-3

Physical protection- - - - - - - ------------------------------------ - - - -2-3

Optimumsecurity - - - - - - - ------- ----------------------------- - - - -2-3

Wiring and configuration- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

MPS-4100 configuration options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

Transmitter S1 (tamper)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

Transmitter jumper - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

Receiver S1 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

Receiver S2 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

Receiver jumpers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

DIP-switch illustration conventions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

Mounting procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-8

Relay output wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-10

tableofcontents

toc - 2 • • • MPS-4100productguide

MPS-4100 Transmitter wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-10

S1 - Transmitter tamper configuration- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-11

Definition of functions (Transmitter tamper)- - - - - - - - - - - - - - - - - - - - - - - - - - - 2-11

MPS-4100 Receiver wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-12

Receiver wiring procedure- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-12

Receiver details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-13

Receiver features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-14

Velocity response - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-14

Receiver DIP-switch functions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-15

Receiver DIP-switch settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-16

Definition of Receiver DIP-switch functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-16

Network wiring (Silver/StarNeT 1000)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-17

Communication Interface Card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-17

Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-18

Software setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-18

System configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-19

Installing the Communication Interface Card- - - - - - - - - - - - - - - - - - - - - - - - - - - 2-19

Setting the network device address - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-20

Setting the baud rate- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-20

Connecting the network wiring- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-21

Mounting the Communications Interface Card - - - - - - - - - - - - - - - - - - - - - - - - - - 2-22

Labelling- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-22

Setting up the MPS-4100 Receiver card- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-23

Wiring the Receiver for Silver/StarNeT 1000 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-24

Single Zone - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-24

Dual Zone (Host/Slave configuration) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-24

Host or Slave Transmitter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-25

Host Receiver - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-25

Slave Receiver - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-26

Network Wiring (MX-5000 Series)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-28

Transmitter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-28

Host Receiver - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-28

Slave Receiver - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-29

3 Power Up and Alignment

Powering up - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Relay output version- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Network version (Silver Network/StarNeT 1000)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Alignment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

Alignment procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

Unstable zones (significant snowfall) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

Final testing and adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

Silver Network Test- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

StarNeT 1000 Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

MX-5000 Series test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

Changing antenna polarity - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-5

Self-Test function- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-5

tableof contents

MPS-4100productguide • • • toc-3

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

Non-detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

High false alarm rate- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

Silver Network/StarNeT 1000 Communication Interface Card - - - - - - - - - - - - - - - - - 3-7

MPS-4100 Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-8

aApplicationnotes

Do’s and Don’ts a planning primer - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-1

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-1

Microwave basics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-1

Microwave detection zone size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-1

Unit separation and the mid-point zone width - - - - - - - - - - - - - - - - - - - - - - - - - - a-3

Physical limitations to the maximum beam width - - - - - - - - - - - - - - - - - - - - - - - - a-4

Site Rules - DO’s and DON’Ts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-4

Ground cover rules for reliable detection- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-6

Low-security applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-6

Rules for areas with significant snow accumulation- - - - - - - - - - - - - - - - - - - - - - - - a-6

Post mounting and grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-7

Stacking bistatic microwaves- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-8

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-8

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-8

Good practice - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-8

Determining the mounting height - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-9

Mounting height procedure- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-10

Heavy snow areas - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-11

Advantages of microwave stacking- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-12

Disadvantages of microwave stacking- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-12

Conclusion - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a-12

b StarNeT 1000 CIC

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - b-1

Communication Interface Card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - b-1

Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - b-2

Software setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - b-2

System configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - b-2

Installing the Com card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - b-3

Setting the network device address - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - b-3

Setting the baud rate- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - b-4

Connecting the network wiring- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - b-4

Mounting the Communications Interface Card - - - - - - - - - - - - - - - - - - - - - - - - - - - b-5

Labelling- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - b-5

MPS-4100productguide • • • 1-1

1Overview

Introduction

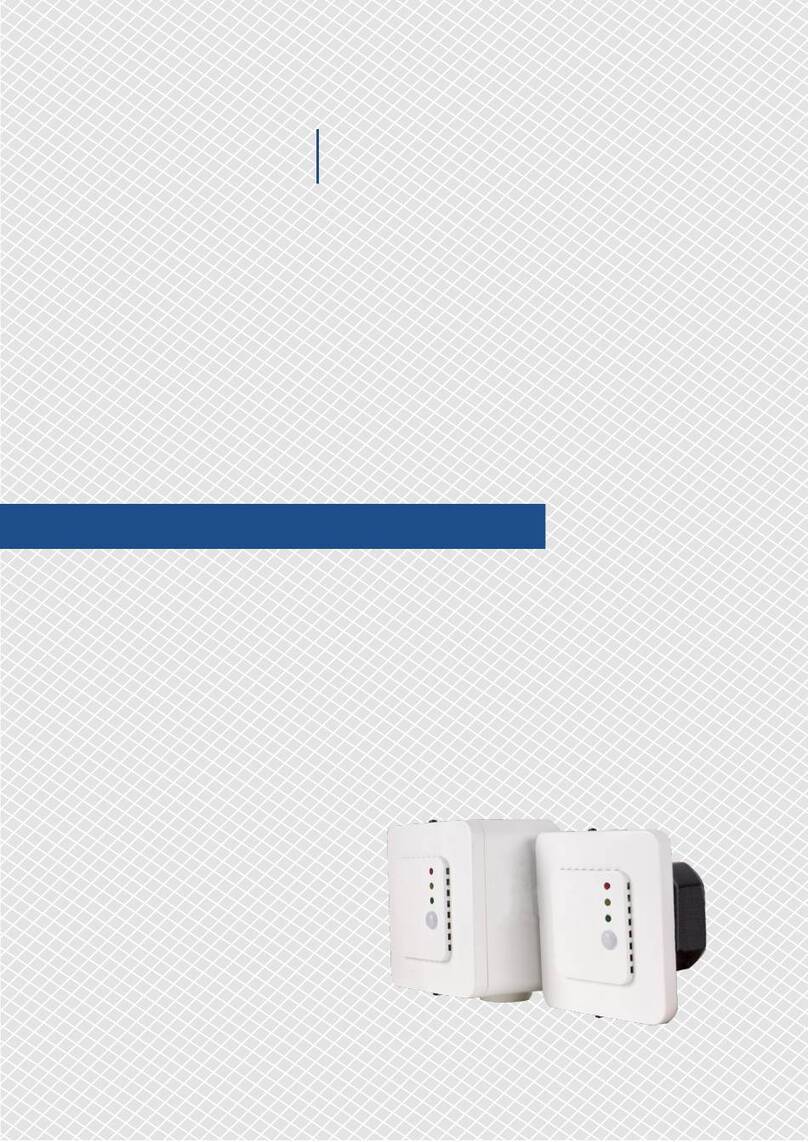

The MPS-4100 Microwave Protection System provides exterior perimeter

intrusion detection coverage. The MPS-4100 detects movement within a

microwave field between the Transmitter and Receiver and initiates an alarm to

alert responding personnel.

General description

The MPS-4100 bistatic microwave system consists of one Transmitter (Tx) unit

and one Receiver (Rx) unit. The Transmitter is a Dielectric Resonant Oscillator

(DRO) designed to radiate microwave power at 10.525 GHz. This oscillator is

pulse modulated (on-off switched at a 50% duty cycle) with a selectable frequency

of 3, 4.5, 7.5, 10.5, 18 or 27 kHz. The transmitted energy is received and

processed by the Receiver using Phase Locked Loop (PLL) technology. An intruder

moving in the pattern causes variations in the signal and is detected. This is

referred to as multi-path detection.

Figure 1-1 MPS-4100 operation

Features

1-2• • • MPS-4100productguide

Features

AntennaPattern

The pattern of the microwave field is established by the Planar Linear Array

Antenna elements housed within the Transmitter and Receiver. The maximum

range is 183 m (600 feet). The pattern width is proportional to the distance

between the Transmitter and Receiver (see Figure 1-4).

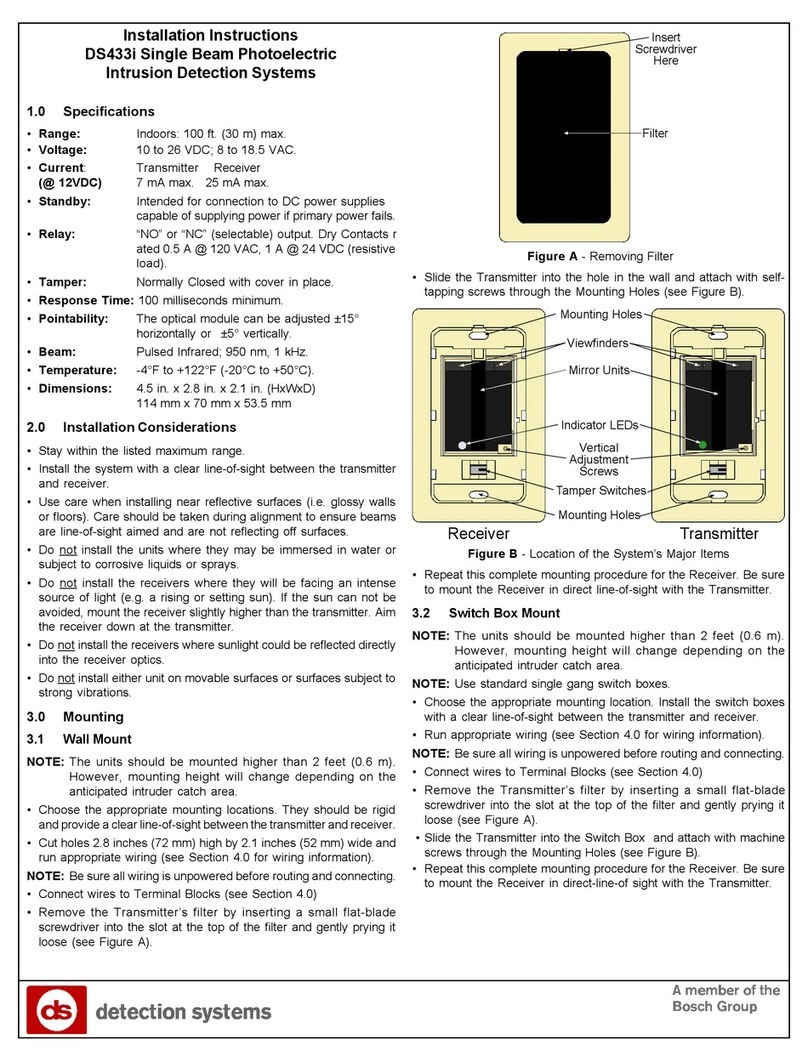

Figure 1-2 MPS-4100 microwave unit

Features

MPS-4100productguide • • • 1-3

Operatingfrequenciesandpolarization

Six selectable modulation frequencies allow multiple sets of MPS-4100 to be used

in either a stacked or linear configuration. Selecting different modulation

frequencies prevents crosstalk between different units located in the same area.

The Planar Linear Array Antenna transmits the microwave signal in either a

vertical or horizontal polarization depending on the orientation of the antenna

assembly. The output polarization can be changed by rotating the antenna

assembly 90 degrees. This reduces interference between multiple units mounted

in close proximity to each other.

Vertical polarization = Narrow Beam;

Horizontal polarization = Wide Beam;

default setting = Narrow Beam.

The Transmitter and Receiver in a microwave link must use the

same modulation frequency and antenna polarization.

Built-inAGC

The received RF amplified signal is processed by an automatic gain control (AGC)

amplifier enabling the amplifier output to be held to a constant level, regardless

of the Transmitter-Receiver separation distance (maximum TX-RX separation

distance = 183 m {600 feet}). The amplifier output is applied to a phase-locked

loop (PLL) detector which operates as a narrow bandpass filter at the selected

modulation frequency. The Receiver’s modulation frequency is selected to match

the modulation frequency of the Transmitter, while rejecting spurious signals and

other Transmitters.

PLLcircuit

The PLL detector output is a voltage level which is held constant under normal

conditions by the slow-acting AGC loop. Rapidly changing signal strength caused

by a target moving into the microwave beam is not affected by the AGC loop and

causes an AC signal to appear at the PLL detector output. The signal is amplified,

filtered and compared with upper and lower alarm threshold voltages. Whenever

a signal exceeds either threshold voltage, an alarm is generated. The gain of the

signal amplifier may be adjusted with a Sensitivity potentiometer on the circuit

board. The signal bandwidth, affecting the MPS-4100 response to moving targets,

may be set to Fast or Slow with a PCB jumper. The Slow setting detects human

intruders (default setting) and the Fast setting detects moving vehicles.

Features

1-4• • • MPS-4100productguide

Alarmoutput

Two alarm reporting formats are available for signalling alarm or tamper

conditions. The formats are dry relay contacts and network communications.

For relay contact notification, the MPS-4100 provides jumper-selectable NC/NO

relay outputs for alarm and tamper conditions. The alarm output relay is

energized on power-up and goes into an alarm condition upon loss of DC power.

A NC/NO tamper output is available on both the Receiver and Transmitter.

For network communications there are three options, the Silver Network, the

StarNeT 1000 Alarm Display and Control system, and the MX-5000 Series

Command and Control Center. For the Silver Network and StarNeT 1000, an

optional Communication Interface Card (CIC) provides redundant

communications between the MPS-4100 and the alarm display and control

system. For the MX-5000 Series system, a network transponder enables multiplex

communication over a twisted pair using the proprietary CEnDe protocol. Each

network communication option requires a CIC, which plugs into header P1 on

the Receiver circuit board. Each CIC can handle two microwave zones, enabling

the reporting of an adjacent relay version MPS-4100 system.

Alignment

Accurate alignment of the Transmitter and Receiver, which establishes the

strongest possible signal, is facilitated by a built-in alignment aid. A series of LED’s

on the Receiver circuit board indicate when optimum alignment and maximum

signal strength have been achieved. A 600 ohm impedance audio jack and voltage

test points are also provided on the Receiver card to enable headphones or a

voltmeter to be used as alignment aids.

Audiooutput

The MPS-4100 Receiver has a built-in audio output that can be used to evaluate

signal variations in the detection path. A tone is generated, which corresponds to

objects moving within the microwave field. The tone varies in frequency and

amplitude according to the disturbance in the microwave field. During quiescent

operation, no tone is generated. As an intruder moves within the protected area,

an audio tone is generated. The tone increases in volume and pitch in relation to

the disturbance of the microwave field. The audio output can be taken to an

amplifier. The Receiver circuit board includes a 3 mm (1/8 in.) audio plug for

connecting a headphone to the local audio output. The local audio output is very

useful in locating the source of nuisance alarms generated by moving objects

within the detection path.

Self-test

The Receiver includes a self-test function to verify proper operation. A 12 VDC

input activates the self-test, which then generates a multi-path signal that

simulates a disruption of the microwave field. The Receiver processes the signal

and generates an alarm.

MPS-4100 Transmitter

MPS-4100productguide • • • 1-5

MPS-4100 Transmitter

The Model MPS-4100 Transmitter consists of two major sub-assemblies, the

antenna assembly and the Transmitter circuit board.

The antenna assembly is a planar or linear patch array (see Figure 1-3) coupled to

a pulse modulated dielectric resonant oscillator located on the back of the

antenna. The antenna directs the microwave energy toward the Receiver. The

antenna assembly and associated DRO attaches to the Transmitter circuit board by

means of stand-off fasteners so that the two form a single removable assembly.

The Transmitter circuit board includes the modulator circuit to drive the

oscillator. One of six modulation frequencies can be selected via jumpers located

on the board.

The Transmitter includes a Tamper switch with selectable NO/NC output that

signals when the cover on the rear of the housing has been removed. The Tamper

switch is a 2-position plunger (secure, alarm) and includes a pull-out position that

disables tamper notification, for servicing the unit.

An optional method for Tamper detection (switched power) which requires no

additional tamper wiring, has been incorporated in the Transmitter. With this

option selected, the power to the Transmitter is interrupted whenever the

enclosure cover is removed. This stops the transmission of microwave energy,

resulting in an alarm condition at the Receiver.

Figure 1-3 Linear patch array antenna

MPS-4100 Receiver

1-6• • • MPS-4100productguide

MPS-4100 Receiver

The Model MPS-4100 Receiver consists of two major sub-assemblies, the antenna

assembly and the Receiver circuit board. The antenna assembly is a planar or

linear patch array antenna, with a signal preamplifier and Schottky diode detector

located on the rear side. The antenna captures the microwave energy from the

Transmitter. The microwave signal is first preamplified. This compensates for

attenuation of the incoming signal due to environmental factors such as objects in

the pattern or rain. The Schottky diode detector converts the modulated X-band

energy into an audio frequency signal for processing by the Receiver circuit

board. The antenna assembly attaches to the Receiver circuit board by means of

stand-off fasteners so that the two form a single removable assembly.

The Receiver circuit board includes the processing circuitry that generates an

alarm when sufficient changes in the microwave signal are detected. The

modulation frequency is set to match that of the Transmitter via jumpers located

on the circuit board. The gain of the signal amplifier may be adjusted by means of

a Sensitivity potentiometer. The higher the sensitivity setting, the lower the

change in received signal required to generate an alarm. The signal bandwidth,

affecting the response to fast moving targets, may be set to Fast or Slow via a

jumper on the Receiver circuit board.

The Receiver circuit board includes three LED’s for indicating Alarm, Wrong

Channel, and Jam conditions. The Alarm LED indicates an alarm condition. The

Wrong Channel LED indicates that the modulation frequency of the Receiver does

not match that of the Transmitter. The Jam LED indicates that the Receiver is

picking up two microwave signals at the same modulation frequency, signifying

interference between two microwave units. A Jam condition can be set to trigger

an alarm output via a switch on the Receiver.

The Receiver circuit board includes header P1 for connecting a Communications

Interface Card. This enables communication via the Silver Network, the StarNeT

1000 system or the MX-5000 Series Control Center. The Receiver also includes a

pre-amp that outputs audio signals enabling audio assessment of activity within

the microwave field.

The Receiver includes an alignment aid consisting of a series of ten LED’s that

indicate the received signal strength. Test points are available for voltmeter

verification of the microwave’s alignment. There is also a local audio output for

connecting a 3 mm (1/8 in.) headphone jack, which is used for audio assessment

of microwave field disturbances. In addition, several operating parameters are

selectable via jumpers and DIP-switches on the Receiver circuit board.

Coverage pattern

The antenna creates a microwave energy field at an approximate 13º angle

(horizontal polarization app. 13º; vertical polarization app. 11º). This results in a

typical maximum width protection pattern of 12 m (40 feet) at a mounting height

of 76 cm (2.5 feet) above level earth (see Figure 1-4). The maximum beam width

Coveragepattern

MPS-4100productguide • • • 1-7

occurs at the maximum Transmitter-Receiver separation distance of 183 m

(600 ft.). Actual patterns will vary depending on the site topography and surface

conditions. Generally, lower mounting heights or a rougher surface will increase

pattern width.

The pattern height above the center-line will be approximately one half of the

pattern width. The protection pattern below center-line will tend to fill the area

between the beam center-line and the ground, except for a dead zone directly in

front of the Transmitter and Receiver.

The energy field development is not immediate, resulting in a dead zone in front

of the Transmitter and Receiver, in which it is possible to crawl under the pattern

undetected. For this reason it is necessary to overlap or offset Transmitters and

Receivers to cover this dead zone. Receivers and Transmitters should be offset at

least 4.5 m (15 ft.) at corners and 9 m (30 ft.) at midpoints in a linear array (see

Figure 1-5 and Figure 1-6).

Large nearby metallic objects such as vehicles, fences and

buildings can be detected well beyond the typical detection

envelope. Refer to Application note #1, Do’s and Don’ts: a

Figure 1-4 Typical MPS-4100 coverage patterns

2 m (6.6 ft.)

@30 m (100 ft.)

6 m (20 ft.)

@91 m (300 ft.)

12 m (40 ft.)

@183 m (600 ft.)

Coveragepattern

1-8• • • MPS-4100productguide

planning primer, in Appendix a for information about zone

lengths and maximum beam widths for microwave zones near

metal objects.

Figure 1-5 provides an example of using offset microwave pairs to eliminate the

dead zone directly in front of the Transmitter/Receiver. Figure 1-5 also

demonstrates the use of a corner overlap to provide complete coverage around a

corner on a protected perimeter.

Figure 1-6 illustrates an intermediate offset, which is used to extend the length of

a straight microwave coverage pattern by using two microwave pairs.

Figure 1-5 Dead zone overlap protection (side view)

Figure 1-6 Intermediate overlap (top view)

corner overlap

4.5 m

(

15 ft.

)

4.5 m

(15 ft.)

full coverage along

dotted lines

4.5 m

(

15 ft.

)

dead zone

(no coverage)

12

unit 1 provides coverage for the

dead zone area of unit 2

top view

beam centerline

offset 46 to 51 cm

(18 to 20 in.)

intermediate overlap

(continuous coverage)

9m

(30 ft.)

MPS-4100productguide • • • 2-1

2Installation

Installation planning

Refer to Do’s and Don’ts a planning primer, in Appendix a for

information about site planning and design.

Begin with a site survey to ensure that the area being protected meets the

MPS-4100 installation requirements. Next, determine the locations of the

Transmitter and Receiver pairs. Install the mounting posts, conduit and junction

boxes in the selected locations. The MPS-4100 can then be mounted, wired and

configured.

There are two methods of wiring and configuring the MPS-4100 depending on the

application. The Wiring and Configuration section of this chapter is divided into

Relay Output wiring and Network wiring.

PositioningtheMPS-4100

First, you must establish the length of each microwave zone. The maximum

separation distance between the Receiver and Transmitter is 183 m (600 ft.)

However, for high security applications, the recommended maximum separation

distance is 100 m (328 ft.). The maximum width of the zone is determined by the

amount of open space to the left and right of the center-line between the

Transmitter and Receiver. The area to be protected must be free of obstructions

and moving objects such as trees, shrubs, bushes, utility boxes and other

structures. Figure 2-1 illustrates the relationship between zone length and width.

Do’s and Don’ts a planning primer in Appendix a includes a formula for

calculating the approximate beam width based on the zone length.

Generally, there must be a clear open space that exceeds one

half the pattern width on each side (i.e., the minimum required

clear area is equal to two times the microwave beam width).

Large nearby metallic objects such as vehicles, fences and

buildings can be detected well beyond the typical detection

Installationplanning

2-2• • • MPS-4100productguide

envelope. Refer to Do’s and Don’ts a planning primer, in

Appendix a for information about zone lengths and maximum

beam widths for microwave zones near metal objects.

Terrain

Since operation of the link requires the transmission of energy from the

Transmitter to the Receiver, you must maintain a clear line of sight between the

units. Therefore, the ground must be flat across the protected area. Any bumps,

hills or ditches must be filled or graded so that the area is level to within 15 cm

(6 in.) (see Figure 2-2).

The protected area’s surface can be any stable, reasonably smooth material such

as concrete, asphalt, soil, or gravel. If there is grass or vegetation in the protected

area, it must be kept cut to a maximum of 8 cm (3 in.) in height. An MPS-4100

should not be operated over open water, or where standing puddles will form.

For environments in which snow accumulates during the winter months, a hard

surface is recommended to facilitate snow removal.

Figure 2-1 Zone length/width relationship

30 m (100 ft.)

91 m (300 ft.)

183 m (600 ft.)

zone length

2 m (6.6 ft.)

6 m (20 ft.)

12 m (40 ft.)

approximate

beam width

microwave field

required clear area

30 m (100 ft.)

91 m (300 ft.)

183 m (600 ft.)

min. require

d

clear area

4 m (13 ft.)

12 m (40 ft.)

24 m (79 ft.)

Installationplanning

MPS-4100productguide • • • 2-3

Microwave signal considerations

Microwave signals can pass through common construction materials such as glass,

plaster and drywall. Microwave signals will reflect off of solid objects and metallic

surfaces.

Microwave signals will pass through standard chain link fences if the beam axis is

at a right angle to the fence. The more the fence deviates from a right angle to the

beam, the less signal penetration, and the more reflection.

Microwave signals that detect a moving or flexing fence, or other large metallic

objects, can generate nuisance alarms. A large metallic object can cause a small

amount of motion to appear as a large moving target.

Other potential nuisance alarm sources include moving machinery parts, as well

as the vibrations caused by machinery, large vehicles such as trucks, buses and

aircraft.

Physical protection

Install the Transmitter and Receiver in a location, which provides protection from

both accidental damage and tampering. If microwave units are being installed

near roadways, or where they are vulnerable to vehicle traffic, install protective

devices such as bumper posts or parking guards.

Optimum security

Choose a location that will provide optimum security, yet be free from nuisance

alarms. Always locate the MPS-4100 inside a fence or controlled access area to

prevent nuisance alarms due to random foot traffic, vehicles, or animals.

Units should be located away from parallel fences to avoid reflection of the

microwave signal off the surface of the fence, and to prevent the possibility of

jumping over the protection pattern. As a general rule, the clear area around a

microwave system should be at least two times the maximum beam width.

For maximum security it is necessary to overlap the ends of links so that the dead

spot below and immediately in front of the adjoining link is protected. A 4.5 m

(15 ft.) overlap is required at corners and a 9 m (30 ft.) overlap at intermediate

Figure 2-2 Level terrain

DO DON'T

Installationplanning

2-4• • • MPS-4100productguide

points. The side-by-side offset of overlapping in-line links should be

approximately 46 cm (18 in.), measured from the center of each unit.

At each point of overlap either two Transmitters or two

Receivers should be installed. This arrangement prevents an

adjacent Transmitter and Receiver from establishing an

unwanted link across the short overlap distance, which could

result in a Jam or Wrong Channel indication at the Receiver

(see Figure 2-3).

Wiringandconfiguration

The MPS-4100 may be configured for Relay Output or for Network

Communications depending on the model installed. All wiring connections are

made on removable terminal blocks, which facilitates maintenance and service

activities.

The MPS-4100 provides dry relay outputs for alarm and tamper that can be wired

to virtually any alarm sensor with auxiliary inputs, including the OmniTrax®

processor, XField®processor, Perimitrax®Sensor Module, Intelli-FLEX™

processor, PLC transponder, etc. The MPS-4100 can report alarm data via the

Silver Network to the SentientTM security management system, or to a Perimitrax

or Intelli-FLEX Central Controller, Senstar®100, StarNeT 1000TM, FPS-3 Central

Controller, MX-5000 Command and Control Center, etc. The Silver Network can

also communicate with a third party alarm display and control system via the

Network Alarm Interface.

Figure 2-3 Perimeter layout (100% coverage)

CAUTION: DO NOT apply power until all wiring connections have been made.

Tx1

Tx2

Rx1

Rx2

Rx3

Tx3

Tx4

Rx4

Rx5

Tx5

Tx6

Rx6

9 m

intermediate

overlap

4

.5

m

corner

offset

46 cm offset

perimeter fence

Corner offsets plus intermediate overlaps and offsets provide 100% coverage around the

inside of the perimeter fence.

Installationplanning

MPS-4100productguide • • • 2-5

For network communication, an optional Communication Interface Card (CIC)

connects the MPS-4100 directly into the Silver Network or the StarNeT 1000

network. An optional network interface transponder enables direct connection of

the MPS-4100 to the MX-5000 Series Command and Control Center. In the

network communication format, a second MPS-4100 can be wired into the Host

MPS-4100 as a Slave system. Power feeds from the Host Receiver to the Slave

Receiver and Transmitter. The alarm and tamper signals from the Slave Receiver

are fed into the Host Receiver. The Host Receiver reports the alarm data to the

head-end system. This configuration reduces the wiring requirements and allows

two MPS-4100 systems to share one communication interface card, reporting to

the head end as two zones.

MPS-4100configurationoptions

The following is a summary of the configuration options for the MPS-4100 via

jumpers and DIP-switches.

Transmitter S1 (tamper)

• S1-1 - ON selects NO tamper output. OFF disables NO output.

• S1-2 - ON selects NC tamper output. OFF disables NC output.

• S1-3 - ON bypasses the 3 kΩend of line resistor (EOLR). OFF adds the 3 kΩ

EOLR in series with the NC output.

• S1-4 - ON enables unswitched power to Transmitter. OFF enables switched

power when S1-5 and S1-6 are set to ON.

• S1-5 - ON enables switched power through the tamper switch. OFF disables

switched power.

• S1-6 - ON enables switched power through tamper switch. OFF disables

switched power.

Transmitter jumper

• JP1-Selects the Transmitter modulation frequency (Channels 1 through 6).

Receiver S1

• S1-1 - OFF for Relay Output operation; ON for network.

• S1-2 - ON enables self-test in Relay mode; OFF for network.

• S1-3 - OFF for Relay Output operation; ON for network.

• S1-4 - ON enables self-test in Relay mode; OFF for network.

• S1-5 - ON enables alarm output on Jam condition. OFF disables alarm on Jam.

• S1-6 - OFF connects tamper for Relay output; ON for network.

Installationplanning

2-6• • • MPS-4100productguide

Receiver S2

• S2-1 - ON enables audio output via TB3. OFF for audio output via TB1.

• S2-2 - Not Used.

• S2-3 - OFF connects tamper for Relay output; ON for network.

• S2-4 - ON enables Alignment Aid LED’s. OFF disables LED’s.

• S2-5 - ON enables alarm relay reset. OFF latches alarm relay.

To reset the latching relay, you must open the receiver

enclosure and toggle S2-5.

• S2-6 - ON enables alarm relay. OFF disables alarm relay.

Receiver jumpers

• JP1 & JP2 - Selects the modulation frequency Channels 1 through 6.

• JP3 - Sets tamper output to either Normally Open or Normally Closed.

• JP4 - Sets the optional 3 kΩend-of-line supervision for tamper NC output.

• JP5 - Sets the alarm output to either Normally Open or Normally Closed.

• JP6 - Sets the optional 3 kΩend-of-line supervision for alarm NC output.

• JP7 - Sets the Receiver’s response to signal disruption to FAST or SLOW.

DIP-switchillustrationconventions

Figure 2-4 illustrates the DIP-switch conventions, used in this guide.

Figure 2-4 DIP-switch conventions

OPEN DIP-switch setting

DIP-switch

CLOSED DIP-switch setting

Illustration

convention

CLOSED

OPEN

Illustration

convention

CLOSE

D

OPEN

DIP-switch

switch OFF switch ON

(OPEN = OFF) (CLOSED = ON)

Other SENSTAR Security Sensor manuals

Popular Security Sensor manuals by other brands

Microsonic

Microsonic crm+25/IU/TC/E instruction manual

Procon

Procon LD160 Series manual

FireAngel

FireAngel Stove Guard SGEL-SN-1 Installation and operating instructions

HomeMatic

HomeMatic HM-Sen-MDIR-O-3 Mounting instruction and operating manual

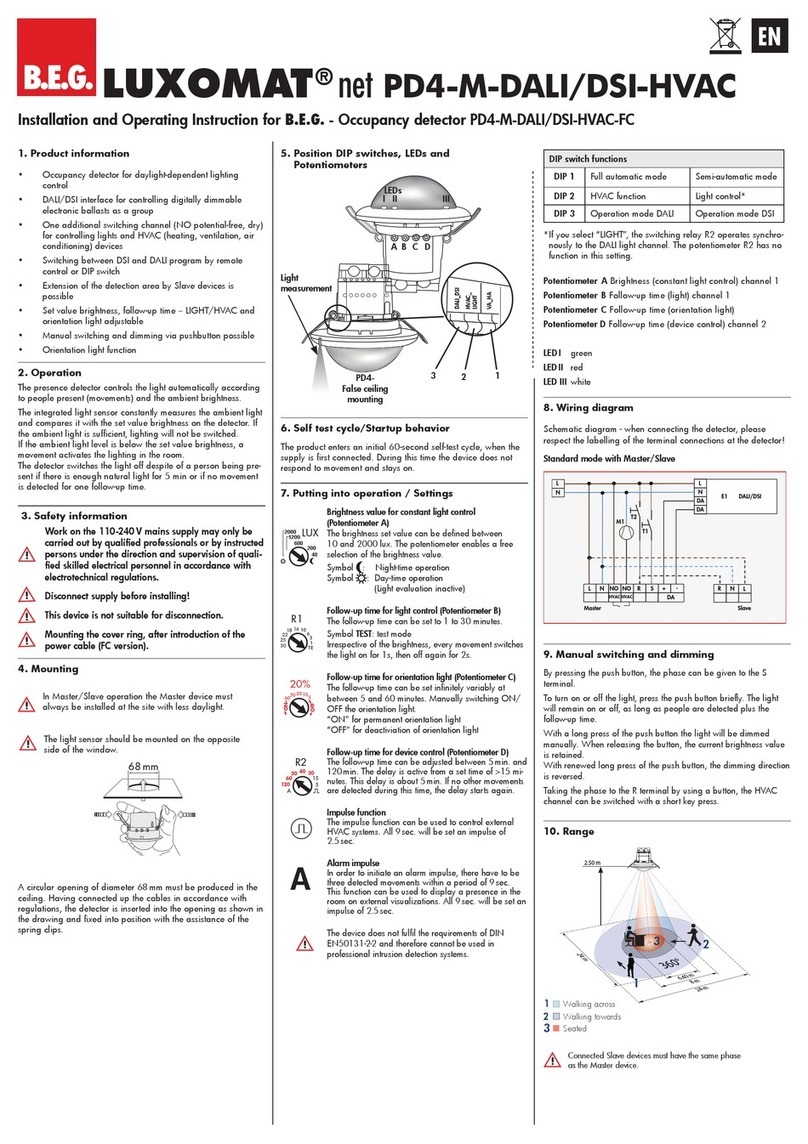

LUXOMAT

LUXOMAT LUXOMAT net PD4-M-DALI Installation and operating instruction

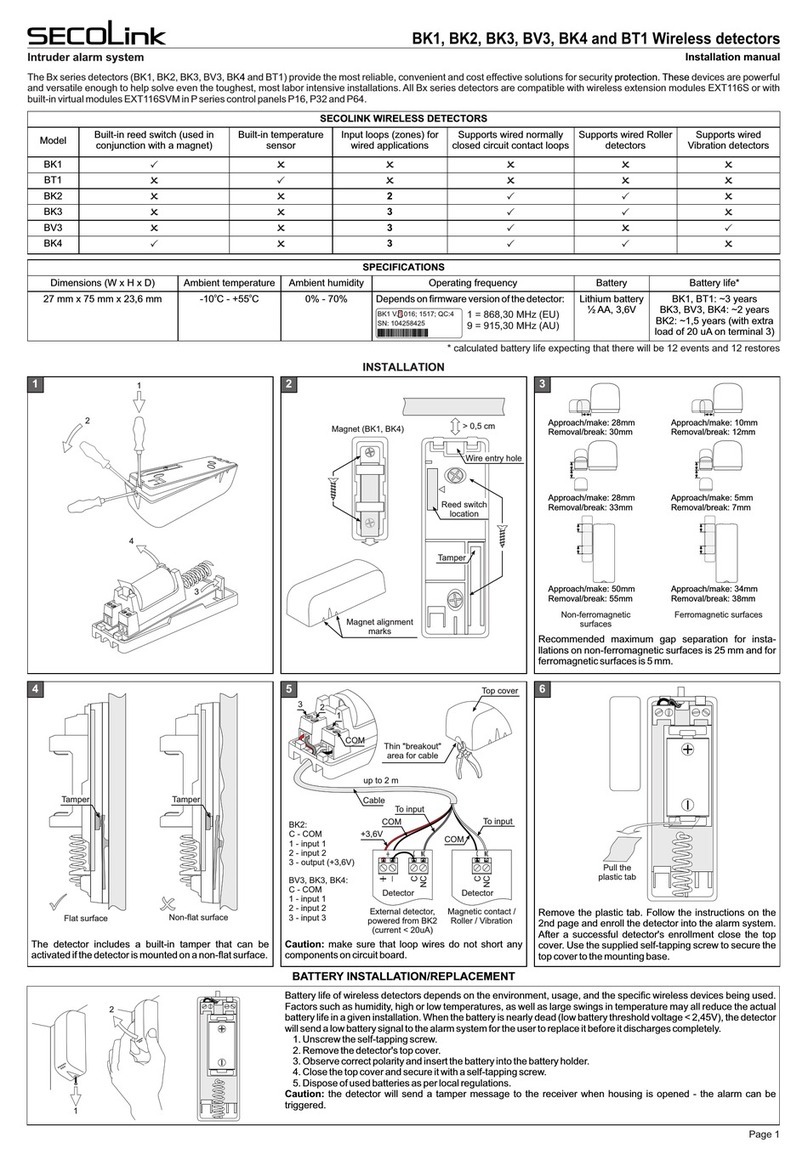

SECOLink

SECOLink BK4 installation manual