SENSTAR FlexPI C8DA0402-001 User manual

Product

Guide

FlexPI®

Interior Intrusion Detection Sensor

C8DA0402-001, Rev B

January 13, 2014

Page 2 FlexPI Product Guide

Senstar Corporation

Website: www.senstar.com

C8DA0402-001, Rev B

January 13, 2014

Senstar, FlexPI and the Senstar logo are registered trademarks of Senstar Corporation. Product names and Company names

included in this document are used only for identification purposes and are the property of, and may be trademarks of, their

respective owners. Copyright © 2014, Senstar Corporation. All rights reserved. Printed in Canada.

The information provided in this guide has been prepared by Senstar Corporation to the best of its ability. Senstar Corporation

is not responsible for any damage or accidents that may occur due to errors or omissions in this guide. Senstar Corporation is

not liable for any damages, or incidental consequences, arising from the use of, or the inability to use, the software and

equipment described in this guide. Senstar Corporation is not responsible for any damage or accidents that may occur due to

information about items of equipment or components manufactured by other companies. Features and specifications are

subject to change without notice.

The figures included in this document are for illustration purposes only, and may differ from the actual equipment.

Approvals

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any interference received, including interference that may cause

undesired operation.

Any changes or modifications to the software or equipment that are not expressly approved by Senstar Corporation void the

manufacturer’s warranty, and could void the user’s authority to operate the equipment.

Europe:

This device conforms to EN 61000-6-4: 2001 relating to Electromagnetic compatibility for emission standards for industrial

environments.

This device conforms to EN 50130-4: 1995 + amendments A1: 1998 & A2: 2003 relating to Electromagnetic compatibility for

immunity requirements for components of fire, intruder, and social alarm systems.

The use of shielded cables is required for compliance.

Senstar Corporation’s Quality Management System is ISO 9001:2008 registered.

Service statement - We ensure that our products are correctly applied to achieve the maximum benefits for the end-user. We

work hand-in-hand with our customers and remain accessible through all stages of a project - from concept to deployment to

long-term support. We provide design assistance, site surveys, installation support, comprehensive documentation, training,

post-installation annual calibration and maintenance visits, electronics and software extended warranty, rapid factory repair

service and on-call/emergency service. Contact Senstar Corporation to inquire about how a package can be customized for

your unique applications.

FlexPI Product Guide Page 3

Table of contents

1 Installation planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5

System description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Operation & alarm outputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Lead-in cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Security planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Installation rules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Security cage protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Wall protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9

Roof protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Floor protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9

Embedding sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Windows and skylights - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Pipes and data cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Installation examples - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

2 Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -15

Installing the sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Cable handling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Installing cable on security cages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Installing cable on walls - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Installing cable on roofs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Installing cable on floors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Embedding sensor cable in buildings and walls - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Protecting windows and skylights - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Protecting pipes and data cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Installing terminators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Splicing cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Outdoor cable installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Installing the processor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Connecting the sensor cable or lead-in cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 23

Wiring the processor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 24

3 Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -27

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

Calibration setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

During calibration: - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Alarm source simulations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Page 4 FlexPI Product Guide

Monitoring nuisance alarm sources - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

UCM Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -29

UCM calibration overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -29

The Calibrate tool - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

UCM detection parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Step 1 - Setting the filters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Step 2 - Calibrating the Gain Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Setting the Cut Alarm parameters (impact attacks) - - - - - - - - - - - - - - - - - - - - - - - - - -32

Setting the Threshold - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 32

Setting the cut Count and time Window - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

The Cut Profile - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

Setting the Climb Alarm parameters (sustained attack) - - - - - - - - - - - - - - - - - - - - - - -33

Setting the climb Time and Window - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 34

Area Preparation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

Bar graph (received signal strength indicator) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

Step 1 - Setting the Filter Response - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Step 2 - Calibrating the FlexPI Gain/Threshold - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Setting the Climb Alarm parameters (sustained attack) - - - - - - - - - - - - - - - - - - - - - - -38

Setting the Cut Alarm parameters (Impact attack) - - - - - - - - - - - - - - - - - - - - - - - - - - -38

Calibration concepts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -40

a Parts list - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -41

b Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -43

FlexPI Product Guide Page 5

1 Installation planning

System description

FlexPI is Senstar’s interior intrusion detection sensor system that provides protection for assets

inside buildings and other structures. FlexPI integrates easily into any existing alarm system and is

typically used in unmanned installations in which an alarm will deter most intruders while alerting

police or security. Each FlexPI system is a self-contained intrusion detection sensor consisting of a

processor, an enclosure, up to 600 m of sensor cable and a terminator. The cable mounting

hardware, power supply, alarm communication wiring and alarm annunciator are Customer

supplied.

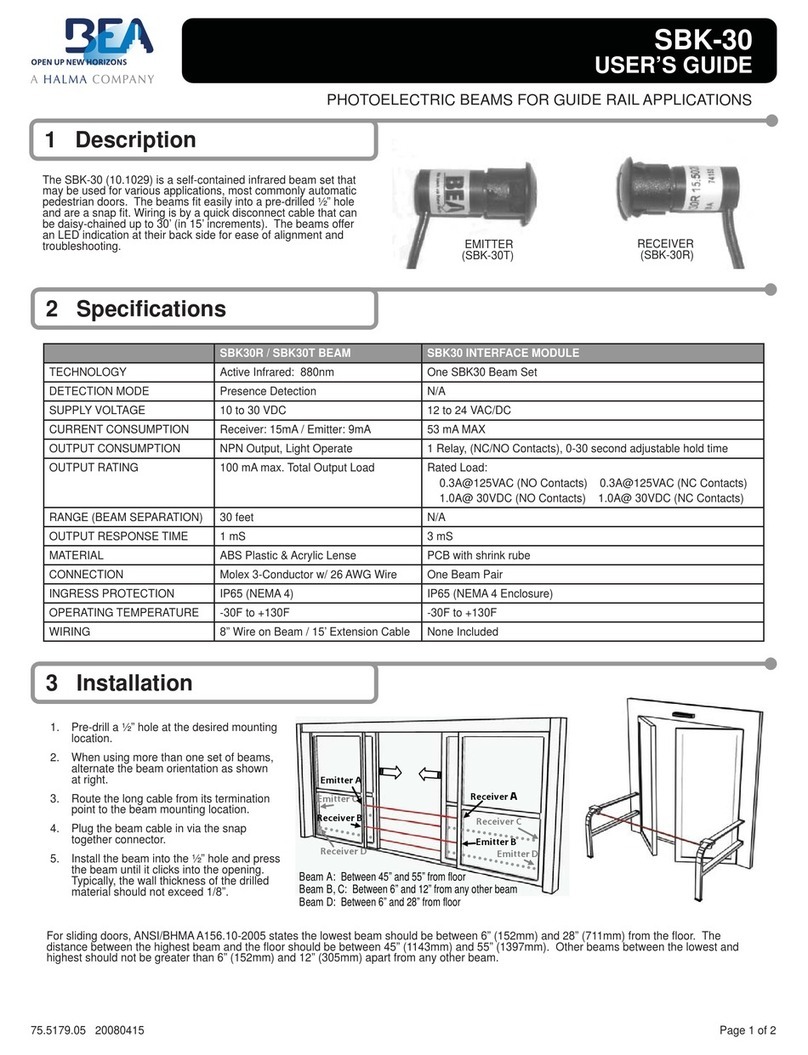

Figure 1: FlexPI system components

300 m sensor cable

30 m lead-in cable data cable

power supply

terminator/splice kit

processor & enclosure

sensor cable mounting

hardware examples

UCM software CD

terminator/splice enclosure

Page 6 FlexPI Product Guide

Operation & alarm outputs

The FlexPI processor operates on 12 - 48 VDC, and consumes 1 W max. It reports alarm and

supervision conditions via two Form C relays. The ALARM relay changes state to indicate a

sensor alarm. The SUPERVISION relay changes state to indicate an enclosure tamper condition,

a cable fault condition, or a processor fault condition. FlexPI includes a user-selectable onboard

audio alarm (beeper) that can be enabled or disabled via the configuration switches. When

enabled, the audio alarm follows the state of the ALARM relay (ALARM relay ON = audio alarm

ON). There is also a N.O. output labelled SONALERT that can be used to activate a remote alarm.

The SONALERT output closes to signal a sensor alarm. The FlexPI processor includes an

enclosure tamper switch and supervises the sensor cable, terminator, and lead-in cable (if used).

The processor also runs diagnostic self-tests to monitor its internal electronic operation.

Calibration

FlexPI calibration and configuration adjustments are made with either onboard switches or

Senstar’s Universal Configuration Module (UCM). The UCM is a Windows-based application that

connects directly to the processor via USB and also provides real time diagnostics and sensor plot

modes.

The processor includes an LED bar graph that indicates the received signal strength (from the

sensor cable). Calibration adjustments include two selectable frequency response bands that

optimize the sensor’s response for the protected surface and the expected type of attack. Other

detection parameters include the Climb Alarm Settings (sustained attack) the Cut Alarm Settings

(number of impacts) Time Window (time in which a sustained attack, or the number of impacts

must occur to generate an alarm) Gain Settings (four discrete signal amplification levels).

FlexPI also includes four miscellaneous controls (MISC.) switches that allow you to select the

frequency response band, setup the bar graph display, enable or disable the audible alarm output,

and select the method of system calibration (onboard switches or UCM).

Sensor cable

The FlexPI sensor cable is a thin diameter (3.6 mm, 0.14 in. O.D. nominal) low profile coaxial

cable that is easily mounted on virtually any surface using commercially available fasteners. The

cable picks up minute vibrations in the surface, and converts the vibrations into electrical signals.

The electrical signals are analyzed by the processor, and when the signals indicate a valid attack,

an alarm is declared. Each processor can monitor the signals from up to 600 m (1970 ft.) of sensor

cable.

The basic FlexPI system requires the following

components: The following optional components can be added to

the basic system:

• FlexPI processor &

enclosure • power supply/cable

(Customer supplied) • Universal Configuration

Module • non-sensitive lead-in

cable

• sensor cable • alarm annunciator

(Customer supplied) • metal conduit

(Customer supplied) • cable splice kit

• cable terminator kit • data cable (Customer

supplied)

• enclosure mounting

hardware (Customer

supplied)

• cable mounting

hardware (Customer

supplied)

FlexPI Product Guide Page 7

Lead-in cable

The FlexPI lead-in cable is virtually identical to the sensor cable, but does not detect vibrations

(non-detecting cable). Lead-in cable is available in 30 m (98 ft.) lengths for installations in which

the processor must be located away from the start point of the detection zone. It can also be used

to bypass sections of the mounting surface.

Applications

The FlexPI sensor system provides penetration detection for virtually any type of building material

(e.g., brick, stone, concrete slabs, poured concrete, cinder-block, stucco, wood, drywall, ceramic,

steel) as well as for security cages, fences, vaults, window casings, doors, ceilings, floors, security

grilles, etc. However, due to the different vibration transmission characteristics of each type of

building material or surface, the sensor cable from one processor should be mounted on only one

type of surface.

Installing a FlexPI system is a four step process:

1. Design the system and obtain the necessary components.

2. Install the sensor cable and terminator.

3. Install the processor and enclosure.

• power supply

• alarm communication wiring

• optional lead-in cable if the processor will be located away from the protected surface

4. Setup and calibrate the system.

Security planning

With security systems, there is a trade off between a high probability of detection (Pd) and an

acceptable nuisance alarm rate (NAR). It is important to determine the security requirements and

expectations for a FlexPI installation. There are a number of factors, which must be considered

when planning the installation. The primary factors are the value of the assets being protected,

and the required level of security.

For a high-security application where a sophisticated attack is possible, the sensor cable spacing

should be kept at a minimum. This will increase the number of cable passes on the protected

surface, and provide the maximum level of protection. Most break-ins occur at the lower levels of a

wall, or roof. Therefore, using additional cable passes on the lower 2 m (6.5 ft.) of the wall or roof

can provide additional security. For lower security applications, where less sophisticated attacks

are more likely (e.g., a smash through intrusion) fewer cable passes can be used to protect the

same surface area. Figure 3:, Figure 4: and Figure 5: illustrate high, medium and low security

applications.

Another factor is the type of surface. Different types of building materials have different vibration

transmission characteristics. Metallic building materials conduct vibrations quite well. Wood,

plasterboard, cladding and drywall tend to absorb vibrations. Hollow cinder-block walls are more

sensitive than solid block, cement, brick, or stone walls. In addition, masonry and concrete are

more difficult to penetrate than drywall, plaster or wooden building materials.

Note The FlexPI processor is intended for indoor installation. However, it is

possible to install the processor indoors, and use lead-in cable to

connect the processor to sensor cable that is mounted outdoors.

Page 8 FlexPI Product Guide

When attaching the sensor cable to the surface, the type and the spacing of the fasteners are both

extremely important. The fasteners must hold the sensor cable firmly against the surface without

pressing into the jacket. Most of the contact between the cable and the mounting surface occurs at

the fasteners. Therefore, using a fastener every 30 cm (1 ft.) will provide good contact between the

sensor cable and the mounting surface (see Figure 11:, Figure 13: and Figure 14:). Select

fasteners that hold the cable directly against the surface. Do not use fasteners which place a layer

between the cable and the mounting surface. This layer prevents direct contact and acts as an

insulator.

There are a wide variety of commercially available cable fasteners for use on any type of building

material. Even permanent tape can be used to attach the sensor cable. When selecting fasteners,

remember that the outside diameter of the sensor cable is 3.6 mm (0.14 in.) nominal. Choose

fasteners that hold the cable firmly against the protected surface without pressing into the cable

jacket. If you are attaching cable to a stock cage, or fence, use cable ties that are pulled hand-

tight. Do not use mechanical cable tie tools. For added security, you can use steel bar ties or

twisted wire. However, do not overtighten the bar ties or wires.

Installation rules

• Use one processor and sensor cable on one type of building material. Do not use one

processor and sensor cable to protect more than one type of surface.

• The maximum recommended cable spacing is 1.25 m (4 ft.).

• The minimum recommended cable spacing is 30 cm (1 ft.).

• Keep roofs separate from other parts of the installation.

• For roof installation on steel beams, the maximum recommended cable spacing is 1.8 m

(6 ft.).

• On roofs with wooden trusses the cable spacing should match the spacing of the trusses,

typically 61 cm (2 ft.).

• Sensor cable can be installed directly on the underside of a roof’s surface.

• For increased security, use additional cable passes on the lower levels of walls and roofs

(i.e., the first 2 m, 6.6 ft.) which is where most break-ins occur.

• Keep floors separate from other parts of the installation.

• When attaching the sensor cable to a surface area, the cable must be in close contact with the

protected surface.

• FlexPI sensor cable can be installed inside metal conduit. The conduit must be in close

contact with the protected surface (maximum 1 m, 3.3 ft. separation between fasteners). After

cutting the conduit, ensure that there are no burrs or sharp edges that could damage the

sensor cable as it is pulled through.

• If windows are included as part of a protected surface, it is recommended that a security grille

be installed over the windows. The sensor cable that is protecting the surface should then be

installed along the outside edge of each window frame.

• For outdoor surface protection (e.g., fences, walls) install the processor indoors, then use

lead-in cable to connect the processor to the sensor cable at the start of the zone. The

maximum cable run for lead-in cable is 30 m (98 ft.).

Security cage protection

To protect security cages, attach the sensor cable to the security cage using nylon cable ties

spaced 30 cm (1 ft.) apart. The cable spacing depends on the required level of security, with 1 m

(3.3 ft.) spacing recommended. The cable should be attached to the secure side of the cage, and

cable loops should be used at support posts for increased sensitivity.

FlexPI Product Guide Page 9

Wall protection

To protect walls, FlexPI sensor cable is attached directly to the wall. The cable spacing depends

on the required level of security, the building material, and the height of the wall. For areas where

the cable may be subject to damage from vandalism or equipment, the cable can be installed

inside metal conduit, which is attached to the protected surface. The type of cable fasteners used

to attach the cable to the wall also depends on the building material. Cable spacing ranges from a

maximum of 1.25 m (4 ft.) to a minimum of 30 cm (1 ft.) and the cable fasteners should be used

every 30 cm (1 ft.).

Roof protection

Most roofing materials can be protected from inside the building (see Figure 7:). For large

industrial buildings, steel beams are frequently used to support the roof. If the beams are 1.8 m

(6 ft.) apart or less, the cable can be attached to the roof beams. If the spacing between beams is

greater than 1.8 m, attach the cable to the underside of the roof. For wooden trusses, which are

typically 60 cm (2 ft.) apart, the cable should be attached to each truss. This will provide a multiple

pass installation which is often necessary on a wooden surface. Proper calibration is critical for

roof installation to ensure adequate detection of a break-in attempt, while rejecting the noise and

vibration caused by heavy rain.

Floor protection

To protect a floor, you must have access to the underside of the floor. Depending on the type of

flooring, you can either attach the sensor cable to the support structure, or to the floor. As with

other parts of the building, the type of building material dictates the number of cable passes

required.

Embedding sensor cable

With careful planning, the sensor cable can be embedded in walls, floors, or even roofs during

construction. The recommended method is to install metal conduit inside the structure during the

construction phase. When the construction is complete, the sensor cable can be pulled through

the conduit. Using conduit for this type of installation allows the cable to be replaced or repaired if

there is cable damage, or a cable fault. Avoid any sharp bends in the conduit. Before installing the

conduit, remove any burrs or sharp edges that were created when the sections were cut.

Windows and skylights

Windows and skylights can create a vulnerability for intrusion attempts. The recommended

method for window/skylight protection is to install a security grille over the opening, and run sensor

cable completely around and in close proximity to the opening (see Figure 6:). In addition, other

technologies such as glassbreakage detectors and magnetic contacts can be used to increase the

level of security for windows and skylights.

Pipes and data cables

The FlexPI system can be used to protect pipes and data cables (see Figure 8: and Figure 9:). To

protect a pipe, the Flex sensor cable is attached directly to the pipe, typically in a spiral pattern

around the outside of the pipe. Any attempt to drill, cut, or otherwise damage the pipe will trigger

an alarm. Data cables that carry sensitive information are generally installed inside conduit. The

addition of a FlexPI cable to the conduit will provide protection against the penetration of the

conduit in an attempt to access the data cable.

Page 10 FlexPI Product Guide

Installation examples

The following figures illustrate FlexPI installation on security cages, walls, roofs, pipes and inside

conduit.

CAUTION The fasteners used to attach the sensor cable to the mounting surface

must hold the cable firmly against thesurface without pressing into the

jacket or damaging the cable. The fasteners must be appropriate for

the specific type of surface.

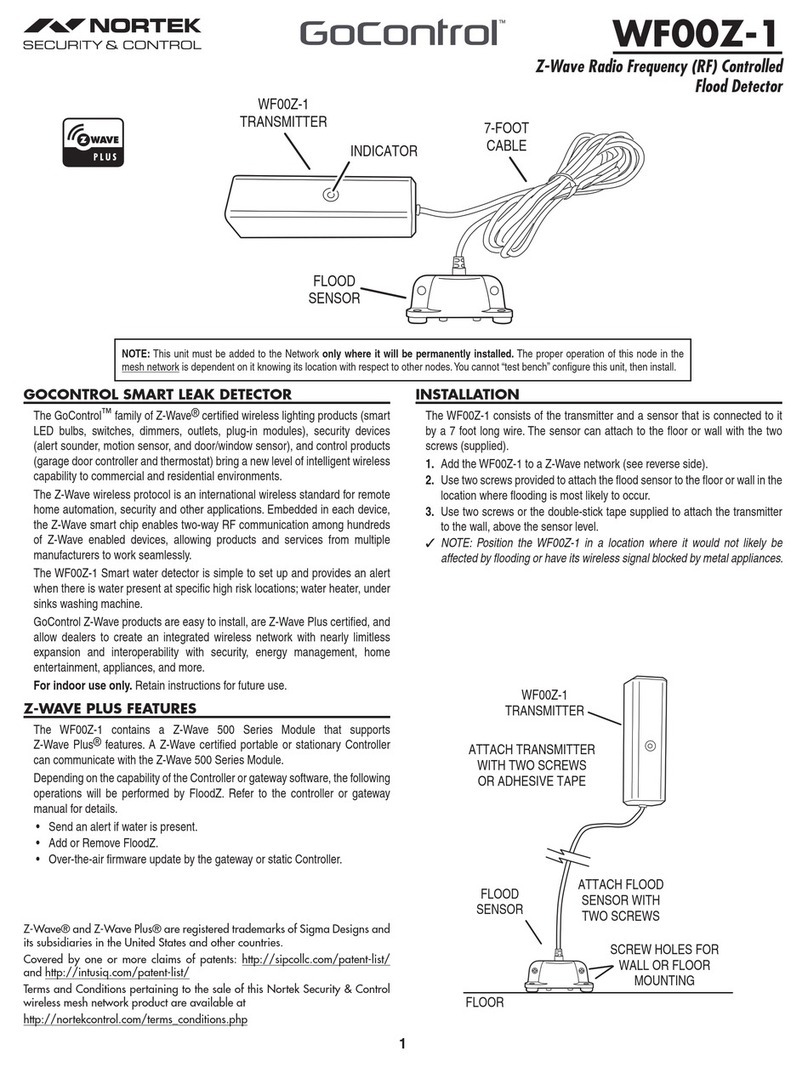

Figure 2: Double pass security cage installation

use cable loops at support

posts for increased sensitivity

double cable pass using 1 m

spacing on 3 m security cage

30cm12in.

recommended cable tie spacing

30 cm (12 in.)

FlexPI Product Guide Page 11

Figure 3: High-security application (triple pass on 8 ft. wall)

Figure 4: Medium-security application (double pass on 8 ft. wall)

Figure 5: Low-security application (single pass on 8 ft. wall)

61 cm (2 ft.)

61 cm (2 ft.)

61 cm (2 ft.)

61 cm (2 ft.)

2.44 m

(8 ft.)

terminator

FlexPI

processor

sensor cable power & data

cable

81 cm (2.7 ft.)

81 cm (2.7 ft.)

81 cm (2.7 ft.)

2.44 m

(8 ft.)

terminator

FlexPI

processor

sensor cable

power & data

cable

1.22 m (4 ft.)

1.22 m (4ft.)

2.44 m

(8 ft.)

terminator FlexPI

processor

sensor cable

power & data

cable

Page 12 FlexPI Product Guide

Figure 6: Wall & windows application

Figure 7: Roof protection

Figure 8: Protecting pipelines

Figure 9: Protecting data cables

Figure 10: Installing sensor cable in conduit

terminator

FlexPI

processor

sensor cable

power & data

cables

sensor cable

around

windows

1.22m

terminator

FlexPI

processor

sensor cable

61cm(2ft.)

(3ft.)

reduced cable spacing

on lower portion of roof

NOTE: Cable installed indoors on

(4ft.)

91cm

the underside of the roof.

sensor cable cable tie

30 - 50 cm

data cable

conduit

sensor cable

metal conduit

fastener

1 m (3.25 ft.) max.

sensor cable

FlexPI Product Guide Page 13

Figure 11: Mounting sensor cable on security cages/fences

Figure 12: Using cable loops for increased sensitivity

Figure 13: Mounting sensor cable on walls/flat surfaces

Figure 14: Installing sensor cable with permanent tape

cable tie

30 cm

sensor cable

12 in.

support post

sensor cable

30 cm

(12 in.)

cable ties

do not allow the

sensor cable to be

pinched between the

post and the cage

If the cage is tightly

secured to the post,

wrap the cable around

the post as illustrated

cable clip

sensor cable

30 cm 12 in.

cable clip

mounting surface

fastener

sensor cable

permanent tape

30 cm

sensor cable

(12 in.) 30 cm

(12 in.)

30 cm

(12 in.)

Page 14 FlexPI Product Guide

Figure 15: Using corner loops

10 - 15 cm

inside corner outside corner

(4 - 6 in.)

corner loop

fastener 10 - 15 cm

(4 - 6 in.)

corner loop

FlexPI Product Guide Page 15

2 Installation

Installing the sensor cable

The number of cable passes required on the mounting surface depends on the height of the

mounting surface, the type of building material, and the required level of security.

• For single cable passes attach the cable horizontally at the half-way height of the mounting

surface (see Figure 5:).

• For double cable passes, space the cable evenly between the bottom and the top of the

mounting surface (e.g., for a 3 m {10 ft.} wall with two cable passes one pass should be at the

1 m {3.3 ft.} level and the second pass should be at the 2 m {6.6 ft.} level) (see Figure 4:).

• For a triple cable pass space the cable evenly between the bottom and the top of the mounting

surface (see Figure 3:).

Cable handling

The FlexPI sensor cable converts vibrations in the mounting surface into electrical signals, which

the cable carries back to the processor for analysis. Any damage to the sensor cable from

mishandling or poor installation practices will have a negative effect on performance. The following

is a list of cable handling Do’s and Don’ts.

• Apply consistent light tension (approximately 2.25 kg, 5 lbs) while mounting the sensor cable.

• Install the sensor cable in metal conduit if the cable is being installed in an area where it may

be prone to damage from vandalism, equipment, or materials (see Figure 10:). DO NOT use

plastic conduit.

• When using cable ties to attach the sensor cable to a security cage, install the ties by hand

and pull them hand-tight until snug (see Figure 11:).

• DO NOT use mechanical tighteners to attach cable ties to a security cage.

• When attaching the sensor cable to a flat mounting surface, use fasteners that hold the cable

firmly against the surface without squeezing or distorting the cable jacket (see Figure 13:).

• DO NOT use a staple gun to attach the sensor cable to a mounting surface.

• DO NOT allow the sensor cable to be pinched between the mounting surface and any object.

• DO NOT bend, twist, or kink the sensor cable.

• DO NOT place objects on the sensor cable or allow anyone to stand or walk on the cable.

• Use cable loops near support structures such as wooden studs, steel beams, posts, etc. as

the support members can have a dampening effect on vibrations (see Figure 12:).

CAUTION Handle the FlexPI sensor cable with care.

Installing the sensor cable

Page 16 FlexPI Product Guide

Installing cable on security cages

Figure 2: shows a double cable pass installation on a 3 m (10 ft.) security cage.

• Use nylon cable ties spaced about 30 cm (12 in.) apart to attach the FlexPI sensor cable to the

security cage.

• Attach the cable ties to the center of each fence link (not at the junctions).

• Pull the cable ties until they are hand tight and the cable is snug to the fence.

• Attach the sensor cable to the secure side of the cage (the side opposite the threat).

• Space the sensor wire evenly on the security cage.

• The recommended separation between cable passes on security cages is 1 m (3.3 ft.).

• Create 30 cm loops at support posts for increased sensitivity.

• To install sensor cable on security cage doors or gates, run the cable from the cage to the door

at the hinged side of the door. Ensure that there is enough slack in the cable to allow the door

to fully open and close. Ensure that the cable cannot be caught and pinched when the door

closes. Run the cable once completely around the door between 15 and 30 cm from the edge

of the door. Run the cable from the door back to the cage at the hinged side of the door.

Continue installing the cable on the security cage. Figure 16: illustrates sensor cable

installation on a security cage door.

Installing cable on walls

The cable spacing depends on the type of building material and the required level of security. The

maximum recommended spacing for any type of wall surface is 1.25 m (4 ft.). The minimum

recommended spacing is 30 cm (1 ft.) (see Figure 3:, Figure 4: and Figure 5:). When attaching the

sensor cable to the mounting surface use fasteners that hold the cable firmly against the surface

and space the fasteners approximately 30 cm apart (see Figure 13: and Figure 14:).

• Begin at the processor location, or if using lead-in cable, at the designated start point of the

zone, and attach the cable to the wall. Leave 0.5 m (20 in.) of sensor cable at the start point, to

make the connection.

• Run the cable along the surface parallel to the floor, using a fastener every 30 cm (1 ft.).

Figure 16: Installing sensor cable on cage doors and gates

use a sheet of rubber to

prevent the cable from being

caught or pinched when

the door opens or closes

install sensor cable along

the top section of the cage

continue the cable run on

the other side of the door

run the sensor cable

around the door app.

30 cm from the edge

run the cable from the cage

to the door on the hinged

side of the door

(if necessary)

Installing the sensor cable

FlexPI Product Guide Page 17

• To continue the cable run around corners, form 10 to 15 cm (4 to 6 in.) cable loops at the

corners (see Figure 15:). Do not make a sharp bend in the cable to go around a corner.

• To double-back the sensor cable for multiple cable pass installations, use two smooth,

rounded 90º turns.

• Cut the sensor cable approximately 15 cm (6 in.) past the specified terminator location. (For

outdoor installation, leave 0.5 m (20 in.) of sensor cable to form a drip loop.

Installing cable on roofs

Install the sensor cable inside the building, on the underside of the roof (see Figure 7:).

• For large industrial buildings with steel beams, install the cable on the beams.

• Space the cable 1.8 m (6 ft.) apart or less.

• If the beams are farther apart, attach the cable to the underside of the roof.

• For wooden trusses, attach the cable to each truss.

• Proper calibration is critical for roof installation to ensure adequate detection of a break-in

attempt, while rejecting the noise and vibration caused by heavy rain.

Installing cable on floors

Attach the cable to the underside of the floor, either directly to the subfloor, or to the support

structure. Base the number of cable passes required, on the type of floor.

Embedding sensor cable in buildings and walls

This type of installation requires the installation of metal conduit inside the walls during the

construction of the building. Senstar recommends hiring an electrical contractor with extensive

experience in conduit installation to embed sensor cables.

Protecting windows and skylights

To use FlexPI to protect windows and skylights, run the cable along the wall or roof to the window

or skylight and then loop the cable once around. The cable should be installed close to the

opening and should be installed only on the same type of surface as the rest of the structure. In

addition, install a security grille over the window/skylight to prevent a quick smash through

intrusion. (see Figure 6:).

Protecting pipes and data cables

To protect pipes, attach the sensor cable directly to the outside of the pipe, in a spiral pattern (use

30 cm, 12 in. spacing). To protect data cables, install the sensor cable inside the conduit with the

data cable (see Figure 8: and Figure 9:).

Installing terminators

Page 18 FlexPI Product Guide

Installing terminators

The FlexPI sensor cable must be properly terminated, to enable processor supervision of the

cable. To terminate the sensor cable, a terminal block is used to install a 1 MΩresistor between the

center conductor and the shield at the end of the cable (away from the processor). Once the

sensor cable is mounted, you can install the terminator. Begin by cutting the cable at the specified

termination point. For outdoor cable installation, cut the cable approximately 0.5 m (20 in.) past the

specified termination point to allow for a drip loop. Create the drip loop by raising the enclosure

15 cm (6 in.) above the sensor cable run (see Figure 19:).

Figure 17: Terminating the sensor cable

12

3

4

78

5

6

Remove 2.5 cm (1 in.) of the outer jacket.

DO NOT nick the braided shield.Carefully, separate the strands of the exposed

braided shield.

Tightly twist the strands into a single conductor, and then

carefully remove 6 mm (0.25 in.) of insulation from the

center conductor. DO NOT nick the center conductor.

Insert the twisted shield into one of the terminals on the

terminal block and tighten the screw. Insert the center

conductor into the adjacent terminal and tighten the screw.

Insert the termination resistor into the opposing two

terminals and tighten the screws.

Line up the terminal block with the center of the enclosure

will fit into the enclosure’s cable guide bars. (*Or use 2

and apply 3 or 4 wraps of electrical tape* where the cable Align the tape over the cable guide bars and press the

terminal block into the gel in the center of the enclosure.

Press the taped section of cable into the cable guide bars.

DO NOT remove the gel in the enclosure.

Snap the enclosure shut, ensuring that both

tabs are locked into the respective slots. Using appropriate fasteners, attach the enclosure to

the mounting surface.

cable ties.)

Splicing cable

FlexPI Product Guide Page 19

Splicing cable

Cable splices are made the same way for sensor cable to sensor cable splices and for lead-in

cable to sensor cable splices. Begin by installing the cables to the point where the splice will be

made. Follow steps 1, 2 and 3 from the termination procedure to prepare the two cables for

splicing (see Figure 17:). For outdoor cable-splices you must create 15 cm (6 in.) drip loops (see

Figure 19:).

Outdoor cable installation

Figure 18: Splice-connecting sensor cable

Figure 19: Creating drip loops for outdoor terminations/splice-connections

7

6

45

8

Insert the 2 twisted shields into 2 opposing terminals, and

tighten the screws. Insert the 2 center conductors into the

2 adjacent, opposing terminals, and tighten the screws.

Ensure that shield meets shield and center conductor

meets center conductor.

Line up the terminal block with the center of the splice

enclosure, and apply 3 or 4 wraps of electrical tape* at each

of the 2 points where the cable will fit into the cable guide bars.

Align the 2 taped sections of cable with the 2 cable guide bars,

and press the terminal block into the center of the gel cavity.

Press the taped sections of cable firmly into the cable guide bars.

Do not remove the gel from the enclosure.

Snap the enclosure shut ensuring that both tabs are locked

into the respective slots.

Attach the enclosure to the protected surface using appropriate

fasteners.

(*Or use 2 cable ties.)

termination splice-connection

15 cm (6 in.)

15 cm (6 in.)

Installing the processor

Page 20 FlexPI Product Guide

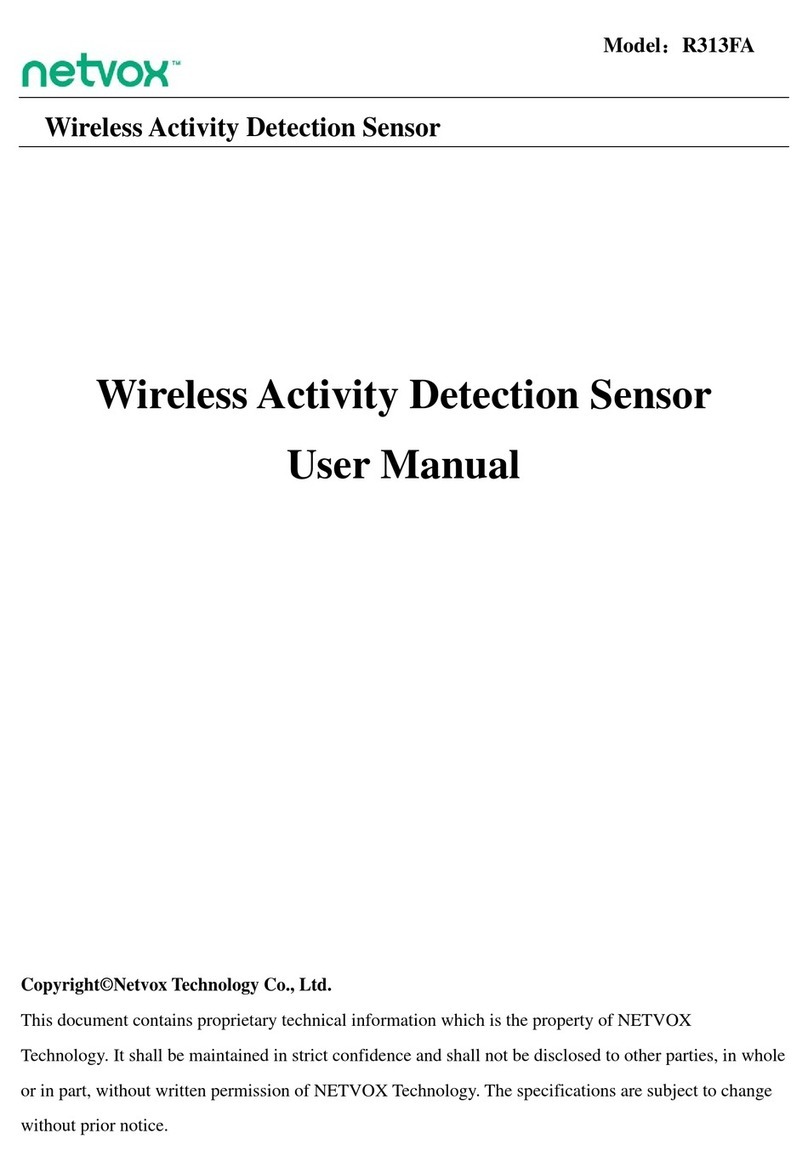

Installing the processor

FlexPI comes in a shielded, indoor-rated, plastic enclosure. The processor can be mounted at the

beginning of the sensor zone by connecting the sensor cable directly to the processor. Alternately,

the processor can be mounted up to 30 m away from the beginning of the zone by connecting

lead-in cable to the processor and splicing the lead-in to the sensor cable. There are two flanges

on the enclosure that include 5 mm (0.375 in.) holes for mounting the enclosure on a flat stable

surface. Figure 20: illustrates the FlexPI processor features and Table 1 includes feature

descriptions. Figure 21: shows a mounted enclosure. The mounting hardware is customer

supplied.

Figure 20: FlexPI processor features

15

14

13

12

16

11

10

9

8

7

6

5

5a

4

4a

3

3a

2

2a

1

1a

Table of contents

Other SENSTAR Security Sensor manuals