SenTech IR-SNIF-MCD Series User manual

SenTech Corporation

5745 Progress Road

Indianapolis, Indiana 46241

888/248-1988

FAX 317/248-2014

INSTALLATION AND OPERATION MANUAL

ENVIRONMENTAL SYSTEM IR-SNIF-MCD

MODELS MCD-1, 4, 8 & 16

ii

APPLICABILITY

Information presented in this manual can be generally applied to all IR-SNIF-MCD refrigerant

monitors. Specific details of programming and operator interface apply to software version

5327K and later versions. To determine the version of an IR-SNIF-MCD, press the “*” key.

This will display momentary screens that provide contact information for SenTech Corporation,

the software version and any options enabled in the monitor. If your monitor has a version that

is older (smaller version number such as 2143), a version specific appendix A, Programming

and Operator Interface, is available. It can be downloaded from the SenTech Corporation

website, www.sentechcorp.com, or directly from SenTech Corporation at 888-248-1988.

iii

Contents

SAFETY PRECAUTIONS and WARNINGS............................................................................ 1

Models MCD-1, 4, 8 & 16 Specifications .................................................................................. 2

INTRODUCTION and OVERVIEW ......................................................................................... 3

Functional Description............................................................................................................ 3

Sensitivity to Refrigerants....................................................................................................... 8

Factory Calibration ................................................................................................................. 8

PPM vs. Leak Rate.................................................................................................................. 8

SYSTEM Block Diagram ........................................................................................................... 9

INSTALLATION ..................................................................................................................... 12

Unpack and Inspect Material ................................................................................................ 12

Identify Location for Monitor, Sample Points and Alarms .................................................. 12

Electrical Power Connection................................................................................................. 13

Electrical Alarm Connections............................................................................................... 14

Other External Connections.................................................................................................. 15

STARTUP and PROGRAMMING........................................................................................... 18

Apply Power ......................................................................................................................... 18

Initial Screens........................................................................................................................ 18

Normal Operation ................................................................................................................. 19

Initial Programming.............................................................................................................. 19

FINAL TESTS .......................................................................................................................... 25

Monitor Sequencing.............................................................................................................. 25

Integration with External Devices ........................................................................................ 25

Response to Refrigerant........................................................................................................ 26

End-to-End System Test ....................................................................................................... 27

Documentation...................................................................................................................... 28

PREVENTIVE MAINTENANCE & REPAIR ........................................................................ 29

Preventive Maintenance........................................................................................................ 29

Commonly Ordered Parts ..................................................................................................... 29

Monitor Repair...................................................................................................................... 29

APPENDIX A: Programming and Operator Interface.............................................................. 30

Summary ............................................................................................................................... 30

Start-up Screens .................................................................................................................... 30

Operational Screens .............................................................................................................. 30

Menu Screens........................................................................................................................ 32

APPENDIX B: SenTech Room Volume Considerations ......................................................... 40

APPENDIX C: Parts List and Wire List................................................................................... 44

TROUBLESHOOTING GUIDE .............................................................................................. 47

SenTech Manufacturer's Limited Warranty.............................................................................. 50

1

SAFETY PRECAUTIONS and WARNINGS

The following general safety precautions and warnings must be observed during all phases of

installation, operation, service and repair of equipment. Failure to comply with these

precautions, given here and elsewhere in the manual violates safety standards of design,

manufacture, and intended use. SenTech Corporation assumes no liability for the customer’s

failure to comply with these requirements.

Definitions of safety symbols used on equipment and in manuals.

AC Voltage Terminal: Indicates areas of equipment where AC line voltages are used

and present a potential risk of electrocution. Areas using line voltages should not be

accessed during operation.

AC-to-DC Power Supply: Indicates AC line voltages are used and present on portions

of the power supply, including the heat sinks. A potential risk of electrocution exists.

Areas using line voltages should not be accessed during operation.

Protective Grounding Terminal: The protective ground is to prevent electric shock in

case of an electrical fault. This symbol indicates that the terminal must be connected to

earth ground before operation of the equipment.

Caution: This sign calls attention to a procedure or practice which if not adhered to

could result in damage or destruction to a part of the product.

Other information and precautions:

Input Power: Power should be supplied through a two-pole circuit breaker located in a

reasonable proximity to the equipment. Ensure that the voltages are correct and an

appropriate ground connection is provided.

Do Not Open the Monitor with Power Applied: Line voltages exist on the terminal board

inside the monitor and on the power supply inside (including the heat sinks). The door to the

monitor and the power supply itself are marked with AC Voltage shock hazard warning labels.

Remove power prior to opening the door.

Installation, Maintenance and Repair: These functions should only be done by qualified

personnel following the instructions outlines in this manual. This is Installation Category III

equipment.

Pollution Degree: This equipment is designed for a Pollution Degree of 1.

Cleaning: This equipment should be cleaned by wiping with a soft clean cloth.

Intended Purpose: This equipment is designed to be used as a continuous refrigerant

monitor. It should not be used for any other purpose.

2

Models MCD-1, 4, 8 & 16 Specifications

Size: 16.5” x 15” x 6.75” (42cm x 38.1cm x 17cm)

Weight: Model MCD-1 - 30.4 lbs. (13.8 kg)

Model MCD-4 - 31.4 lbs. (14.2 kg)

Model MCD-8 - 33.8 lbs. (15.3 kg)

Model MCD-16 - 36.0 lbs. (16.3 kg)

Power: 120 or 240 Volts AC 50/60hz (41 Watts)

Temperature: 32 deg F – 125 deg F (0 deg C – 50 deg C)

Humidity: 0 – 95 % non-condensing

Atmospheric

Pressure:

75-106 Kpa

Equipment rated for indoor use only

Range: 0 – 1000 ppm Standard

Tube Length: 0 – 250 ft (0 – 76 m)

Sample

Areas:

Model MCD-1 - 1 Area

Model MCD-4 - 4 Areas

Model MCD-8 - 8 Areas

Model MCD-16 - 16 Areas

Trip Point: Low Alarm 0 – 1000 ppm

Main Alarm 0 – 1000 ppm

High Alarm 0 – 1000 ppm

Horn Alarm Programmable to Low, Main or High

Leak Wait: Varies from seven (7) seconds to three (3) minutes depending on

refrigerant concentration

Alarm

Output:

Low, Main, High and Horn alarm relays, each with four (4) form C

contacts rated 5 amps maximum

Analog

Output:

0 – 10 volt proportional to 0 – 1000 ppm

4-20 mA (optional)

Computer

Interface:

RS-485 (optional)

3

INTRODUCTION and OVERVIEW

The SenTech Environmental System IR-SNIF-MCD refrigerant monitor provides an early

warning of developing refrigerant leaks. The unit samples ambient air and measures the

amount of halogen based refrigerant gas in the air sample. When the proportion of refrigerant

present exceeds a trip point, the system goes into alarm mode. Should the system assess the

presence of refrigerant as a leak, using SenTech’s “LEAK WAIT” algorithm, the user is notified.

By discovering a leak shortly after it starts, the potential loss can be reduced to ounces of

refrigerant, saving money and helping protect the environment.

Functional Description

The refrigerant monitor is composed of four major functional blocks: Pneumatics, Infrared

Bench, Control Electronics and Power Supply. Refer to figure 1 for an overall block diagram.

The pneumatics pulls sample air or reference air from up to 250 feet and pumps the air

through a filter, to a pressure sensor, through the infrared bench and out the exhaust port of

the monitor. The infrared bench provides an infrared source and measures the presence of

refrigerant based on measured changes in the infrared light. The control electronics switches

the pneumatic valves from one area to reference air and on to the next area, measures and

stores the information from the infrared bench, provides a human machine interface for

programming and provides analog, digital and relay outputs to interface with building systems

and alarms.

IR Bench

Press. Switch

Diaphragm Pump

Relays

Terminal Board

Control Electronics

LOW MAIN HIGH

Valves

Area 1

Reference Air

Power Supply

Valve Driver Board

TB3

Terminal Board

TB6 (opt.)

HORN

Area 5

Area 6

Area 2

Area 4

Area 7

Area 8

Area 3

Exhaust

Figure 1 Overall Block Diagram

4

Pneumatics: Refer to the figure 2 for pneumatics block diagram. Tubing from the areas to be

monitored and from a reference air source (either fresh, outside air, or interior conditioned air

that is free of refrigerants) is connected to the valve manifold. The MCD1 has a single sample

valve and a reference valve, for a total of two valves. The MCD4 has four sample valves, the

MCD8 has eight and the MCD16 has 16, for a total of five, nine and seventeen valves

respectively. The electronics alternates between energizing the Sample air and the Auto zero

air valves. Following an Auto zero cycle, the pneumatics will be switched to the next sample

valve in order. The diaphragm pump draws air from the selected inlet and feeds the air

through a five micron filter, through an orifice restrictor, through the infrared bench and to the

exhaust port located on the lower right side of the unit. The pressure switch monitors the

pressure created by the flow from the pump and the restriction created by the orifice. Should

pressure fall, a flow failure is detected, and signal is sent to the electronics.

IR Bench

Press. Switch

Diaphragm Pump

Valves

Area 1

Reference Air

Area 5

Area 6

Area 2

Area 4

Area 7

Area 8

Area 3

Exhaust

Figure 2 Pneumatics Diagram

5

Infrared Bench: Refer to the figure 3 for Infrared Bench diagram. The infrared bench has an

integrated source circuit with infrared source at one end and an integrated detector circuit with

filter and detector at the other. Presence of refrigerant in the sample air will cause a change in

the output of the detector.

IR Bench

Control Electronics

Figure 3 Infrared Bench

6

Control Electronics: Refer to the figure 4 for control electronics block diagram. The signal

from the infrared bench is analyzed by the control circuit and converted into a digital

measurement in ppm (parts per million). The ppm level is compared to trip points set for Low,

Main and High alarm levels. If the ppm level exceeds the Low alarm threshold, the “Leak Wait”

algorithm is used to determine whether the monitor has experienced a transient exposure, or a

leak truly exists. If the ppm level remains above the Low alarm threshold on completion of leak

wait, the Low alarm relay is energized. If the signal continues to increase, the Main alarm

relay will be energized and ultimately the High alarm relay. Once the system enters Low, Main

or High alarm, it will remain in that mode until the problem is cleared and the system is reset.

IR Bench

Press. Switch

Relays

Terminal Board

Control Electronics

LOW MAIN HIGH

Valves

Area 1

Reference Air

POWER SUPPLY

Valve Driver Board

TB3

Terminal Board

TB4 (opt.)

HORN

Area 5

Area 6

Area 2

Area 4

Area 7

Area 8

Area 3

Figure 4 Control Electronics Diagram

7

Power Supply: Refer to the figure 5 for Power Supply diagram. Power is supplied to the

monitor through terminals 1, 2 and 3 of the terminal board. Line voltage is fed through the fuse

on the left side of the monitor (not shown), and to the diaphragm pump and power supply. The

power supply converts AC line voltage to dc voltage. DC Voltage is fed through the terminal

board to all of the electrical components of the monitor.

Terminal Board

Control Electronics

Power Supply

Figure 5 Power Supply Diagram

8

Sensitivity to Refrigerants

The system is sensitive in varying amounts

to all of the halogen-based refrigerants,

those containing molecules of fluorine,

chlorine or both. As part of the initial setup,

the specific refrigerant to be monitored is

entered into the system. The control

electronics compensates for the differing

sensitivities, resulting in a true ppm reading

for the refrigerant specified.

Factory Calibration

The IR-SNIF-MCD is calibrated at the

factory prior to shipment. The system

maintains accuracy through automatic

rezeroing. Periodically, the system

switches to the fresh air inlet, and

reestablishes a reference signal to which it

compares sample air. This process

eliminates the potential variations caused

by changes that develop in electronics as

components age. If a change in infrared

energy or detection of the infrared energy

develops, that change will be first measured

in the reference signal, then also in the

sample. The ppm level is based on the

ratio of the sample to the reference. This

ratio eliminates the effect of any variations,

and eliminates the need to periodically

calibrate a monitor in the field.

PPM vs. Leak Rate

The relationship between the actual amount

of product lost and the resulting ppm level

refrigerant in the air is complex. There is

no direct relationship between the amount

of refrigerant leaking and the concentration

being measured. The size of the room, the

location of the pick up point, the location of

the leak and airflow in the room will all

affect the actual concentration at the inlet.

However, by judicious location of the inlets

(see installation section) and maintaining

the alarm set points at a level not too far

above ambient, leaks should be detected

substantially before they otherwise would

be noticed. See Appendix B for a detailed

discussion of room volume considerations.

This appendix will help to provide a

correlation between pounds of refrigerant

lost over a given period to the ppm level

measured. This correlation can be

developed for a specific application.

9

SYSTEM Block Diagram

Item Part

Number

Description Comments

Monitor Model:

IR-SNIF-MCD1

IR-SNIF-MCD4

IR-SNIF-MCD8

IR-SNIF-MCD16

MCD1

MCD4

MCD8

MCD16

Sample Area

Connections:

ACC 030

410144

410357

1 to 16 sample tubes, routed to each

sample area

1 /4” OD 1/8” ID, FRPE Tube, 250 ft roll

Coarse Tube Filter

Barb Fitting for FRPE Tube

Terminate tube 12”-18” above floor

Purchased separately from monitor, or customer supplied

Included inside monitor

Included inside monitor

Reference Air

Connection:

ACC 030

410144

410357

Reference air for ‘Auto Zero’

1 /4” OD 1/8” ID, FRPE Tube, 250 ft roll

Coarse Tube Filter

Barb Fitting for FRPE Tube

Terminate tube in area free of refrigerants and interfering

chemicals (12”-18” from ceiling if indoors)

Purchased separately from monitor, or customer supplied

Included inside monitor

Included inside monitor

Power

Connection:

Field Wiring

120 or 240 VAC

50/60 hz

12 or 14 AWG

Voltage jumper selected inside monitor

Provided by customer, Install in accordance with NEC and

local codes

Valves

Area 1

Reference Air

Area 5

Area 6

Area 2

Area 4

Area 7

Area 8

Area 3

Exhaust

Remote

Link

Modem

Monitor

Horn

Strobe

Combo

From Circuit Breaker

To Computer

Control

Comm

To Phone Line

To Fan Control

Analog To BMS

Binary To BMS

Binary To BMS

(AC power)

(switched AC)

(switched AC)

(switched AC)

(switched AC or control voltage)

(rs-485)

(dry contacts)

(optional individual alarm relays - control voltage only)

(0-10 vdc or optional 4-20mA)

(cat-3) (rs-232)

(rs-232)

(sample tube and filter)

(sample tube and filter)

(sample tube and filter)

10

Alarm

Connections:

ACC 020

ACC 026

ACC 025

Field Wiring

Combination Horn/Strobe Alarm

120 vac alarm, surface mounted using

included 4x4 box, or flush mounted

using customer provided 4x4 box

installed in finished wall, horn and

strobe portions of alarm can be

controlled by separate relays, or

common relay, multiple tones available

(switch selectable inside alarm)

Strobe Alarm

120 vac alarm, surface mounted using

included 4x4 box, or flush mounted

using customer provided 4x4 box

installed in finished wall

Horn Alarm

120 vac alarm (240 vac version

available), surface mounted

12 or 14 AWG

Optional - Purchased separately from monitor, Install in

mechanical room so that it can be seen and heard from all

areas, control Strobe portion with LOW alarm relay,

control Horn portion with HORN relay

Optional - Purchased separately from monitor, Install

outside mechanical room so that it can be seen prior to

entrance into area, Control with LOW alarm relay

Optional - Purchased separately from monitor, Install in

mechanical room so that it can be heard from all areas

Provided by customer, Install in accordance with NEC and

local codes, Provide power for alarms from same circuit

providing power to monitor, use alarm relays to switch line

voltage

Exhaust Fan

Control:

Field Wiring

12 or 14 AWG (line voltage control) or

18 or 22 AWG (low voltage control)

Provided by customer, Install in accordance with NEC and

local codes, use HIGH alarm relay to switch line voltage

for contactor, or to switch control voltage for exhaust fan

control

BMS Control

Connections:

Analog:

Binary:

---

OP 001

OP 001(2

nd

)

Field Wiring

---

OP 002

Field Wiring

Analog 1 output, 0-10 volts, provides

measurement of current area being

monitored

Analog 1 output, 4-20 mA, provides

measurement of current area being

monitored

Analog 2 output, 0-10 volts and 4-20

mA, provides current area being

measured

18 or 22 AWG

LOW, MAIN and HIGH alarm relays,

each with 4 sets of dry contacts

Individual Zone Alarm Output, provides

8 relays, each with 1 set of NO/NC

contacts, for control voltages only (24

vac or vdc only)

18 or 22 AWG

Standard feature of monitor, Optional connection – useful

in measuring trends, DO NOT use to determine alarm

conditions, to do so defeats key features of the refrigerant

monitor

Optional feature of monitor, used for control systems that

prefer 4-20 mA input, DO NOT tie control system loop

power to monitor 24 volts

Optional feature of monitor, Order qty 2 OP 001 to have

analog 2 installed, Not normally used, Typically most

sample areas are in the same room

Provided by customer, Install in accordance with NEC and

local codes

Standard feature of monitor, NO and NC contacts are

available for BMS connection

Optional feature of monitor, provides indication of which

area is in alarm, can be selected for different alarm

configurations, refer to separate Individual Zone Alarm

Output Manual for details

Provided by customer, Install in accordance with NEC and

local codes

11

Remote Digital

Interface

Connections:

ACC 065

Field Wiring

ACC 070

Field Wiring

ACC 071

Field Wiring

Remote Control Panel Interface, full

function remote control for monitor

14 or 16 AWG (Line voltage supply to

transformer)

18 or 22 AWG (24 VAC from

transformer to Remote)

18 or 22 AWG (twisted shielded wire for

rs-485 connection to monitor)

COMM LINK, PC to refrigerant monitor

interface

Wall outlet transformer (Provides 24

VAC to COMM LINK)

Cable and Adapters (rs-232 interface

from COMM LINK to PC)

18 or 22 AWG

(twisted shielded wire for rs-485

connection to monitor)

MODEM, Interface for Remote PC

Connection to COMM LINK

Wall outlet transformer (Provides 24

VAC to Modem)

Cable and Adapters (rs-232 interface

from Modem to COMM LINK)

Optional – Purchased separately from monitor, provides

complete remote interface for all monitors in building via

rs-485 interface (subject to cable length limitations of rs-

485), powered by 24 vac transformer

Provided by customer, Install in accordance with NEC and

local codes

Optional – Purchased separately from monitor, provides

complete remote interface from PC to all monitors in

building via rs-485 interface (subject to cable length

limitations of rs-485), used with Windows based software

provided with COMM LINK

Provided with COMM LINK, if multiple devices are

powered by the same transformer, polarity must be

maintained the same for all devices

Provided with COMM LINK

Provided by customer, Install in accordance with NEC and

local codes

Optional – Purchased separately from monitor, provides

connection via phone line from PC to COMM LINK, allows

off premises remote PC to dial in to all monitors in building

via rs-485 interface (subject to cable length limitations of

rs-485), Requires COMM LINK and Windows based

software provided with COMM LINK

Provided with ACC 071, if multiple devices are powered

by the same transformer, polarity must be maintained the

same for all devices

Provided with ACC 071

12

INSTALLATION

Unpack and Inspect Material

IR-SNIF-MCD Package: The IR-SNIF-

MCD package contains the following

material:

1. IR-SNIF-MCD Refrigerant Monitor

2. Installation and Operation Manual

3. Hose barb fittings and coarse tube

end filters (one hose barb and filter

for each sample area and one each

for fresh air reference – two, five,

nine or seventeen of each are

provided)

4. CTS/Warranty form to be completed

and returned to Sentech

Optional Purchases: The IR-SNIF-MCD

package may also contain the following

material:

1. Plastic FRPE tubing, ¼ inch OD for

sample tube

2. Combination Horn/Strobe alarm

3. Horn alarm

4. Strobe alarm

Other Required Material: The following

material is required but not provided by

SenTech:

1. Primary power wiring

2. Wiring for connection to alarm

devices or other building systems

3. Relay contactors for building system

loads greater than 5 amps

4. ¼ inch tubing (if not purchased from

SenTech, or if copper tube is

required by local code)

If any material is missing, or appears to be

damaged, contact Sentech Corporation for

assistance.

Identify Location for Monitor, Sample

Points and Alarms

Monitor Location: ASHRAE-15 specifies

that the refrigerant monitor is to be located

in the mechanical room. There are two

interpretations of this: the unit itself is to be

installed in the mechanical room; or the

sample point is to be located in the

mechanical room. Because the IR-SNIF-

MCD is an active air draw monitor, it can be

installed nearly anywhere in the vicinity of

the area to be monitored.

If local codes allow, the monitor can be

installed at the entrance to the mechanical

room, with the sample tube routed into the

mechanical room and the fresh air

reference routed to an appropriate location.

If the monitor is located outside the

mechanical room, a fitting should be

installed and an exhaust tube routed either

into mechanical room, or outdoors. If it is

routed outdoors, it must not be located near

the fresh air reference.

If local codes require the monitor to be

physically installed in the mechanical room,

it should be installed in the best location for

ease of use and routing of sample and

fresh air tubing. If the monitor is installed in

the same room as the sample pick-up-point,

no exhaust tube is required.

Caution: Liquid can affect the

performance of the monitor. Pick-

up-points must be protected from

exposure to water and other

liquids.

Sample Location: Since the monitor

measures the concentration of refrigerant in

13

the air, the pick up point should be mounted

where it is most likely to sense leaking

refrigerant. The criteria to consider in

selecting the sample pick up point location

include:

1. As close to the area of potential

leaks as possible. On the

‘downstream’ side of the air flow

pattern in the room.

2. Since refrigerants are typically

heavier than air, the pick up tube

should be terminated approximately

18 inches above the floor.

3. The sample tube should be located

such that it will require no more than

250 feet (75 m) of tubing.

Reference Location: Since the monitor

compares a fresh air reference to the

sample, care must be taken in choosing a

location. The fresh air reference tube

should be routed to a location that will be

free of refrigerant. This can be, but does

not necessarily have to be, located

outdoors. When routing the fresh air

reference, the following criteria should be

used:

1. Since refrigerants are typically

heavier than air, the fresh air

reference should be terminated

above any possible source of

refrigerant.

2. The tube end filter must be located

such that it can be inspected as part

of the recommended quarterly

preventive maintenance.

3. If located indoors, the fresh air

reference should be located in an

area free of refrigerants, and

located approximately 18 inches

from the ceiling.

4. If located outdoors, the tube end

filter must be protected from the

elements. Water, ice or insects can

partially obstruct the tube end filter

and change the reference signal.

5. If located outdoors, the tube end

filters must not be located near

exterior HVAC equipment, or any

potential source of refrigerant.

Exhaust Location: The exhaust tube is

required only if the monitor is not located in

the same room as the sample pick-up-point.

If an exhaust tube is installed, it should be

run to the room being monitored, or to an

exterior location. An exhaust tube must not

be terminated near the fresh air reference.

Alarm Location(s): A combination

horn/strobe alarm is recommended for a

mechanical room. The alarm should be

located inside the room such that it can be

seen and heard from any area of the room.

Additionally, a strobe alarm can be installed

at each entrance to the room to alert the

user of an alarm prior to entry to the room

itself. Note that the IR-SNIF-MCD has

visual indicators of its alarm status. If the

monitor is installed at the entrance to the

room, a strobe should not also be required.

Electrical Power Connection

Caution: All installation wiring,

service and maintenance should

be performed by a qualified

electrician in accordance with

national and local codes.

TB-1 Power Wiring: The IR-SNIF-MCD

monitor is designed to operate on only 110

vac or 240 vac, but not both. It will operate

on either 50 or 60 hz. The power supply in

the monitor automatically detects the supply

voltage. The diaphragm pump is designed

to operate only on 110-120 vac or on 220-

14

240 vac. Refer to figure 6 for a diagram of

the TB1 terminal board.

Caution: Verify that the monitor is

designed for the appropriate line

voltage. Connection of the

incorrect voltage will damage the

unit.

Figure 6.

Connect primary power to TB1 as follows:

1. Connect Earth Ground to TB1-1

2. Connect AC Line to TB1-2

3. Connect AC Neutral or Common to

TB1-3

It is strongly recommended that power be

supplied from a two-pole circuit breaker,

located in reasonable proximity to the

system. Power MUST NOT be supplied by

plugging into a wall socket. The unit is a

continuous monitor, and as a continuous

monitor should be provided dedicated,

permanent power. If a wall socket is used,

there is a risk that the unit will inadvertently

be unplugged, putting it off-line.

Electrical Alarm Connections

Relay Connections: The IR-SNIF-MCD

monitor alarm relay sockets have four sets

of NO/NC dry contacts. Refer to figure 7 for

a diagram of the relay socket.

Figure 7.

The terminals are grouped as follows:

Terminal 9 = Common

Terminal 1 = NC

Terminal 5 = NO

Terminal 10 = Common

Terminal 2 = NC

Terminal 6 = NO

Terminal 11 = Common

Terminal 3 = NC

Terminal 7 = NO

Terminal 12 = Common

Terminal 4 = NC

Terminal 8 = NO

Caution: Ensure that external

relay connections do not touch

relay control terminals 13 and 14.

A short circuit from the alarm

wiring to the relay control wiring

could damage the monitor, the

alarms or both.

TB2 Relay Interface: One set of contacts

from each relay is wired to TB2 terminal

board to allow easier connection of field

wiring. The normally open contact, and

common contact of each relay is wired to

15

TB2 to provide a switch closure for external

control of alarms. Refer to figure 8 for a

diagram of the terminal board.

Figure 8.

Alarm-to-Relay Connection: The typical

Alarm connection uses the common

terminal and normally open (NO) terminal to

switch AC line voltage to the strobe alarm,

horn alarm or combination horn strobe.

Unless specified otherwise, SenTech

Corporation recommends the following

connections for alarms:

1. Strobe Alarm, or Strobe portion of

Combination Horn/Strobe connected

through LOW RELAY, terminals 1

and 2 on TB2.

2. Horn Alarm, or Horn portion of

Combination Horn/Strobe connected

through HORN RELAY, terminals 7

and 8 on TB2.

Caution: Ensure that external

relay connections do not touch

relay control terminals 13 and 14.

A short circuit from the exhaust

fan wiring to the relay control

wiring could damage the monitor,

the alarms or both.

Fan-to-Relay Connection: The IR-SNIF-

MCD monitor alarm relay can support a

load of up to 5 amps at line voltage. The

typical high-speed exhaust fan will have a

startup current in excess of the relay rated

amp capacity. A pilot relay or contactor will

normally be required to energize an

exhaust fan. Unless specified otherwise,

SenTech Corporation recommends the

following connections for exhaust fans:

1. Fan, pilot relay or contactor

connected through HIGH RELAY,

terminals 5 and 6 on TB2.

BMS-to-Relay Connection: The IR-SNIF-

MCD monitor alarm relay can provide alarm

indications to the typical building

management system (BMS) for Low, Main

and High alarm levels. This connection is

normally accomplished by switching a

control voltage through the normally open

(NO) contacts of the respective relay.

Unless specified otherwise, SenTech

Corporation recommends the following

relay connections for building management

systems:

1. BMS discrete input connected

through LOW, MAIN and/or HIGH

RELAYS, terminals 7 and 11.

Other External Connections

TB3 User Interface: Terminal board TB3

The IR-SNIF-1,2,3 is designed to provide

two standard 0-10 volt analog outputs or

two optional 4-20 mA analog outputs, and

external reset input and optional rs-485

interface for use with ACC 070 SenTech

COMM LINK PC to Refrigerant Monitor

Interface, or ACC 065 SenTech Remote

Control Panel Interface. Refer to figure 9

for a diagram of TB3 terminal board.

16

Figure 9.

0–10 Volt Analog Outputs: The IR-SNIF-

MCD monitor provides two 0–10 volt analog

outputs. Analog 1 provides a signal

proportional to 0-1000 ppm indicating the

current ppm level. Analog 2 provides a

signal proportional to the area being

measured, based on 0-10 volts proportional

to 0 to 32 areas. For simple installations

this signal will not normally be used. For

applications where the IR-SNIF-MCD is

installed inside a mechanical room, the

analog 1 signal can be used to drive an

optional remote analog display at the

entrance to the room. This signal could be

used to provide an analog input to building

management systems for remote

monitoring of the ppm level and for trending

of levels. This signal should NOT be used

as a replacement for discrete alarm relay

connections to a BMS. Analog output

connections are as follows:

1. Use twisted pair wire for analog 1

connection, or four conductor twisted

wire for both analog 1 and analog 2.

Typical low voltage solid conductor

wire is suitable for this signal.

Shielded cable is preferred, but not

always required.

2. Route twisted pair wire into the

monitor and along the wire harness

from the back-plate to the TB3 on

the back-plate. Secure the twisted

pair periodically to the wire harness

using tie wraps.

3. Connect the appropriate wires to

TB3-1, analog 1 plus, and TB3-3,

reference ground.

4. Connect the appropriate wires to

TB3-2, analog 2 plus, and TB3-3,

reference ground.

4–20 mA Optional Analog Outputs: The

IR-SNIF-MCD monitor provides a optional

4–20 mA analog outputs in place of the

standard 0-10 volt analog outputs. To

identify whether a monitor has 4-20 mA

analog output installed, examine the control

board installed on the door of the monitor.

Locate the chip sockets labeled U13 and

U14. U13 and U14 are located in the

center of the board, approximately 3.5

inches and 2 inches from the bottom of the

board. If the monitor is configured for the

standard 0-10 volt analog outputs, the

sockets will be empty. If configured for 4-

20 mA outputs, the sockets will have 4-20

mA drive chips installed. Connection to the

4-20 mA outputs is the same as for 0-10

volt outputs.

RS-485 Optional Serial Output: The IR-

SNIF-MCD monitor provides an optional

RS-485 interface for use with ACC 070

SenTech COMM LINK PC to Refrigerant

Monitor Interface, or ACC 065 SenTech

Remote Control Panel Interface.

This interface provides the ability to display

the refrigerant levels in each area and

modify setpoints via a pc based interface.

Used in conjunction with the ACC 070

COMM LINK, the interface allows for

complete remote monitoring of multiple

refrigerant monitors in the same facility.

This interface also provides the ability to

display the refrigerant levels in each area

and modify setpoints via a digital remote

17

control interface. Used in conjunction with

the ACC 065 Remote Control Panel

Interface, the RS-485 interface allows for

complete remote control and monitoring of

multiple refrigerant monitors in the same

facility.

RS-485 digital connections are as follows:

1. Use twisted wire for RS-485

connection, either twisted triple wire,

or four conductor twisted wire.

Shielded cable is preferred, but not

always required.

2. Route twisted pair wire into the

monitor and along the wire harness

from the back-plate to the TB3 on

the back-plate. Secure the twisted

wire periodically to the wire harness

using tie wraps.

3. Connect the transmit conductor to

TB3-6.

4. Connect the receive conductor to

TB3-8.

5. If twisted triple wire is used, connect

the remaining wire to TB3-7,

reference or shield ground.

6. If two twisted pairs are used, connect

one conductor from each pair to

TB3-7, reference ground or shield.

Custom Control Inputs/Outputs: The IR-

SNIF-MCD monitor has the capability to be

programmed for additional optional inputs

or outputs. The control circuit in the

monitor is versatile and can accommodate

additional analog or discrete measurement

and control signals. This circuit also has

the capability to provide additional discrete

control signals. Please contact SenTech

Corporation technical support to determine

whether specific requirements can be

provided.

This manual suits for next models

4

Table of contents

Other SenTech Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Diestro

Diestro 103APV4R Operator's and service manual

Perfect Prime

Perfect Prime AR1890 instruction manual

LOVATO ELECTRIC

LOVATO ELECTRIC EXP10 01 instruction manual

TX Testing Instruments

TX Testing Instruments ED-400 user manual

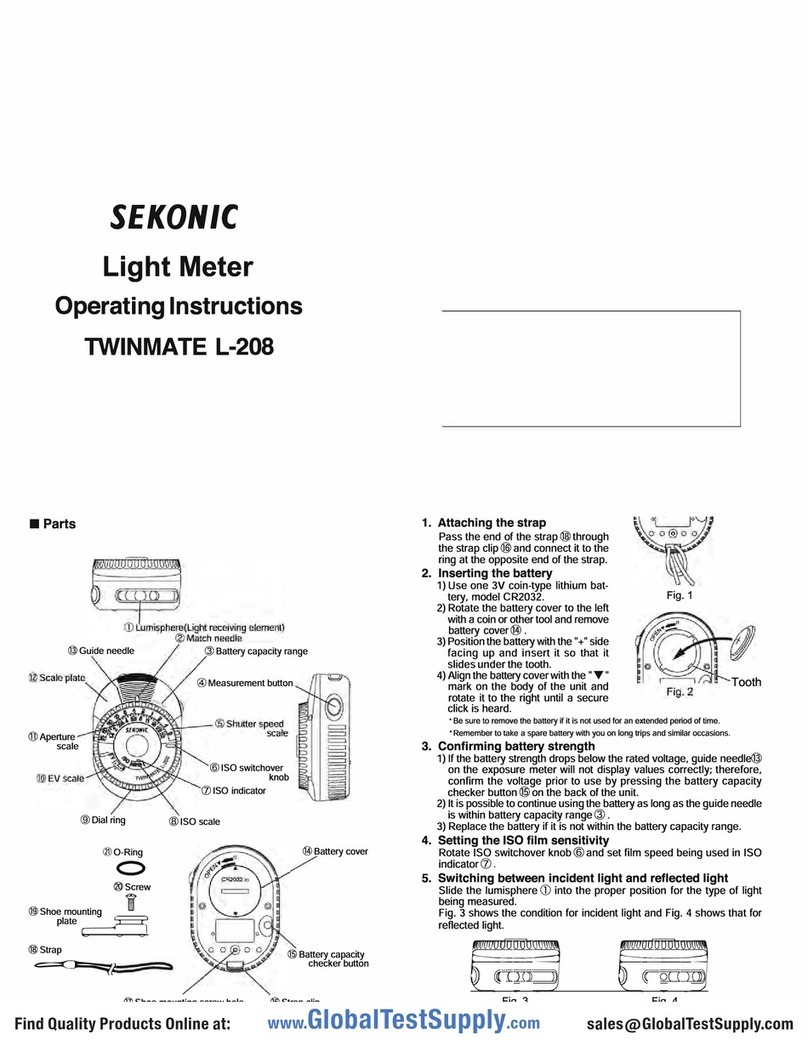

Sekonic

Sekonic TWINMATE L-208 operating instructions

Victor

Victor 4000 manual