senva HD User manual

INSTALLATION INSTRUCTIONS

senvainc.com 1-866-660-8864 (F)1-503-296-2529 9290 SW Nimbus Ave. Beaverton Oregon 97008

HD, Duct Mount

RH and RH/T Transmitters

PRODUCT APPLICATION LIMITATION:

Senva products are not designed for life or safety applications. Senva products

are not intended for use in critical applications such as nuclear facilities, human

implantable device or life support. Senva is not liable, in whole or in part, for

any claims or damages arising from such uses.

INSTALLATION

1. Drill a 3/4” hole in duct. Install sensor using gasket and

screws provided. The pickup tube will ensure adequate air ow

regardless of air ow direction.

2. If installing with a conduit adapter, remove and replace the

factory-installed cable gland.

3. Select output type using “OUTPUT SELECT” switch (not

applicable for thermistors.)

4. Wire sensor as appropriate for the selected output type.

5. Temperature transmitter models only: Select temperature

output range using “TEMP SELECT” jumper. Not applicable to

thermistors.

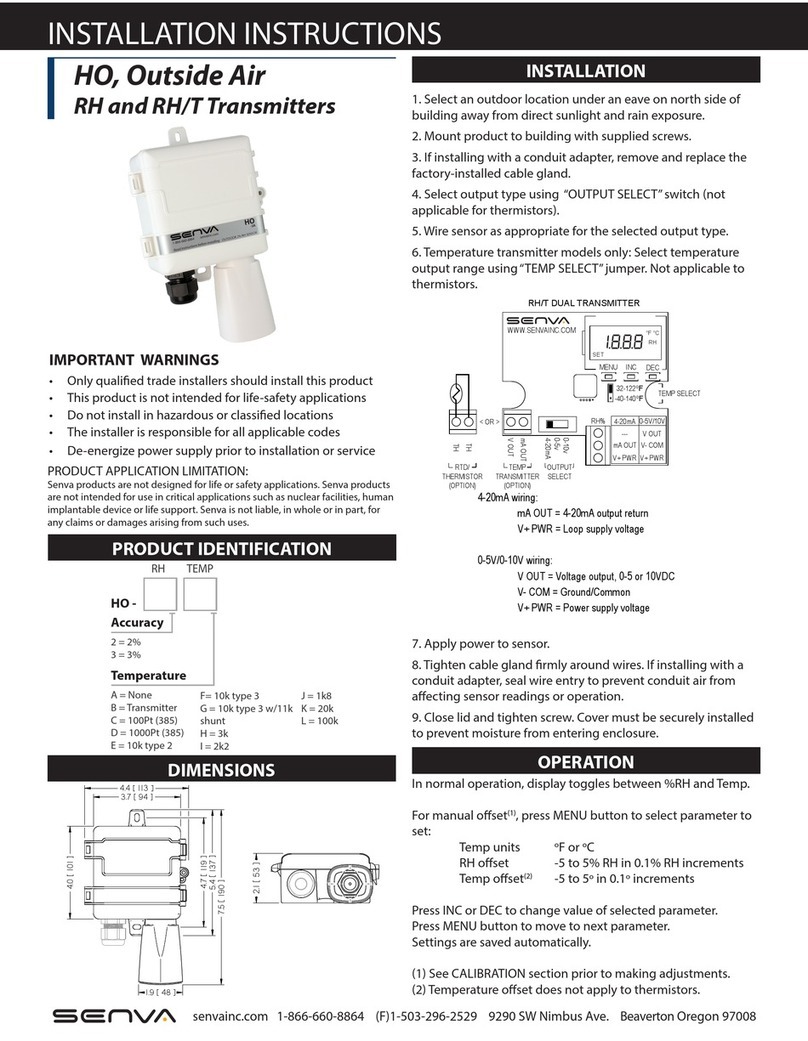

4-20mA wiring:

mA OUT = 4-20mA output return

V+ PWR = Loop supply voltage

0-5V/0-10V wiring:

V OUT = Voltage output, 0-5 or 10VDC

V- COM = Ground/Common

V+ PWR = Power supply voltage

MENU INC DEC

RH

OF OC

SET

V+ PWR

mA OUT

4-20mA 0-5V/10V

---

V+ PWR

V- COM

V OUT

RH%

TEMP

V OUT

mA OUT

0-10v

0-5v

4-20mA

32-122OF

-40-140OF

RH/T DUAL TRANSMITTER

WWW.SENVAINC.COM

TRANSMITTER

(OPTION)

RTD/

THERMISTOR

(OPTION)

TH

TH

< OR >

OUTPUT

SELECT

TEMP SELECT

6. Apply power to sensor.

7. Tighten cable gland rmly around wires. If installing with a

conduit adapter, seal wire entry to prevent conduit air from

aecting sensor readings or operation.

8. Close lid and tighten screw. Cover must be securely installed

to prevent moisture from entering enclosure.

IMPORTANT WARNINGS

• Only qualied trade installers should install this product

• This product is not intended for life-safety applications

• Do not install in hazardous or classied locations

• The installer is responsible for all applicable codes

• De-energize power supply prior to installation or service

DIMENSIONS OPERATION

In normal operation, display toggles between %RH and Temp.

For manual oset(1), press MENU button to select parameter to

set:

Temp units oF or oC

RH oset -5 to 5% RH in 0.1% RH increments

Temp oset(2) -5 to 5oin 0.1oincrements

Press INC or DEC to change value of selected parameter.

Press MENU button to move to next parameter.

Settings are saved automatically.

(1) See CALIBRATION section prior to making adjustments.

(2) Temperature oset does not apply to thermistors.

DRAWN

CHECKED

ENG APPR

MGR APPR

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

ANGLES ±X.X°

2 PL ±X.XX 3 PL ±X.XXX

NAME

daniel.engel

DATE

02/17/17

Solid Edge

TITLE

SIZE

DDWG NO REV

FILE NAME: ProbeAssembly-DUCT.dft

SCALE: WEIGHT: SHEET 1 OF 1

REVISION HISTORY

REV DESCRIPTION DATE APPROVED

4.0 101

2.1 53

4.7 119

5.4 137

8.9 226

3.7 94

4.4 113

RH TEMP

HD -

Accuracy

2 = 2%

3 = 3%

Temperature

A = None

B = Transmitter

C = 100Pt (385)

D = 1000Pt (385)

E = 10k type 2

PRODUCT IDENTIFICATION

F= 10k type 3

G = 10k type 3 w/11k

shunt

H = 3k

I = 2k2

J = 1k8

K = 20k

L = 100k

DRAWN

CHECKED

ENG APPR

MGR APPR

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

ANGLES ±X.X°

2 PL ±X.XX 3 PL ±X.XXX

NAME

daniel.engel

DATE

02/17/17

Solid Edge

TITLE

SIZE

DDWG NO REV

FILE NAME: ProbeAssembly-DUCT.dft

SCALE: WEIGHT: SHEET 1 OF 1

REVISION HISTORY

REV DESCRIPTION DATE APPROVED

4.0 101

2.1 53

4.7 119

5.4 137

8.9 226

3.7 94

4.4 113

Units: in [mm]

CALIBRATION

Senva RH sensors are factory calibrated to NIST traceable

standards. No eld calibration is necessary or recommended.

However, to facilitate compliance with commissioning

requirements eld calibration osets are allowed.

1. Locate calibration instrument and sensor in close proximity

to each other in a controlled environment free of drafts, people,

and equipment to reduce inuence on RH and temperature.

2. Allow both readings to stabilize (10-30 minutes). Compare

reading of sensor to calibration instrument, and calculate

dierence.

3. Refer to OPERATION section to change osets as needed.

Setting an oset of zero restores factory calibration.

SPECIFICATIONS

TROUBLESHOOTING

Power supply 3-wire voltage mode (0-5V/10V)

2-wire current mode (4-20mA)

12-30VDC/24VAC (1), 15mA max.

12-30VDC, 30mA max.

Outputs RH and Temperature (option) 3-wire 0-5V/10V(4) or 2-wire 4-20mA

Output scaling RH 0-100%RH

Temp. transmitter (jumper selectable) 32~122oF (0~50oC) or -40~140 oF (-40~60oC)

Thermistor/RTD options See ordering table

Media lter PBT with water vapor-permeable membrane

Relative Humidity

Accuracy 2% models: ±2% over 10 to 90% range

3% models: ±3% over 20 to 80% range

Resolution 0.05%RH

Hysteresis ±1%RH

Non-linearity Factory linearized <1%RH

Temperature coecient Fully compensated by on-board sensor

Response time (2) 30s

Output update rate 2s

Operating range 0 to 100%RH (non-condensing)

Long term drift <0.5%RH per year

Operating conditions (3) -4 to 140oF (-20 to 60oC) @ RH >90%

-4 to 158oF (-20 to 70oC) @ RH = 50%

Temperature (Transmitter)

Accuracy (-20 to 70oC range) 2% models: < ±1oC; 0.5oC typ@25oC

3% models: < ±2oC; 0.5oC typ@25oC

Resolution 0.01oC

Repeatability ± 0.1oC

Response time (2) 30s

Output update rate 2s

Operating range -40 to 158oF (-40 to 70oC)

Enclosure Materials ABS/Polycarbonate

Dimensions 4.0”h x 4.4”w x 2.1”d (+6.8” probe)

(1) One side of transformer secondary is connected to signal common. Dedicated transformer is recommended.

(2) Time for reaching 63% of reading at 25oC and 1 m/s airow.

(3) Long term exposures to conditions outside normal range or high humidity may temporarily oset the RH reading (+3%RH after 60 hours).

(4) 15-30VDC/24VAC power supply voltage required for 10 volt output.

Symptom Solution

No output Check wiring. Ensure power

supply meets requirements.

Temp or RH reading

error

Verify control panel software is

congured for correct output

scaling.

Verify accuracy of test instrument.

Observe installation and

calibration guidelines.

Verify unit is securely installed on

duct without excessive air leakage.

Oset calibration only if necessary.

Sensor damage,

contamination, or

long-term drift

Replace sensor element. Consult

factory for ordering information.

Revised 3/21/2017 Document #152-0080-0B

This manual suits for next models

2

Other senva Transmitter manuals

Popular Transmitter manuals by other brands

Geo

Geo Web Pack quick start guide

Inovonics

Inovonics EchoStream EN1210W installation instructions

IKONNIK

IKONNIK KA-6 quick start guide

Rohde & Schwarz

Rohde & Schwarz SR8000 Series System manual

Audio Technica

Audio Technica UniPak ATW-T93 Installation and operation

NIVELCO

NIVELCO EasyTREK SCA-300 Series Programming manual