Service Manual

Integra E-Z Oxygen Concentrators

Chart SeQual Technologies Inc. Page 2 of 34 P/N 2917

TABLE OF CONTENTS

1. INTRODUCTION..........................................................................................................................................................3

1.1. Explanation of Terms..........................................................................................................................................3

1.2. Definitions............................................................................................................................................................3

1.3. Introduction to the ATF ......................................................................................................................................3

1.4. Basic Mechanical Layout....................................................................................................................................5

1.5. Theory of Operation ............................................................................................................................................5

2. SET-UP AND OPERATION.........................................................................................................................................8

2.1. The proper location..............................................................................................................................................8

2.2. Air intake filter.....................................................................................................................................................8

2.3. Control Panel Display..........................................................................................................................................8

2.4. Plug the unit in. ...................................................................................................................................................8

2.5. Starting the Integra E-Z......................................................................................................................................9

2.6. Service Mode......................................................................................................................................................10

3. MAINTENANCE ...........................................................................................................................................................9

3.1. Cleaning air intake filter ...................................................................................................................................11

3.2. Scheduled Preventive Maintenance..................................................................................................................12

4. TEST PROCEDURES ................................................................................................................................................. 13

4.1. Unit Test Procedure - Preferred Method ..........................................................................................................13

4.2. Unit Test Procedure-Alternate Method.............................................................................................................14

4.3. Alarm Verification Test.....................................................................................................................................14

5. TROUBLESHOOTING............................................................................................................................................... 15

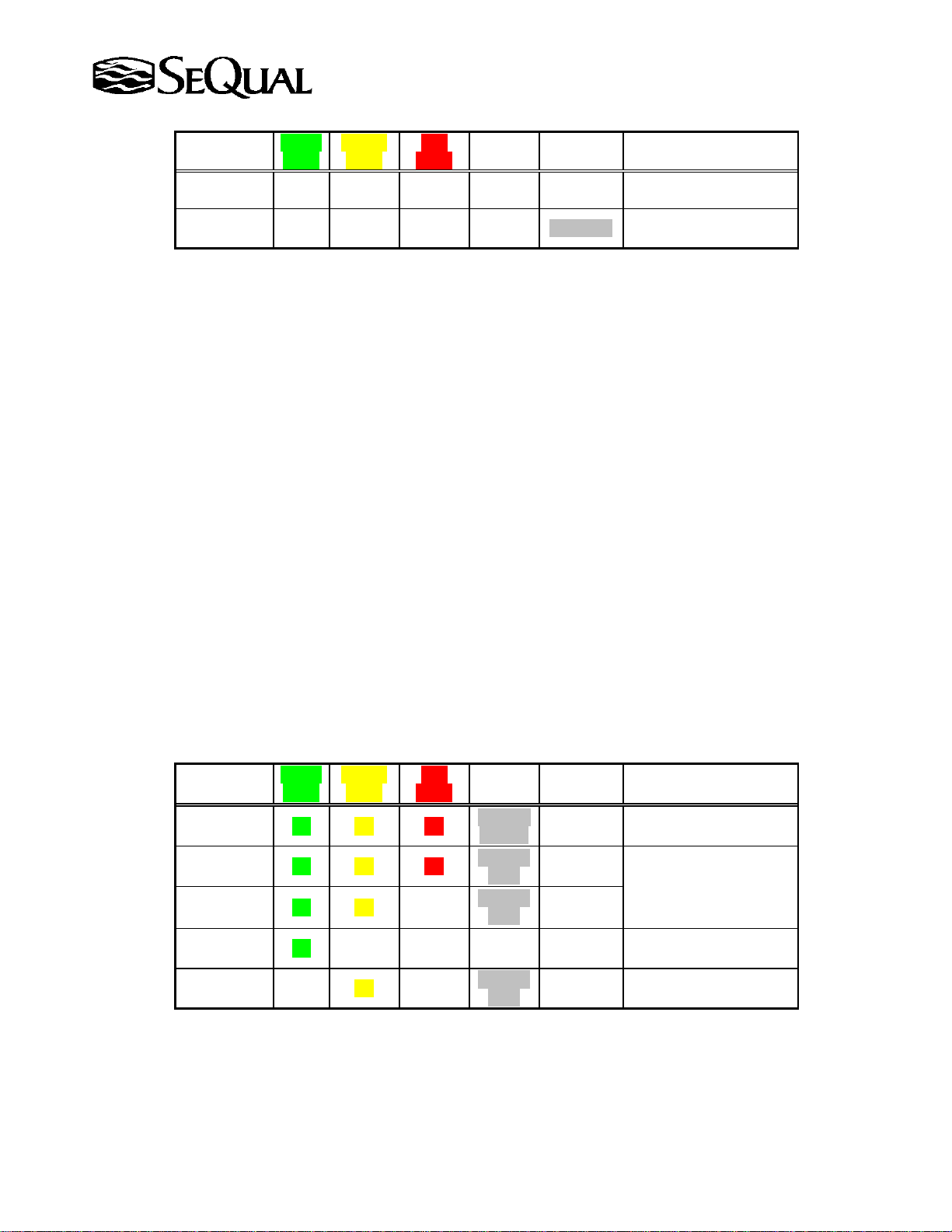

5.1. Alarm Conditions............................................................................................................................................... 15

5.2. Unit fails to start ................................................................................................................................................ 17

5.3. Unit tries to start but shuts down alarming....................................................................................................... 17

5.4. Unit does not produce adequate oxygen flow. ..................................................................................................18

5.5. Unit starts but shuts down after a short period of operation............................................................................18

5.6 Compressor pressure relief valve actuates........................................................................................................18

5.7 Compressor Noisy..............................................................................................................................................19

5.8 Trouble Shooting Guide for Integra E-Z units................................................................................................. 20

6. REPAIR PROCEDURES ............................................................................................................................................23

6.1 Removal and installation of covers ...................................................................................................................23

6.2 Removal and installation of the POD Assembly...............................................................................................23

6.3 Printed Circuit Board Assembly (PCBA) Replacement Procedure.................................................................. 24

6.4 Removal and installation of the ATF module................................................................................................... 26

6.5 Removal and installation of the Compressor Assembly....................................................................................27

6.6 Compressor Top-End rebuild............................................................................................................................ 29

7. INTEGRA E-Z 5L SPECIFICATIONS ..................................................................................................................... 31

8. INTEGRA E-Z 7L SPECIFICATIONS ..................................................................................................................... 32

9. INTEGRA E-Z 10L SPECIFICATIONS ................................................................................................................... 33

10. PART NUMBERS.................................................................................................................................................... 34

10.1. Preventive Maintenance Parts...........................................................................................................................34

10.2. Recommended Spare Parts Inventory...............................................................................................................34

11. SEQUAL ADDRESS AND WEBSITE INFORMATION.....................................................................................35