Sequoia Advantage Series User manual

Congratulations

,

You

have

a

brand

new

Sequoia

Advantage

Central

Vacuum

Accessory

Kit

.

Use

this

kit

along

with

any

central

vacuum

system

to

help

you

efficiently

clean

your

home

.

We

stand

behind

our

products

and

hope

to

earn

your

trust

and

support

.

Happy

cleaning

!

This

manual

covers

safety

,

operations

and

maintenance

of

your

hose

and

tool

kit

.

All

information

in

this

publication

is

based

on

the

latest

product

information

available

at

the

time

of

printing

.

Seqouia

Central

Vacuum

reserves

the

right

to

make

changes

at

any

time

without

notice

and

without

incurring

any

obligation

.

No

part

of

this

publication

may

be

reproduced

without

prior

written

permission

.

This

manual

should

be

considered

a

permanent

part

of

your

vacuum

system

and

should

remain

with

the

vacuum

system

after

purchase

and

installation

.

If

any

problems

should

arise

,

or

if

you

have

any

questions

about

your

hose

and

tool

kit

,

consult

Sequoia

Central

Vacu

-

um

at

1

-

800

-

234

-

6268

,

or

visit

our

comprehensive

website

.

Sequoia

,

ADVANTAGE

SERIES

OWNER

’

S

MANUAL

Sequoia

Advantage

Vacuum

Kit

Sequoia

Advantage

Vacuum

Kit

includes

:

•

Sequoia

Advantage

Vacuum

Power

Brush

•

Crushproof

Electric

Hose

•

13

”

Axis

Floor

Brush

•

Dusting

Brush

•

Upholstery

Tool

•

12

”

Crevice

Tool

•

Integrated

Telescopic

Wand

•

Telescopic

Button

Lock

Wand

•

Mesh

Tool

Caddy

•

Wire

Hose

Hanger

•

Clip

-

on

Tool

Caddy

Full

Two

-

Year

Warranty

Sequoia

Central

Vacuum

,

warrants

the

Sequoia

Advantage

Power

Brush

and

attachment

kit

from

defects

in

material

and

workmanship

under

normal

household

usage

for

a

period

of

two

2

-

years

from

date

of

purchase

.

This

warranty

does

not

include

damage

to

the

product

resulting

from

accident

,

misuse

,

commercial

applications

or

if

repairs

have

been

performed

by

unauthorized

personnel

.

Ordinary

wear

and

tear

is

also

not

covered

under

this

warranty

for

parts

such

as

belts

and

bulbs

.

If

the

product

should

become

defective

within

the

warranty

period

,

or

for

questions

regarding

the

warranty

or

service

,

first

call

the

original

Authorized

Dealer

from

whom

the

purchase

was

made

.

If

that

dealer

is

not

available

within

a

reasonable

period

of

time

,

please

call

Sequoia

Customer

Service

at

1

-

800

-

234

-

6268

.

A

return

authoriza

-

tion

number

will

be

required

for

items

sent

to

Sequoia

Central

Vacuum

.

The

customer

is

responsible

for

the

cost

of

sending

any

item

to

Sequoia

Central

Vacuum

.

Returned

items

that

are

repaired

under

warranty

will

be

repaired

and

returned

for

free

.

Sequoia

reserves

the

right

to

replace

the

product

with

one

of

equal

or

greater

value

.

12

/

17

WHEN

USING

AN

ELECTRICAL

APPLIANCE

,

BASIC

PRECAUTIONS

SHOULD

ALWAYS

BE

FOLLOWED

,

INCLUDING

THE

FOLLOWING

:

IMPORTANT

SAFETY

INSTRUCTIONS

Read

these

operating

instructions

carefully

.

Do

not

suck

up

matches

,

ash

or

cigarettes

that

are

still

burning

.

Be

sure

hose

is

inserted

securely

into

the

inlet

valve

before

attempting

to

vacuum

Do

not

suck

up

flammable

liquid

materials

or

any

other

liquid

material

.

•

Always

keep

hands

,

feet

,

hair

and

clothes

away

when

vacu

-

uming

.

•

Do

not

use

on

any

wet

sur

-

faces

.

Avoid

vacuuming

hard

or

sharp

objects

or

damage

may

result

.

Do

not

leave

the

vacuum

on

unattended

and

do

not

allow

the

vacuum

to

be

used

as

a

Do

not

vacuum

over

electri

-

cal

cord

.

It

can

become

tangled

and

create

and

electrical

hazard

.

toy

.

•

Do

not

leave

hose

plugged

in

when

not

in

use

or

during

ser

-

vicing

of

your

central

vacuum

Do

not

handle

hose

,

outlets

or

vacuum

unit

with

wet

hands

.

unit

•

Do

not

put

any

objects

into

openings

.

Do

not

use

with

any

openings

blocked

:

keep

free

of

dust

,

lint

,

hair

,

and

anything

that

may

reduce

air

flow

Use

only

as

described

in

this

manual

.

Use

only

manufacturer

’

s

recommend

-

ed

attachments

.

Page

2

Installing

your

hose

hanger

Install

your

hose

hanger

close

to

your

general

use

area

.

The

most

common

installation

is

in

an

entry

or

utility

closet

.

Install

at

shoulder

/

chest

height

and

use

appropriate

wall

anchors

to

secure

the

hose

hanger

’

s

two

metal

back

posts

.

Installing

your

tool

caddy

on

the

hose

hanger

After

the

hose

hanger

is

mounted

,

simply

hang

the

caddy

’

s

handle

over

the

entire

hose

hanger

,

not

on

the

front

hooks

.

Install

your

wand

wall

clamp

on

a

stud

at

chest

level

using

drywall

mounting

anchors

.

Coiling

your

hose

Either

place

one

end

of

the

hose

on

the

ground

or

draped

over

the

hose

hanger

.

Grabbing

large

sections

of

hose

,

twist

it

as

you

lay

it

down

in

four

or

five

circles

.

For

best

results

disconnect

attachments

before

coiling

.

Assembling

and

starting

Step

1

:

Stretch

out

the

new

hose

and

let

it

relax

.

Extend

your

telescopic

wand

by

holding

the

plastic

lever

down

and

lifting

the

top

section

up

.

Step

2

:

Slide

the

tapered

end

of

the

wand

into

the

neck

of

the

power

brush

by

aligning

the

button

lock

with

the

button

hole

.

Step

3

:

Insert

the

short

metal

hose

end

into

the

inlet

valve

.

If

your

hose

has

a

cord

on

it

,

plug

it

into

the

nearest

electrical

outlet

.

Depress

hose

handle

rocker

switch

to

left

for

suc

-

tion

only

(

position

“

I

”

)

,

depress

to

right

for

suction

and

electric

power

brush

(

position

“

II

”

)

.

Both

are

turned

off

at

position

“

0

”

.

DETACHING

:

To

detach

hose

handle

simply

push

the

button

lock

in

and

pull

apart

.

How

to

switch

hose

to

direct

connect

:

If

your

vacuum

wall

inlet

plates

accommodate

direct

electrical

pin

connections

then

switch

the

hose

from

“

corded

”

to

“

direct

connect

”

using

the

included

two

pin

plug

.

Simply

slide

the

hose

cuff

off

the

end

of

the

hose

and

replace

the

cord

assembly

with

the

prong

assembly

.

Depress

the

plastic

tab

under

the

sticker

to

remove

cuff

.

Use

needle

nose

pliers

to

remove

and

reattach

the

wire

connections

.

*

*

*

TURN

POWER

OFF

(

HOSE

“

0

”

POSITION

)

BEFORE

DISCONNECTING

THE

HOSE

HANDLE

OR

THE

HOSE

FROM

THE

WALL

INLET

*

**

6

=

^

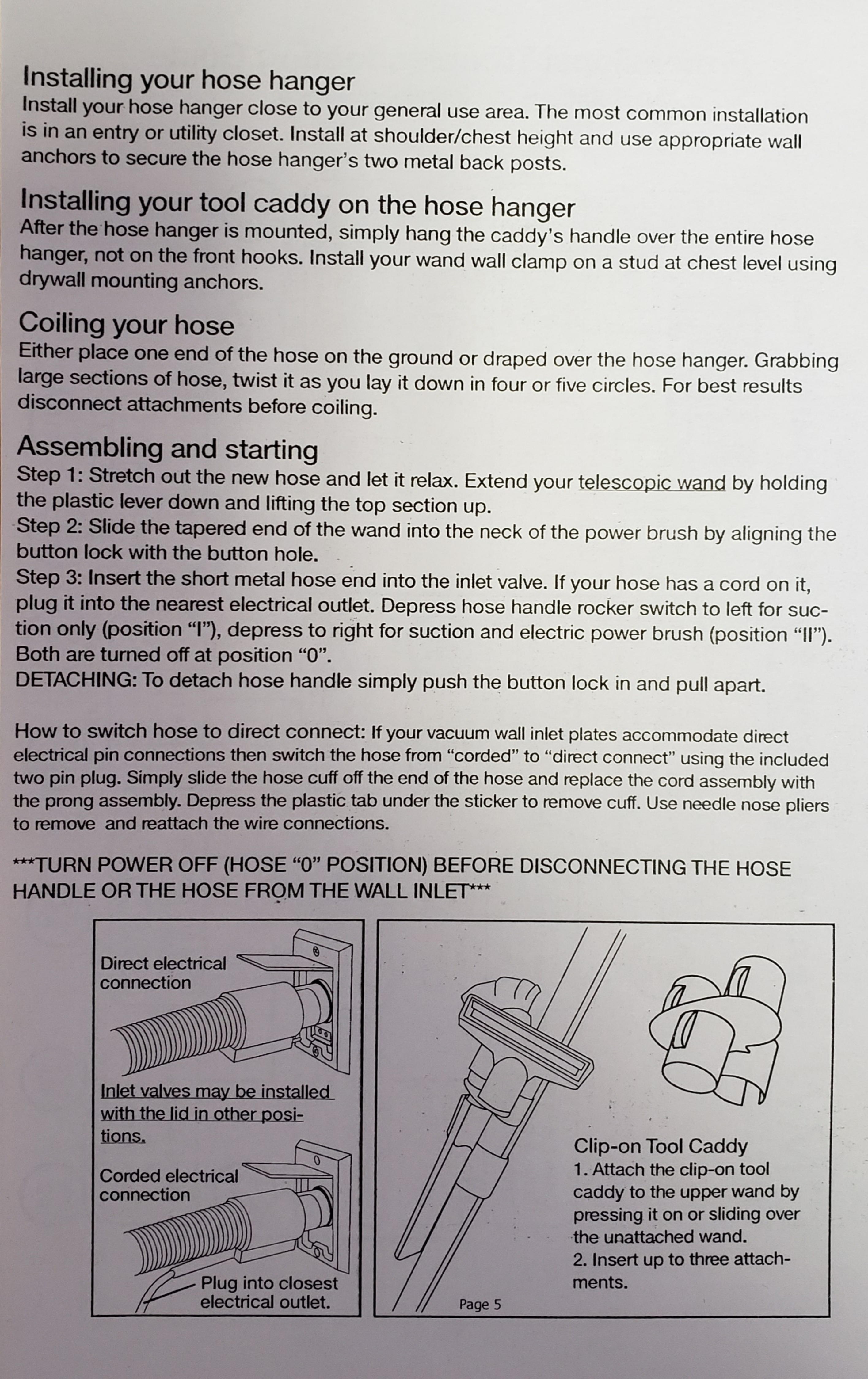

Direct

electrical

connection

Inlet

valves

may

be

installed

with

the

lid

in

other

posi

-

tions

.

Clip

-

on

Tool

Caddy

1

.

Attach

the

clip

-

on

tool

caddy

to

the

upper

wand

by

pressing

it

on

or

sliding

over

the

unattached

wand

.

2

.

Insert

up

to

three

attach

-

ments

.

f

'

f

'

ri

Corded

electrical

connection

—

Plug

into

closest

electrical

outlet

.

Page

5

ft

.

'

*

-

V

^

'

d

USING

YOUR

NEW

KIT

Sequoia

Advantage

Power

Brush

With

the

electric

power

beater

brush

and

the

vacuum

suction

on

,

glide

the

brush

along

the

carpet

.

Turn

the

brush

by

slightly

twisting

the

hose

handle

.

Dusting

Brush

Use

for

baseboards

,

window

sills

,

and

more

.

Crevice

Tool

Great

for

narrow

,

hard

-

to

-

reach

-

places

.

Upholstery

Brush

Excellent

for

sofa

,

car

,

drapes

;

attach

brush

strip

for

aggressive

agitation

.

/

Page

4

Installing

your

hose

hanger

Install

your

hose

hanger

close

to

your

general

use

area

.

The

most

common

installation

is

in

an

entry

or

utility

closet

.

Install

at

shoulder

/

chest

height

and

use

appropriate

wall

anchors

to

secure

the

hose

hanger

’

s

two

metal

back

posts

.

Installing

your

tool

caddy

on

the

hose

hanger

After

the

hose

hanger

is

mounted

,

simply

hang

the

caddy

’

s

handle

over

the

entire

hose

hanger

,

not

on

the

front

hooks

.

Install

your

wand

wall

clamp

on

a

stud

at

chest

level

using

drywall

mounting

anchors

.

Coiling

your

hose

Either

place

one

end

of

the

hose

on

the

ground

or

draped

over

the

hose

hanger

.

Grabbing

large

sections

of

hose

,

twist

it

as

you

lay

it

down

in

four

or

five

circles

.

For

best

results

disconnect

attachments

before

coiling

.

Assembling

and

starting

Step

1

:

Stretch

out

the

new

hose

and

let

it

relax

.

Extend

your

telescopic

wand

by

holding

the

plastic

lever

down

and

lifting

the

top

section

up

.

Step

2

:

Slide

the

tapered

end

of

the

wand

into

the

neck

of

the

power

brush

by

aligning

the

button

lock

with

the

button

hole

.

Step

3

:

Insert

the

short

metal

hose

end

into

the

inlet

valve

.

If

your

hose

has

a

cord

on

it

,

plug

it

into

the

nearest

electrical

outlet

.

Depress

hose

handle

rocker

switch

to

left

for

suc

-

tion

only

(

position

“

I

”

)

,

depress

to

right

for

suction

and

electric

power

brush

(

position

“

II

”

)

.

Both

are

turned

off

at

position

“

0

”

.

DETACHING

:

To

detach

hose

handle

simply

push

the

button

lock

in

and

pull

apart

.

How

to

switch

hose

to

direct

connect

:

If

your

vacuum

wall

inlet

plates

accommodate

direct

electrical

pin

connections

then

switch

the

hose

from

“

corded

”

to

“

direct

connect

”

using

the

included

two

pin

plug

.

Simply

slide

the

hose

cuff

off

the

end

of

the

hose

and

replace

the

cord

assembly

with

the

prong

assembly

.

Depress

the

plastic

tab

under

the

sticker

to

remove

cuff

.

Use

needle

nose

pliers

to

remove

and

reattach

the

wire

connections

.

*

*

*

TURN

POWER

OFF

(

HOSE

“

0

”

POSITION

)

BEFORE

DISCONNECTING

THE

HOSE

HANDLE

OR

THE

HOSE

FROM

THE

WALL

INLET

*

**

6

=

^

Direct

electrical

connection

Inlet

valves

may

be

installed

with

the

lid

in

other

posi

-

tions

.

Clip

-

on

Tool

Caddy

1

.

Attach

the

clip

-

on

tool

caddy

to

the

upper

wand

by

pressing

it

on

or

sliding

over

the

unattached

wand

.

2

.

Insert

up

to

three

attach

-

ments

.

f

'

f

'

ri

Corded

electrical

connection

—

Plug

into

closest

electrical

outlet

.

Page

5

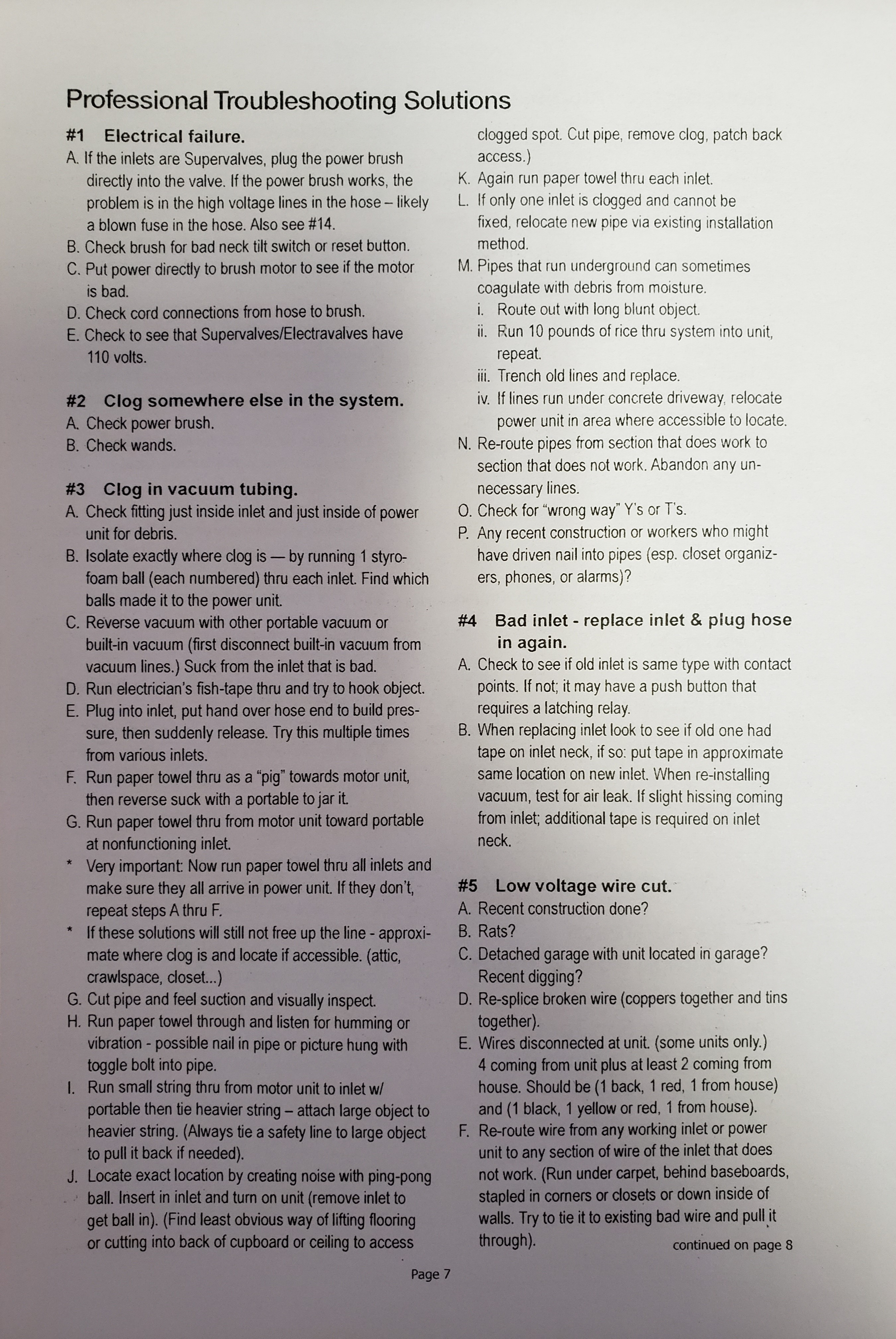

CMW

Central

Vacuum

Service

Solutions

Also

available

online

at

builtinvacuum

.

com

/

flov

/

chrt

.

html

CENTRAL

VACUUM

cmwVacs

.

com

CMW

COMPANY

,

INC

.

f

AM

At

the

unit

will

it

turn

on

manually

?

Does

it

have

good

suction

at

the

unit

with

.

the

hose

?

f

Does

it

have

suction

at

the

unit

without

^

the

hose

?

Yes

Yes

No

Yes

(

No

No

(

*

Remove

inlet

.

Do

wires

leading

to

inlet

start

system

when

touched

together

?

i

When

you

turn

it

on

at

the

unit

do

you

near

a

click

?

Arc

across

the

contact

points

in

the

inlet

valve

neck

.

Does

the

power

unit

start

?

Does

the

hose

have

a

switch

on

the

handle

?

:

No

Is

it

always

running

?

Yes

(

\

j

^

Yes

No

/

SEE

\

Uiiy

No

Yes

Yes

Try

another

appliance

in

the

outlet

.

Does

it

work

?

Properly

plug

-

in

hose

to

inlet

.

Activate

the

switch

on

hose

handle

Does

power

unit

start

?

Disconnect

power

unit

from

pipes

.

Disconnect

house

low

voltage

system

.

Does

the

system

have

a

electric

brush

?

C

Yes

c

J

>

No

Ye

>

-

k

fSEE

\

(

SEE

\

ui

2

y

wmy

fSEE

\

J

No

Yes

Does

the

electric

brush

turn

on

when

activated

v

,

l

by

the

switch

?

)

,

,

,

J

^

Yes

NO

3

?

NqCCT

^

LYes

No

j

/

JU

,

Yes

No

-

L

/

SEE

\

/

SEA

(

SEE

\

/

SEE

\

SSEE

\

fSEE

\

fSEE

\

\

u

2

j

ts

#

3

>

J

Does

it

still

run

continuously

?

Good

suction

at

all

the

inlets

?

Does

the

unit

alone

have

good

suction

?

Yes

Copyright

©

10

/

2011

M

D

Manufacturing

Inc

Professional

Troubleshooting

Solutions

#

1

Electrical

failure

.

A

.

If

the

inlets

are

Supervalves

,

plug

the

power

brush

directly

into

the

valve

.

If

the

power

brush

works

,

the

problem

is

in

the

high

voltage

lines

in

the

hose

-

likely

a

blown

fuse

in

the

hose

.

Also

see

#

14

.

B

.

Check

brush

for

bad

neck

tilt

switch

or

reset

button

.

C

.

Put

power

directly

to

brush

motor

to

see

if

the

motor

is

bad

.

D

.

Check

cord

connections

from

hose

to

brush

.

E

.

Check

to

see

that

Supervalves

/

Electravalves

have

110

volts

.

clogged

spot

.

Cut

pipe

,

remove

clog

,

patch

back

access

.

)

K

.

Again

run

paper

towel

thru

each

inlet

.

L

.

If

only

one

inlet

is

clogged

and

cannot

be

fixed

,

relocate

new

pipe

via

existing

installation

method

.

M

.

Pipes

that

run

underground

can

sometimes

coagulate

with

debris

from

moisture

.

i

.

Route

out

with

long

blunt

object

.

ii

.

Run

10

pounds

of

rice

thru

system

into

unit

,

repeat

.

iii

.

Trench

old

lines

and

replace

.

iv

.

If

lines

run

under

concrete

driveway

,

relocate

power

unit

in

area

where

accessible

to

locate

.

N

.

Re

-

route

pipes

from

section

that

does

work

to

section

that

does

not

work

.

Abandon

any

un

-

necessary

lines

.

O

.

Check

for

"

wrong

way

”

Y

'

s

or

T

’

s

.

P

Any

recent

construction

or

workers

who

might

have

driven

nail

into

pipes

(

esp

.

closet

organiz

-

ers

,

phones

,

or

alarms

)

?

#

2

Clog

somewhere

else

in

the

system

.

A

.

Check

power

brush

.

B

.

Check

wands

.

#

3

Clog

in

vacuum

tubing

.

A

.

Check

fitting

just

inside

inlet

and

just

inside

of

power

unit

for

debris

.

B

.

Isolate

exactly

where

clog

is

—

by

running

1

styro

-

foam

ball

(

each

numbered

)

thru

each

inlet

.

Find

which

balls

made

it

to

the

power

unit

.

C

.

Reverse

vacuum

with

other

portable

vacuum

or

built

-

in

vacuum

(

first

disconnect

built

-

in

vacuum

from

vacuum

lines

.

)

Suck

from

the

inlet

that

is

bad

.

D

.

Run

electrician

’

s

fish

-

tape

thru

and

try

to

hook

object

.

E

.

Plug

into

inlet

,

put

hand

over

hose

end

to

build

pres

-

sure

,

then

suddenly

release

.

Try

this

multiple

times

from

various

inlets

.

F

.

Run

paper

towel

thru

as

a

“

pig

"

towards

motor

unit

,

then

reverse

suck

with

a

portable

to

jar

it

G

.

Run

paper

towel

thru

from

motor

unit

toward

portable

at

nonfunctioning

inlet

.

*

Very

important

:

Now

run

paper

towel

thru

all

inlets

and

make

sure

they

all

arrive

in

power

unit

.

If

they

don

’

t

,

repeat

steps

A

thru

F

.

*

If

these

solutions

will

still

not

free

up

the

line

-

approxi

-

mate

where

clog

is

and

locate

if

accessible

,

(

attic

,

crawlspace

,

closet

..

.

)

G

.

Cut

pipe

and

feel

suction

and

visually

inspect

.

FI

.

Run

paper

towel

through

and

listen

for

humming

or

vibration

-

possible

nail

in

pipe

or

picture

hung

with

toggle

bolt

into

pipe

.

I

.

Run

small

string

thru

from

motor

unit

to

inlet

w

/

portable

then

tie

heavier

string

-

attach

large

object

to

heavier

string

.

(

Always

tie

a

safety

line

to

large

object

to

pull

it

back

if

needed

)

.

J

.

Locate

exact

location

by

creating

noise

with

ping

-

pong

ball

.

Insert

in

inlet

and

turn

on

unit

(

remove

inlet

to

get

ball

in

)

.

(

Find

least

obvious

way

of

lifting

flooring

or

cutting

into

back

of

cupboard

or

ceiling

to

access

#

4

Bad

inlet

-

replace

inlet

&

plug

hose

in

again

.

A

.

Check

to

see

if

old

inlet

is

same

type

with

contact

points

.

If

not

;

it

may

have

a

push

button

that

requires

a

latching

relay

.

B

.

When

replacing

inlet

look

to

see

if

old

one

had

tape

on

inlet

neck

,

if

so

:

put

tape

in

approximate

same

location

on

new

inlet

.

When

re

-

installing

vacuum

,

test

for

air

leak

.

If

slight

hissing

coming

from

inlet

;

additional

tape

is

required

on

inlet

neck

.

#

5

Low

voltage

wire

cut

.

A

.

Recent

construction

done

?

B

.

Rats

?

C

.

Detached

garage

with

unit

located

in

garage

?

Recent

digging

?

D

.

Re

-

splice

broken

wire

(

coppers

together

and

tins

together

)

.

E

.

Wires

disconnected

at

unit

,

(

some

units

only

.

)

4

coming

from

unit

plus

at

least

2

coming

from

house

.

Should

be

(

1

back

,

1

red

,

1

from

house

)

and

(

1

black

,

1

yellow

or

red

,

1

from

house

)

.

F

.

Re

-

route

wire

from

any

working

inlet

or

power

unit

to

any

section

of

wire

of

the

inlet

that

does

not

work

.

(

Run

under

carpet

,

behind

baseboards

,

stapled

in

corners

or

closets

or

down

inside

of

walls

.

Try

to

tie

it

to

existing

bad

wire

and

pull

it

continued

on

page

8

through

)

.

Page

7

Professional

Troubleshooting

Solutions

,

con

’

t

.

#

6

Clog

in

hose

.

A

.

Reverse

the

hose

at

inlet

on

power

unit

.

Suck

it

out

.

B

.

Drop

kitchen

knife

01

heavy

object

thru

hose

-

sling

it

or

squeeze

hose

and

twist

to

get

through

.

C

.

Shove

garden

hose

thru

vac

hose

(

don

'

t

turn

water

#

9

Short

in

power

unit

.

A

.

Directly

isolate

low

voltage

leads

alone

(

discon

-

nect

all

auxiliary

switches

)

.

B

.

Short

in

relay

(

very

rare

)

.

on

!

)

.

#

10

Short

in

low

voltage

system

.

A

.

Recent

attic

work

or

someone

in

crawlspace

?

B

.

Rats

chewed

through

wire

?

C

.

Disconnect

any

spiices

you

can

find

and

check

continuity

ol

short

.

D

.

Worst

case

'

re

-

ioute

wire

from

any

other

working

inlet

or

wire

.

(

Possibly

running

wire

behind

base

-

boards

,

under

carpet

,

in

closets

,

or

in

ait

ducts

.

)

#

7

Unit

is

good

,

pipes

have

leaks

.

A

.

Recent

work

done

on

house

?

B

.

Recent

wallpapering

or

paneling

?

Inlet

removed

or

re

-

installed

wrong

?

C

.

Inlet

lid

broken

?

D

.

Hidden

or

forgotten

inlet

?

E

.

Inlets

installed

in

floor

;

pipe

fell

down

or

loose

.

F

.

Turn

unit

on

and

walk

around

house

listening

for

leak

.

G

.

Inlet

roughed

in

but

not

found

on

finish

?

H

.

Pipe

running

underground

has

break

in

it

.

I

.

Recent

gardening

or

tree

has

strangled

it

.

#

11

Relay

or

circuit

board

getting

power

but

not

starting

unit

.

A

.

Most

likely

motor

brushes

.

B

.

Isolate

motor

and

see

if

it

works

.

C

.

Check

wiring

from

relay

or

circuit

board

to

motor

.

D

.

Motor

can

fail

even

with

brand

new

brushes

.

#

8

The

Power

unit

has

bad

suction

.

A

.

If

multi

-

motored

unit

:

are

boih

working

?

3

.

Check

power

unit

gaskets

and

cracks

in

housing

.

C

.

Improper

voltage

into

power

unit

.

D

.

Loose

wires

.

E

.

Mini

-

breaker

has

malfunctioned

.

F

.

On

cyclonic

unit

:

1

)

Unit

and

debris

in

motor

fan

blades

;

2

)

Lint

and

debris

on

screen

on

intake

;

3

)

Too

much

back

pressure

from

exhaust

run

being

far

.

Something

is

blocking

exhaust

line

.

G

.

On

bag

type

unit

:

Excessive

amount

of

very

fine

plaster

dust

clogging

primary

or

secondary

filter

.

H

.

Motor

loose

.

Lid

not

tight

/

filter

in

the

way

.

#

12

The

power

unit

is

not

getting

electricity

.

A

.

Check

house

circuit

breaker

.

B

.

Try

vacuum

in

another

outlet

.

C

.

Is

the

circuit

breaker

the

right

size

for

the

power

unit

?

D

.

See

what

is

on

the

circuit

-

is

it

overloaded

?

E

.

Continually

recheck

the

system

after

you

get

power

to

see

if

it

was

the

vac

that

had

tripped

the

circuit

.

F

.

If

necessary

,

have

an

electrician

look

at

it

.

#

13

Transformer

and

motor

not

getting

power

.

A

.

Bad

circuit

board

?

Bad

cord

(

rare

)

?

B

.

Bad

transformer

,

check

for

spark

between

two

low

voltage

wires

out

of

transformer

.

C

.

Bad

relay

,

check

points

:

arc

across

to

see

if

it

solves

it

.

Available

Accessories

:

Vac

-

U

-

Reach

Garage

Hose

&

Tool

Kit

Miniblind

Tool

Ceiling

Fan

Tool

Micro

Attachments

Pet

Brushes

Unique

Brushes

Long

Thin

Flex

Tool

Vacuum

Bumpers

and

more

!

#

14

Low

voltage

in

hose

is

not

working

.

A

.

If

switch

feels

“

mushy

"

then

it

needs

to

be

replaced

.

B

.

Remove

hose

from

wall

and

take

apart

the

handle

end

.

Look

for

lint

or

other

debris

in

contact

points

.

C

.

Make

sure

hose

is

being

fully

inserted

into

inlet

.

D

.

Hose

may

need

to

be

replaced

.

Page

8