SERFILCO EFB Series Operation manual

WWW.SERFILCO.COM 2900 MacArthur Blvd. Northbrook, IL. USA 60062 (800) 323-5431

Operation and Service Guide

O-3180 - Page 1 of 8

03/05/21

© 2021 Serfilco Ltd, All Right Reserved.

®

2900 MacArthur Blvd. Northbrook, IL. USA 60062 WWW.SERFILCO.COM (800) 323-5431

Series 'EFB' | Sump Pumps

⚠CAUTION

It is important that the entire contents of this booklet

be studied before installation.

All parts of the pump below the mounting plate are

constructed of corrosion resistant non-metallic

materials except the pump shaft. The shaft is stainless

steel encased in a CPVC sleeve. The major parts are

made from CPVC. These parts have been carefully

designed to safely handle all operating loads

anticipated. They should still be treated with care, to

avoid damage to the pump. All piping must be

independently supported and all temporary external

loads on the pump must be avoided. Be careful not to

over-tighten the fasteners used on the pump. Please

pay strict attention to the maximum torque values listed

below for the various fasteners.

Auxiliary connections (Bearing lubrication lines):

Do not install metal pipe fittings directly onto pipe

connections on non-metallic parts. These items are

polypropylene and included with pump.

Pump bolting: All plastic bolting below mounting

plate not to exceed 10 foot-pounds torque. All metal

bolting at underside of mounting plate not to exceed 20

foot-pounds torque.

SAFETY

This manual contains instructions for installation,

operation and maintenance of your Series 'EFB'

centrifugal pump. It has been designed to provide safe

and reliable service. However, it is both a pressure

vessel and a piece of rotating machinery. Therefore, the

operator(s) must exercise good judgment and proper

safety practices to avoid damage to the equipment and

surroundings and prevent personal injury. The

instructions in this manual are intended for personnel

with a general training in operation and maintenance of

centrifugal pumps.

INSTALLATION, OPERATION AND

MAINTENANCE

In these instructions you will encounter the words

WARNING, CAUTION and NOTE. These are intended to

emphasize certain areas of personal safety and

satisfactory pump operation and maintenance. The

definitions of these words are as follows:

⚠WARNING: An operating procedure, practice, etc.

which, if not correctly followed, could result in personal

injury, or loss of life.

⚠CAUTION: An operating procedure, practice, etc.

which, if not strictly observed, could result in damage to,

or destruction of, equipment.

⚠NOTE: - An operating procedure, condition, etc. which

is essential to highlight.

Safety precautions before starting pump

1. Read operating instruction and instructions supplied

with chemicals to be used.

2. Refer to a chemical resistance data chart for

compatibility of materials in pump with solution to

be used.

3. Note temperature and pressure limitations.

4. Personnel operating pump should always wear

suitable protective clothing: face mask or goggles,

apron and gloves.

5. All piping must be supported and aligned

independently of the pump.

6. Always close valves slowly to avoid hydraulic shock.

7. Ensure that all fittings and connections are properly

tightened.

Before changing application or performing

maintenance

1. Wear protective clothing as described in Item 4

above.

2. Flush pump thoroughly with a neutralizing solution

to prevent possible harm to personnel.

3. Verify compatibility of materials as stated in Item 2,

Safety Precautions above.

4. Shut off power to motor at disconnect switch.

⚠Important:

1. Even though you have determined that CPVC is

chemically compatible with the solution, care should

be taken to protect the pump components against

unnecessary wear and physical abuse.

2. Record all models and serial numbers for future

reference. This information will be required when

contacting the Application Engineering Department.

3. Pump should be handled with care when removing

from shipping crate, or when placing pump in tank

or sump.

APPLICATION

The pump has been designed to operate safely and

reliably under normal service conditions. It is extremely

important that the pump be used within the limits

specified in the following sections of this instruction

book: The corrosion-resistant nonmetallic "wet-ends" of

the pump were designed to handle a wide variety of

liquids; however, do not use this pump on any other

service than that for which it was intended without first

checking a chemical resistance data chart and other

appropriate sources to determine its applicability and

suitability for any change in service.

Materials in solution contact

CPVC: Pump column, Shaft sleeve, Casing, impeller,

Discharge pipe, Casing bolts

EPDM or Viton: O-Ring

Alumina: Bearing Liner

Graphite (160°F)or Rulon (140°F): Bearing

Polyethylene: Suction strainer

Polypropylene: Bearing cooling lines

WWW.SERFILCO.COM 2900 MacArthur Blvd. Northbrook, IL. USA 60062 (800) 323-5431

Operation and Service Guide

O-3180 - Page 2 of 8

03/05/21

© 2021 Serfilco Ltd, All Right Reserved.

®

2900 MacArthur Blvd. Northbrook, IL. USA 60062 WWW.SERFILCO.COM (800) 323-5431

Series 'EFB' | Sump Pumps

CHECK UPON ARRIVAL

The unit should be inspected immediately upon

arrival, and any irregularities arising due to shipment

should be reported to the carrier.

Care should be taken when unpacking pumps (see

Uncrating and Handling). A copy of this instruction

book as well as instruction sheets for other various

components (such as driver) will be included in the

shipment. Put these papers in a safe, accessible place

for ready reference when required. It is important that

the entire contents of this booklet be studied before

installation.

Pump parts and accessories may be packed inside

shipping containers, or attached to skids in individual

packages. Inspect all containers, crates and skids before

discarding.

Storage

The pump is protected against contamination for the

period of shipment and installation only.

If the pump is not to be installed at once, find a

clean, dry location for storage. Unit should be stored in

an approximately level position with no strains applied.

Protective coverings should be left in place. The pump

should be left in its shipping container or skid for

storage.

Pumps are furnished with a corrosion-resistant shaft

material and CPVC sleeved so no special preservation

measures are required.

Uncrating

1. Raise shipping skid/crate into vertical position

(driver end up) before uncrating and removing

pump. Do not sling on the pump column or motor

support to raise into the vertical position. Sling on

either the shipping skid itself or the pump mounting

plate.

2. Remove only enough of the skid/crate to allow

access to all the foundation holes on the pump

mounting plate. Install eyebolts in 3 or 4 of the

foundation holes in the pump mounting plate. Use

large flat washers on both sides of the mounting

plate when installing eyebolts. Carefully sling pump

using these eyebolts. Use a spreader between slings

to prevent damage to the motor support when

lifting.

3. Remove rest of shipping crate.

Handling

Pump should be handled only in the vertical position.

Use care when moving pumps. Rough handling of

the pump can cause breakage or permanent

misalignment.

Take care that bearing lubrication lines will not be

bent or damaged when handling.

Do not handle the pump by using the motor support.

Use the pump mounting plate, whether lifting the pump

alone or the pump/motor combination. The motor

eyebolts should be used only to lift the motor by itself.

Make sure that any equipment used to lift the pump

or any of its components is capable of supporting the

weights encountered. Make sure that all parts are

properly rigged before attempting to lift.

Cleaning the pump

Before putting the pump into operation, the liquid

end of the pump should be flushed out with water to

remove any foreign matter which may have

accumulated during shipment, storage, or installation.

If pump has been in storage over 6 months, it should

be inspected and cleaned as required before putting

into service.

Location

In the initial consideration of sump pump location,

attention should be paid to room and facilities to lift and

install the pump, plus access to auxiliary sources such

as electrical power, air and water, if required.

Also important, especially in the larger-flow units, is

proper sump design. Liquid velocity approaching the

pump should be one foot per second or less. When

more than one pump is installed and used at the same

time in the same sump, the location and spacing of the

pumps is important.

The guidelines for sump design and pump placement

as outlined in "Hydraulic Institute Standards" are

recommended.

Proper pump submergence will prevent pumping

troubles due to air or gas being drawn into the pump or

vortexing of the liquid as it enters the pump. Minimum

liquid level should not be confused with NPSH, since in

some cases the NPSHR of the pump could be greater

than the pump submergence.

Pumps furnished with suction extensions should be

used only on draw-down and stop service with optional

level control.

⚠CAUTION: Liquid level in sump must be above pump

casing whenever pump is started.

FACTORY ASSEMBLY AND TEST

All Series 'EFB' Pumps are factory checked and tested

for alignment, free rotation, flow, TDH and current draw,

to assure the assembly meets performance

specifications.

Handling during shipment, storage, or preparation

for installation could have caused distortions resulting

in pump shaft binding or disabling damage. If either

situation occurs, do not install or operate until

corrected.

When installing auxiliary equipment on the pump

(such as float controls) or while lowering the pump into

the pit, check all bolts and nuts for tightness. Check to

see that the discharge pipe is not causing any

distortions to the pump or column which could cause

shaft binding.

WWW.SERFILCO.COM 2900 MacArthur Blvd. Northbrook, IL. USA 60062 (800) 323-5431

Operation and Service Guide

O-3180 - Page 3 of 8

03/05/21

© 2021 Serfilco Ltd, All Right Reserved.

®

2900 MacArthur Blvd. Northbrook, IL. USA 60062 WWW.SERFILCO.COM (800) 323-5431

Series 'EFB' | Sump Pumps

Pump mounting

The pump may be mounted directly on the pit using

the pump mounting plate or in conjunction with a pit

cover.

Carefully lower the assembled pump into the pit,

taking care not to damage lube lines. Make sure that

any equipment used to lift the pump or any of its

components is capable of supporting the weights

encountered. Make sure that all parts are properly

rigged before attempting to lift.

Pump mounting plate and/or pit cover must be level,

and supported evenly at all points before being bolted

down.

The foundation for the mounting plate or pit cover

must be sufficiently rigid to prevent vibration.

Supporting members must be sufficiently strong to

prevent spring action and /or lateral movement.

Electrical

With power off and solution in sump and water in

bearing cooling lines:

Rotate the motor shaft by hand to make sure it is

free to rotate when energized.

Connect the motor terminals to the leads from the

starter panel.

Start the motor, immediately hit the stop button, and

check for proper rotation which should be clockwise

when looking down on top of the motor. If rotation is

wrong, interchange any two motor connections on

three-phase motors. On single phase motors, follow the

motor manufacturer's instructions. After changing the

connections, again check the rotation.

Motors are suitable for VFD operation.

⚠CAUTION: Failure to follow this instruction can result

in serious damage to pump and driver if rotation is

wrong.

Piping

⚠NOTE: The design of piping systems, foundations and

other areas of system design is the responsibility of the

customer. This data and comments are offered as an

aid, but we cannot assume responsibility for the

installation design and operation.

We recommend that the customer consult a

specialist skilled in the design of piping, sumps and

related systems so as to supplement and interpret the

information and ensure a successful installation.

Discharge piping should be connected to the pump

such that no strain or weight of the piping is carried by

the pump. Check pump shaft for freedom of rotation by

hand to make sure discharge piping strain is not causing

binding.

A check valve is required to prevent back-flow

through the pump on shut-down. Manufacturer will not

be responsible for damages resulting from failure to

install a check valve.

⚠NOTE: If quick-closing valves are installed in the

discharge piping system, protection MUST be provided

to ensure that no surge or water hammer is transmitted

to the pump.

PRE-STARTING CHECKS

Motor preparation

Prepare the driver for operation as instructed by the

driver manufacturer. Re-check all connections to the

motor and control with the wiring diagram. Make sure

voltage and frequency on the motor and control

nameplates correspond with the line voltage.

If the driver has not been checked for rotation, it

must be done now.

Pre-start-up

1. Verify that materials of construction are compatible

with solution being pumped. Refer to ‘Materials in

Solution Contact’ table Page 1.

2. Verify that operating temperature is not in excess of

maximum recommended. Refer to ‘Materials in

Solution Contact’ table Page 1.

3. Carefully place pump into sump or tank and secure

in position using bolts, clamps, etc. Check alignment

and position of level controls as instructed above.

4. Connect electrical supply to motor starter.

A Soft Starter is recommended to prolong the

life of the pump. If starter is furnished, verify that

starter and motor are wired for the correct

operating voltage, and the starter contains the

correct overload heaters. It is recommended that a

motor starter be installed if one was not provided

with the pump assembly.

5. If mounting plate bolts or pump-motor lock nuts are

loosened, pump alignment must be checked.

6. Do not energize motor until pump is immersed

in liquid and then follow startup no.1.

7. Secure the assembly, complete all piping and firmly

support.

8. Check for correct high-low operation of level control

by manually positioning float rod or a current check

of conductivity level controls.

9. Check for correct operation of motor starter and

Dri-Stop when included.

Product flush lubricated pump bearings

Check to see that the product flush lines are

connected to the pump discharge elbow. Check that no

damage has occurred to the lubrication lines during

shipment or installation.

⚠NOTE: If solution being pumped crystalizes when

exposed to air and bearings are not always submerged

in solution, pump bearing lubrication with water is

recommended.

Water-lubricated pump bearings

Clean water from an external source must be used

when pumps are furnished with bearings for which

water lubrication is required. Check to see that

connections are made to bearing lubrication fittings on

pump mounting plate, and that 0.5 GPM of water per

bearing at 10 PSIG is available. Do not install metal pipe

fittings directly onto pipe connections on non-metallic

parts. Check to see that no damage has occurred to the

lubrication lines during shipment or installation.

WWW.SERFILCO.COM 2900 MacArthur Blvd. Northbrook, IL. USA 60062 (800) 323-5431

Operation and Service Guide

O-3180 - Page 4 of 8

03/05/21

© 2021 Serfilco Ltd, All Right Reserved.

®

2900 MacArthur Blvd. Northbrook, IL. USA 60062 WWW.SERFILCO.COM (800) 323-5431

Series 'EFB' | Sump Pumps

OPERATION & START-UP

After all pre-starting checks have been performed,

the pump is ready to start. Observe the following

procedure to put the pump into operation:

1. Rotate the pump shaft by hand through at least one

complete revolution to see that there is no rub or

bind.

2. Leave open very slightly, the control valve in the

discharge line.

3. Start the motor.

4. As soon as the pump is up to rated speed, slowly

open the discharge valve to desired capacity or

pressure.

Operating checks

Costly shut-downs will be avoided by making routine

checks on pump operation.

1. Check to see if liquid is being discharged. A

discharge pressure gauge is an easy way to check

whether or not the liquid is being pumped.

Compare discharge pressure to pump flow curve to

determine flow rate. If, at any time, the gauge

should drop to zero, or register an abnormally high

pressure, shut down the pump immediately.

2. Observe pump for any abnormal noise or vibration.

Any CHANGE in pump noise or vibration will require

shut down and inspection.

3. At maximum flow conditions, measure amperage on

all lines. If in excess of motor nameplate ratings,

stop and consult Application Engineering Dept.

Stopping the pump

Normal operation of level controls will stop and start

the pump when MANUAL-OFF-AUTO motor starter is at

AUTO position. When performing maintenance, turn

starter to OFF, disconnect electrical supply and follow

standard safety procedures.

⚠CAUTION: When operating for some time at reduced

capacity, much of the pump horsepower will go into the

liquid in the form of heat. A bypass must be provided

under these conditions to prevent the liquid in the

pump from becoming hot enough to vaporize. Damage

to pump may result from prolonged operations at

reduced capacities. See Minimum flow.

⚠WARNING: In the interest of operator safety, the unit

must not be operated above the nameplate conditions.

Such operation could result in unit failure causing injury

to operating personnel. Consult instruction book for

proper operation and maintenance of the pump and its

supporting components.

Minimum flow

Always maintain sufficient flow through the pump to

prevent flashing of the liquid passing through the pump.

At low flows, a large proportion of the horsepower input

is absorbed by the liquid as heat, so the flow must be

maintained at a point sufficient to keep the temperature

rise through the pump within a safe limit.

⚠CAUTION: Damage to pump may result from

prolonged operations at reduced capacities.

In addition to heat rise considerations for minimum

flow, there is also a minimum flow requirement for

mechanical protection of the pump. Damage to the

pump may occur at reduced capacities due to increased

hydraulic thrust loads. These higher loads cause

increased vibration and shaft deflection, and decreased

bearing life. Also encountered at low flows is the

damage which could be done by erosive swirl. At low

flows, much of the pumped liquid is recirculated

through the pump. This can result in localized damage

to the pump by erosive action particularly when

pumping light slurries or "dirty" liquids.

Both heat rise and mechanical protection must be

considered when determining correct minimum flow.

The pump has been designed to operate at low flows

without problems due to hydraulic thrust; however, a

minimum flow of 50 GPM is required for satisfactory

operation and pump life.

TROUBLE CHART

If any of the following troubles are encountered, they

may be due to the causes listed below.

No liquid delivered:

1. Liquid level in sump too low (pump casing not

submerged).

2. Speed too low - check motor voltage.

3. Air or gas in liquid.

4. Strainer clogged.

5. Impeller clogged.

6. Casing or discharge line clogged.

7. Wrong direction of rotation.

8. Discharge valve closed; check valve installed

backwards (or stuck)

9. Not enough NPSH available

Not enough pressure:

1. Liquid level in sump too low (pump casing not

properly submerged)

2. Speed too low - check motor voltage

3. Air or gas in liquid

4. Wrong direction of rotation

5. Impeller partially clogged or damaged

6. Excessive impeller running clearance

7. Liquid vortexing in sump

Not enough liquid delivered:

1. Liquid level in sump too low (pump casing not

properly submerged)

2. Speed too low- check motor voltage

3. Air or gas in liquid.

4. Strainer partially clogged.

5. Impeller partially clogged or damaged.

6. Casing or discharge line partially clogged.

7. Wrong direction of rotation.

8. Discharge valve partially closed.

9. Not enough NPSH available.

10. Discharge head too high.

11. Excessive impeller running clearance.

12. Liquid vortexing in sump.

WWW.SERFILCO.COM 2900 MacArthur Blvd. Northbrook, IL. USA 60062 (800) 323-5431

Operation and Service Guide

O-3180 - Page 5 of 8

03/05/21

© 2021 Serfilco Ltd, All Right Reserved.

®

2900 MacArthur Blvd. Northbrook, IL. USA 60062 WWW.SERFILCO.COM (800) 323-5431

Series 'EFB' | Sump Pumps

Pump uses too much power:

1. Speed too high

2. Head lower than rating (allows pump to handle too

much liquid)

3. Liquid heavier and more viscous than rating.

4. Rotor binding.

5. Impeller dragging.

6. Wrong direction of rotation.

Excessive vibration:

1. Air or gas in liquid.

2. Badly worn bearings.

3. Bent shaft.

4. Pump running backwards.

5. Impeller plugged or damaged.

6. Pump foundation not rigid.

7. Liquid level in sump too low (pump casing not

properly submerged).

8. Not enough NPSH available.

9. Pump and driver shafts misaligned.

10. Liquid vortexing in sump.

MAINTENANCE

⚠WARNING: Do not attempt any maintenance,

inspection, repair or cleaning in the vicinity of rotating

equipment. Such action could result in personal injury

to operating personnel.

Before attempting any inspection or repair of the

pump, the driver controls must be in the "OFF" position,

locked and tagged to prevent injury to personnel

performing service on the pump.

Preventive maintenance

Pumps are ruggedly constructed, and with proper

care will give years of satisfactory service. It is

recommended that operating personnel become

familiar with "Operating Checks" described previously in

this book, and that these checks be made as a matter of

routine.

Periodically, depending upon your service schedule,

the unit should be dismantled, and all internal parts and

passages cleaned and inspected for wear. Any foreign

matter found in the pump should be removed, and all

excessively worn parts replaced.

Manufacturer assumes no responsibility or liability

for improper start-up, unattended pump operation or

routine inspection performance checks or maintenance.

The following is a list of normal maintenance

procedures that might be performed between major

overhauls:

Pump bearing lubrication - 'Product'

Pumps furnished with pumped-product bearing

lubrication need no maintenance checks other than

observing that product is flowing to bearings when

motor is energized. If there is no flow to bearings then

immediately de-energize motor, clean and flush bearing

tubing and fitting.

Pump bearing lubrication - 'Water'

Check frequently to see that water is flowing to

pump bearings. Water lubrication is needed to dissipate

heat and abrasives. Some bearings may always or

temporarily be above solution level. Flow of water

lubrication must be checked. To prevent motor from

being energized without proper and adequate water

lubrication to bearings, a DRI-STOP 2 flow switch can be

installed in the water to manifold. If this pump protector

device was included with pump assembly, then refer to

Operating Instructions and Service Guide O-1685, which

is included with the DRI-STOP.

⚠WARNING: Operation of the unit without proper

lubrication can result in overheating of the bearings,

bearing failures, pump seizures and actual breakup of

the equipment exposing operating personnel to

personal injury.

Overhaul instructions

Use extreme care in removing and dismantling

pump. Refer to pump assembly drawing for part

nomenclature.

1. Close control valve in discharge line.

2. Lock out power supply to driver.

3. Disconnect all electrical connections.

4. Disconnect any external auxiliary piping

connections.

5. Disconnect discharge piping from pump.

6. Unbolt pump support plate and lift pump from pit

(let casing drain thoroughly before removing pump

completely).

7. Remove liquid level controls (if any).

8. Lay pump horizontally on supports.

⚠IMPORTANT: These models have pressure lubricated

bearings, whereby the bearing cooling / lubricating

solution enters the pump column equidistant between

each pair of bearings.

Cleaning and inspection

All parts should be clean for inspection and

reassembly. Wash all parts and spread them out in a

clean area.

Dry the parts with compressed air or lint-free cloths

and carefully inspect them as described below. Discard

O-Ring and gaskets, as new ones should be used during

reassembly.

1. Inspect impeller for excessive wear and etching due

to corrosion. Large nicks and deep pits will

unbalance the impeller and cause vibration and

wear in other parts of the pump. Be sure O-Ring

sealing surfaces are clean.

2. Check pump shaft for straightness. Inspect the

surface of the shaft in the bearing areas to make

sure it is smooth. It must be free of grooves,

scratches, corrosion or wear. Check ends of shaft for

burrs. Make sure that shaft threads are clean.

3. Inspect casing thoroughly, removing all burrs and

foreign matter. Check hydraulic passages for

cleanliness.

WWW.SERFILCO.COM 2900 MacArthur Blvd. Northbrook, IL. USA 60062 (800) 323-5431

Operation and Service Guide

O-3180 - Page 6 of 8

03/05/21

© 2021 Serfilco Ltd, All Right Reserved.

®

2900 MacArthur Blvd. Northbrook, IL. USA 60062 WWW.SERFILCO.COM (800) 323-5431

Series 'EFB' | Sump Pumps

4. Check all other parts for burrs, wear, damage or

corrosion.

5. Inspect inside diameter or bearings. Check for

cracks uneven or excessive wear scoring or heat

discoloration, and corrosion. Bearings should be

replaced in accordance with the instructions given.

PUMP SERVICE

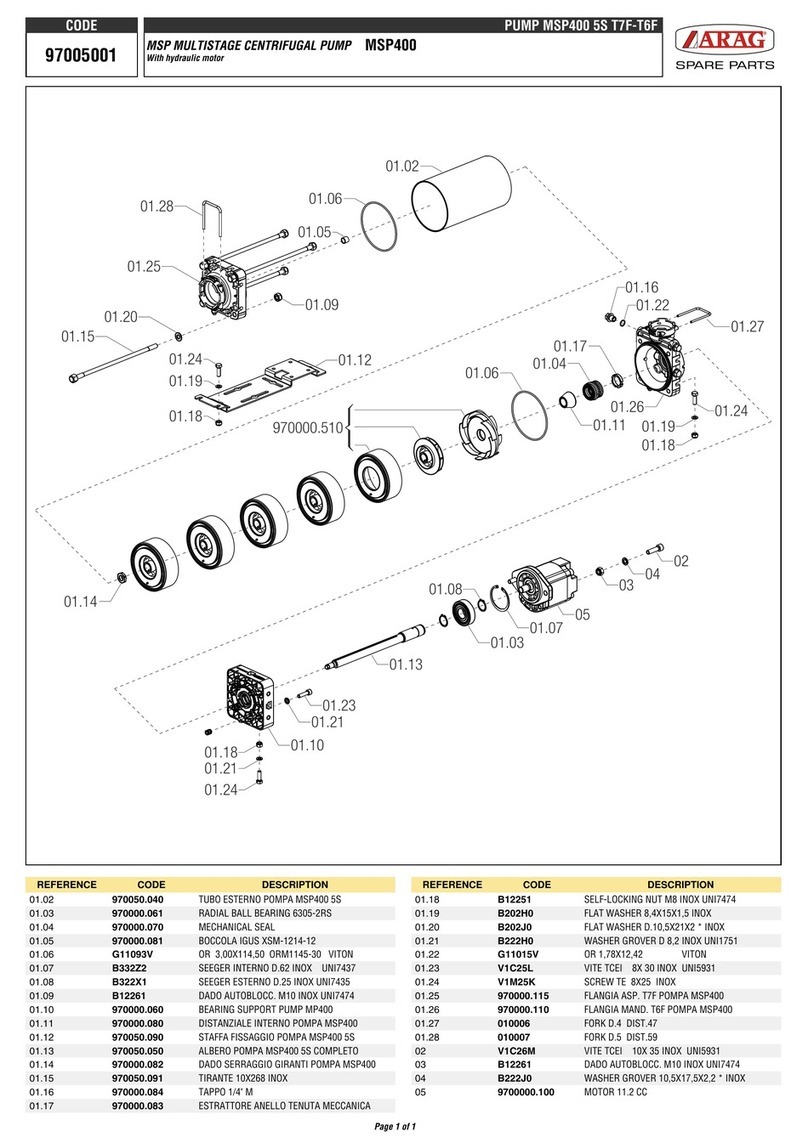

Refer to parts list P-3180 (Single Bearing Pump) or

parts list P-3182 (Double Bearing Pump). The only parts

considered for normal replacement are the ceramic

casing liner and the rotating bearings (2) (Rulon or

graphite) for each bearing assembly. Under abnormal

conditions of service these components, the impeller,

the impeller sleeve assembly and even the stainless

steel drive shaft may fail prematurely. Major causes for

premature failure are:

1. Clogged suction strainer.

2. Clogged cooling/lubricating lines to bearings when

product flushed.

3. Failure of water supply to bearings when water

lubricated

4. Motor energized before suction casing is immersed

in solution.

5. Incorrect direction of rotation.

Before proceeding with pump service, be sure the

assembly is disconnected from piping and electrical,

drained and flushed.

Replace impeller and bearing bushings

1. Loosen and remove casing bolts and lock nuts.

Remove suction casing and O-Ring. Note correct

position of suction casing for reassembly.

2. With vise grips or channel lock pliers, hold pump

shaft just below motor (or hold motor armature at

fan blade). With a chain wrench around the impeller,

turn the impeller-sleeve-bearing assembly in a

counterclockwise direction until the assembly is

unscrewed from the pump shaft, and remove with

care.

3. With vise grips or channel lock pliers now on the

sleeve assembly (above bottom bearing), the

impeller may be turned in a Clockwise Direction

(Left Hand Thread) to remove from sleeve.

4. Note position angle of grooves and slide old

bearings off sleeve. Replace with new bearings,

noting correct angle of grooves, and new bearing

spacer.

5. If pump has only a single pair of bearings, then

proceed to step 9.

6. Second set of bearing rings are removed by turning

top shaft sleeve from bottom shaft sleeve in a

Clockwise Direction (Left Hand Thread) to loosen.

7. Replace with new bearings, noting correct angle of

grooves, and new bearing spacer.

8. Replace or inspect shaft sleeve O-Ring then thread

top shaft sleeve to bottom shaft sleeve in a Counter

Clockwise Direction to tighten.

9. Replace or inspect impeller O-Ring, thread new

impeller to sleeve Counter Clockwise Direction

tighten.

10. Replace impeller-sleeve-bearing assembly to drive

shaft.

11. Replace or inspect suction casing O-Ring.

12. Reassemble suction casing and if removed, fan

blade and fan housing.

WWW.SERFILCO.COM 2900 MacArthur Blvd. Northbrook, IL. USA 60062 (800) 323-5431

Operation and Service Guide

O-3180 - Page 7 of 8

03/05/21

© 2021 Serfilco Ltd, All Right Reserved.

®

2900 MacArthur Blvd. Northbrook, IL. USA 60062 WWW.SERFILCO.COM (800) 323-5431

Series 'EFB' | Sump Pumps

Replace lower ceramic liner

1. Refer to: "Replace impeller and bearing

bushings", steps 1 and 2 to remove impeller sleeve-

bearing assembly.

2. Remove Support Casing by unscrewing the (6) Cap

Nut Studs.

3. Remove Pin Holder Ring by spreading it apart to

slide over inside pins. Remove the two Liner Lock

Pins. Remove ceramic liner by sliding it out of the

Column.

4. Install new liner into Column and lining up holes.

Insert the two Liner Lock Pins. Longer part of the pin

goes in first.

5. Replace Pin Holder Ring by spreading it apart to

slide over inside pins.

6. Replace the Support Casing with the (6) Cap Nut

Studs. Make sure to replace the (2) O-Ring at each

Cap Nut Stud.

7. Replace impeller-sleeve-bearing assembly to drive

shaft.

8. Replace or inspect suction casing O-Ring.

9. Reassemble suction casing and if removed, fan

blade and fan housing.

Replace upper ceramic liners

1. Refer to: "Replace impeller and bearing

bushings", steps 1 and 2 to remove impeller sleeve

bearing assembly.

2. Remove lubrication hose from upper bearing.

3. Unscrew 3/4NPT Column Locking bushing from

column coupling.

4. With strap wrench, securely hold column above

bearing assembly and using second strap wrench,

unscrew lower column from bottom of bearing

assembly.

5. Remove the two pins in the ceramic liner. Note the

position of the flush hole in ceramic liner Remove

ceramic liner by sliding out.

6. Install new liner making sure flush hole is in same

position and secure using the two pins.

7. Tighten lower column into upper column, making

sure you see ceramic flush hole through coupling.

8. Replace 3/4NPT Column Locking Bushing into

column coupling

9. Install impeller-sleeve-bearing assembly. View

through flush hole in bearing housing to verify that

bearing spacer is in view. Then reinstall lubrication

hose.

REFERENCE DOCUMENTS:

Product Bulletin

Series 'EFB' Sump Pumps P-318

Technical Bulletin

Series 'EFB' Sump Pumps T-P-318

Parts List

Series 'EFB' Single Bearing Sump Pump P-3180

Series 'EFB' Sump Pumps Double Bearing P-3182

WWW.SERFILCO.COM 2900 MacArthur Blvd. Northbrook, IL. USA 60062 (800) 323-5431

Operation and Service Guide

O-3180 - Page 8 of 8

03/05/21

© 2021 Serfilco Ltd, All Right Reserved.

®

2900 MacArthur Blvd. Northbrook, IL. USA 60062 WWW.SERFILCO.COM (800) 323-5431

Series 'EFB' | Sump Pumps

TABLE OF CONTENTS

⚠Caution ............................................................................1

Auxiliary connections......................................................1

Pump bolting: .................................................................1

Safety..................................................................................1

Installation, operation and maintenance ............................1

Safety precautions before starting pump ..........................1

Before changing application or performing maintenance .1

⚠ Important: ......................................................................1

APPLICATION ......................................................................1

Materials in solution contact ............................................. 1

Check upon arrival ..............................................................2

Storage ...............................................................................2

Uncrating............................................................................2

Handling .............................................................................2

Cleaning the pump .............................................................2

Location..............................................................................2

Factory assembly and test...................................................2

Pump mounting..................................................................3

Electrical ............................................................................. 3

Piping..................................................................................3

PRE-STARTING CHECKS .......................................................3

Motor preparation .............................................................3

Pre-start-up ........................................................................3

Product flush lubricated pump bearings............................ 3

Water-lubricated pump bearings.......................................3

Operation & start-up ..........................................................4

Operating checks................................................................4

Stopping the pump............................................................. 4

Minimum flow .................................................................... 4

Trouble chart ......................................................................4

No liquid delivered: ............................................................4

Not enough pressure:......................................................... 4

Not enough liquid delivered:..............................................4

Pump uses too much power: .............................................5

Excessive vibration: ............................................................ 5

Maintenance.......................................................................5

Preventive maintenance .................................................... 5

Pump bearing lubrication - 'Product' ................................. 5

Pump bearing lubrication - 'Water' ....................................5

Overhaul instructions .........................................................5

Cleaning and inspection ..................................................... 5

Pump service ......................................................................6

Replace impeller and bearing bushings ............................. 6

Replace lower ceramic liner ...............................................7

Replace upper ceramic liners .............................................7

Reference documents: ........................................................7

Product Bulletin..................................................................7

Technical Bulletin ...............................................................7

Parts List ............................................................................. 7

Table of Contents................................................................8

Table of contents

Popular Water Pump manuals by other brands

Grizzly

Grizzly GP 2736 K Translation of the original instructions for use

Franklin Electric

Franklin Electric FLS-400 manual

Oase

Oase AquaMax Eco Classic 3600 operating instructions

Salamander Pumps

Salamander Pumps CTFORCEU manual

Xylem

Xylem Lowara Ecocirc Premium Series manual

Crane

Crane burks pumps WB4 Installation and operation manual

emaux

emaux SPV Series user manual

Alemite

Alemite 7886-S5 Service guide

Pentair

Pentair Sta-Rite DMC Series Installation and operation manual

Spirax Sarco

Spirax Sarco APT10-2 Installation and maintenance instructions

Grundfos

Grundfos GT-C Installation and operating instructions

DROPSA

DROPSA 3414 Series User and maintenance manual