Serigstad FLEXIFEED User manual

INSTRUCTION MANUAL

08.07.2019

Automate heavy and time consuming work!

FLEXIFEED

Etbl. 1864

CONTENTS

INTRODUCTION

DECLARATION OF CONFORMITY

SAFETY

INSTALLATION

CONNECTING

CUSTOMIZATION

USE

MAINTENANCE

TROBLESHOOTING

SPARE PARTS

OPTIONAL EQUIPMENT

RECYCLING

CONTACT

3

4

5 - 11

12

13 - 15

17 - 19

21 - 22

23 - 25

26

27 - 34

35 - 38

39

40

A great deal of the heavy silage

handling is taken away due to

Serigstad feed solutions.

We appreciate the trust shown to our company purchasing Serigstad

FlexiFeed. The product is tested and built on a highly reliable and known

technology. The product fulll strict safety and quality requirements.

On delivery our distributor will give you information about control,

maintenance and adjustments on the machine. The brief introduction

is not a compensation for the more detailed and necessary information

given in this instruction manual.

This instruction manual includes detailed safety instructions, use and

maintenance guidance, knowledge of functions and use of FlexiFeed.

Dear customer!

INTRODUCTION

The system has one year warranty against fabrications- and material

defects. Serigstad Agri reserve the right to change the design without

obligation for previously delivered products.

We hope the product meets your expectations and needs!

Best regards

Helge Njærheim

Research & Development Manager

Serigstad Agri

4

DECLARATION OF CONFORMITY

SAFETY INSTRUCTIONS

DANGER

WARNING

WARNING!

ALWAYS CHECK MACHINE BEFORE USE TO ENSURE PROPER AND SAFE

OPERATION.

COVERS AND PROTECTIVE MEASURES MUST ALWAYS BE CLOSED DURING

OPERATION.

KEEP VISUAL SUPERVISION OF MACHINE DURING STARTUP AND OPERATION.

MACHINES PLACED ON STANDS, PLATFORMS OR IN RAILS MUST BE

SECURED WITH OBSTRUCTIONS OR SAFE ZONE TO PREVENT ACCESS TO

HAZARD AREAS.

Indicates an imminent dangerous situation which, if not avoided, may

result in serious injury or death.

Indicates a potential dangerous situation which, if not avoided, may

result in serious injury.

The label shows exposed danger areas when he covers are opened or

removed.

SAFETY

6

Read instruction

manual before use.

Keep distance to run-

ning equipment.

Do not stand in danger

zone during startup or

operation!

Serial number plate

Lifting: See dened lifting points labeled on

machine.

Use labeled points when lifting the machine.

Use labeled points for lifting the machine with forklift.

Keep clear to hanging load!

SAFETY FIRST!

Crushing hazard, op-

erating machine can

cause serious injury

or death.

Transport

Covers must be closed

during operation.

Figure 1 FlexiFeed with machine labels

DANGER ZONE

Tighten conveyor belt after

use of new machine.

(Paint is worn o).

Check frequently!

SAFETY

Danger sign 996745 - red zone

WARNING! Disconnect power supply before entering

high risk area for maintenance or adjustments.

Standing in danger zone during operation may cause

serious injury or death.

Warning sign 996746 - red and yellow zone

Be careful! High voltage. Disconnect power supply

before opening control cabinet.

Warning sign 996763 - red zone

Be careful! Crushing hazard that may cause serious

injury or death! Keep distance when machine is

running.

Warning sign 996766 - red zone

Be careful! All covers must be closed when machine

is running. Fingers and limbs can be damaged if they

are in contact with rotating parts.

Warning sign 7996765 - red and yellow zone

Be careful! Keep distance to running equipment. Do

not stand in hazard area during startup or operation.

Objects may be thrown out of machine during

operation.

Warning sign 996760 - red and yellow zone

Be careful! Make sure you read and understand the

instruction manual before startup, maintenance and

adjustments are made.

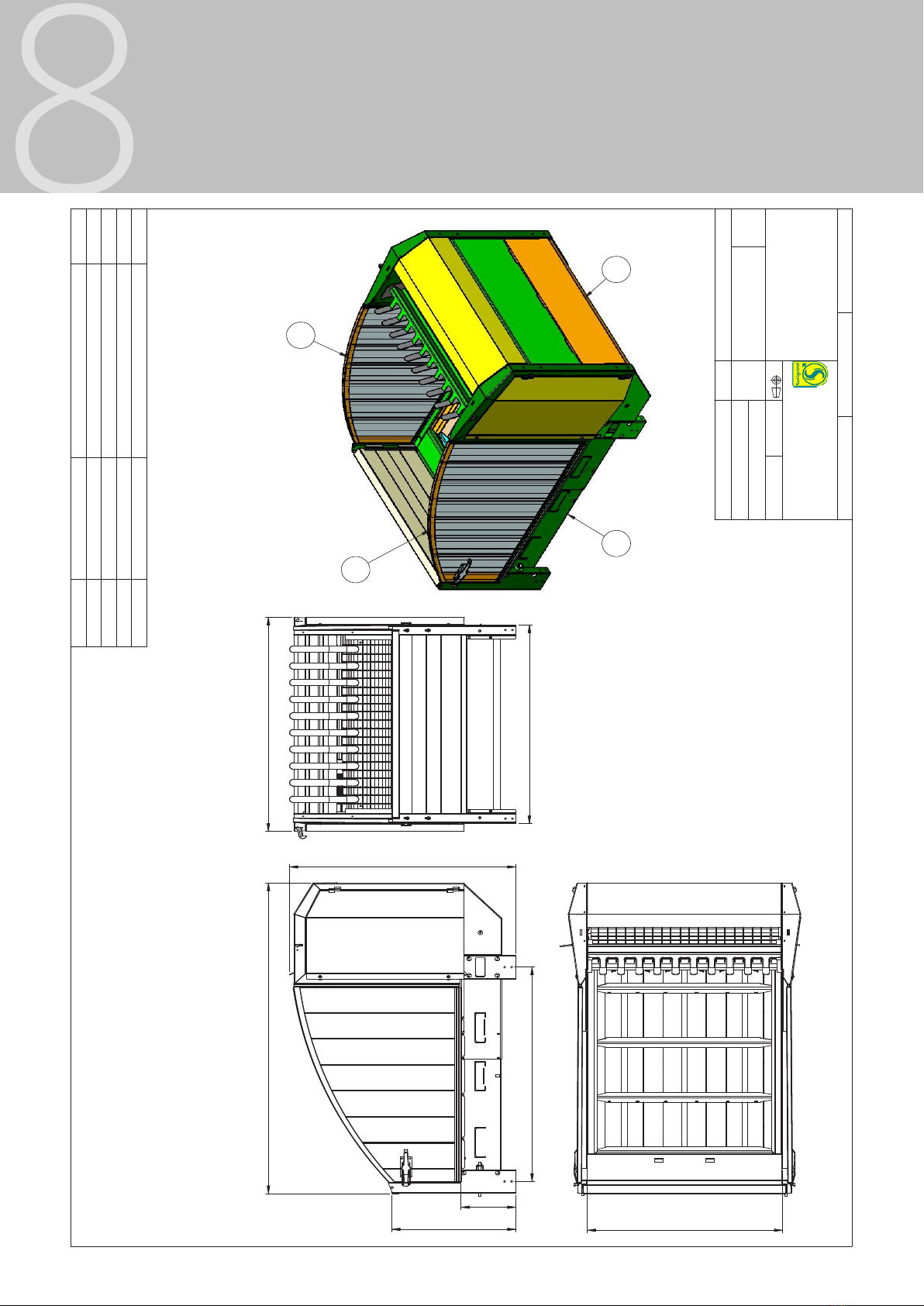

DIMENSIONS

8

Figur 2 Dimensional sketch of FlexiFeed

2 1

4

3

1386,0

1649

1529,0

T1

16.10.2012

RBK Flexifeed

Weight

Material: Thickness: Surface treatment:

Sheet scale: Drawing number. Revisjon:

Serigstad Agri AS

Helge

Projection:

Content in: Replaced by:

A3

Designed by:

Project:

RBK Flexifeed

1:1

Helge

7104682

NS-1430:

Tolerance not specified according to:

390

1606

881

2392

1652

ITEM NO. PART NUMBER DESCRIPTION QTY.

1 17036 Montert frontseksjon 1

2 17035 Bunnramme 1

3 17058 Høyre sidedør 1

4 17059 Venstre sidedør 1

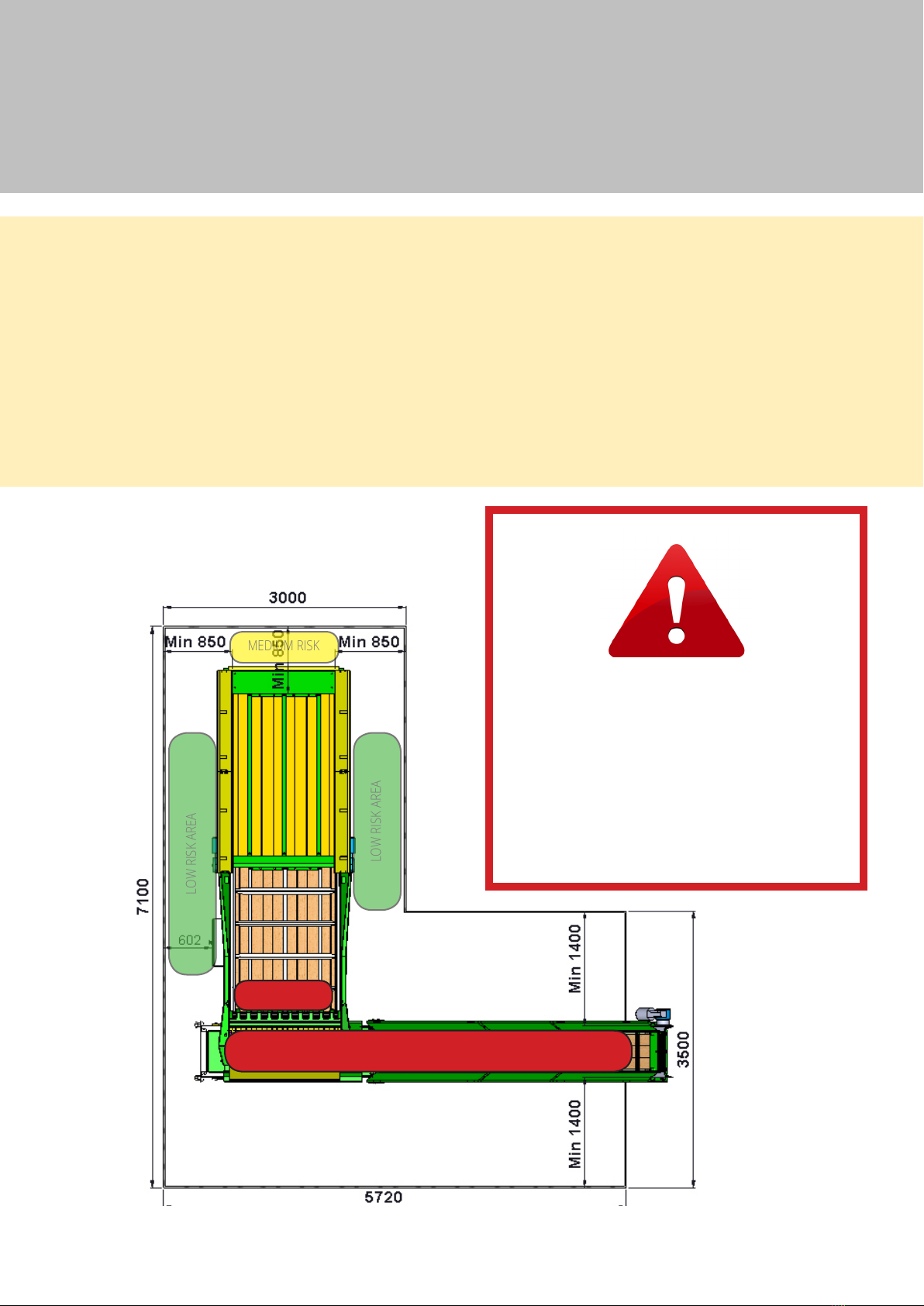

HAZARD AREAS

HIGH RISK AREA

LOW RISK AREA

MEDIUM RISK

LOW RISK AREA

HIGH RISK AREA

Outside safety barrier = low risk zone

Inside safety barrier = high risk zone

Safety zones around the equipment with

minimum distances must be followed to

prevent damage to humans and animals.

Before entering high risk areas for

maintenance, adjustments or repairs,

always turn o and lock the main power

switch.

Represents hazard area which may cause serious injury during operation

Represents potential hazard area which may cause accidents and injuries

during operation.

Represents low risk of accidents and injuries during operation

Red area

Yellow area

Green area

Figure 3 Hazard areas around FlexiFeed

10

HAZARD AREAS

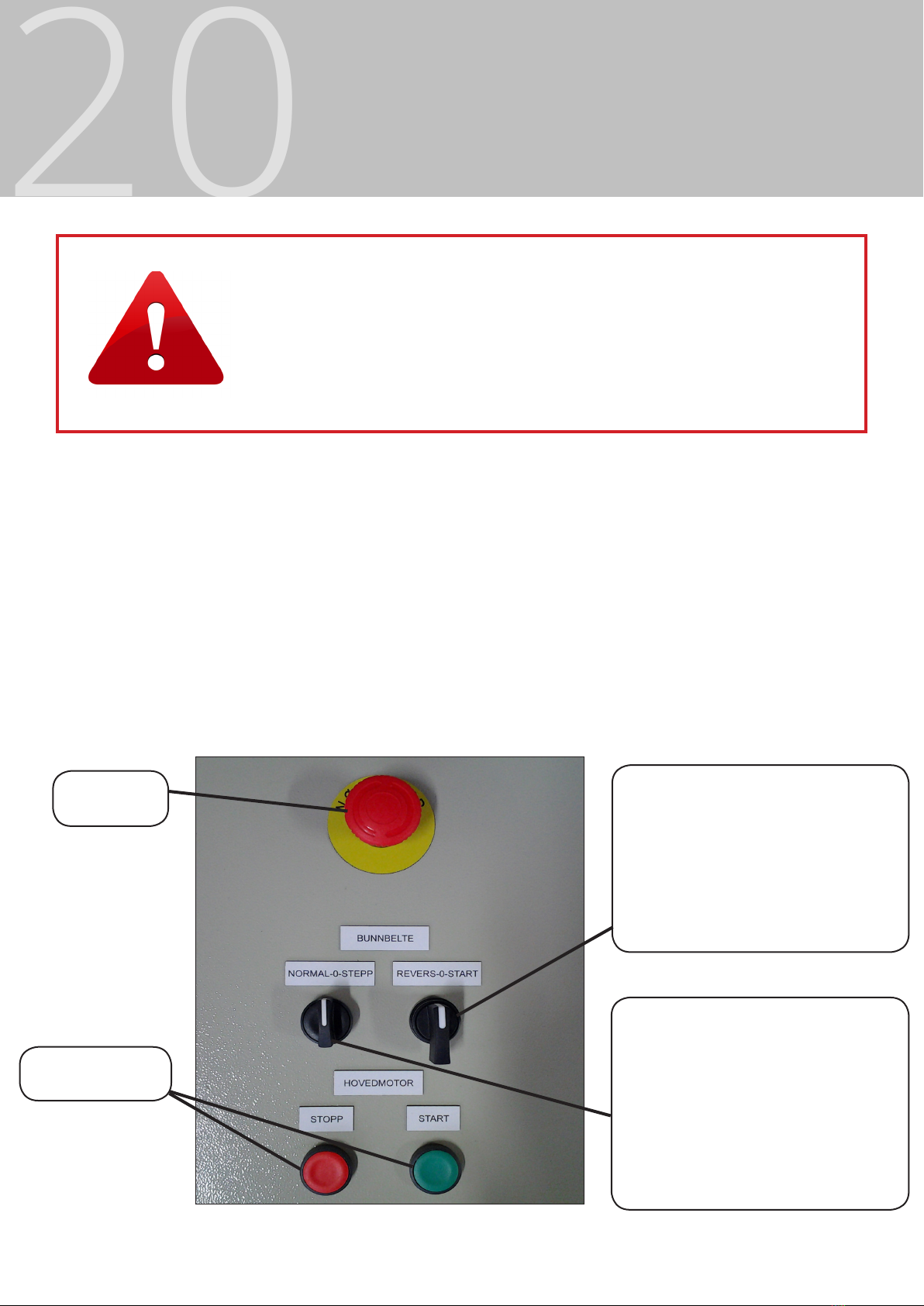

SAFETY FUNCTIONS

• Emergency stop button is placed on front of control cabinet.

• Lockable main power switch is placed on left side of control cabinet.

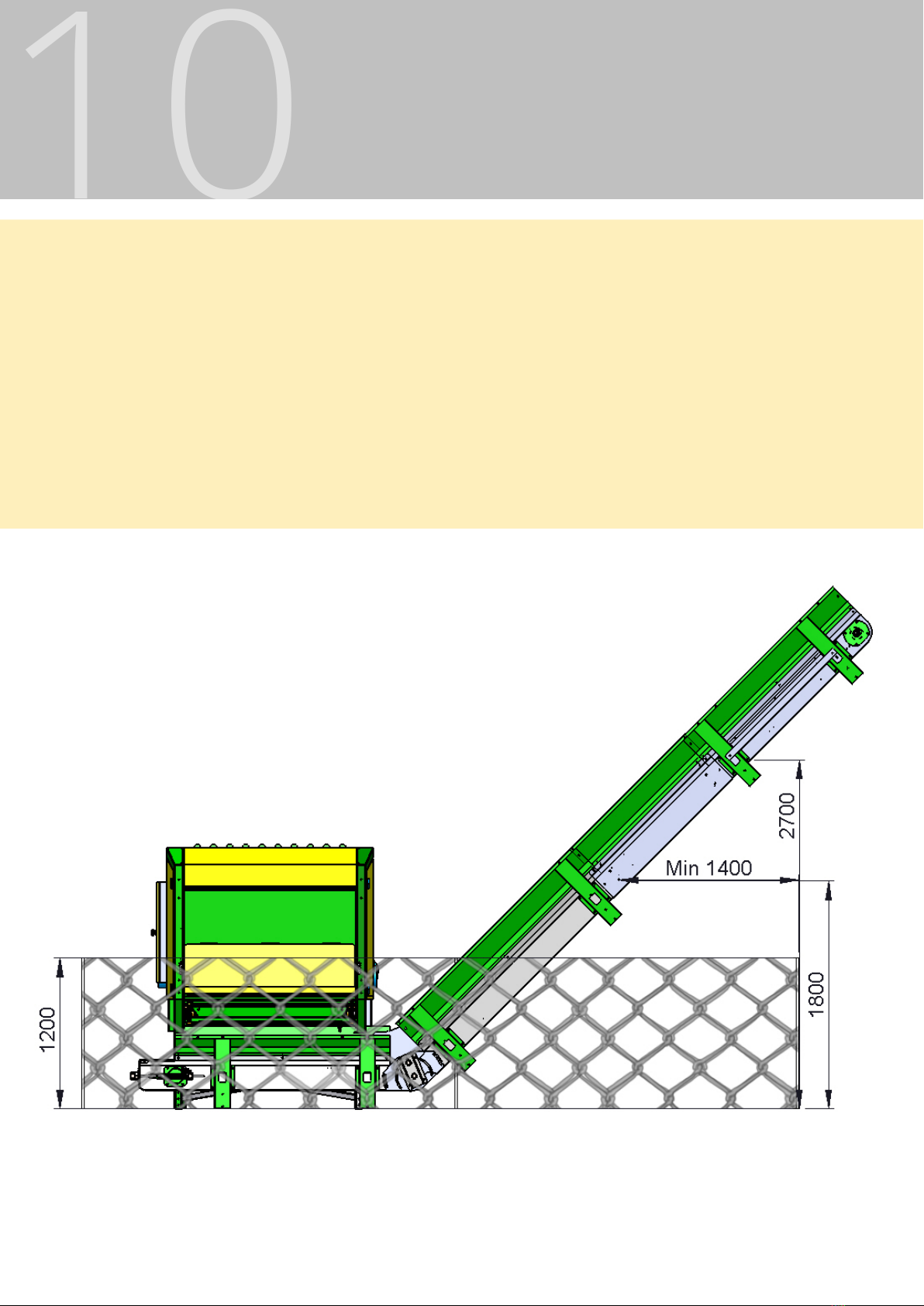

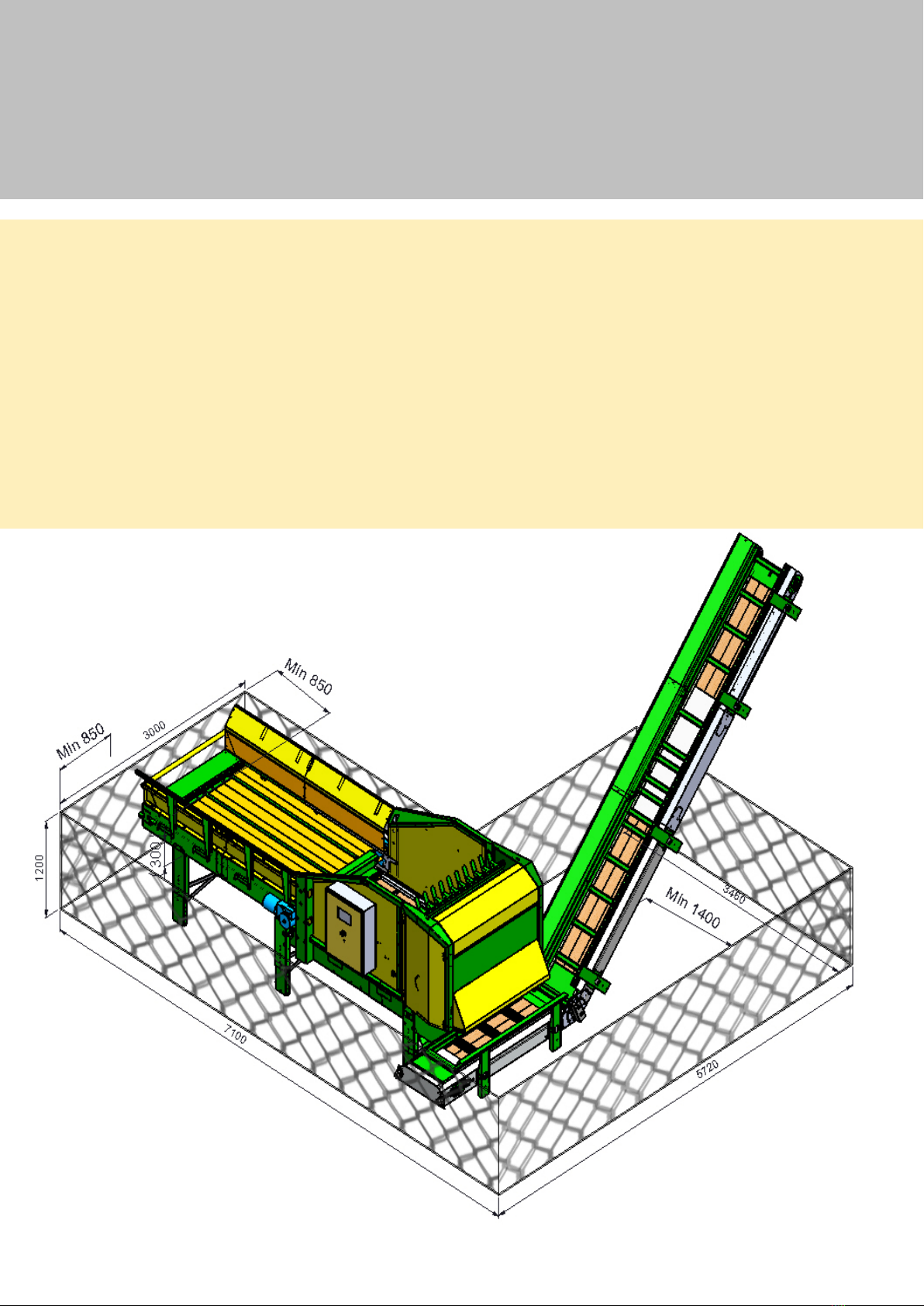

Figure 4 FlexiFeed with chained conveyor and safety fence.

HAZARD AREAS

Height of safety fence (according to standard: EN ISO 13857:2008):

• If FlexiFeed is raised with extended leg set, the height of the safety fence must be at least

300 mm higher than the lower frame on the feed table. See gure 4 and 5.

• As an alternative to higher safety fences all distances of at least 850 mm can be raised to a

minimum of 1400 mm.

• Minimum recommended distance from safety fence to conveyor is 600 mm, safety fence

towards the conveyor is always to be a minimum of 2000 mm high.

Conveyor

Figure 5 FlexiFeed with feed table,

chained conveyor and safety fence.

INSTALLATION

12

INSTALLATION OF EXTENSION LEGS AND SUPPORT RODS

When extended leg sets are used for FlexiFeed, and optionally free standing or integrated feed

table, it is important to assemble the support rods correctly. The legs on the FlexiFeed as well as

the feed table are mounted to the oor, taking the oor material and quality into account. The

support rods are then mounted on the legs.

Figure 6 FlexiFeed with integrated feed

table. If the feed table consists of multiple

sections, the support rods are placed in the

top position.

On the machine itself the legs are mounted in the

lowest position, due to the design of the machine.

On the feed table the support rods are assembled

on the highest position. This takes care of the

loads and stress on the feed table during loading

of bales. Mounting the support rods in the top

position makes it easy to access the underside of

the machine for cleaning and maintenance.

FLEXIFEED VERSIONS

FlexiFeed can be delivered in a range of dierent

versions to suit your installation. It is possible to

have xed sides, or one or two side doors for

loading from the side. The standard length is

240 cm long. A 280 cm version with xed sides is

available.

A version with integrated feed table is also available (shown in gure 6).

CONNECTING

CONTROL CABINET

The control cabinet is factory-tted and assembled in front or on either side of the machine,

according to the order.

Always keep the machine under observation during operation to avoid damage to people or

animals.

All connections must be performed by authorized personnel.

VOLTAGE

FlexiFeed is available in 230V and 400V versions.

Motor eect 230 V 400 V

Cutter 7,50 kW 25,35 A 14,64 A

Conveyor belt 0,75 kW 3,34 A 1,93 A

CrossFeeder 0,75 kW 3,34 A 1,93 A

Conveyor (external) 2 x 2,20 kW 8,34 A 4,34 A

Feed table 2 x 0,55 kW 2,85 A 1,65 A

Recommended fuse size

3 phase + ground for 230 V

3 phase + neutral + ground

for 400 V

Min. 35 A Min. 25 A

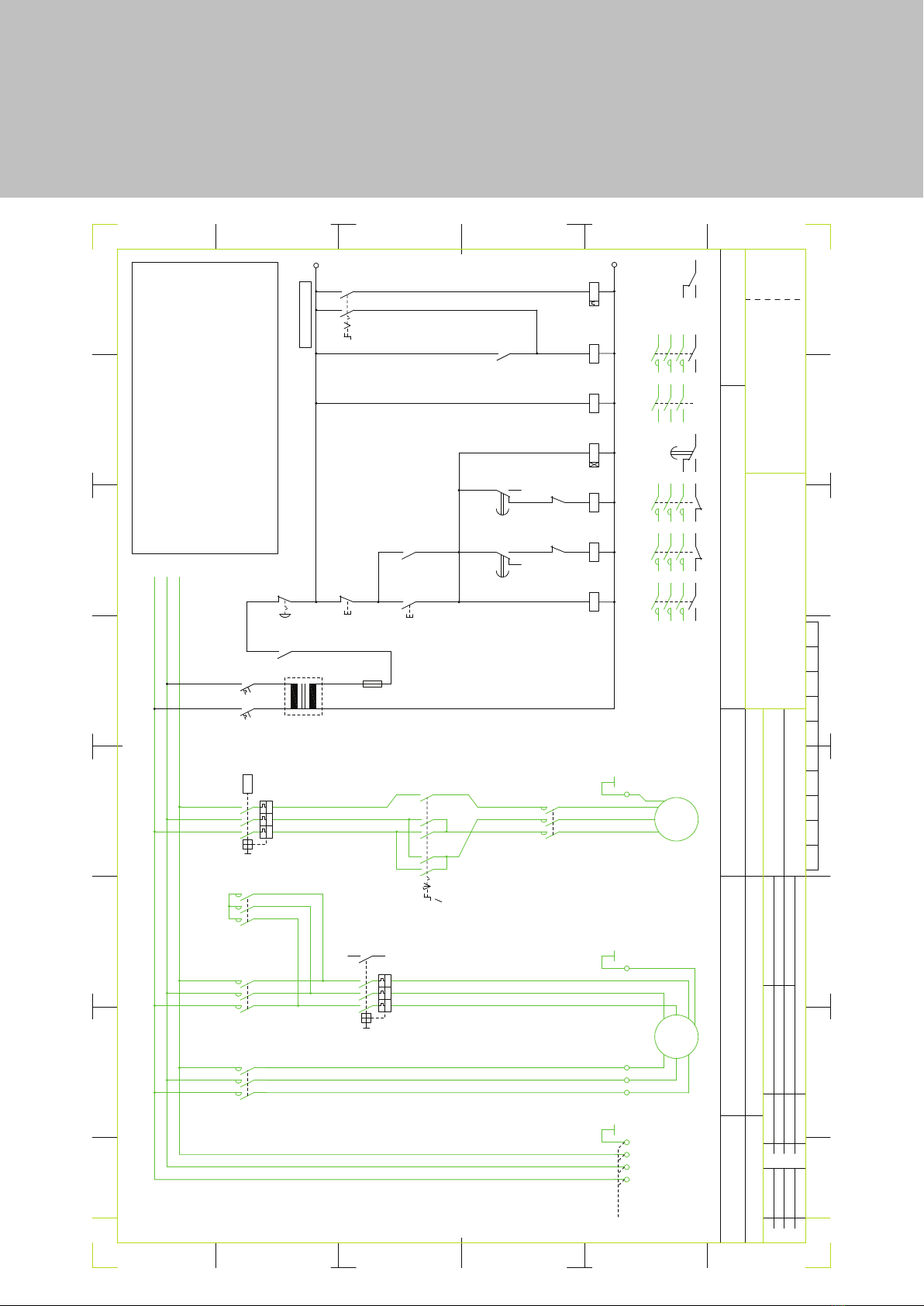

CONNECTION 230V

14

-S3

-X1-X1

FLEXIFEED FFS-7,5kW 230VAC (7466827)

(+ STEPP/CYKL)

STYRESKAP

FLEXIFEED FFS-11kW 230VAC (74668**)

-X1

-K2

-K1

-K3

3E-06/916

-F2

-K1T

-K3

-K2

-K4T

-K4

-Q1

-K4

-K1T

-S2

-K1

-S1

-K1

-K2

-K3

-Q2

-FA1

-F2

-Q1

-S0

-K1T

-K4T

-S4

-X2 -X2

10 9

2 1

4 3

6 5

8 7

REVERS-0-START

v

3x230 V AC / max. 40 A

STROMTILFORSEL

Revision

Revision

1

F

PG29, 2xPG16

E

PG29, PG21

L3

L1

L2

[11 kW]

(add)

L1

L2

L3

STYRESTROM 230V AC

Circuit diagram

0,75 kW7,5 kW [11kW]

KABEL F.TRANSPORTBELTE 230VAC

Nákladní 1032, 415 01 TEPLICE, CZ

EMCOS

s.r.o.

KABEL HOVEDMOTOR 230VAC-7,5kW; [230VAC-11kW]

04.12.2003

Date

Assembly place

2

Prepared by

Agreed by

Molnár

Molnár

SERIGSTAD AS, Norway

3

FLEXI4S.dwg

Order No.

Ident.

Title

6

PE

RUNDBALLEKUTTER

W1

U1

V1

PE

W2

3~ U2

V2

M

3

2

1

PE

PE

TRANSPORTBELTE

PG13,5

V1

U1

PE

W1

3~

M

14

22

13

/.6.C /.6.D

21

/.2.B /.3.B

PE

A2 A1

A2 A1

/.6.E

22 21

7

Drawing No.

8

Index

F

13

22

16

18 15

21

/.6.D /.6.D

/.3.B /.4.B

14

16

18 15

STEPP/CYKL 230V AC

/.7.D

/.4.D

E

D2 D1

A2 A1

A2 A1

U<

/.6.E

22 21

A2 A1

A2 A1

D

C

B

A

1

Q1/7,5kW

Q1/11kW

4

2

[23A]

16,3A

I> I>

14 13

6

I>

/.5.B

16

/.7.E

18 15

4

6

2

/.8.E

3

5

1

START

13 14

4 3

/.6.E

STOPP

2 1

/.6.E /.6.E /.6.E

U<

I>I> I>

/.7.E

4 3

2 1

v

v

B6A

14 13

/.3.C

1 2

NODSTOPP K1T

FA1

K3

Q2

F2

L3

3PE AC 50Hz 230V

K2

K1

L1

L2

16

/.7.E

18 15

/.8.E

15 18

D

C

14 13

GV-AU225 (220-240VAC)

RE11 RA MU (10s, 24-230VAC)

C60H-B6A, 2P

B

S4

S3

S2

S1

S0

LC1-D12 P7(M7)

GV2-ME20, GV-AE1

GV2-ME21, GV-AE1

GV2-ME08

LC1-D25 P7(M7)

LC1-D25 P7(M7)

ZB5-AA3, ZBE-101 (NO)

A

K1SE 54602Z

ZB5-AD3, 2x ZBE-101 (NO)

ZB5-AA4, ZBE-102 (NC)

ZB5-AS844, ZBE-102 (NC)

2345678

21

2AC 50Hz 230V

PG16

K4T RE11 RL MU (24-230VAC)

LC1-D09 P7(M7)K4

PG13,5

a) 21.06.04

d

b) 25.01.05

24 23

NORMAL-0-STEPP

c) 09.05.06

d) 21.09.06

AD VB8/4

2xAD VB8/4

-CYA6/4

1xWK4SL/U

-CYA0,75

-CYA2,5 -CYA2,5 -CYA2,5 -CYA1,5

3xWK4/U 1xWK4SL/U

2xWK2,5/U, 1xWK4SL/U

6xWK6/U, 1xW6SL/U,

3xWK6/U, 1xW6SL/U,

CONNECTION 400V

FLEXIFEED FFS-7,5kW 400VAC (7466828)

FLEXIFEED FFS-11kW 400VAC (74668**)

(+ STEPP/CYKL)

STYRESKAP

-X1

-X1

-K1

3E-06/917

-K3

-K1T

-K2

-K3

-K2

-K4T

-K4

-F2

-Q1

-S2

-S1

-FU1

-K1

-K2

-K3

-FA1

-Q2

-F2

-Q1

-S0

-T1

-K1T

-K1T

-K4T

-K1

-K4

-X2

-X2

-S3

-S4

STROMTILFORSEL

3x400 V AC / max. 25 A

Revision

F

E

/.6.C

/.2.B

0,75 kW7,5 kW [11kW]

FLEXI4S.dwg

SERIGSTAD AS, Norway

KABEL HOVEDMOTOR 400VAC-7,5kW; [400VAC-11kW]

Agreed by

Assembly place

Prepared by

Revision

Date

12

04.12.2003

3

Molnár

Molnár

Ident.

Order No.

EMCOS

s.r.o.

Nákladní 1032, 415 01 TEPLICE, CZ

KABEL F.TRANSPORTBELTE 400VAC Title

W1

V1

PG29, PG21

PE

RUNDBALLEKUTTER

W2

U1 3~ U2

V2

M

1

PEN

2

3

PE

TRANSPORTBELTE

13

Drawing No.

Circuit diagram

678

Index

F

18 15

16

STEPP/CYKL 230V AC

18 15

22

16

22

14

STYRESTROM 230V AC

21

/.6.D /.6.D

21

/.6.D

/.3.B /.3.B

13

14

/.4.B /.4.C

A2 A1

A2 A1

A2 A1

A2 A1

/.6.E

22 21

/.6.E

22 21

A2 A1

D2 D1

U<

/.7.D

E

A2 A1

D

C

B

A

3PEN AC 50Hz 400V

0 0

230 400

14 13

4

I>

9,3A

I>

2

[13,1A]

I>

6

/.5.B

2A

2 1

START

STOPP

/.6.E /.6.E /.6.E

U<

I>I> I>

/.7.E

14 13

400/230V

100VA

/.3.C

4 3

2 1

v

v

B6A

NODSTOPP

16

/.7.E

18 15

/.7.E

16

18 15

/.8.E

15 18

4 3

13 14

/.6.E

2 1

D

C

14 13

1 2

L3

L1

L2

B

A

12345678

3

5

3~

M

V1

U1

2

PG13,5

PE

W1

PE

4

6

/.8.E

1

PG13,5

1

2

LC1-D09 P7(M7)

LC1-D18 P7(M7)

LC1-D18 P7(M7)

LC1-D09 P7(M7)

C60H-B6A, 2P

GV2-ME07

GV-AU225 (220-240VAC)

RE11 RA MU (10s, 24-230VAC)

GV2-ME14, GV-AE1

GV2-ME16, GV-AE1

RE11 RL MU (24-230VAC)

K1T

FA1

Q2

F2

K4T

K3

K2

K1

K4

Q1/7,5kW

Q1/11kW

CSTN100, 100VA

400/230VAC

ASK1, SF-2A/250VFU1

T1

6 5

v

2 1

4 3

10 9

8 7

L3

L1

L2

(add)

PG16

ZB5-AA3, ZBE-101 (NO)

ZB5-AA4, ZBE-102 (NC)

ZB5-AS844, ZBE-102 (NC)

K1SE 54602Z

ZB5-AD3, 2x ZBE-101 (NO)S4

S3

S2

S1

S0

NORMAL-0-STEPP

24 23

c

a) 25.01.05

b) 09.05.06

c) 21.09.06

REVERS-0-START

AD VB8/4

3xWK4/U

-CYA2,5

-CYA0,75

-CYA2,5 -CYA2,5 -CYA2,5 -CYA1,5

1xWK4SL/U

2xWK2,5/U, 1xWK4SL/U

3xWK6/U, 1xW6SL/U, 1xWK4SL/U

16

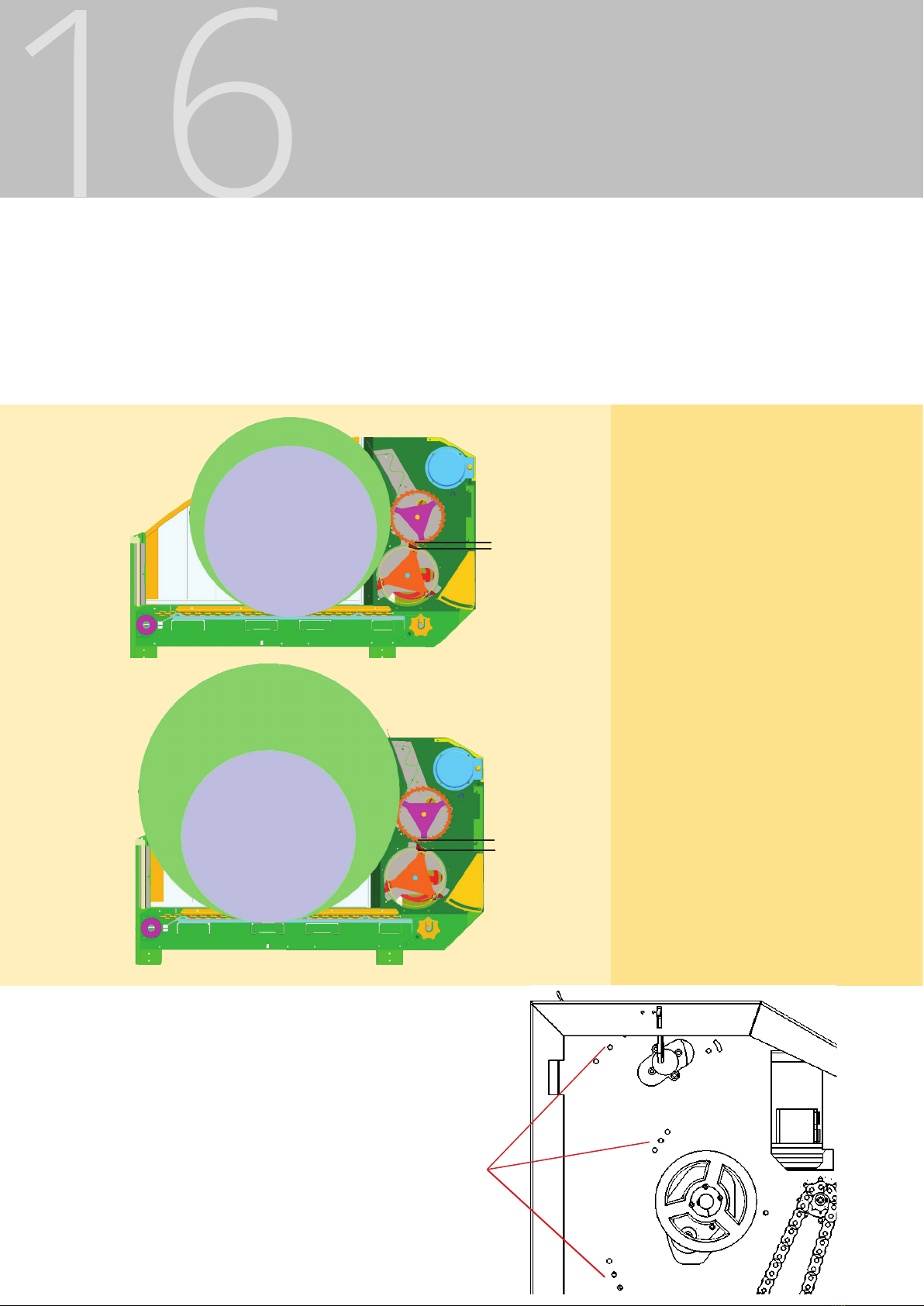

CUSTOMIZATION

Figure 7 The smallest

opening between knife drum

and spiked reel. Maximum

recommended bale size is

1,4 m diameter.

1,4 m

Figure 8 The largest

opening between knife

drum and spiked reel.

To adjust drum opening, remove

these three bolts on each side.

Place gate in desired position and

fasten bolts

Figure 9 Holes for adjusting the drum opening

DRUM OPENING AND BALE SIZE

There are three selectable drum openings to choose from.

- Minimal drum opening processes the grass more and prolongs operating time.

- The centre drum opening is the factory setting, and is used in most cases.

- Large drum opening for bales with diameter 1,8 m and high capacity.

1,8 m

1,4 m

TILPASNING AV MASKIN

18

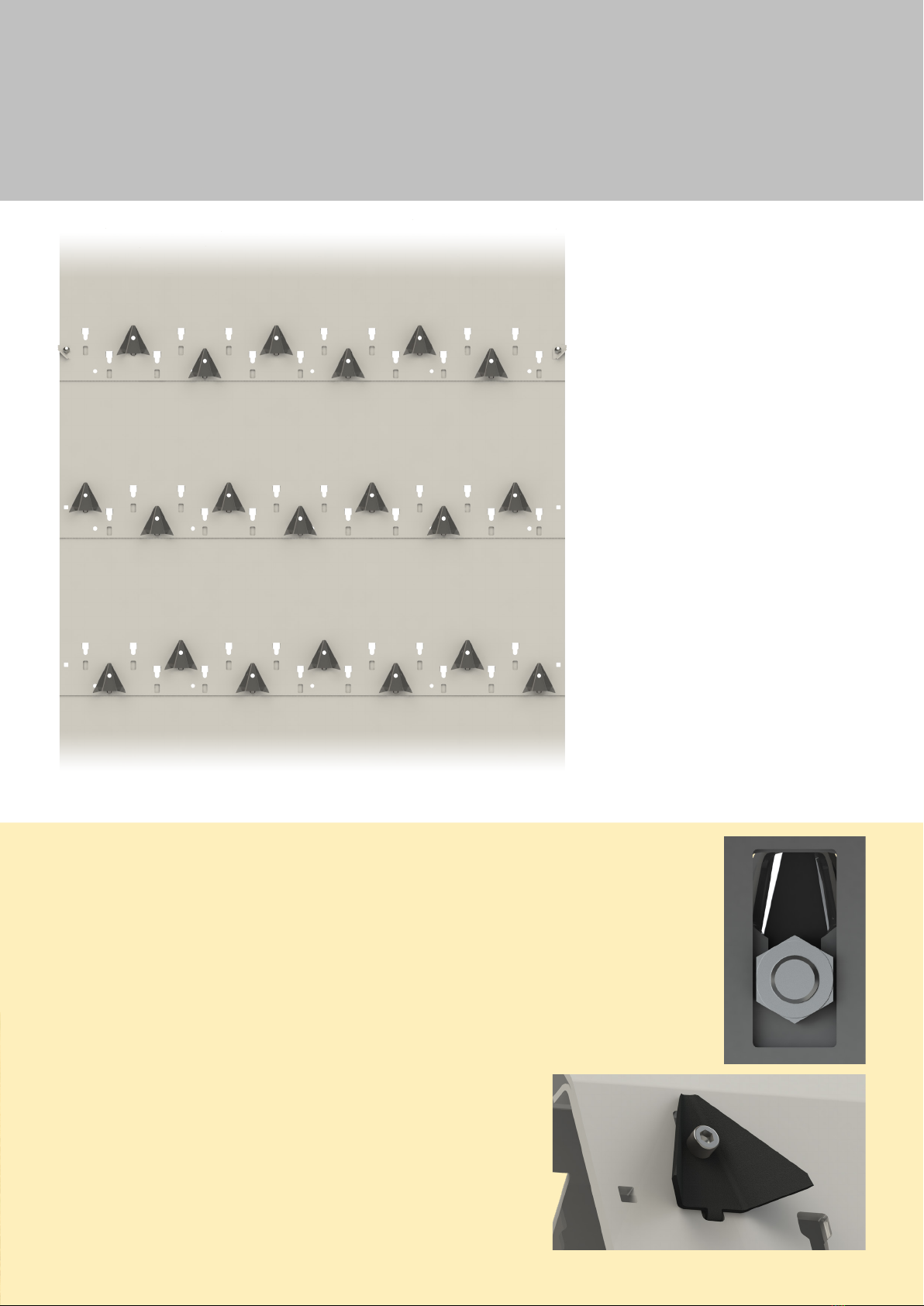

KNIFE SETUP

TYPES AND PLACEMENT OF KNIVES

FlexiFeed is delivered with a knife drum capable of holding up to 60 knives as standard.

Correct type and placement of knives is important to ensure optimal feeding as well as reliable

operation. The choice is governed by several factors including dry matter content, reliability and

cutting rate.

As a starting point a standard set of 20 standard knives, placed in the pattern as shown on next

page, is recommended for FlexiFeed.

The number of knives can be increased with the intention of increasing

the rotation of the bale and thereby increase the capacity. Increased

number of knives will not necessarily provide better cutting, as the extra

knives will go in the same groove as the knives in the standard setup. If

it is desirable to increase the number of knives, the rear row on every

segment may be lled, for a total of 40 knives, or ll all holes with 60

knives for reduced feeding. This is only examples on possible solutions.

To nd out which setup works best for your conditions, use the standard

setup as a starting point and then adapt the setup to the actual

conditions until desired cutting length is achieved.

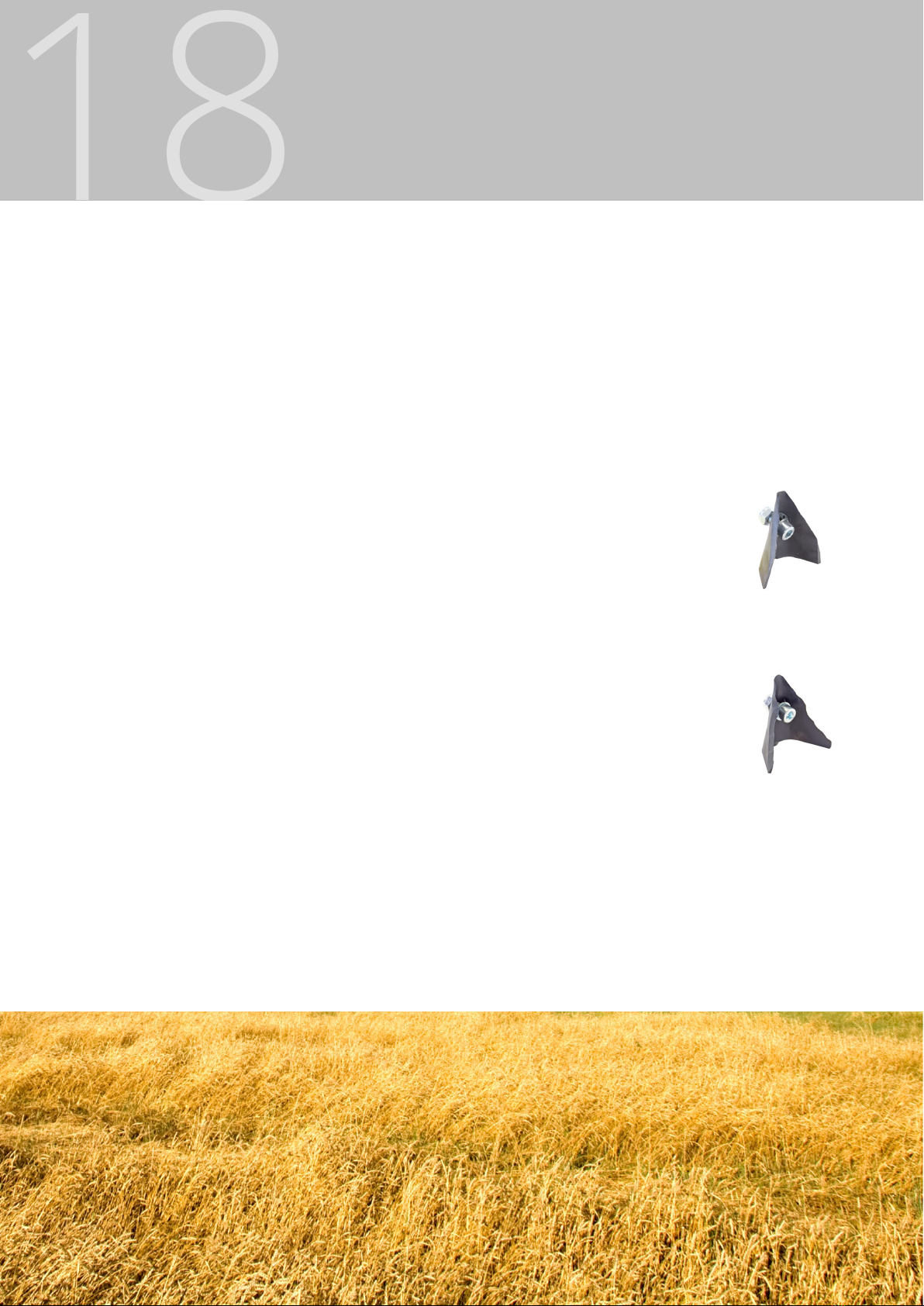

Figure 10 Knife for

reduced feeding.

Figure 11

Standard knife

KNIFE SETUP

Flattened view of knife drum with

standard setup with 20 knives.

This setup gives a balanced

rotation of the knife drum. The

scrapers are placed on both

sides of the segment with fewer

knives, as shown on the rst row

on gure 12.

REPLACING KNIVES

The knives are secured with a bolt and a nut that

goes into a keyhole slot in the drum. To replace the

knife, loosen the bolt a little bit, the knife is then

loose and can be pushed up and taken out the wide

part of the keyhole. The nut is held by the geometric

design of the keyhole. Make sure not to loosen too

much, the nut will then fall o and into the drum.

New knives are assembled by placing bolt and nut in

the wide end of the keyhole, push down and secure

the knife by tightening the bolt. Make sure the pin

on the back of the knife is placed in the slot on the

drum.

Figure 12 Flattened knife drum with standard knife setup.

Figure 13 Inside of

the drum, with nut

in the keyhole slot

which is used for

fastening the knife.

Figure 14 Knife assembled to the drum.

USE

STARTUP PROCEDURE

1 Reverse the conveyor belt for a maximum

of 3 seconds

2 Start the main motor

3 Select operating mode (normal or step)

4 Start conveyor belt and feeding starts

20

NB! Unplug power before performing service or maintenance!

Make sure no animals or people are located in hazard areas before

startup.

Due to the aforementioned reasons, it is not allowed to extend the cables

for the control cabinet to control the machine from a dierent room.

Emergency

stop

OPERATING MODE

Normal Continuous feeding.

Stepp Reduced feeding. Is used

to easy startup and feeding with

silo, soft or new bales.

CONVEYOR BELT

Revers Benyttes først dersom

det ligger fôr inntil kuttetrommel

før oppstart av hovedmotor.

Start Kjøring av bunnbelte.

Main motor stop

and start button

Figure 15 Operating the control cabinet

STOP PROCEDURE

1 Stop conveyor belt

2 Press stop button

3 The machine stops

Note!

It is very uncommon that the motor protection for the conveyr belt is activates. In these rare

cases, a voltage loss over 20% has been present. Contact electrician for power upgrade.

Table of contents

Other Serigstad Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Valtra

Valtra BP603 Workshop service manual

Workzone

Workzone AET14 user manual

Amazone

Amazone Precea 3000 Original operating manual

Landoll

Landoll Tilloll 877 Operator's manual

Concept Perugini

Concept Perugini PTR Series Instruction book

Pottinger Landsberg

Pottinger Landsberg EUROCAT 311 ALPHAMOTION MASTER Operator's manual