10

PTO Shaft

If necessary, cut the PTO shaft to the right length following the shaft

manufacturer instructions.

When attaching the PTO shaft to the machine and tractor make certain that if the

PTO shaft is fi tted with an overrun clutch this must be installed on the implement.

When connecting to the tractor verify that the locking pin is correctly located and

secure in place. Before use make sure all the chains and guards are correctly

fi tted.

The height of the machine from the ground is controlled by the rear roller, skids

and top link. Before using the fl ail mower make sure that the fl ails do not hit the

ground, this will result in extreme wear will damage the rotor.

Always adjust the top link to keep the machine parallel to the ground when

adjusting the height of the rear roller.

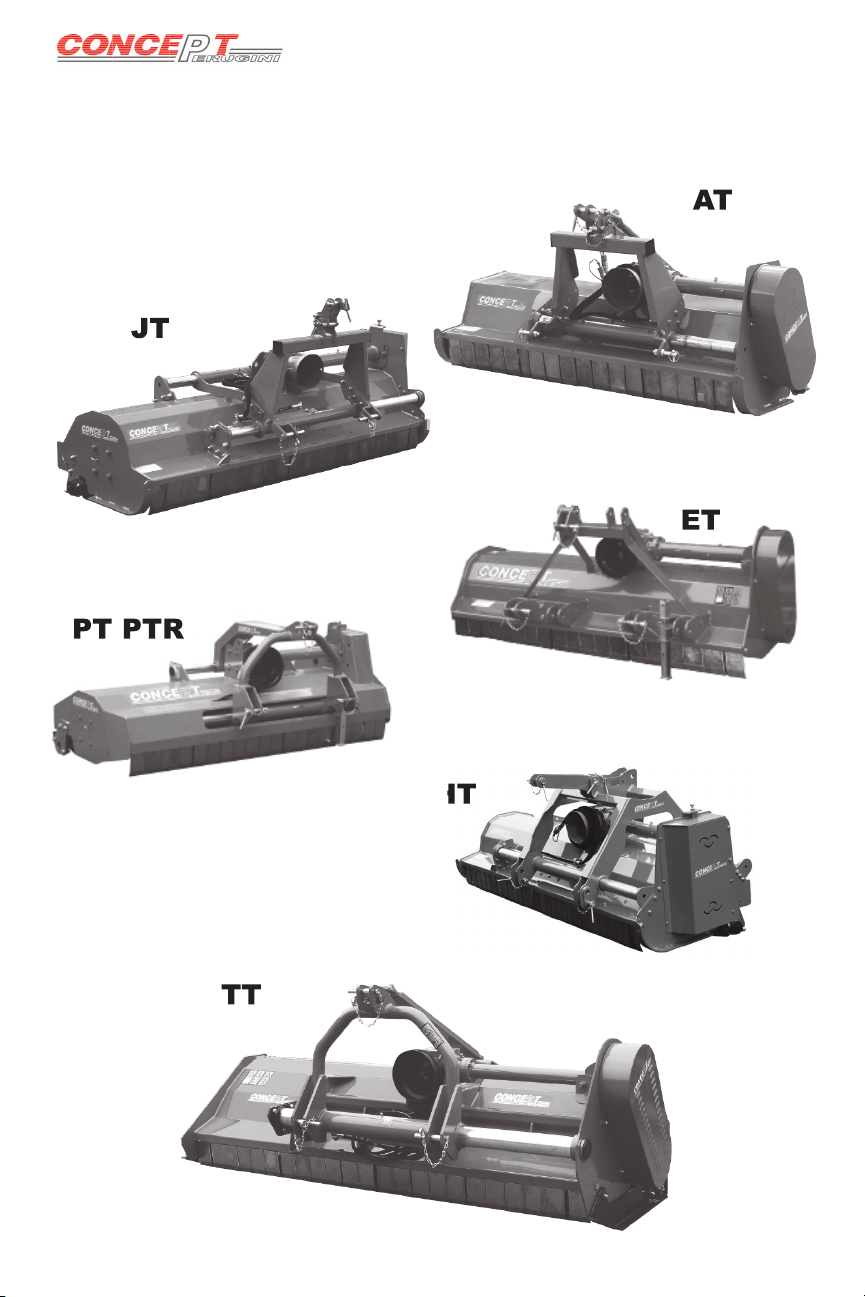

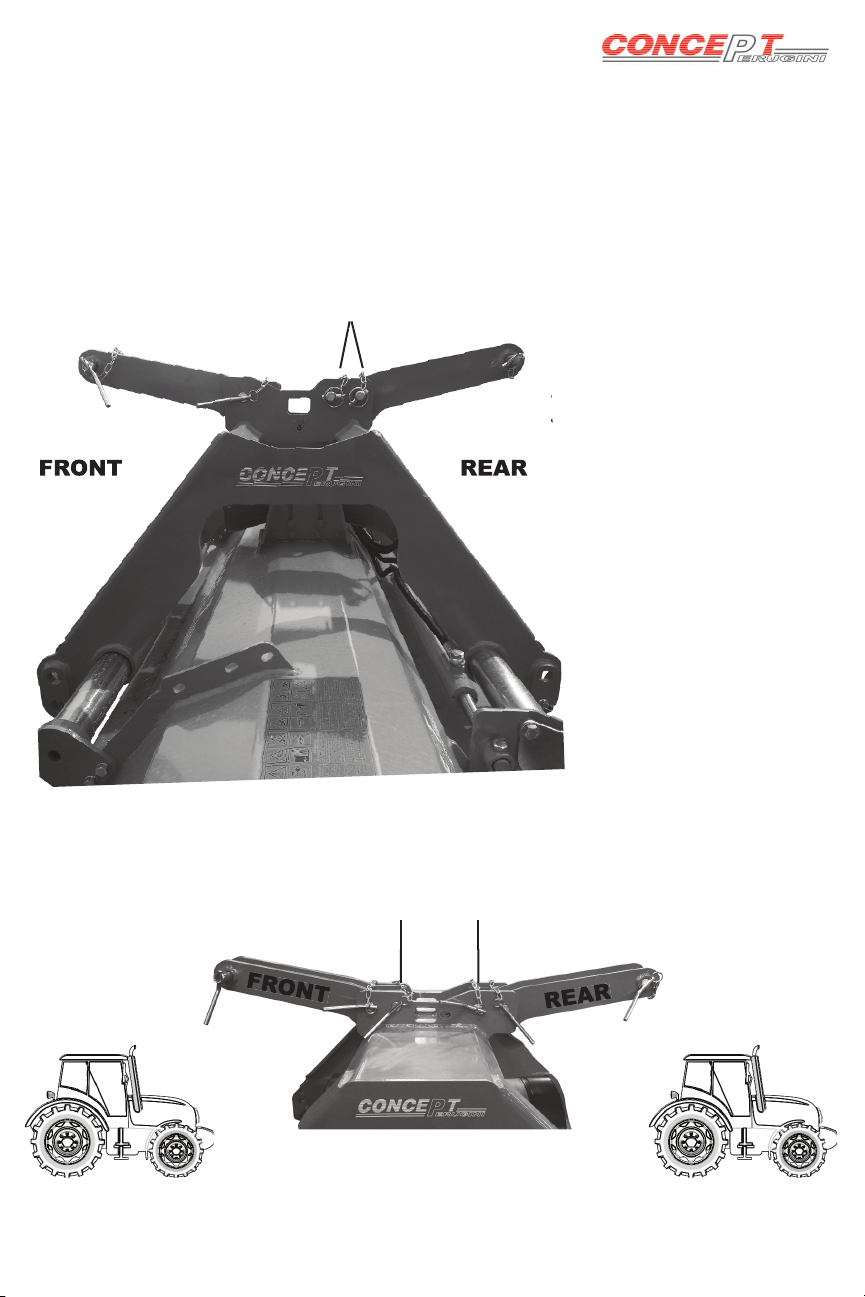

AT ET JT have the supports pictured in fi g.1 to alter the height of the roller

simply remove bolts A, position the plate so the holes align with either the higher

or lower holes on the plate and replace bolts A. On some of these models the

plates may be positioned on the inside of chassis. By moving the supports into

a horizontal position the roller can be moved further away from the fl ail rotor

allowing more space for rotor to discharge the cuttings.

TT model has the skids pictured in fi g.2 to alter simply remove bolt Band loosen

C, reposition the skid in the desired height and tighten B and C.

PT HT have the roller brackets shown in fi g.3. Undo bolts E move the plate to the

desired height and tighten bolts E. Depending on the width of the machine the

plates may be either on the inside of the chassis or the outside.

Working Depth

A

A

B

C

EE

1

2

3