Introduction.........................................................

Declaration of conformity..................................

Safety....................................................................

Dimensional sketch.............................................

Hazard areas........................................................

Installation............................................................

Technical data.....................................................

Connecting ..........................................................

Customization......................................................

Knife setup...........................................................

Dunctional description.......................................

Use MaxiMag.......................................................

Use MaxiFeeder...................................................

App.......................................................................

Maintenance........................................................

Troubleshooting..................................................

Spare parts...........................................................

Recycling...............................................................

Contact..................................................................

page 3

page 4

page 5-7

page 8

page 9-11

page 12-15

page 16

page 17-27

page 28-29

page 30-31

page 32-35

page 36-37

page 38-41

page 42-43

page 44-47

page 48

page 49-54

page 55

page 56

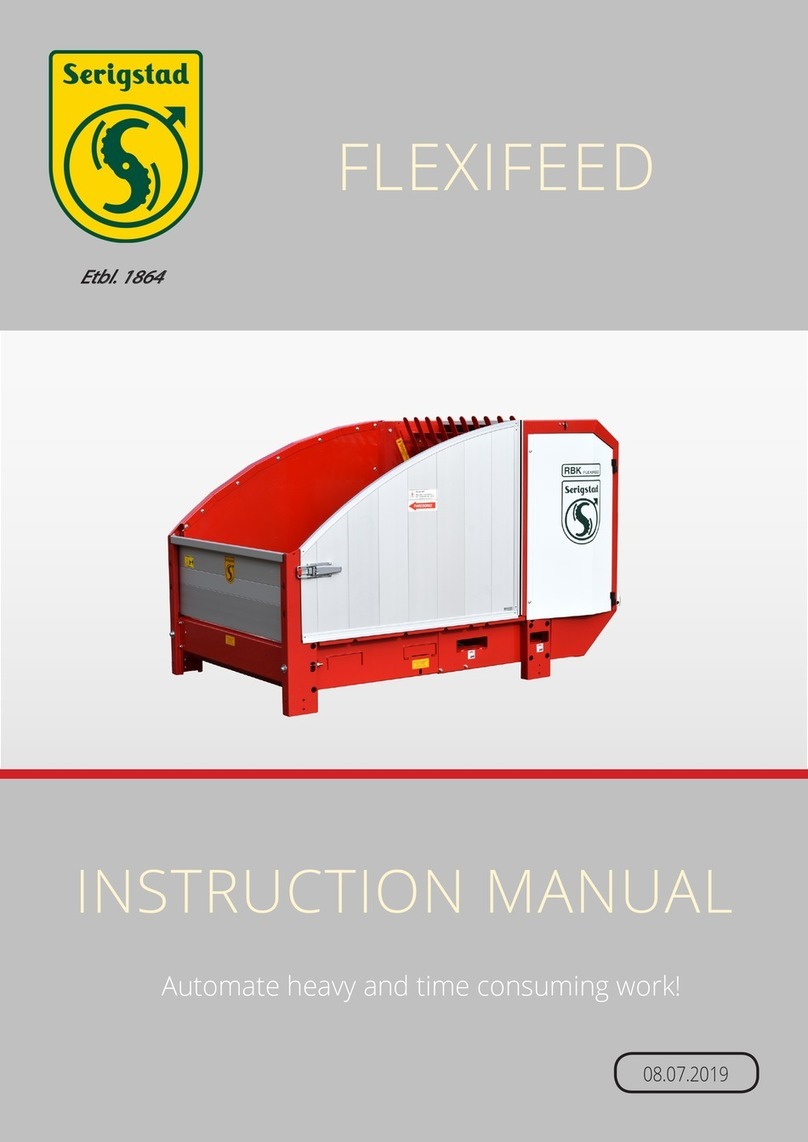

CONTENT INTRODUCTION

2