Hello and thank you for building the Doug ADSR for 4U modular. We hope you will find its mix most

pleasing!

Assembly Instructions:

1. Install surface mount components on the rear of the PCB. We recommend using No-Clean liquid flux

on the board before applying quality solder paste such as Chip-Quik SMD291SNL, tweezing components

onto the board, and reflowing with a hot air station or oven. However, the size of these components

(0805) means they can also be hand-soldered by anyone with reasonable soldering experience.

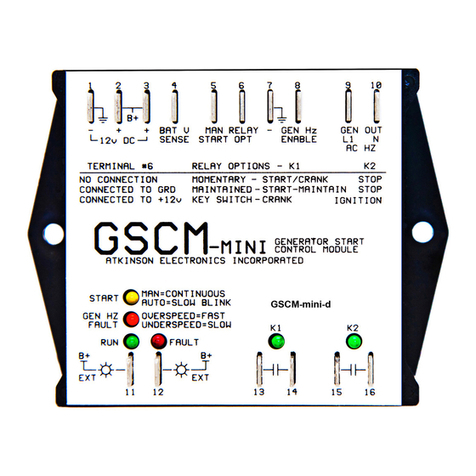

2. Solder rear through-hole parts: Gain trimmer and MTA-156 power header.

3. Prepare the panel: banana jacks and M3 spacers should be fastened securely to the panel.

4. Insert all frontal hardware and the LED into the other side of the PCB (make sure the short leg/cathode

matches the square pad), but do not solder these parts yet. Double check minor details, such as that

proper potentiometer values (B100k for every footprint on Doug) are used for each footprint. If your

potentiometers have solder tabs, be sure to break them off with edgecutters.

5. Place the panel over the hardware and hand-tighten the appropriate nuts over the potentiometers and

switch. Use M3 screws to fasten the PCB to the panel via the three corner spacers.

6. With the PCB facing up and panel facing down, double check that all hardware is properly seated in the

appropriate PCB holes. If it is, position the front LED so it sits in the front panel hole and solder one leg.

Double check its position, then solder the other leg. Once the LED is set up, solder the potentiometers

and switches in place.

7. Fill each pad labeled for use with banana jacks with solder, then insert a resistor leg or wire so proper

connection is made. Solder the other ends to each corresponding banana jack.

8. Double check your work. Make sure all components have properly flowed and that all hardware is

properly soldered to the PCB. If everything looks good…

9. Plug in your Doug. Patch a repetitive Gate signal of decent length (about 1 second is good, or at least

enough to trigger a slow Attack) into the Gate input and adjust the A, D, S, R and Shape parameters while

monitoring the output. Then, patch the Gate signal (or any Trigger sequencer, etc) to the Trigger input, set

Attack, Decay, and Sustain controls fully CCW, and continue to monitor the output. This should create a

Release-style envelope with variable Shape.

If everything appears to be working:

10. Calibrate your Doug.

Doug has one trimpot on the back which sets the envelope’s maximum output level. Since no real

standard exists, it is possible to calibrate the envelope output to either the typical 0-5V used in Serge

Modular or 0-8V used in Eurorack. We recommend you consult the manuals of your other modules to

determine the Doug’s ideal output range in your system.