Bray Controls STM Series User manual

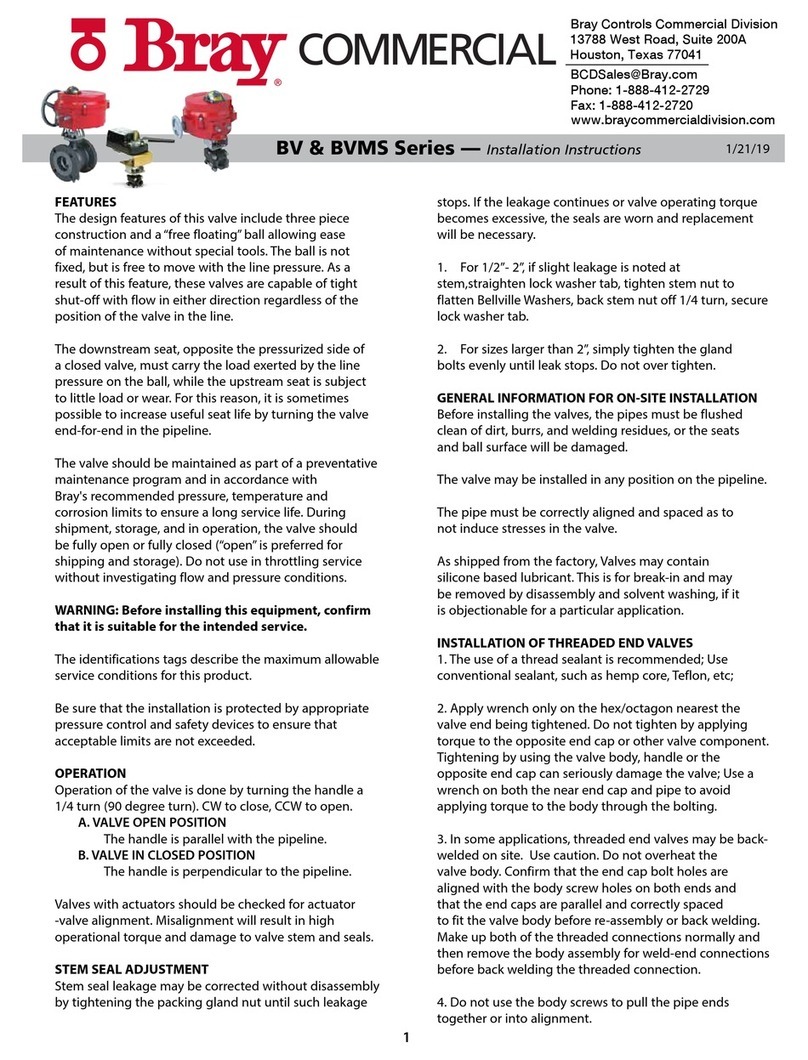

STM Series - Flanged Characterized Ball Valves — Installation Instructions

Bray Controls Commercial Division

13788 West Road, Suite 200A

Houston, Texas 77041

Phone: 1-888-412-2729

Fax: 1-888-412-2720

www.braycommercialdivision.com

1

Applications

The STM Series Flanged Ball Valves are designed to

regulate hot and chilled water, 50/50 glycol solutions,

and 25 psig steam in Heating, Ventilating, and Air

Conditioning (HVAC) systems.

IMPORTANT: The STM Series Flanged Ball Valves are intended

to control saturated steam, hot water, and chilled water flow

under normal equipment operating conditions. Where failure or

malfunction of the valve could lead to personal injury or pro

perty damage to the controlled equipment or other property,

additional precautions must be designed into the system. In-

corporate and maintain other devices, such as supervisory or

alarm systems or safety or limit controls, intended to warn of or

protect against failure or malfunction of the valve.

Installation

Install the STM Series Flanged Ball Valves with the actua-

tor at or above the centerline of the horizontal piping, as

shown in Figure 1.

IMPORTANT: In steam applications, install the valve with the

stem horizontal to the piping. Failure to follow these guidelines

may shorten the life of the actuator.

To minimize heat transfer in steam applications, wrap the

valve and piping with insulation.

Allow at least 4 in. (102 mm) of clearance from the top of

the shaft to remove the actuator (as noted in dimensions).

When mounting the actuator in the field and before

installing the actuator, use an adjustable wrench to man-

ually rotate the valve stem several times. This rotation

breaks the torque that may have built up during long-

term storage.

IMPORTANT: Do not attempt to manually rotate the drive

shaft while the actuator is installed without first releasing the

actuator gears. Manually rotating the drive shaft without

releasing the actuator gears may result in permanent damage

to the actuator.

IMPORTANT: Take care to prevent foreign material such as weld

slag, thread burrs, metal chips, and scale from entering the

piping system. This debris can damage or severely impede the

operation of the valve by embedding itself in the seats, scor-

ing the valve, and ultimately resulting in seat leakage. If the

debris becomes embedded in the seats, subsequent flushing and

filtering of the piping system with the valve installed does not

remedy the problem.

Figure 1: Recommended Mounting Positions for Non-Steam Applications

A AB

AAB

AAB

AAB

AAB

AAB

AAB

A

AB

01/30/19

2

STM Series - Flanged Characterized Ball Valves — Installation Instructions Continued

STM - 2-Way Dimensions

- Allow a minimum of 4 inches for actuator removal.

- Weights are for valve bodies only.

- Dimensions may vary depending on the actuator

- Dimensions Shown are based on largest actuator available for this series.

Valve Models Size

in.(mm)

Flow Coefficient

Cv Kv

Bolt Hole

Diameter

Number of

Bolt Holes

5.50

(139)

6.00

(152)

7.50

(191)

4

4

8

3.50

(89)

3.75

(95)

4.50

(114)

5.71

(145)

6.10

(155)

6.89

(175)

11.42

(290)

12.20

(310)

13.77

(350)

10.25

(260)

10.25

(260)

10.25

(260)

34

36

44

15

16

20

A B C D E Weight

STM 250-2-47

STM 250-2-74

STM 250-2-117

STM 3-2-74

STM 3-2-117

STM 3-2-176

STM 3-2-211

STM 4-2-117

STM 4-2-176

2 1/2

(65)

3

(80)

4

(100)

47

74

117

74

117

176

211

117

176

40.7

64.0

101.2

64.0

101.2

152.2

182.5

101.2

152.2

2-Way STM Dimensions

lbs. kg.

A

B

C

E

D

2.05

(52.1)

2.49

(63.2)

3.09

(75.5)

3

STM Series - Flanged Characterized Ball Valves — Installation Instructions Continued

STM - 3-Way Dimensions

Valve Models Flow Coefficient

Cv Kv

Bolt Hole

Diameter

Number of

Bolt Holes

5.50

(139)

6.00

(152)

7.50

(191)

4

4

8

3.50

(89)

3.75

(95)

4.50

(114)

5.71

(145)

6.10

(155)

6.89

(175)

11.42

(290)

12.20

(310)

13.77

(350)

10.25

(260)

10.25

(260)

10.25

(260)

5.87

(149)

6.26

(159)

7.05

(179)

0.75

(19.1)

0.75

(19.1)

0.75

(19.1)

43

49

62

20

22

28

A B C D E F

2.05

(52.1)

2.49

(63.2)

3.09

(75.5)

G Weight

STM 250-3-47

STM 250-3-74

STM 250-3-117

STM 3-3-74

STM 3-3-117

STM 3-3-176

STM 3-3-211

STM 4-3-117

STM 4-3-176

47

74

117

74

117

176

211

117

176

40.7

64.0

101.2

64.0

101.2

152.2

182.5

101.2

152.2

3-Way STM Dimensions

lbs. kg.

- Allow a minimum of 4 inches for actuator removal.

- Weights are for valve bodies only.

- Dimensions may vary depending on the actuator

- Dimensions Shown are based on largest actuator available for this series.

- Bypass Cv/Kv is 50% of the nominal service Cv.

Size

in.(mm)

2 1/2

(65)

3

(80)

4

(100)

A

B

C

D

E

F

G

4

STM Series - Flanged Characterized Ball Valves — Installation Instructions Continued

STM - Piping Diagrams

STM - Mounting

COIL

SUPPLY

RETURN

PORT

A

PORT

B

2-Way

SUPPLY

RETURN

COIL

PORT

A

PORT

B

PORT

AB

3-Way

Location Considerations

IMPORTANT: Protect the actuator from dripping

water, condensation, and other moisture. Water or

moisture could result in an electrical short, which

may damage or affect the operation of the actuator.

IMPORTANT: Do not cover the actuator with

thermal insulating material. High ambient

temperatures may damage the actuator, and a hot

water pipe, a steam pipe, or other heat source may

overheat it.

Piping

Be sure to wire the input lines to the electric actuator

correctly for the valve to move in the proper direction.

See piping diagrams below for typical two and three-

way piping configurations.

Note: Mount the valve downstream from the coil to

minimize heat transfer to the actuator.

IMPORTANT: Use copper conductors only. Make all wiring

connections in accordance with local, national, and regional

regulations. Do not exceed the actuator’s electrical ratings.

5

STM Series - Flanged Characterized Ball Valves — Installation Instructions Continued

STM - Setup and Adjustments

STM - Troubleshooting

Port A has the flow characterizing disk. Connect Port A

to the outlet from the coil. On three-way models, use

Port B as the bypass port.

Two-way STM Series Ball Valves are fully open

when the electric actuator is fully Counterclockwise

(CCW) and fully closed when the electric actuator is

fully Clockwise (CW).

For three-way valves, the Coil Port A and Common

Port AB are fully open when the electric actuator is

fully CCW, as shown in Figure 1. The Bypass Port B and

Common Port AB are fully open when the actuator is

fully CW, as shown in Figure 2.

For non-spring return and spring-to-open proportional

control models in the Direct Acting (DA) mode, a

minimum control signal drives the electric actuator to

the fully CCW position while a maximum control signal

drives the electric actuator in the fully CW position.

For spring-to-close proportional control models in the

DA mode, a minimum control signal drives the electric

actuator to the fully CW position, while a maximum

control signal drives the electric actuator to the fully

CCW position.

Servicing the Actuator or Piping System

When servicing the electric actuator or the piping system:

• Disconnect the power supply to the actuator.

WARNING: Risk of Electric Shock. Disconnect each of multiple power

supplies before making electrical connections. More than one disconnect

may be required to completely de-energize equipment. Contact with

components carrying hazardous voltage can cause electric shock and may result

in severe personal injury or death.

• Relieve the pressure in the piping system

CAUTION: Risk of Property Damage. Do not apply power to the system before

checking all wiring connections. Short circuited or improperly connected wires

may result in permanent damage to the equipment.

FIGURE 1 FIGURE 2

Figure 1: STM Series Three-Way Ball Valve

(Coil Port A Open to Common PortAB)

Port A

Coil

Port AB

Common

Port B — Bypass

Figure 2: STM Series Three-Way Ball Valve

(Bypass Port B Open to Common Port AB)

Port A

Coil

Port AB

Common

Port B — Bypass

Table of contents

Other Bray Controls Control Unit manuals

Popular Control Unit manuals by other brands

Gemu

Gemu 605 Installation, Operating and Maintenance Instruction

Assa Abloy

Assa Abloy OneSystem N5952 Installation instructions and functional description

Heatit

Heatit Z-PUSH BUTTON 2 Installer manual

TIS

TIS TIS-SEC-SM installation manual

Tunstall

Tunstall 77 3411 00 installation instructions

Erica Synths

Erica Synths PICO VC EG manual