SevenStar CS210-C MFC User manual

This manual suits for next models

1

Table of contents

Other SevenStar Measuring Instrument manuals

SevenStar

SevenStar D08-2F User manual

SevenStar

SevenStar D07-7C / ZM User manual

SevenStar

SevenStar CS100A MFC User manual

SevenStar

SevenStar CS200-A MFC User manual

SevenStar

SevenStar CS200-C User manual

SevenStar

SevenStar D08-8C User manual

SevenStar

SevenStar CS200-D MFC User manual

SevenStar

SevenStar CS200-J User manual

SevenStar

SevenStar D07-60B User manual

SevenStar

SevenStar CS100D MFC User manual

Popular Measuring Instrument manuals by other brands

Martin Lishman

Martin Lishman Protimeter Balemaster instruction manual

Dinamica Generale

Dinamica Generale DG600 Operator's manual

PCB Piezotronics

PCB Piezotronics 080B185 Installation and operating manual

Texmate

Texmate Tiger 320 Series User's manual supplement

Sealey

Sealey Auto Service Series instructions

Kobold

Kobold DFT operating instructions

Rosemount

Rosemount 5401 Reference manual

Badger Meter

Badger Meter Recordall Turbo Series user manual

RS PRO

RS PRO RS-135 instruction manual

PCB Piezotronics

PCB Piezotronics 333B55 Installation and operating manual

Agilent Technologies

Agilent Technologies 4286A user guide

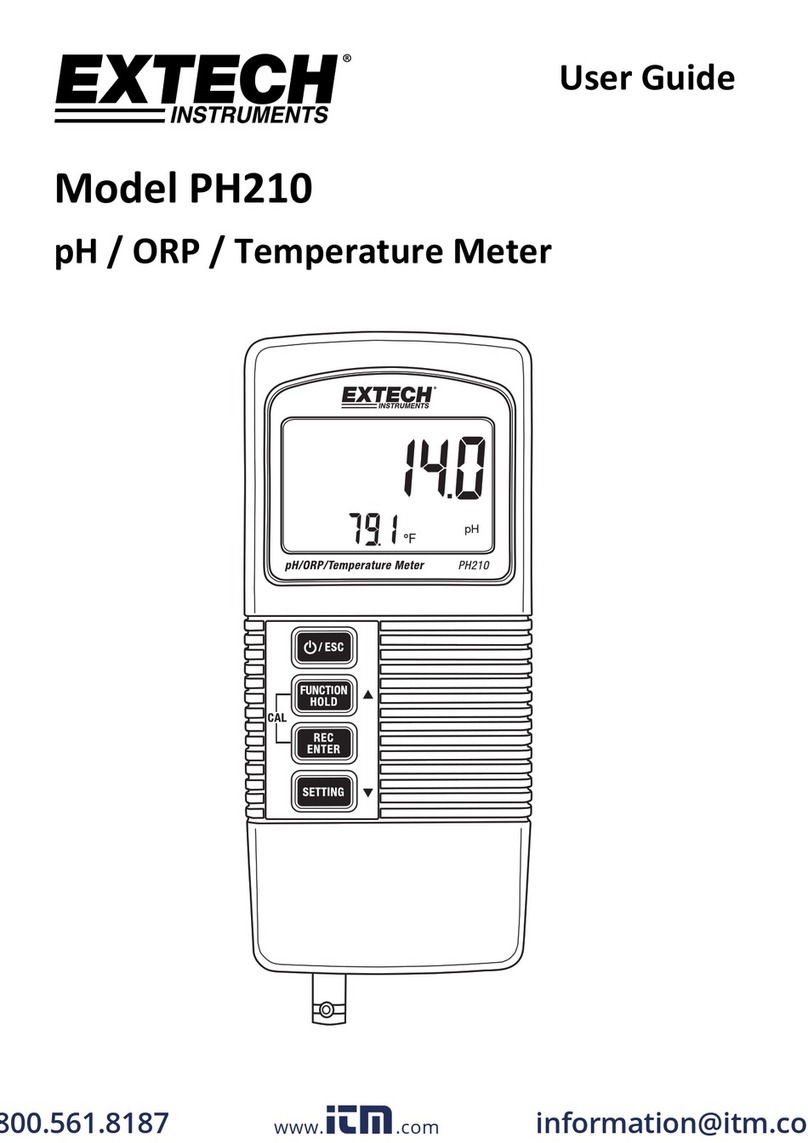

Extech Instruments

Extech Instruments PH210 user guide