Contents

Service Kit – EI7. Encoder 3

Contents

1Service kit content..................................................................................................................... 4

2Procedure................................................................................................................................... 5

2.1 Recommended accessories ........................................................................................... 5

2.2 Disposal ......................................................................................................................... 5

3Conversion of encoder generation A to encoder generation B ............................................ 6

3.1 Without brake ................................................................................................................. 6

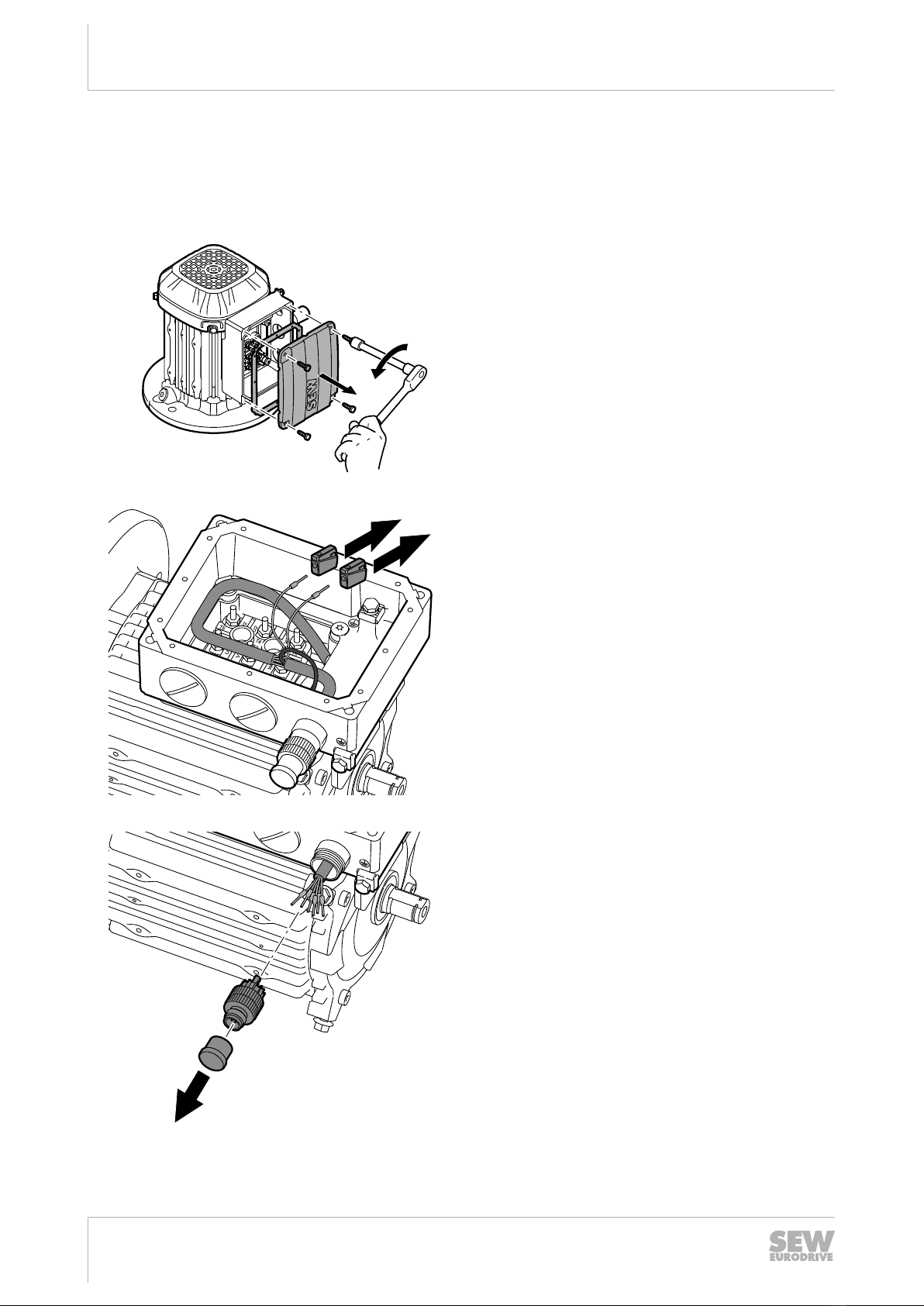

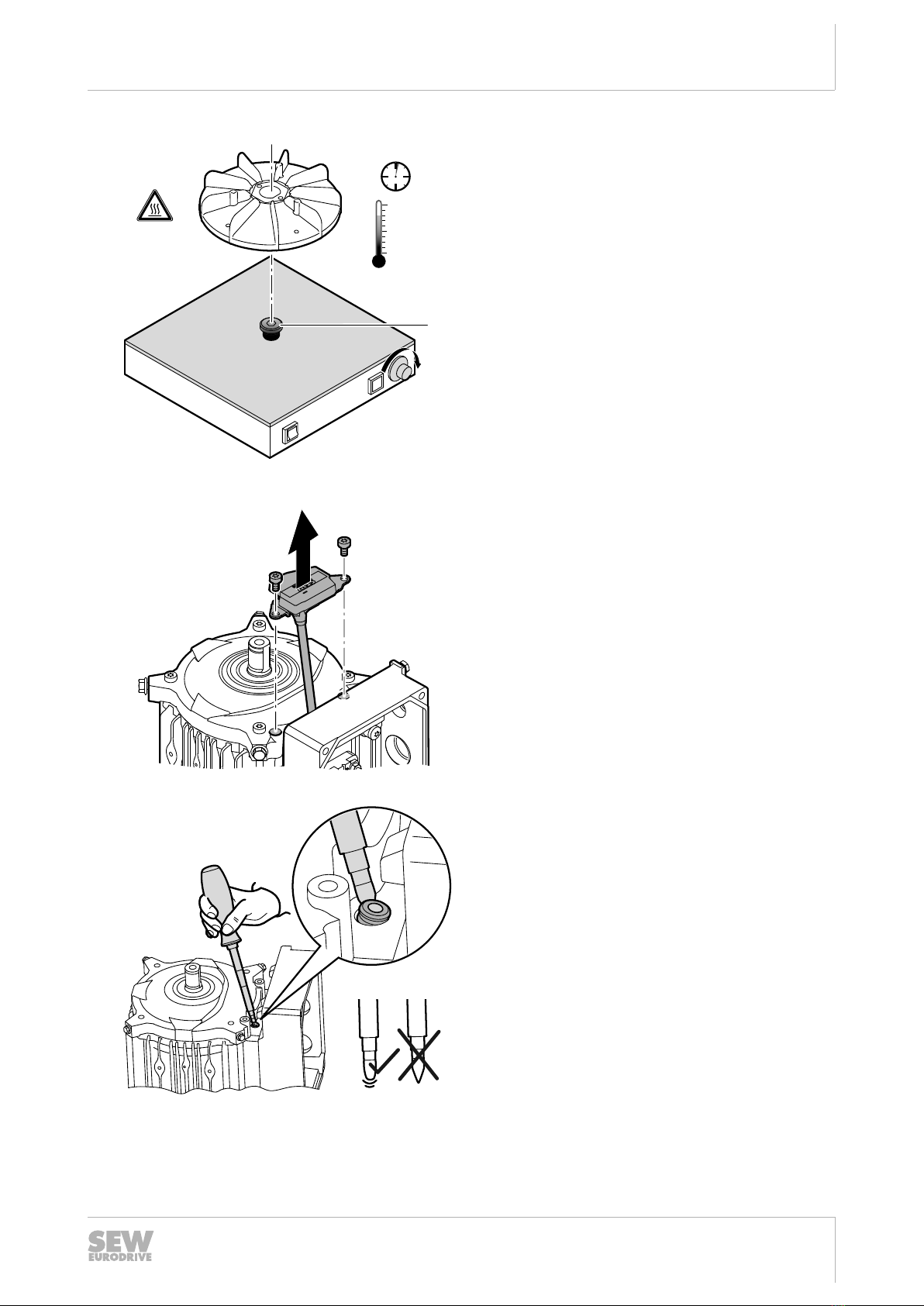

3.1.1 Removal of the EI7.A encoder ........................................................................ 6

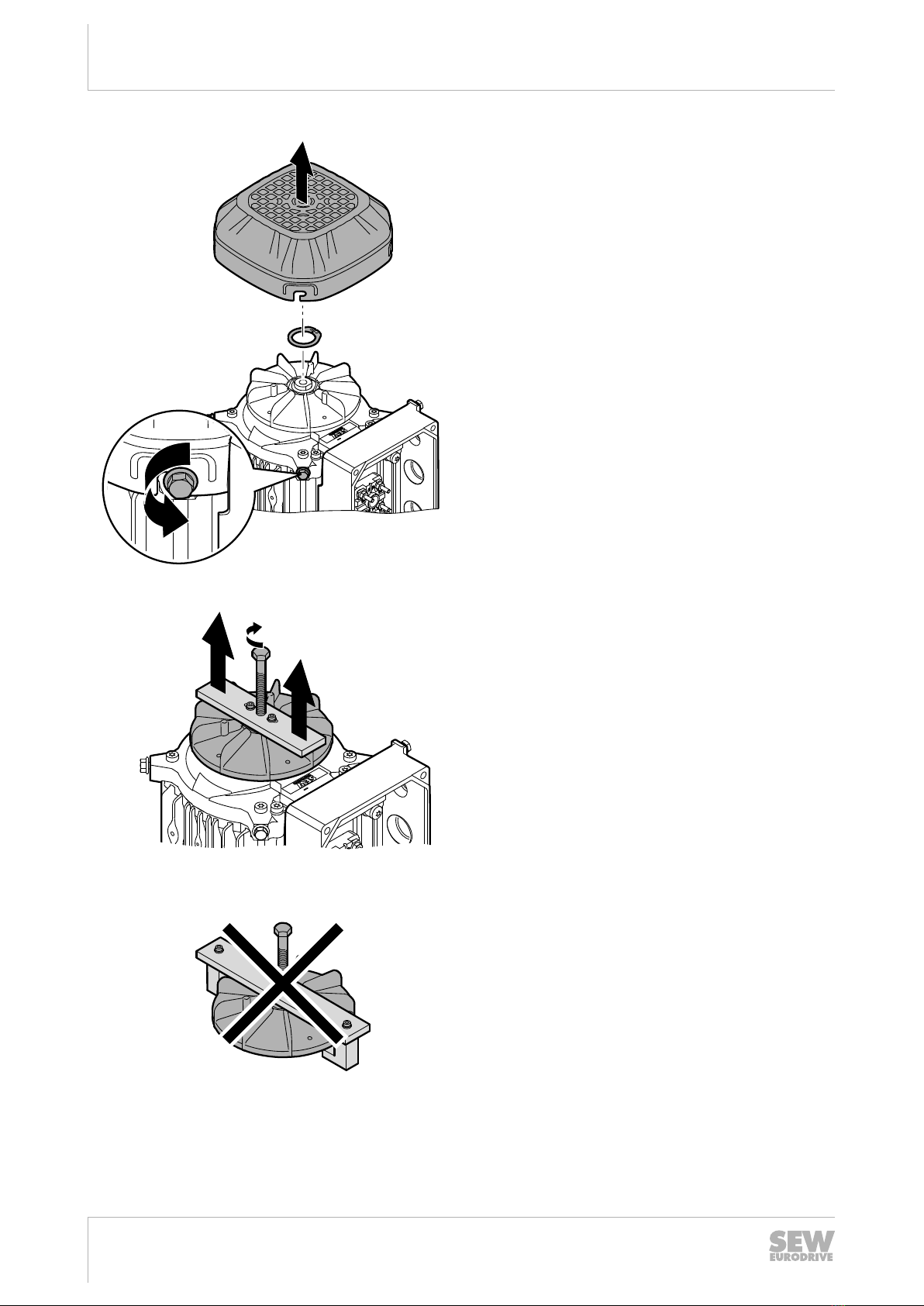

3.1.2 Installation of the new EI7.B encoder ........................................................... 10

3.1.3 Wiring the EI7.B encoder to the connection box........................................... 11

3.1.4 Wiring the EI7.B encoder to the connection unit........................................... 15

3.2 With brake .................................................................................................................... 18

3.2.1 Removal of the EI7.A encoder ...................................................................... 18

3.2.2 Installation of the new EI7.B encoder ........................................................... 22

3.2.3 Wiring the EI7.B encoder to the connection box........................................... 24

3.2.4 Wiring the EI7.B encoder to the connection unit........................................... 28

4Replacement of encoder generation B with encoder generation B.................................... 31

4.1 Without brake ............................................................................................................... 31

4.1.1 Removal of the EI7.B encoder ...................................................................... 31

4.1.2 Installation of the new EI7.B encoder ........................................................... 35

4.1.3 Wiring the EI7.B encoder to the connection box........................................... 37

4.1.4 Wiring the EI7.B encoder to the connection unit........................................... 41

4.2 With brake .................................................................................................................... 44

4.2.1 Removal of the EI7.B encoder ...................................................................... 44

4.2.2 Installation of the new EI7.B encoder ........................................................... 49

4.2.3 Wiring the EI7.B encoder to the connection box........................................... 50

4.2.4 Wiring the EI7.B encoder to the connection unit........................................... 54

5Appendix .................................................................................................................................. 57

5.1 Pin assignment for 8-pin M12 connector (AVRE) ........................................................ 57

5.1.1 Connection box ............................................................................................. 57

5.1.2 Connection via M12 connector ..................................................................... 57

5.2 Pin assignment for 4-pin M12 connector (AVSE) ......................................................... 58

5.2.1 Connection box ............................................................................................. 58

5.2.2 Connection via M12 connector ..................................................................... 58

5.3 Pin assignment without M12 connector ....................................................................... 59

5.3.1 Connection unit ............................................................................................. 59

21362599/EN – 02/2015