Manual – Data Matrix Positioning System PCV80A-F200-R4-V19-SEW 3

Contents

Contents

1 General Information ............................................................................................ 5

1.1 How to use this documentation................................................................... 5

1.2 Structure of the safety notes ....................................................................... 5

1.2.1 Meaning of signal words .............................................................. 5

1.2.2 Structure of the section safety notes ........................................... 5

1.2.3 Structure of the embedded safety notes...................................... 5

1.3 Rights to claim under warranty ................................................................... 6

1.4 Content of the documentation..................................................................... 6

1.5 Exclusion of liability..................................................................................... 6

1.6 Product names and trademarks.................................................................. 6

1.7 Copyright..................................................................................................... 6

2 Safety Notes ........................................................................................................ 7

2.1 Preliminary information ............................................................................... 7

2.2 Target group ............................................................................................... 7

2.3 Designated use ........................................................................................... 8

2.4 Other applicable documentation ................................................................. 8

2.5 Functional safety technology ...................................................................... 8

2.6 Transport..................................................................................................... 8

2.7 Installation/assembly................................................................................... 8

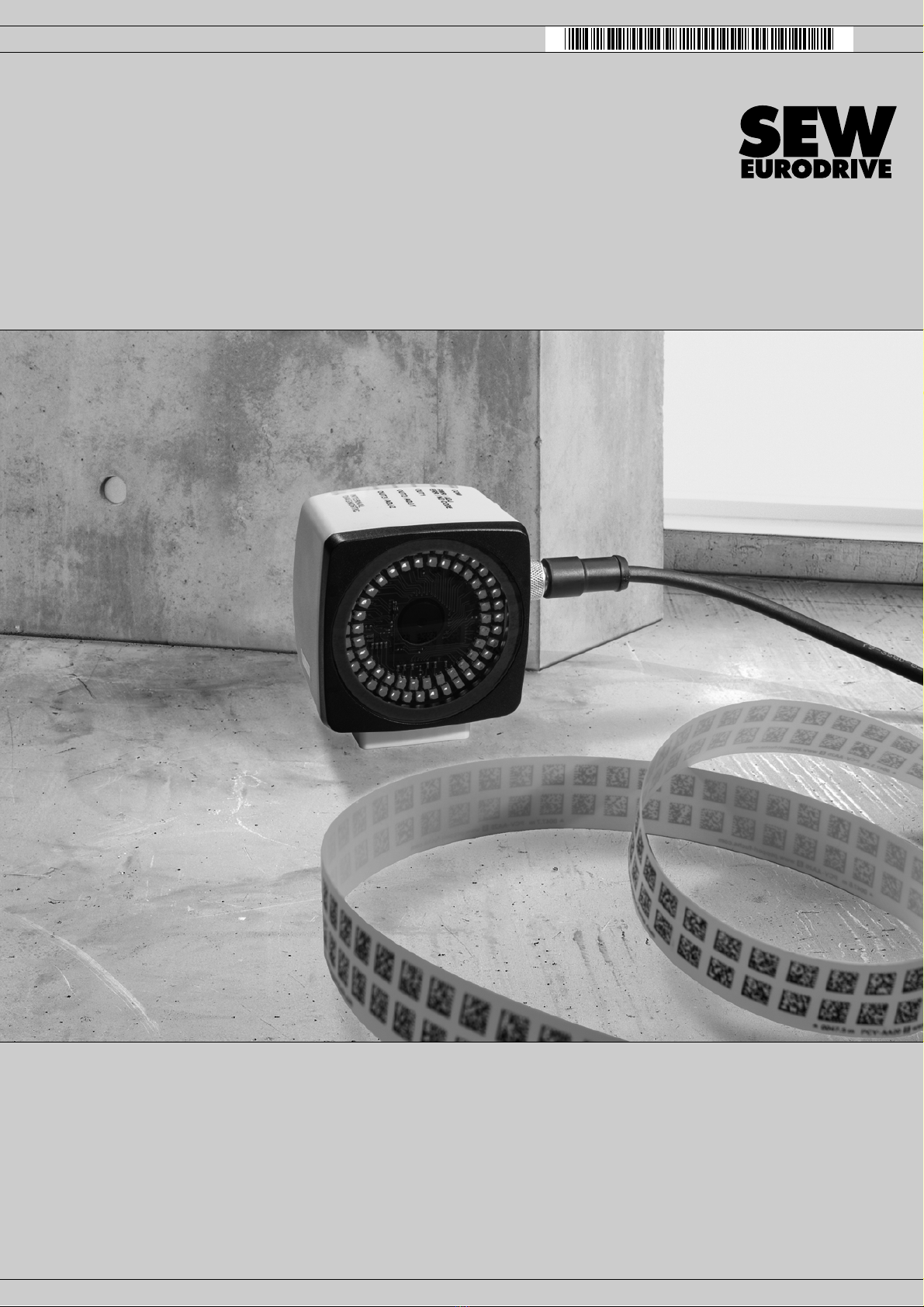

3 Product Description............................................................................................ 9

3.1 Use and application .................................................................................... 9

3.2 RS485 interface .......................................................................................... 9

3.3 LED indicators and control elements ........................................................ 10

3.4 Accessories............................................................................................... 11

4 Installation ......................................................................................................... 12

4.1 Installing the code strip ............................................................................. 12

4.1.1 Code strips with a starting position of 0 m ................................. 13

4.1.2 Code strips with different starting positions ............................... 14

4.2 Mounting the read head ............................................................................ 15

4.2.1 Optimum read distance (z-axis)................................................. 16

4.2.2 Dimension drawing for the read head........................................ 17

4.3 Electrical connection ................................................................................. 18

4.3.1 Wiring diagram for the 8-pin connector of PCV80A................... 18

4.3.2 X4011: RS485 interface – externally of PFF-HM31................... 19

4.3.3 Shielding cables......................................................................... 19

5 Startup................................................................................................................ 20

5.1 Aligning the read head .............................................................................. 20

5.2 Parameter setting...................................................................................... 21

5.2.1 Internal parameterization using parameter setting software...... 21

5.2.2 External parameterization using code cards.............................. 21

5.3 Operation with repair tape......................................................................... 23