tissin TS610 Series User manual

Pneumatic Positioner

TS610 Series

Instruction Manual

Ver. PM-TS610EN_08/2023

2

P-P Positioner

TS610 Series

tissin

Table of Contents

1 Introduction-------------------------------------------------------------------------------------- 3

1.1 General information for the user--------------------------------------------------------- 3

1.2 Limited warranty and disclaimer---------------------------------------------------------- 3

1.3 Requirement for safety--------------------------------------------------------------------- 4

2 Product---------------------------------------------------------------------------------------------- 5

2.1 Function---------------------------------------------------------------------------------------- 5

2.2 Features---------------------------------------------------------------------------------------- 5

2.3 Options----------------------------------------------------------------------------------------- 5

2.4 Applications----------------------------------------------------------------------------------- 5

2.5 Label-------------------------------------------------------------------------------------------- 6

2.6 Product code---------------------------------------------------------------------------------- 7

2.7 Specification----------------------------------------------------------------------------------- 8

2.8 Operation Logic------------------------------------------------------------------------------ 9

2.9 Exploded view drawing--------------------------------------------------------------------- 10

2.10 Dimension------------------------------------------------------------------------------------- 11

3

Installation

---------------------------------------------------------------------------------------- 12

3.1 Safety------------------------------------------------------------------------------------------- 12

3.2 TS610L Linear type-------------------------------------------------------------------------- 12

3.3 TS610R Rotary type------------------------------------------------------------------------- 14

4 Air connection--------------------------------------------------------------------------------- 15

4.1 Before the air connection------------------------------------------------------------------ 15

4.2

TS610L air connection----------------------------------------------------------------------

--

15

4.3 TS610L RA/DA settings-------------------------------------------------------------------- 15

4.4 TS610R air connection--------------------------------------------------------------------- 16

4.5 TS610R RA/DA settings-------------------------------------------------------------------- 16

5 Adjustment--------------------------------------------------------------------------------------- 17

6 Troubleshooting----------------------------------------------------------------------------- 18

6.1 Common problems-------------------------------------------------------------------------- 18

6.2 Orifice Installation---------------------------------------------------------------------------- 18

6.3 Other problems and solutions------------------------------------------------------------- 19

3

P-P Positioner

TS610 Series

tissin

1 Introduction

1.1 General information for the user

This instruction includes installation, operation, maintenance, and parts information for Tissin

TS610 Valve Positioner. Keep these instructions in a location which is easily accessible to

every user and make these instructions available to every new owner of the device.

Installation, commissioning and maintenance of the product may only be performed by

trained specialist personnel who have been authorized by the plant operator to do so.

To avoid possible injury to personnel or damage to valve parts, WARNING, CAUTION

and NOTICE should be strictly followed.

Before installing or commissioning, be sure to read and thoroughly understand the

product manual and operate the product properly.

Operators must strictly observe the applicable national regulations with regards to

installation, function tests, repairs, and maintenance of electrical products.

For additional information or if specific problems occur that are not discussed in these

instructions, contact the manufacturer.

The manual can be altered or revised without any prior notice.

Please visit our website (http://www.tissin.co.kr ) check the latest documentation.

1.2 Limited warranty and disclaimer

The manufacturer warranty period of the product is 18 months after the product is

shipped from Tissin in Korea.

For any failure or damage reported within the warranty period which is clearly our

responsibility, a replacement product or necessary parts will be provided. This limited

warranty applies only to our product independently, and not to any other damage

incurred due to the failure of the product.

Using the device in a manner that does not fall within the scope of its intended use,

disregarding this manual, using under unqualified personnel, or making unauthorized

alterations releases the manufacturer from liability for any resulting damage. This

renders the manufacturer's warranty null and void.

4

P-P Positioner

TS610 Series

tissin

1.3 Requirement for safety

This manual contains notices you have to observe in order to ensure your personal safety, as

well as to prevent damage to property. These safety instructions are intended to prevent

hazardous situations and/or equipment damage. For the safety, it is important to follow the

instructions in the manual.

WARNING Failure to observe the warning may result in serious injuries or death.

CAUTION Failure to observe this warning may result in product failure or injuries.

NOTICE Failure to observe this warning may result in product failure or performance

degradation.

CAUTION

Only trained and authorized person should operate machinery and equipment.

Do not use this positioner out of the range of its specifications as this can cause failure.

Do not service or attempt to remove product and machinery/equipment until safety is

confirmed.

Before loosening the pneumatic lines and valves, turn off the pressure and vent the

pneumatic lines.

5

P-P Positioner

TS610 Series

tissin

2 Description of products

2.1 Function

Pneumatic valve positioner TS610 series product is a control device for control valves that

receives a 0.02~0.1 MPa pneumatic signal from a pneumatic output device (ex. Control room,

IP convertor) and proportionally adjusts the opening degree of the valve by adjusting the

supply pressure supplied to the valve actuator.

2.2 Features

Applied to various control valve system

Fast response time, excellent stability and durability

Simple zero and span adjustment

IP 66 enclosure

Easy maintenance due to built-in module type

By-pass valve (A/M switch) installed

2.3 Options

Position transmitter (4~20mA DC Feedback signal)

Limit switch (Mechanical or Proximity type)

2.4 Applications

TS610 series are mounted on Control valves and are used for fluid control in industrial

parts.

Oil and gas

Chemicals

Power plant

Paper

Water treatment

Pharmaceutical

Printing and dyeing processing

Food and beverage

Etc.

6

P-P Positioner

TS610 Series

tissin

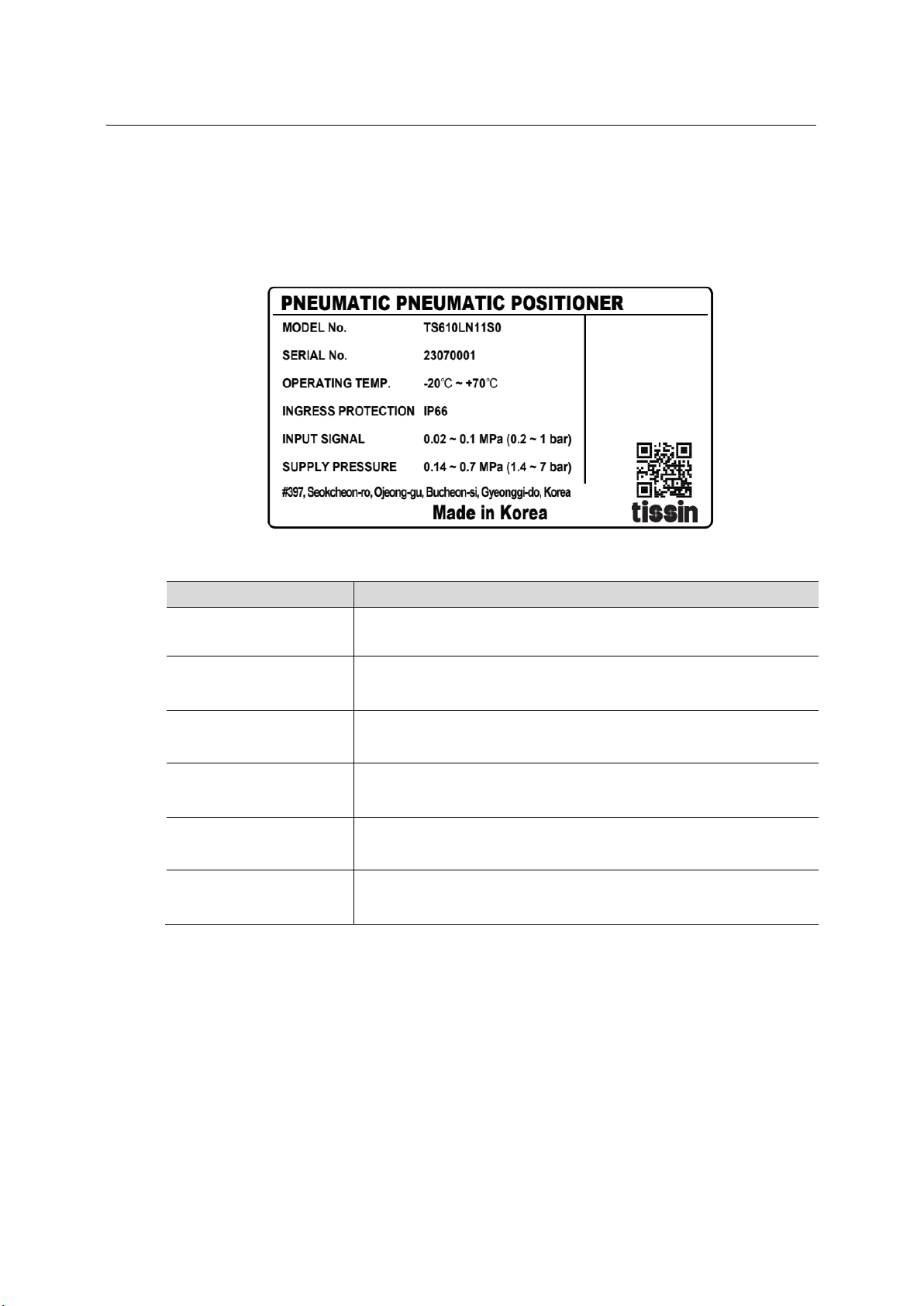

2.5Label

Item Description

MODEL No. Indicates model number.

SERIAL No. Indicates serial number.

OPERATING TEMP. Indicates allowable operating temperature.

INGRESS

PROTECTION Indicates enclosure IP grade.

INPUT SIGNAL Indicates pneumatic input signal range.

SUPPLY PRESSURE Indicates supply pressure range.

7

P-P Positioner

TS610 Series

tissin

2.6Product Code

Model TS610

Acting type Linear type L

Rotary type R

Connection type PT1/4 1

NPT1/4 2

G1/4 3

Lever type (Linear)10~40mm 1

40~70mm 2

70~100mm 3

100~150mm 4

1

Lever type (Rotary)M6 x 39L (Fork lever type)

NAMUR Type 5

Operating temp. -20~70℃(standard) S

-20~120℃H

-40~70℃L

-60~70℃(for EAC certificate) U

Options None 0

With Dome cover 1

External Position transmitter (+TS500) 2

External Position transmitter (+TS510) 3

External Limit switch (+TS400) 4

External Limit switch (+TS410) 5

External Position transmitter and Limit switch (+TS510)

6

With Limit switch mounting device 7

*Note : Option no. 1~7 are only available with TS610R (Rotary type).

8

P-P Positioner

TS610 Series

tissin

2.7Specification

TS610(Single) TS610(Double)

Input signal 0.02~0.1MPa

Supply pressure 0.14~0.7MPa

Stroke 10~150mm (Linear type), 0~900 (Rotary type)

Air connection PT1/4, NPT1/4, G1/4

Gauge connection NPT1/8

Enclosure IP66

Ambient temp. -20℃∼70℃(standard)

Linearity ±1.0% F.S ±2.0% F.S

Sensitivity ±0.2% F.S ±0.5% F.S

Hysteresis ±1.0% F.S

Repeatability ±0.5% F.S

Air consumption Below 2.5LPM (Sup=0.14MPa)

Flow capacity Over 80LPM (Sup=0.14MPa)

Material Aluminum die cast

Paint Polyester powder coating

Weight 2.8kg

9

P-P Positioner

TS610 Series

tissin

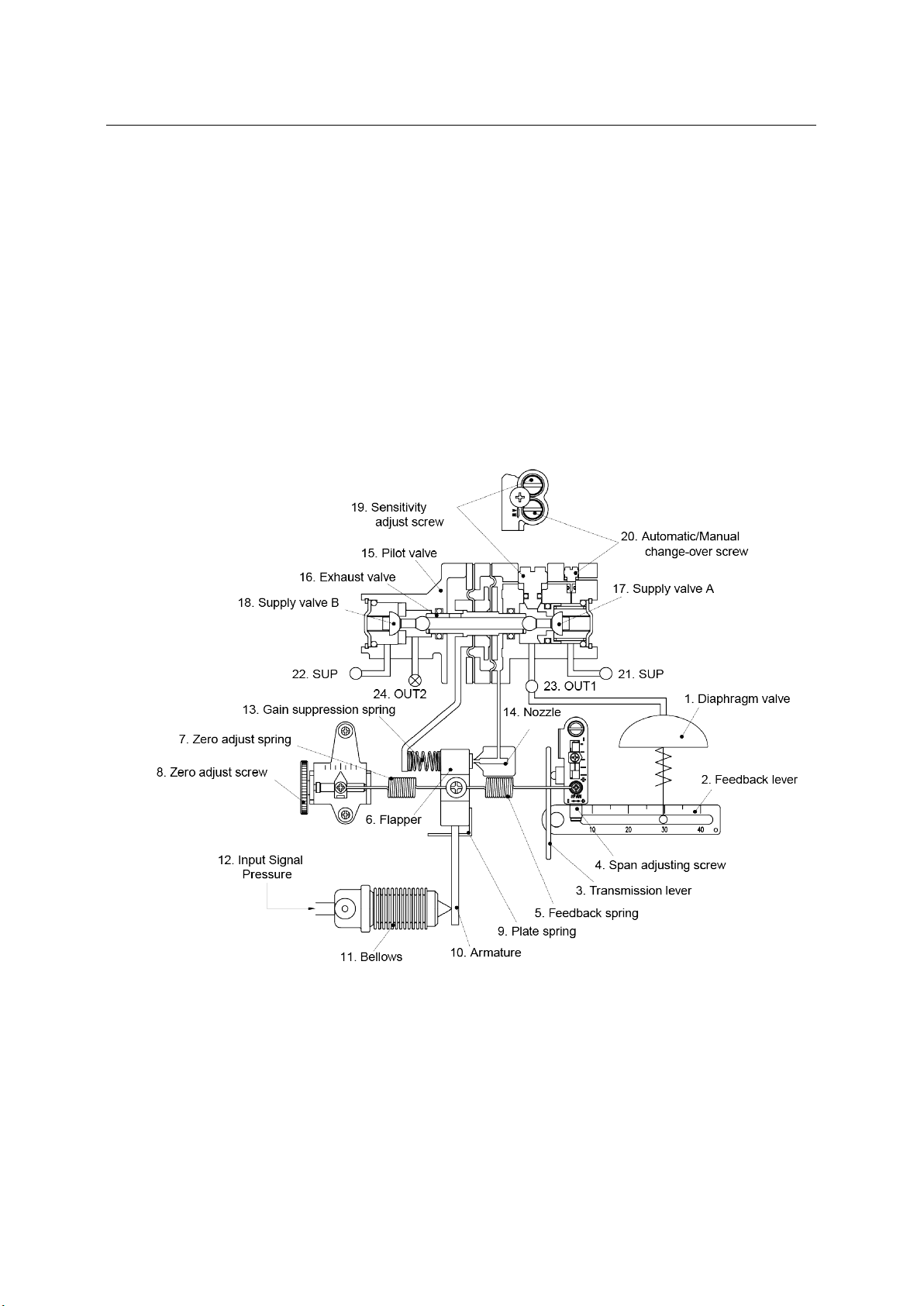

2.8 Operation Logic

If (12)Input signal pressure(0.02~0.1MPa) increase, (11)Bellows pushes (10)Armature in the

right direction and (6)Flapper moves left around (9)Plate spring. The gap between (6)Flapper

and (14)Nozzle lowers the nozzle back pressure and reduces the internal pressure of (15)Pilot

valve connected to (14)Nozzle, causing (16)Exhaust valve to move to the right. At the same

time, (17)Supply valve A on (23)OUT1 also moves to the right to open (17)Supply valve A.

(21)SUP increases the pneumatic pressure to (1)Diaphragm valve via (17)Supply valve A and

(23)OUT1, and moves (1)Diaphragm valve down. The movement of the valve is transmitted to

(5)Feedback spring via (2)Feedback lever and eventually increases the force to pull (6)Flapper

to the right. (1)Diaphragm valve is balanced at a position that is equilibrium with the force of

(11)Bellows contraction and expansion generated by the force of (5)Feedback spring and

(12)Input signal pressure above. (13)Gain suppression spring is intended to immediately

feedback the movement of (15)Pilot valve to (6)Flapper, which improves the stability of the loop.

* The above description is based on the TS610L linear type and Reverse Action (RA) type

diaphragm valve. TS610R rotary type has different feedback part structure and the operating

logic is same.

* Nozzle back pressure : Pressure inside Nozzle caused by the degree to which Flapper

controls Nozzle

* Loop : Positioner and Control valve form a closed circuit through Feedback lever

10

P-P Positioner

TS610 Series

tissin

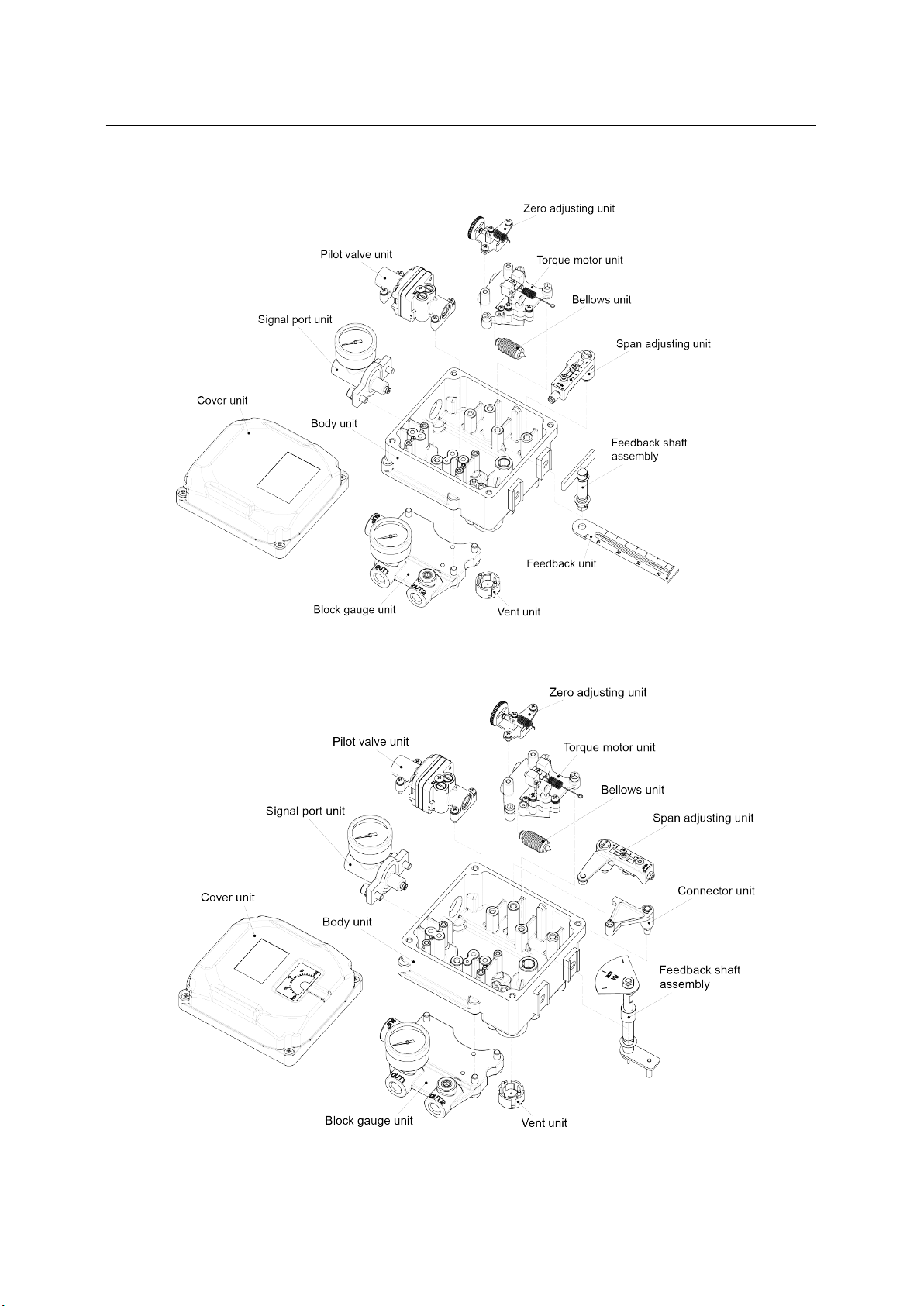

2.9Exploded-view drawing

<TS610L linear type>

<TS610R Rotary type>

11

P-P Positioner

TS610 Series

tissin

2.10 Dimension

2.10.1 TS610L Dimension

2.10.2 TS610R Dimension

12

P-P Positioner

TS610 Series

tissin

3 Installation

3.1 Safety

WARNING

Before installation, make sure that TS610 meets the valve and actuator installation

conditions and field requirements.

Incorrect installation may result in bad TS610 control characteristics.

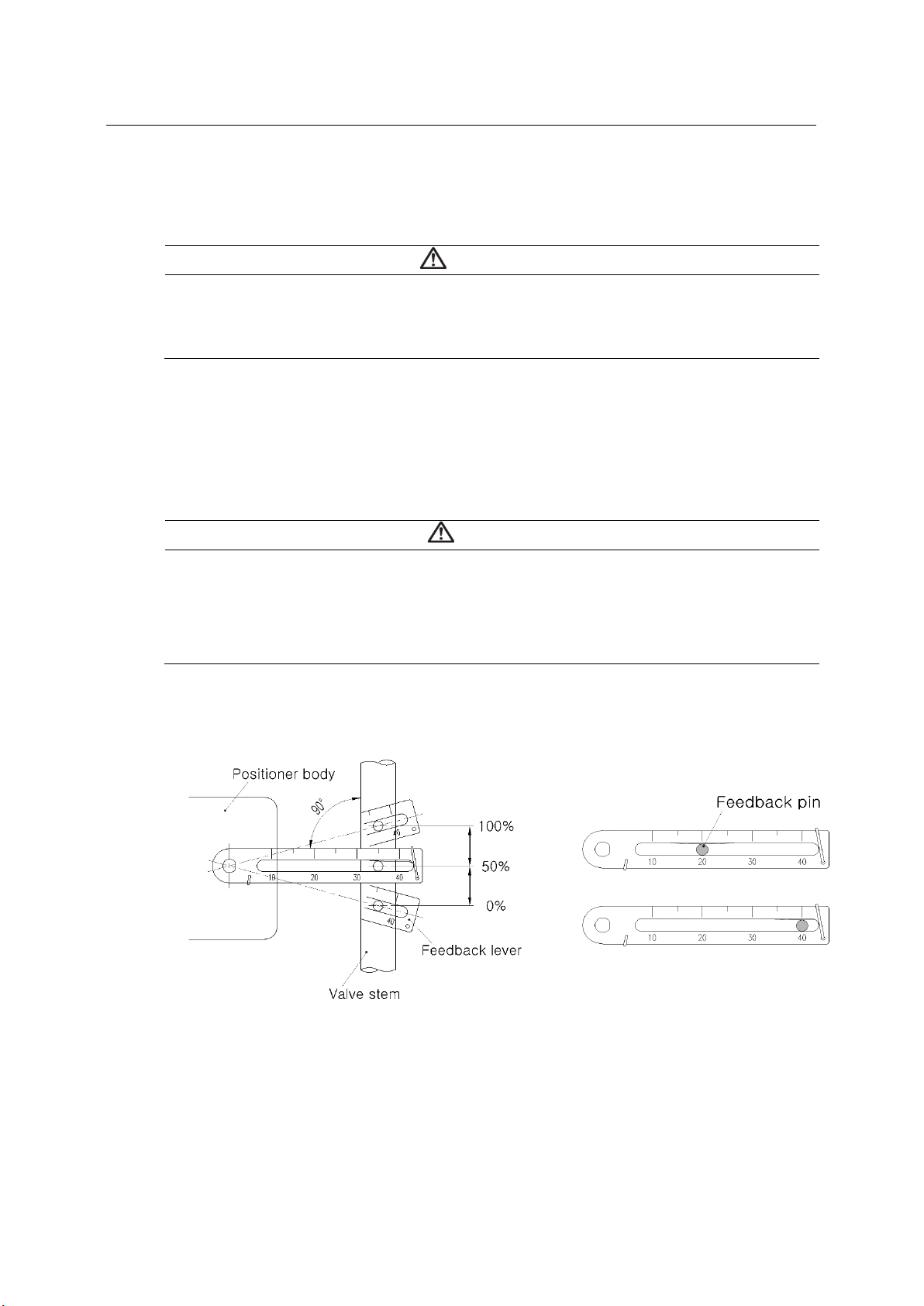

3.2 TS610L linear type

When making mounting brackets and fastening levers to the actuator stem, the following two

must be observed. Otherwise, it can affect the performance of the product, such as linearity.

<Figure 1> <Figure 2>

CAUTION

①

Check if Feedback lever is parallel to the ground at 50% of the valve stroke. <Figure 1>

②Feedback lever connection with the pin of the actuator clamp should be installed in such

a way that the valve’s total stroke and numbers which indicated on the feedback lever

must be fitted. <Figure 2>

13

P-P Positioner

TS610 Series

tissin

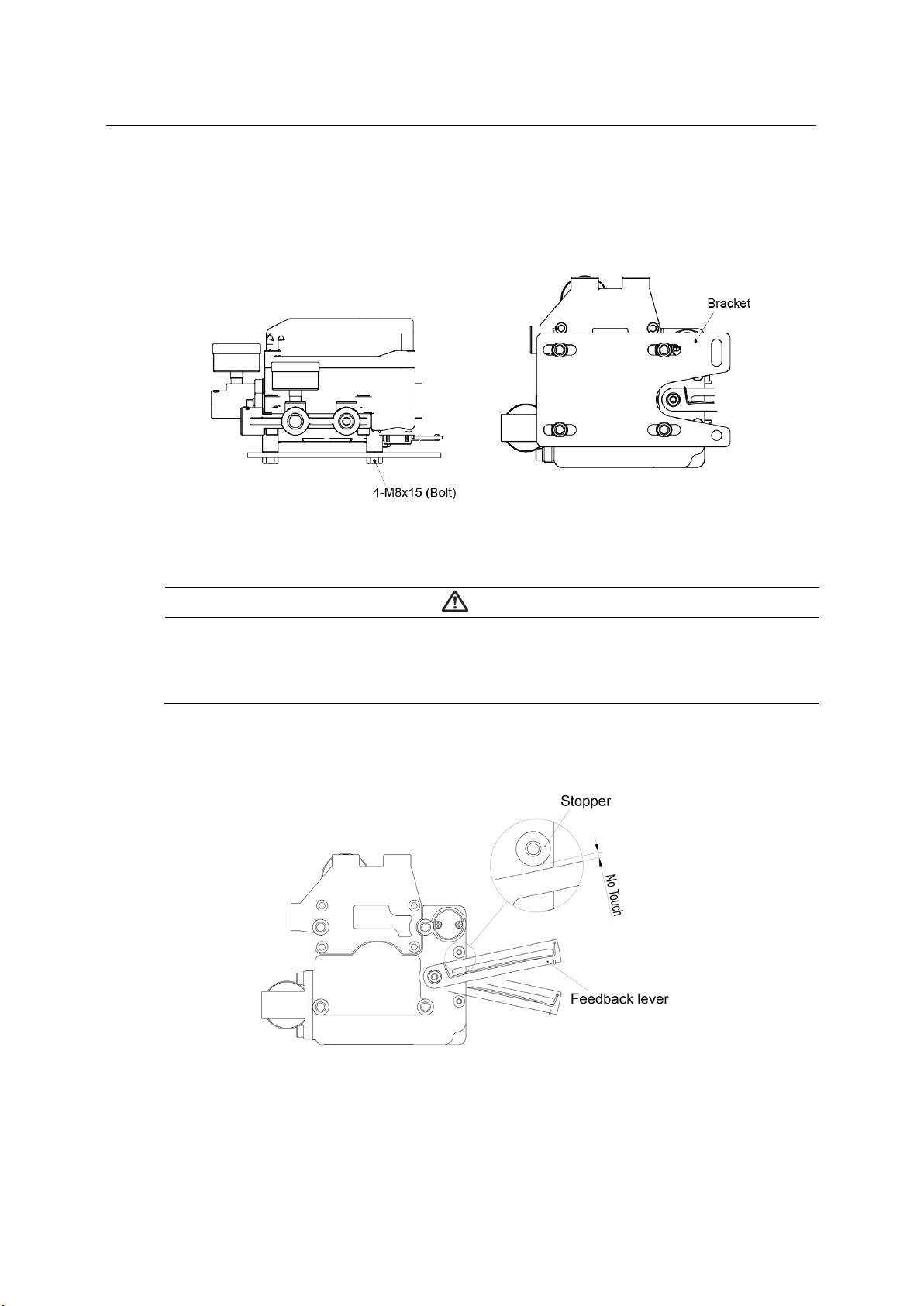

TS610L bracket Installation

Please consider the above two cautions, and make a suitable bracket for the actuator by

referring to the product dimension drawing and the installation example below.

<TS610L bracket installation example>

CAUTION

If correct installation, Feedback lever should not touch Stopper when the valve is Full

open/close.

If Feedback lever touches Stopper, please check the installation again.

<TS610L Feedback lever and Stopper>

14

P-P Positioner

TS610 Series

tissin

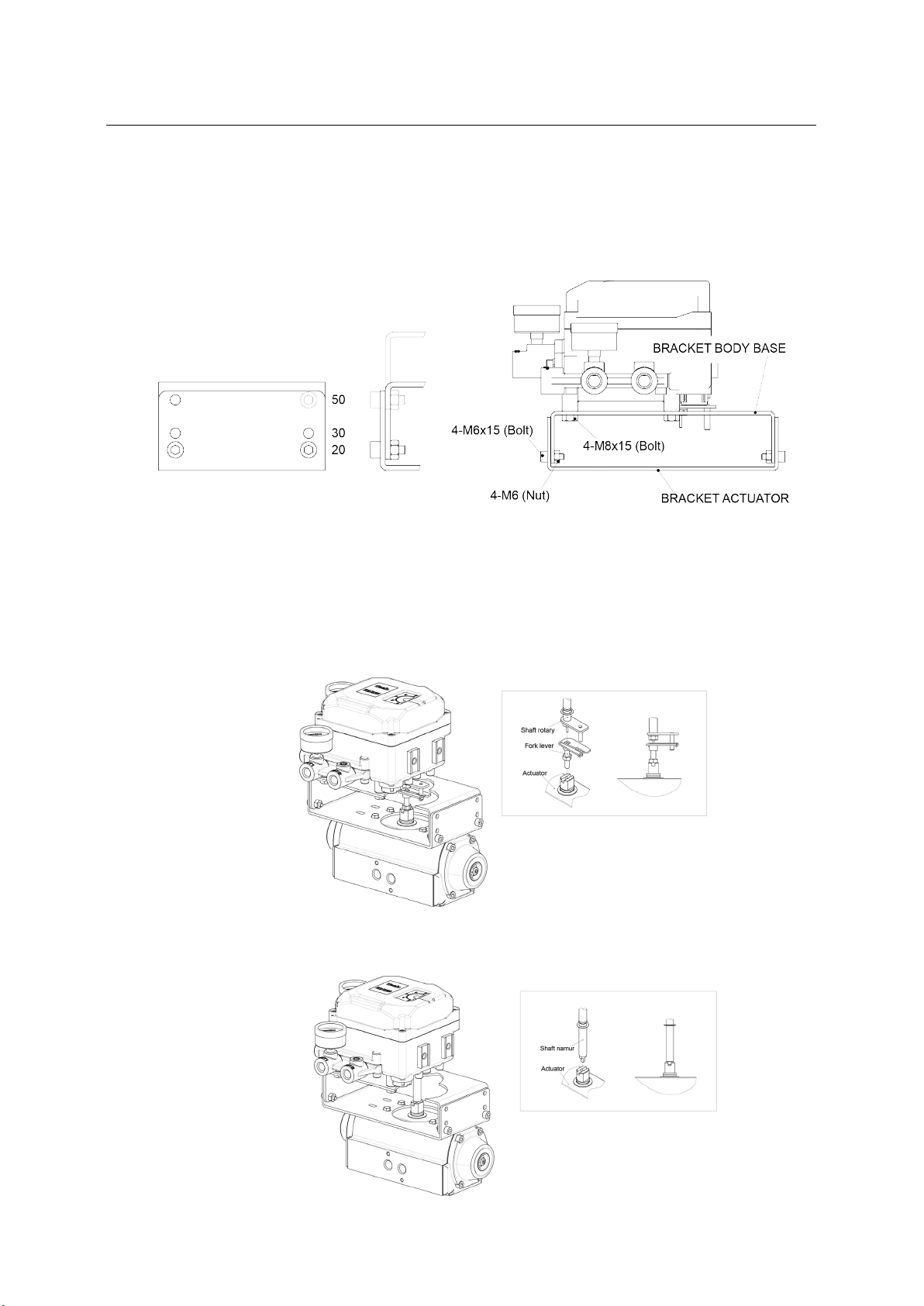

3.3 TS610R Rotary type

TS610R Rotary type includes the mounting brackets in the package box. Please install the

bracket by referring to the manual.

<TS610R bracket installation example>

Fork Leve type

Mount Fork lever to actuator as shown below.

NAMUR type

Mount Positioner’s shaft to Actuator stem as shown below.

15

P-P Positioner

TS610 Series

tissin

4 Air connection

4.1 Before the air connection

NOTICE

Please supply the dehumidified/dust removed clean air

The pneumatic ports must be equipped with a regulator to supply a constant pressure of

pneumatic pressure.

When the input pneumatic signal (0.02 to 0.1 MPa) increases, the pneumatic output of

OUT1 port increases.

4.2 TS610L air connection

<TS610L Single actuator> <TS610L Double actuator>

4.3 TS610L RA/DA settings

The product is set as RA at factory. If you want to change it to DA, please change the

OUT1/OUT2 piping and the direction of Span adjust unit.

<DA> <RA>

16

P-P Positioner

TS610 Series

tissin

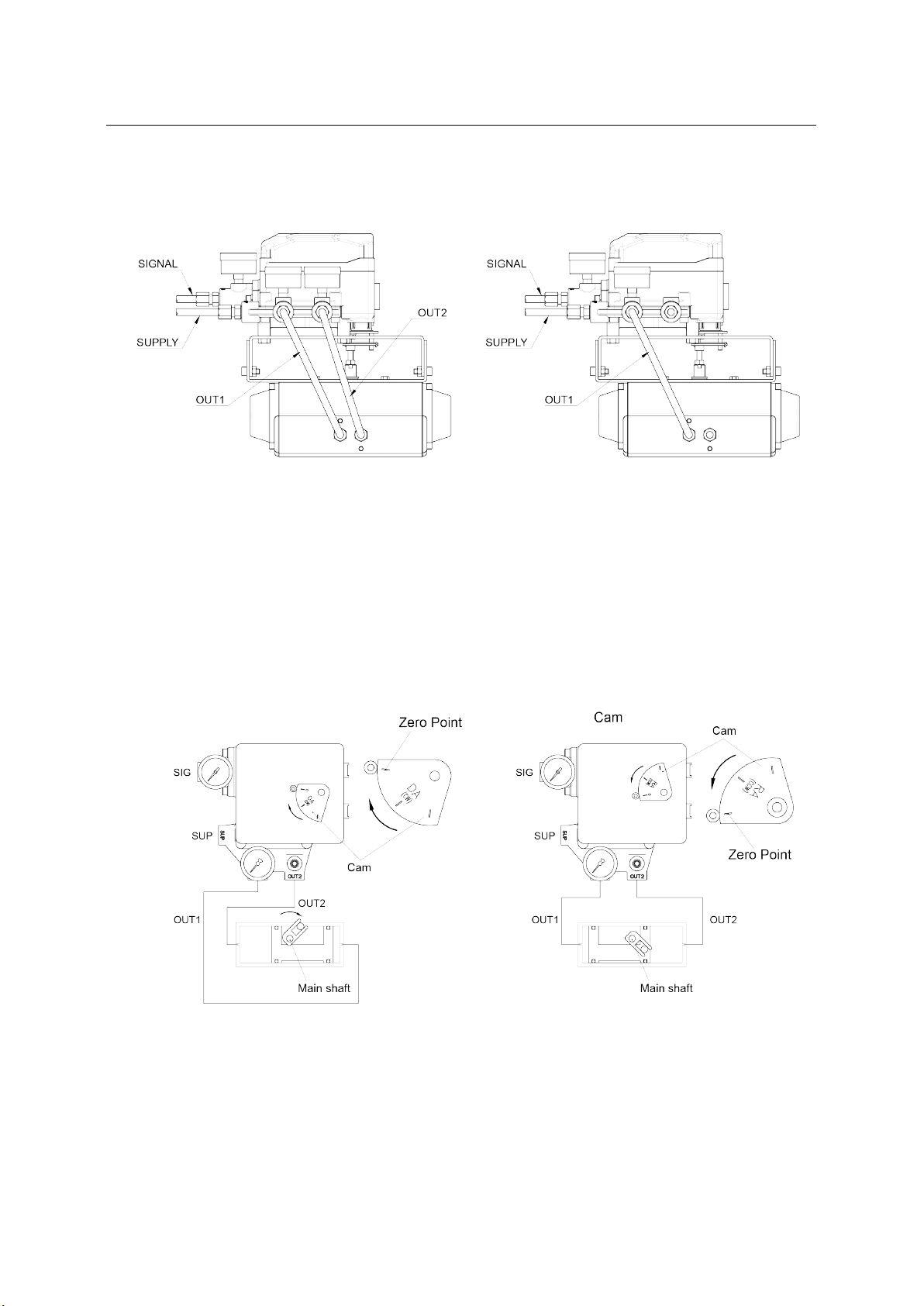

4.4 TS610R air connection

<TS610R Double type actuator > < TS610R Single type actuator >

4.5 TS610R RA/DA settings

The product is set as RA at factory. If you want to change it to DA, please change the

OUT1/OUT2 piping and turn CAM upside down to showing DA on CAM.

<DA > <RA>

17

P-P Positioner

TS610 Series

tissin

5 Adjustment

CAUTION

Zero and Span must be set correctly so product can be operated normally. If the setting is

not correct, impact on performance like linearity. So please set Zero and Span position

correctly.

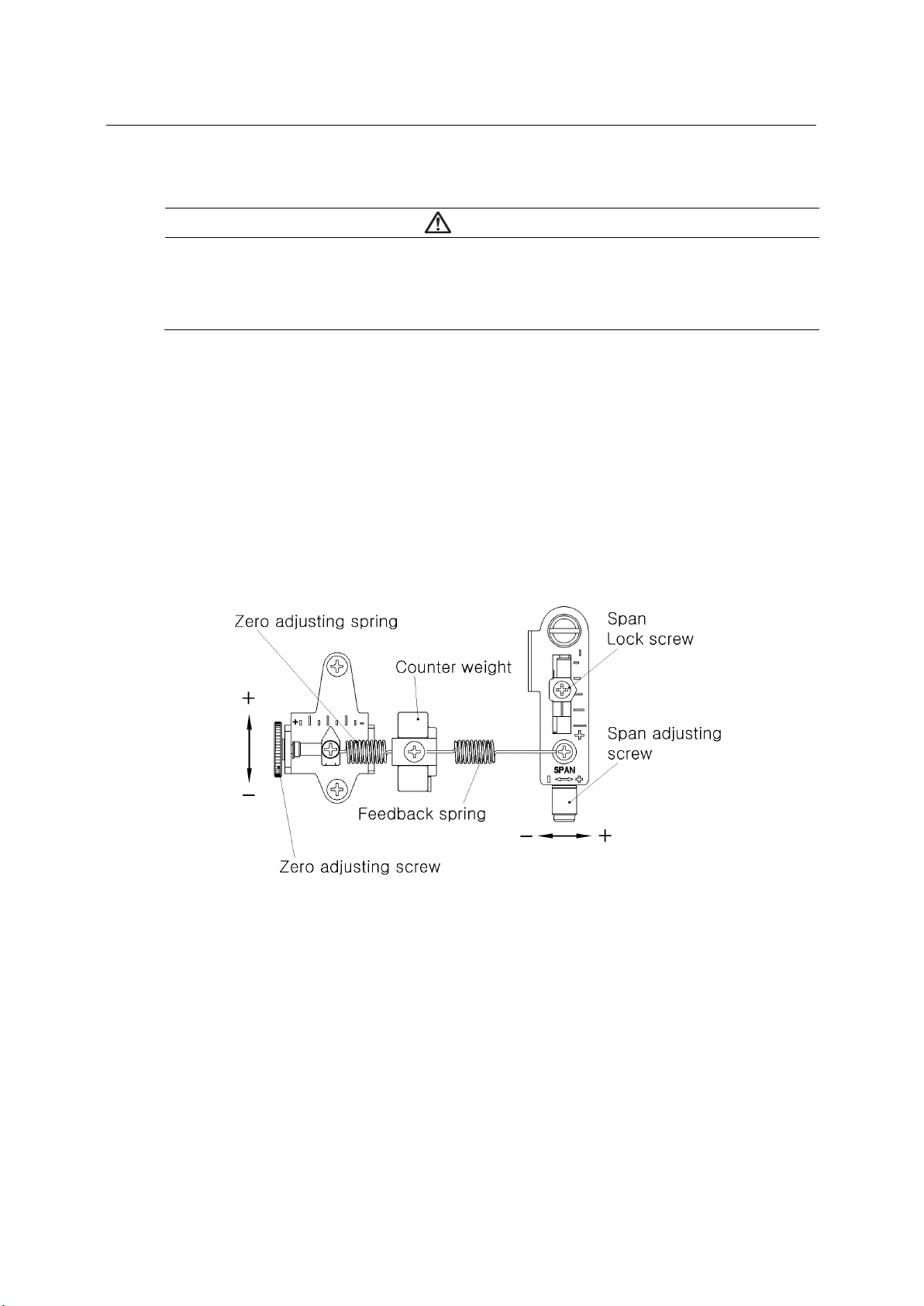

Zero and Span adjustment

①Supply 0.02 MPa to Signal port, and adjust Zero adjust unit to make the valve 0%.

②Supply 0.1 MPa to Signal port, and adjust Span adjust unit to make the valve 100%.

③If adjust Span adjust unit, the valve’s 0% position you set in STEP 1 will be changed, so

please do STEP 1 again.

④Please repeat STEP 1~2 until find the valve’s Open/Close position correctly.

<Zero and Span unit>

18

P-P Positioner

TS610 Series

tissin

6 Troubleshooting

6.1 Common problems

Failure The valve is fully open regardless of the input signal

Causes

The hole of A / M switch of pilot valve is blocked by foreign matter

such as dust

Solution

As shown below, loosen the stopper screw and separate A / M switch

and clean the bottom of the hole with 0.2mm drill or wire and re-fitted

as original.

< A/M switch structure>

CAUTION

The sensitivity adjustment screw is set optimally at the factory, so do NOT adjust it.

6.2 Orifice Installation

Failure

When mounted on small size actuator (capacity less than 180cm3)

occurs hunting.

Causes

The pneumatic output of the positioner is too large compared to the

actuator chamber size.

Solution As shown below, please remove O-Ring at OUT1 and OUT2 at the

bottom of Pilot valve, and install Orifice to Pilot valve.

<Orifice installation example>

19

P-P Positioner

TS610 Series

tissin

6.3 Other problems and Solutions

☞

The positioner does not operate

Checklist Causes Corrective action

Reference

page

If it does not work by moving

the nozzle flapper

A/M switch is loose

Check to see if A/M

switch is connected

18

Nozzle clogged

Nozzle needs clean up

18

☞

The actuator works only with ON / OFF control but not intermediate control.

Checklist Causes Corrective action

Reference

page

Linear type, check span

mounting

Span is mounted upside

down

Turn the span body 15

Rotary type, check cam

mounting

Cam is mounted upside

down

Mount the cam

correctly

16

Check OUT1, OUT2 pipeline

OUT1 and OUT2 Pipelines

are connected in opposite

directions

Install pipeline correctly 15~16

☞

Hunting occurs

Checklist Causes Corrective action

Reference

page

Hunting period is too short

and the width is too large

(pressure gauge moves at

the same time of valve stem)

Actuator volume is too low Install the orifice on the

bottom part of the pilot 18

Hunting period is too long

and the width is too small

(Gauge markings move and

valve stem slowly follow)

High temperature high

pressure valve stem has a

large frictional force

1 Perform a necessary

action to minimize

resistance of actuator

or valve stem

2 Increase actuator size

N/A

☞

Linearity is too bad

Checklist Causes Corrective action

Reference

page

Zero and span setting zero and span setting is

incorrect

Resetting zero and

span 17

Check Input pressure is

constant

Input pressure is not

constant

Check the pressure

relief valve on supply

pressure is normal.

N/A

Verify lever installation Lever does not provide

optimum rotation angle

Adjust bracket and

place drawbar on valve

opening mark

12~13

☞

Hysteresis is too bad

Checklist Causes Corrective action

Reference

page

Check connection of lever

spring

Gap between the lever

Tighten the connection

to remove the gap

12~13

20

P-P Positioner

TS610 Series

tissin

Solutions for Control Valve System

Tissin Co.,Ltd.

201-1105, No 397, Seokcheon-ro,Ojeong-gu,

Bucheon-Si, Gyeonggi-do, Korea 14449

Tel : +82-32-624-4573,

Fax : +82-32-624-4574

www.tissin.co.kr

Table of contents

Other tissin Valve Positioner manuals

Popular Valve Positioner manuals by other brands

Aventics

Aventics R431004052 Service information

Avid Technology

Avid Technology SMARTCAL Installation and operation manual

Samson

Samson 4785 Mounting and operating instructions

Samson

Samson 3760 Mounting and operating instructions

CONFLOW

CONFLOW Power Genex PPR Series Installation and maintenance manual

Econ

Econ 3300 Series operating manual