Contents

EB 8384-6S EN 3

1 Safety instructions and measures ...................................................................7

1.1 Notes on possible severe personal injury .......................................................10

1.2 Notes on possible personal injury .................................................................10

1.3 Notes on possible property damage..............................................................11

2 Markings on the device ...............................................................................13

2.1 Nameplate..................................................................................................13

2.2 Article code.................................................................................................14

2.3 Firmware versions........................................................................................15

3 Design and principle of operation ................................................................17

3.1 Safety function (SIL)......................................................................................18

3.2 Type of application.......................................................................................19

3.3 Mounting versions........................................................................................19

3.4 Additional equipment...................................................................................19

3.5 Communication ...........................................................................................21

3.6 CongurationusingtheTROVIS-VIEWsoftware .............................................21

3.7 Device overview and operating controls.........................................................21

3.8 Accessories .................................................................................................23

3.8.1 Travel tables ................................................................................................28

3.9 Technical data .............................................................................................29

3.10 Dimensions in mm........................................................................................35

3.10.1 FixinglevelsaccordingtoVDI/VDE3845(September2010) ..........................39

4 Measures for preparation............................................................................41

4.1 Unpacking ..................................................................................................41

4.2 Transporting ................................................................................................41

4.3 Storage.......................................................................................................41

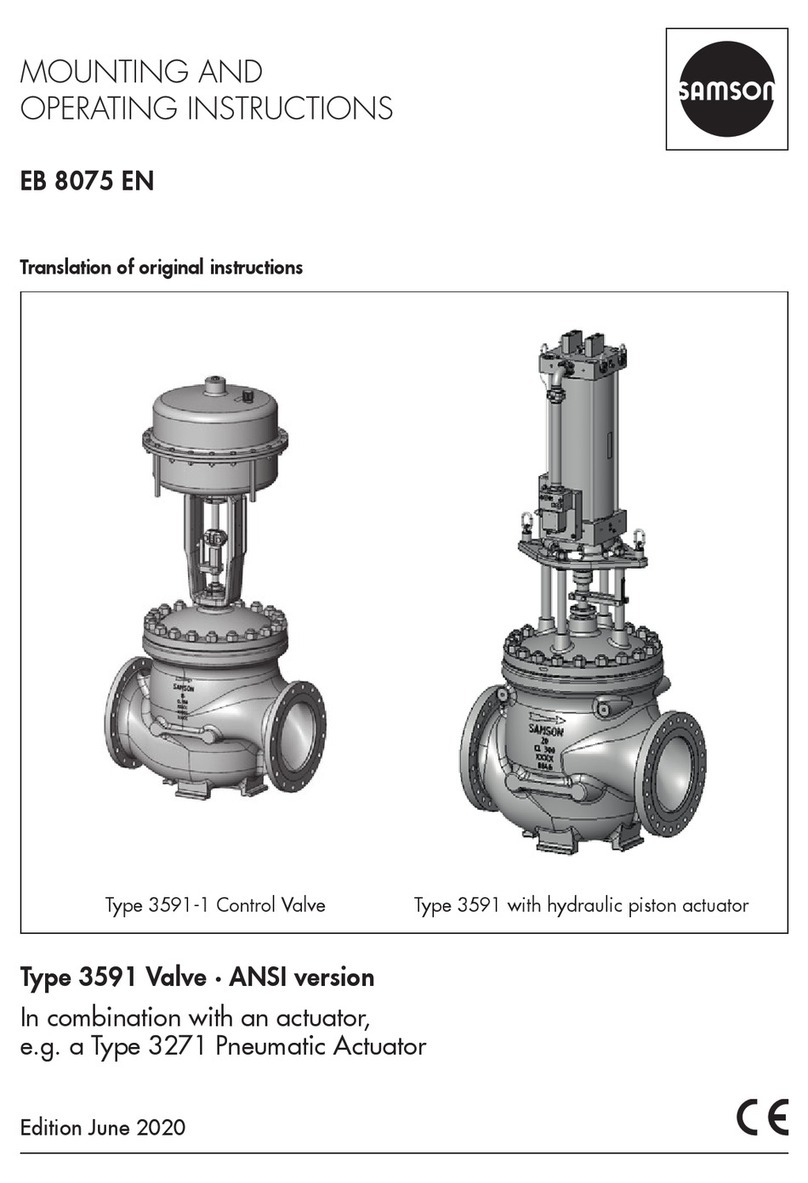

5 Mounting and start-up.................................................................................43

5.1 Mounting position........................................................................................43

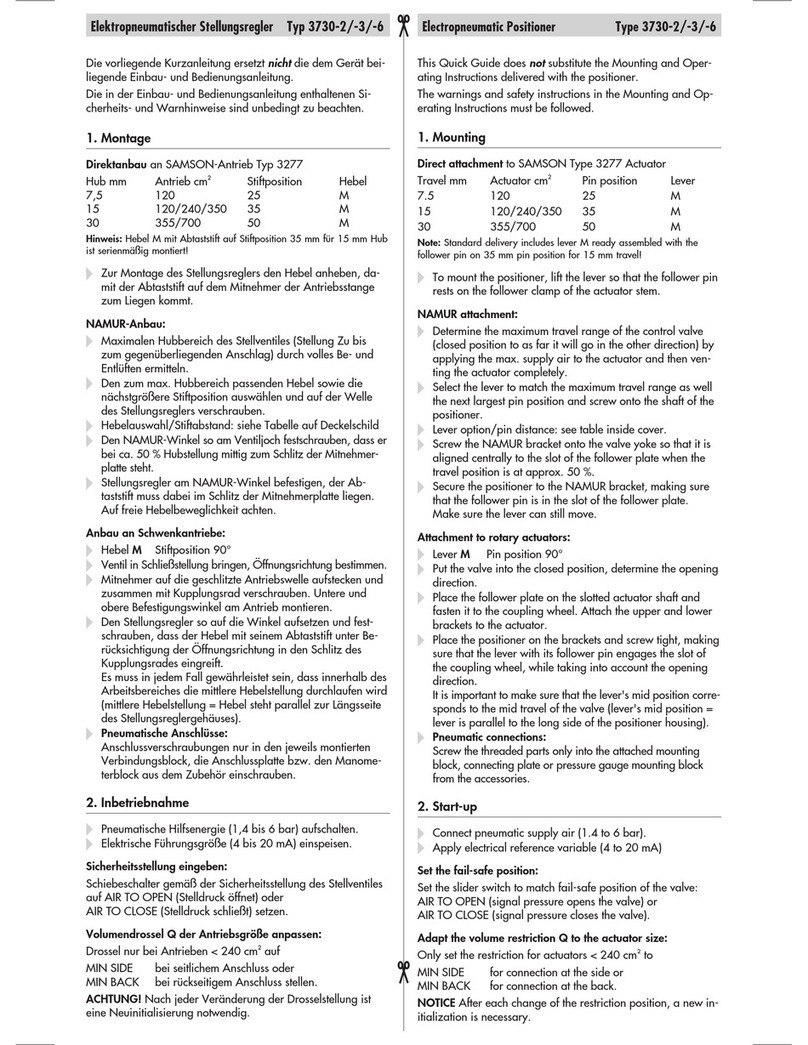

5.2 Lever and pin position..................................................................................43

5.3 Direct attachment.........................................................................................46

5.3.1 Type3277-5Actuator ..................................................................................46

5.3.2 Type3277Actuator .....................................................................................48

5.4 AttachmentaccordingtoIEC60534-6...........................................................50

5.5 AttachmentaccordingtoVDI/VDE3847-1....................................................52

5.6 AttachmentaccordingtoVDI/VDE3847-2....................................................56

5.6.1 Versionforsingle-actingactuator ..................................................................58

5.6.2 Versionfordouble-actingactuator.................................................................60

5.7 AttachmenttoType3510Micro-owValve ....................................................64