Spirax Sarco SP7-10 User manual

Other Spirax Sarco Valve Positioner manuals

Spirax Sarco

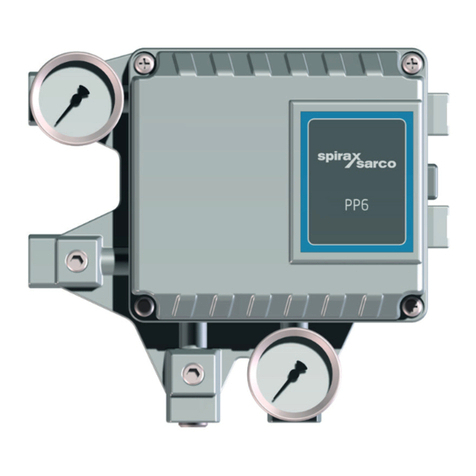

Spirax Sarco PP6 User manual

Spirax Sarco

Spirax Sarco SP2 User manual

Spirax Sarco

Spirax Sarco SP400 User manual

Spirax Sarco

Spirax Sarco EP5 Series User manual

Spirax Sarco

Spirax Sarco SP400 User manual

Spirax Sarco

Spirax Sarco EP6 User manual

Spirax Sarco

Spirax Sarco SP7-10 User manual

Spirax Sarco

Spirax Sarco SP500 User manual

Spirax Sarco

Spirax Sarco SP7-20 User manual

Spirax Sarco

Spirax Sarco PP 5 Series User manual

Spirax Sarco

Spirax Sarco SP7-10 User manual

Spirax Sarco

Spirax Sarco EP500 User manual

Spirax Sarco

Spirax Sarco SP7-21 User manual

Spirax Sarco

Spirax Sarco CVS10M User manual

Spirax Sarco

Spirax Sarco SP8-10 User manual

Spirax Sarco

Spirax Sarco EP500 User manual

Spirax Sarco

Spirax Sarco SP7-10 User manual

Spirax Sarco

Spirax Sarco SP200 User manual

Spirax Sarco

Spirax Sarco SP7-11 User manual

Spirax Sarco

Spirax Sarco PP 5 Series User manual

Popular Valve Positioner manuals by other brands

CVS Controls

CVS Controls 1200 instruction manual

Westlock

Westlock Quantum 2800 Installation & operating instructions

Samson

Samson 3730-0 Mounting and operating instructions

Samson

Samson TROVIS 3730-3 Mounting and operating instructions

ESCO Technologies

ESCO Technologies ETS LINDGREN 2302-001 user manual

Parker

Parker MX80L series product manual